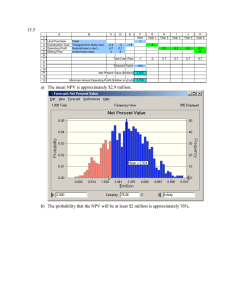

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/320306810 The Uncertainty Quantification in Optimizing Reactive Intelligent Well Control Strategy Conference Paper · January 2014 CITATIONS READS 0 121 3 authors, including: Kwame Sarkodie Bennet Nii Tackie-Otoo Kwame Nkrumah University Of Science and Technology Universiti Teknologi PETRONAS 18 PUBLICATIONS 23 CITATIONS 9 PUBLICATIONS 68 CITATIONS SEE PROFILE SEE PROFILE Some of the authors of this publication are also working on these related projects: Investigation of non intrusive sensing for Multiphae flow characterisation View project well test analysis; Power Spectral Density (PSD)p analysis for improved draw down Test View project All content following this page was uploaded by Kwame Sarkodie on 10 October 2017. The user has requested enhancement of the downloaded file. The Uncertainty Quantification in Optimizing Reactive Intelligent Well Control Strategy Benjamin Kyeremeh, Kwame Nkrumah University of Science and Technology (KNUST); Kwame Sarkodie, KNUST; and Bennet Nii Tackie-Otoo, KNUST Abstract Production and NPV forecast from oil fields are affected by different forms of uncertainties; geological (static and dynamic) and economical. This study investigates the impacts of these uncertainties to quantify them and to prove the fact that intelligent well (IW) technology under an appropriate control strategy reduces the impacts of these uncertainties better that conventional well (CW). First, an optimized base case was defined for both CW and IW in the same trajectory. The IW performed better than the CW in terms of productivity and profitability due to controlled water production in the IW. Second, different reservoir scenarios were created by varying reservoir parameters; (porosity, permeability and NTG) for static case and (rel perms, OWC, skin and aquifer permeability) for dynamic case. In each case, a pessimistic and an optimistic case were investigated. The impacts of the various uncertainties were analysed deterministically and stochastically. In both the static and dynamic case under the deterministic analysis, the CW offered a better productivity than the IW in the pessimistic cases nevertheless the IW was better in terms of profitability. In the optimistic cases, the IW performed better than the CW both in terms of productivity and profitability. However, the dynamic optimistic case presented a platform for clear distinction between the performance of IW and CW. Moreover, the economic uncertainties were also scrutinized and the margin between their performances increased as conditions become favourable. Lastly, the stochastic analysis showed that the IW reduces uncertainty range in all cases and the oil production is the most sensitive parameter in NPV forecast. Introduction The exploration and subsequent discovering of oil in reservoirs gave rise to the need for development of measures of extracting and producing this oil. Conventional wells (CW’s), which are vertical or slightly deviated, were the first types of wells used by oil producing companies. Due to the heterogeneous nature of most oil-bearing formations, the need arose for better means of recovering oil. These included drilling of highly deviated, multilateral and horizontal wells known as non-conventional wells (NCW’s). An intelligent well is best drilled in reservoirs where wellbore hydraulics (water coning or cusping) and heterogeneity (fractures causing early water breakthrough) exist (Zeid M. Al- Ghareeb, June 2009). An Intelligent well (IW) is an advanced type of non-conventional well. It is made up of a combination system of down-hole sensors which are used to monitor the well and reservoir conditions; and inflow control valves (ICV’s) which control the inflow of reservoir fluids to the well bore. These sensors, valves and inflow control devices are installed on the production tubing and they permit the continuous monitoring of fluid flow rates and pressure and periodic adjustments of ICV’s. In optimizing production from an intelligent well, two control strategies are followed by reservoir engineers. These control strategies include the proactive (defensive) control