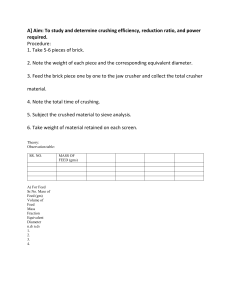

INDIAN INSTITUTE OF TECHNOLOGY, KHARAGPUR Date of Examination: 16.09.2016 Time: 2 hours Full Marks: 30 Mid-Autumn Semester, 2016-2017 3rd Year B.Tech.(Hons.)/Integrated M.Tech. Sub. Name: Mechanical Operations Subject No. - CH31 007 No. of Students - 87 Chemical Engineering Instructions: 1. Attempt ALL questions. 2. Assume, if necessary, clearly stating them. 3. Write the answers of each question in one place. 4) Credit will be given for stepwise calculations and neatness. 5) No queries will be entertained during examination. I. The screen analysis shown in the table bellow applies to a sample of crushed quartz. The density of the particle is 2650 kg/rrr', and the geometric constants are a = 2 and b = 3.5. For the material in the size range between 4.699 mm to 0.417 mrn, calculate (a) Aw, in sq. mm/g, b) Nw, in particles/g and volume surface mean diameter D, in mrn. [5J Screen Analysis Mesh Screen opening, mm Mass fraction retained Av. Particle dia., mm Cumulative fraction passing 4 4.699 0.0000 - 1.0000 6 3.327 0.0251 4.013 0.9749 8 2.362 0.1250 2.845 0.8499 10 1.651 0.3207 2.007 0.5292 14 1.168 0.2570 1.409 0.2722 20 0.833 0.1590 1.001 0.1132 28 0.589 0.0538 0.711 0.0594 35 0.417 0.0210 0.503 0.0384 48 0.295 0.0102 0.356 0.0282 65 0.208 0.0077 0.252 0.0205 100 0.147 0.0058 0.178 0.0147 150 0.104 0.0041 0.126 0.0106 200 0.074 0.0031 0.089 0.0075 pan - 0.0075 0.037 0.0000 P.T.O. 2. A crusher is in closed circuit with a screen, crushing 1000 tons of dry ore per day. Screen analysis of crusher discharge, screen over flow and screen under flow are as follows: Mesh 28 35 48 Crusher discharge cumulative % 57.6 72.8 78.9 Screen OfF cumulative % 7.8 27.4 39.8 Screen cumulative 73.9 87.7 91.8 Calculate the circulating load of the crusher U/F % [3] 3. Assuming Stoke's law, calculate the time required by a spherical glass beads (Dp = 0.98 rrun) to reach half of its terminal velocity when settling in a pool of stagnant water at 20°C. The density of the particle is 1600kglm3. [4] 4. If crushing rolls, 102 cm diameter, are set so that the crushing surfaces are 1.2 em apart and the angle of nip is 31°, what is the maximum size of particle