strategy and the reactive control strategy. The proactive control strategy is a “preventive measure”. In this approach, down-hole inflow control devices are used together with a predictive reservoir model to obtain the best configuration of ICV’s which will yield a maximum oil recovery over a given period of time. The reactive control strategy is a “corrective measure”. Here, a production problem (example; water coning) is allowed to occur then instrumentation is reset to mitigate the problem. That is, ICV’s operate only when there is an adverse change in flow (such as the influx of unwanted fluids). The degree of variation in rock properties with location in a reservoir or formation is termed heterogeneity. This heterogeneity makes petroleum system modeling, formation evaluation and reservoir simulation critical to maximizing production and NPV forecast. These uncertainty variations are mainly geologic (static and dynamic) and economic. The main objective of this study is to quantify the effect of uncertainties involved in the optimization of reactive intelligent well control strategy as it affects productivity and profitability and to validate that intelligent wells reduce uncertainty imparts on NPV and production forecast Literature Review A few authors have previously addressed the optimization of IWs. We shall briefly discuss some of these works but throw more light on what Burak Yeten et al did, and introduce the gap we seek to close in their works. Brouwer et al started it all when they presented a static optimization methodology that maximized sweep in a water flood study. They focused on smart horizontal injection by penetrating it fully. They looked at the segments of the well with the highest productivity index and shared the production from these segments to the other well segments. Gai H. introduced a new dimension to the works. He did an optimization method for multi-zone flow control completions. Inflow performance relationships were used to model valve performance relationships to optimize valve settings. He further proposed the use of graphical applications to performance curves and said optimal application of IWs should be addressed. Nyhavn et al made similar argument. The choice of an efficient control strategy is always a difficult problem. F. Ebadi and D. R. Davies (2006) made a study on determining which technique should be chosen when specifying the requirements for an effective Intelligent Well Management System. They specified the objectives of zonal flow control using ICVs as to maximize the oil production and NPV, minimize the unwanted fluid productions or a combination of these objectives. Yeten et al (2002) presented a general method for the optimization of a well equipped with ICVs. Their method entails the use of an optimization tool based on a conjugate gradient algorithm. This optimization tool was linked to a commercial reservoir simulator containing a wellbore flow model capable of modeling ICVs. Aitokhuehi et al (2005) combined IW optimization on the basis of Yeten et al work and history matching techniques. Naus in 2004 came out with a sequential linear programming approach. This was basically aimed at optimizing production in heterogeneous reservoirs. This however suffered from the convergence problems caused by non – linearities and oscillations and could not fully tackle the problems of production optimization and uncertainties. Sarma and Aziz also conducted a work in 2005. This work was geared towards a more efficient well optimization. They used an algorithm for the control of intelligent well. They also considered increasing the value of the recovered hydrocarbons. This was primary aimed at establishing a proactive strategy that could change the invading front’s behaviour, delaying the breakthrough time and increasing the sweep efficiency. João Paulo Q. G. da Silva et al. said smart wells were able to improve oil production and reduce water production but the net present value (NPV) indicated that the use of conventional well was, on average, slightly more advantageous. Yeten and Jalali (2001) studied an optimum allocation method to smart wells, considering the reactive control strategy, in a field limited by aquifer and gas cap. They both compared the performance of smart and conventional wells. As results, it was showed that intelligent completions are good to be used in horizontal wells with high pressure drop. They also demonstrated the benefits of smart wells to prevent the unwanted fluids production and, consequently, increase the oil production over the use of conventional wells. This work investigates the uncertainties involved in intelligent well optimisation using the reactive method. It compares the performances of both an intelligent well and a conventional well to validate that with intelligent wells the effects of these uncertainties are reduced better. Methodology Our approach in the study is to simulate the flow of reservoir fluids in a conventional well as well as a multi-segment well with ICV’s using ECLIPSE 100. We also made use of crystal ball software which uses Monte Carlo Simulation to quantify uncertainties. In this study, the expected outcome would be to quantify uncertainties (static, dynamic and economic) and to prove the fact that intelligent wells, under the reactive control strategy, tend to reduce the uncertainties associated with the productivity and profitability forecast of oilfields. Therefore a range of reservoir situations were created to investigate the effects of various parametric uncertainties on the well control strategies This methodology was basically divided into two parts; The first part which focuses on production strategy optimization (base case) The second part which involves the quantification of uncertainties with the application of deterministic and stochastic (Monte Carlo Simulation) to generate probability density functions (PDF) for the NPV forecast for both CW and IW Optimized Base Case Definition The definition of the optimized base case involved; Making use of data available for horizontal wells completed in the first layer of the PUNQ-S3 reservoir model, the best horizontal well was chosen based on maximum NPV and well productivity (FOE). With the chosen optimal well in it preferred trajectory, a production strategy was introduced. Introduction of a reactive control strategy by using pressure drop and water cut data from the segmented well to place ICVs in the segment modeled in eclipse. With an optimized production and estimated NPV for the IW, it was compared with the CW. Production Strategy The objective of the production strategy introduced for both the IW and the CW was to reduce water production and maximize hydrocarbon recovery therefore providing a better NPV for the field. For both the CW and IW, the production strategy was to commingle flow from the first layer under maximum liquid flow rate constraint of 1000 sm3. This was specified in eclipse 100 using the COMPDAT and WCONPROD keywords In this study, the conventional well completion used for the optimised base case was only controlled using a surface choke. It was designed to produce till vertical lift die out then it shut in the well. The intelligent well completion uses binary (on/off) ICV for the segments completed in the first layer. After every time step of sixty days, the design of the ICVs, is for the ICV with the highest segment water cut (SWCT) to shut. Modeling this was achieved in eclipse using the ACTIONX keyword. This was to offer an optimal reactive control strategy for the intelligent well by delaying breakthrough of water. The figure below is a flow schematic diagram showing the intelligent well reactive control strategy Figure 1: Flow schematic illustrating the IW reactive control strategy for a comingled flow Economic Model The relationship used in this study for the NPV calculation is given by; NPV = (FOPR*Po + FGPR*Pg – FWPR*Pw – CAPEX) * ⁄ ⁄ ……… (1) Note: Each variable in the above equation represents its meaning as stated in The List of Abbreviations. Economic Inputs Economic parameters used for the NPV calculation is summarized in table 1 below. Assumptions made are as follows: The price of oil (80$/bbl) assumed is based on current oil price but a bit lower to compensate for taxes and tariff charges. A CAPEX of 10.5 MMUS$ is assumed for the intelligent well which include the cost of well completion plus ICV installation cost. The CAPEX for the conventional well include 10 MMUS$ initial well completion cost and a workover cost of 3 MMUS$ which is based on the assumption that there will be a workover when water production rate exceeds that of oil. It is assumed that produced oil and gas would be sold and the produced water treated at the surface. Economic parameters Oil price ($/bbl) Gas price ($/MSCF) Water handling cost ($/bbl) Discount rate (%) Cost of IW completion (MMUS$) Cost of CW completion (MMUS$) Well workover cost (MMUS$) Table 1: Summary of economic inputs used for NPV calculation Estimates 80 4 7 10 10.5 10 3 Uncertainty Quantification Process The purpose of this part of our methodology is to investigate how the various uncertainties affect the production strategies defined for both wells (IW and CW). This is done by using the deterministic and stochastic approaches. Deterministic Approach In this approach we; The various uncertainties (static, dynamic and economic) were taking into consideration. Suitable variations of these parameters for a pessimistic and an optimistic case made for CW and IW. Variation of these parameters was put in ECLIPSE to generate new production data for various cases. Production data generated by ECLIPSE were fed into the economic model to generate discrete NPV estimates. The various reservoir situations created by the variation of the uncertain parameters offered a platform to compare the CW and IW based on incremental NPV and well productivities. Stochastic Approach This approach involves the; Selection of average production data for pessimistic and optimistic from which most likely estimates for the base case are chosen for the NPV forecast. PDFs of NPV are created by random sampling using Crystal Ball Software (Monte Carlo simulation). Quantification of the impacts of the well types on the NPV forecast by overlying the NPV PDFs for each uncertainty range for the CW and IW. Uncertainty ranking using tornado charts and trend charts to investigate the level of risk for each simulated case and the parameters that affect the NPV distribution more. Results and Discussion Optimized Base Case With the optimized production strategy defined for both CW and IW, the IW performed better than the CW in terms of both productivity and profitability as shown by the figure below (a) (b) Figure 2: Comparison of IW and CW – (a) Based on FOE and (b) Based on NPV The reactive control strategy for the IW impeded the intake of water and enhanced the flow of oil thereby providing less water handling cost and more revenue Parameters CW IW FOPR (SM3/D) 440.88 464.41 5320000 5539888 FGPR (SM /D) 43543.47 45450.28 FGPT (SM3) 524750.2 543310.5 FWPR (SM3/D) 554.14 498.23 FWPT (SM3) 6682721 6077302 FOE 0.41 0.43 FLPT (SM3) 12000000 11617190 FOPT/FLPT (SM) 0.44 0.48 NPV (MM$) 492.941 573.9396 3 FOPT (SM ) 3 ΔNPV (MM$) Table 2: Summary of optimized base case results 80.9983 Static Uncertainties The static uncertainty parameters in this study are: porosity, permeability (in the X, Y and Z direction) and the net-to-gross (NTG). We have varied these parameters in two ways; the pessimistic case and the optimistic case. These variations helped to acknowledge the possible worst outcome (pessimistic case) and the best outcome (optimistic case). Details of the results obtained are discussed below. Effects of Static (Geological) Uncertainties Uncertainties Static parameters NTG POROSITY PERM (X, Y) PERM Z Case 1 (pessimistic) Multiplier 0.5 0.5 0.4 0.32 Base case Multiplier 0.9 1 1 1 Case 2 (optimistic) Multiplier 1 2 1.6 1.28 Table 3: Static Uncertainty Parameters Variation Static Case 1 (Pessimistic Case) In the pessimistic case, a reduction in the values of the porosity and permeability distribution and net-to-gross (NTG) led to the CW performing better than the IW in terms of productivity. This was as a result of the IW not producing till lift die out because all the valves had equal water cut at 7380 days causing all the valves to shut. The IW still performed better economical because the CW produced significant amount of water which was to be handled and workover was also required in the course of the wells life. (a) (b) Figure 3: Comparison of wells in static case 1 – (a) FOE verses time and (b) NPV verses time (a) (b) Figure 4: (a) SWCT verses time for IW and (b) FWPT verses time for both wells Static Case 2 (Optimistic Case) In the optimistic case, increasing the porosity and permeability distribution and net-to-gross (NTG) values led to the IW performing better both in productivity and profitability as in the base case. This is as a result of reduced water production by ICVs allowing more production of oil. Parameters CW IW 630.632 660.94 7605450 7970947 FGPR (SM /D) 71844.92 74176.01 FGPT (SM3) 866362.9 894469.4 FWPR (SM3/D) 364.39 334.08 FWPT (SM ) 4394550 4029053 FOE 0.29 0.31 FLPT (SM ) 12000000 12000000 FOPT/FLPT (SM) NPV (MM$) ΔNPV (MM$) 0.63 875.2525 0.66 901.6422 3 FOPR (SM /D) 3 FOPT (SM ) 3 3 3 26.3897 Table 4: Summary of the static case 2 results Dynamic Uncertainties Dynamic uncertainty deals with the parameters within the reservoir that are likely to change with time during the reservoir producing life, some of which include aquifer permeability, fluid contacts, relative permeability of fluids and skin effects. Effect of Dynamic Uncertainties Uncertainties AQUIFER PERM (mD) SKIN FACTOR REL PERMS OWC Case 1 (pessimistic) 229 8 Shaly sand model 2390 Base case 137.5 0 BASE 2395 Case 2 (optimistic) 46 -1 Sand model 2405 Table 5: Dynamic Uncertainty Parameters Variation Dynamic Uncertainties Case 1(Pessimistic) An increase in the aquifer permeability causes an increase in the water production total at the surface. An early water breakthrough was then realized for the CW whilst the ICV’s in the IW controlled the production of water hence delaying water breakthrough. (a) (b) Figure 5: (a) Early water breakthrough in CW and (b) Delayed water breakthrough in IW A positive skin effect (8) indicates additional drawdown pressure due to extra flow resistance near the wellbore. This causes an increase in reservoir pressure decline but it is masked by the two strong aquifers which support reservoir pressure. The shaly sand model used for the relative permeability reduced the Krw and increased Kro making the IW’s total water production less with the aid of the ICV’s controlling the water production. This case also resulted in the IW performing poorly in terms of productivity yet the it was again better in terms profitability which was due to the handling of water production. Dynamic Uncertainties Case 2 (Optimistic) Low aquifer strength (permeability of 26mD) resists the flow of water into the reservoir resulting in a reduction in the water saturation (Sw) and increasing the Kro within the reservoir causing a late water breakthrough for both the CW and IW. The sand model used for relative permeability also led to a reduction in the Krw and hence contributed to late water breakthrough observed for both CW and IW. However the IW presented the best water production control in this case as compared to all the other cases discussed earlier. Figure 6: Delayed water breakthrough for the Dynamic case 2 Economic Uncertainties Analysis was made on the impact of economic uncertainties on NPV by varying the various economic parameters (oil price, gas price and water handling cost) for a pessimistic and an optimistic case from the base case. Results are summarized on Table 6 below. Uncertainties OIL PRICE GAS PRICE WATER COST IW NPV (MM$) CW NPV (MM$) ∆NPV (MM$) Case 1 (pessimistic) 60 1 10 218.6067 144.0916 74.5151 Table 6: Summary results for economic uncertainties Base case 80 4 7 573.939 492.91 81.029 Case 2 (optimistic) 110 7 5 1073.734 980.7404 92.9936 Stochastic Analysis (Monte Carlo Simulation) Production data from the various scenarios created were used to generate deterministic estimate values for a pessimistic, optimistic with the average serving as the most likely estimate. Triangular distributions which are able to estimate central tendency for three values served as the stochastic assumptions for the NPV distribution forecast. 10,000 simulations runs of the Monte Carlo simulation per scenario in crystal ball were carried out. NPV distributions were generated which have uncertainty ranges and their impact on each well completion on the distribution were analyzed using overlay, tornado and trend charts. The results were as follows: Static NPV Distribution Inputs FOPR (sm3) FGPR (sm3) FWPR (sm3) Oil Price ($/bbl) Gas Price($/bbl) Water Cost ($/bbl) NPV (MM$) Pessimistic 51.27 3481.34 592.34 80 4 7 Conventional well Most likely 384.86 42337.11 371.53 80 4 7 102.8498767 Optimistic 995.597 185633.9 4.4 80 4 7 Assumptions Triangular Triangular Triangular Triangular Triangular Triangular Forecast Optimistic 995.6 185697.4 4.41 80 4 7 Assumptions Triangular Triangular Triangular Triangular Triangular Triangular Forecast Table 7: Stochastic inputs for static NPV distribution of CW Inputs FOPR (sm3) FGPR (sm3) FWPR (sm3) Oil Price ($/bbl) Gas Price($/bbl) Water Cost ($/bbl) NPV (MM$) Pessimistic 274.71 16323.34 300 80 4 7 Intelligent well Most likely 383.65 42397.94 229.885 80 4 7 103.0549161 Table 8: Stochastic inputs for static NPV distribution for IW Setting a minimum NPV forecast value of about $100MM, CW gives a 68.84% confidence level of achieving it. With a large range of uncertainty, CW has a very low rate of coping with adverse uncertainties in the reservoir. IW on the other hand gives a 90.45% confidence level of achieving it which means under appropriate reactive control strategy it is able to deal better with adverse uncertainties in the reservoir. (a) (b) Figure 7: NPV distribution for static uncertainty – (a) CW and (b) IW Dynamic NPV Distribution Inputs FOPR (sm3) FGPR (sm3) FWPR (sm3) Oil Price ($/bbl) Gas Price($/bbl) Water Cost ($/bbl) NPV (MM$) Pessimistic 116.26 6883.87 883.74 80 4 7 Conventional well Most likely 367.35 55069.7 546.13 80 4 7 98.55220711 Optimistic 1000 425025 11.22 80 4 7 Assumptions Triangular Triangular Triangular Triangular Triangular Triangular Forecast Table 9: Stochastic inputs for Dynamic NPV distribution for CW Inputs FOPR (sm3) FGPR (sm3) FWPR (sm3) Oil Price ($/bbl) Gas Price($/bbl) Water Cost ($/bbl) NPV (MM$) Pessimistic 118.54 8234 350.81 80 4 7 Intelligent well Most likely 443.105 60419.5 310.335 80 4 7 103.0549161 Optimistic 1000 419143 0.001 80 4 7 Table 10: Stochastic inputs for Dynamic NPV distribution for IW Assumptions Triangular Triangular Triangular Triangular Triangular Triangular Forecast (a) (b) Figure 8: NPV distribution for dynamic uncertainty – (a) CW and (b) IW With the dynamic uncertainties same analysis as in the static case was made with CW having a confidence level of 76.46% for achieving a minimum NPV of $100MM with wider range of uncertainties whiles the IW gives a confidence level of 82.27% of achieving the same minimum NPV value with a narrow range of uncertainties. Impact of Intelligent Wells on Uncertainties (a) (b) Figure 9: An Overlay of NPV Distributions (CW, IW) – (a) static and (b) dynamic From figure 9, IW has a higher mean than CW in both cases and the range of uncertainties for the IW fell within that of CW showing that the IW has a narrower range of uncertainty therefore reduces the impact of reservoir uncertainties. Ranking of Uncertainties Ranking of the uncertainties using to tornado chart is now done to know which parameter is most sensitive to the project so that much attention will be given to it to get a better NPV forecast. Figure 10: Tornado chart for the wells in various reservoir scenarios In all the cases, it was observed that the Oil Production is the most sensitive parameter to the NPV distribution followed by gas production, because we intend to sell the gas this parameter is also very important to our NPV forecast. Having noticed this trend, it therefore means that in order to have a better oil production and NPV forecast, an appropriate reactive control strategy must be adapted to the IW. In much the same way, if an appropriate work over strategy is adapted to the CW it could perform the similar to the IW. Comparison of NPV Trend for all Cases Figure 11: NPV Trend Charts for all Cases Both the NPV STATIC IW and NPV DYNAMIC NPV IW have the highest certainty bands, meaning they cover a wider range of certainties, thereby reducing the entire range of uncertainties. IWs are therefore able to lower level of risk as compared to their counterparts CWs which have the lowest certainty bands and hence ,a wider range of uncertainty. CW is therefore very poor in reducing the impact of risk associated with project NPV evaluation. It is interesting to note that the certainty bands of the IW correspond with the high NPV forecast whereas the certainty bands of the CW correspond with the low NPV estimates. Conclusions As it was expected, the IW was able to reduce the reservoir uncertainties to a large extent under the proposed reactive control strategy but faired averagely under severe reservoir uncertainties. In terms of profitability, IW offset CW in almost all the scenarios meaning, IW is able to deal better with adverse economic uncertainties. In the stochastic analysis, it was observed that the oil production is a very sensitive parameter and both IW and CW could do better depending on the control strategy adopted by each. Acknowledgements This paper is based on the work conducted in a BSc final year project from the Kwame Nkrumah University of Science and Technology (KNUST), Department of Chemical Engineering. We would like to thank all lecturers and colleges who aided in making this project a success. Nomenclature CAPEX = Capital Expenditure IW = Intelligent Well CW = Conventional Well Kro = Oil relative permeability FGPR = Field Gas Production Rate Krw = Water relative permeability FGPT = Field Gas Production Total NPV = Net Present Value FLPT = Field Liquid Production Total NTG = Net to Gross Ratio FOE = Field Oil Efficiency OWC = Oil-Water Contact FOPR = Field Oil Production Rate PERM X, Y, Z = Permeability in x, y, z FOPT = Field Oil Production Total FWCT = Field Water Cut Total FWPR = Field Water Production Rate FWPT = Field Water Production Total GOC = Gas-Oil Contact ICV’s = Inflow Control Valves direction Pg = Gas Price PO = Oil Price Pw = Water handling cost Sw = Water Saturation SWCT = Segment Water Cut t = Total time in days References 1. Burak Yeten, Louis J. Durlofsky and Khalid Aziz, 2002, “Optimisation Of Smart Well Control”, Paper SPE 79031, Presented at 2002 SPE International Thermal Operations And Heavy Oil Symposium And International Horizontal Well Technology Conference, Calgary, Alberta, Canada, 4-7 November. 2. B. Yeten, D. R. Brouwer, L. J. Durlofsky and K. Aziz, 2004, “Decision Analysis under Uncertainty for Smart Well Development”, Journal of Petroleum Science and Engineering, 183-199. 3. F. Ebadi and D. R. Davies, Heriot-Watt University 2006, “Should Proactive And Reactive Control Be Chosen For Intelligent Well Management?”, paper SPE 99929, Presented at the SPE Intelligent Energy Conference and Exhibition, Amsterdam, The Netherlands, 1113 April. 4. F. T. Al-Khelaiwi, 2007, “Inflow Control Device: Application and Value Quantification of a Developing Technology”, paper SPE 108700 presented at the International Oil Conference and Exhibition, Veracruz, Mexico, 27-30 June. 5. I. M. Grebenkin and D. R. Davies, 2010, “Analysis of the Impact of an Intelligent Well Completion on the Oil Production Uncertainty”, paper SPE 136335, Russian Oil and Gas Technical conference and Exhibition, Moscow, Russia, 26-28 October. 6. M. A. Sampaio, C. E. A. G. Barreto, A. T. F. S. G. Ravagnani and D. J. Schiozer 2011, “Comparison between Smart Wells Optimization under Economic Uncertainty”, paper OTC 22426- PP, presented at the Offshore Technology conference, Rio de Janeiro, Brazil, 4-6 October. 7. M.A. Sampaio, C. E. A. G Barreto and D. J. Schiozer, 2012, “Comparison between Conventional and Intelligent Wells with Reactive and Proactive Controls under Economic Uncertainty”, paper SPE 155657, presented at SPE International Production and Operations conference and Exhibition, Dona, Qatar, 14-16 May. 8. Michael Konopczynski and Arachi Ajayi, 2007, “Control of Multiple Zone Intelligent Wells to Meet Production Optimisation Requirements”, paper SPE 106879, presented at SPE Production and Operations Symposium, Oklahoma city, Oklahoma, USA, 31 March– 3 April. 9. Vasily Mihailovich Birchenko, 2010, “Analytical Modelling of Wells with Inflow Control Devices”, DPhil Report, Institute of Petroleum Engineering, Heriot-Watt University 10. Zeid M. Al-Ghareeb, 2009, “Monitoring and Control of Smart Wells”, Masters Report, Department of Petroleum Engineering, Stanford University, California View publication stats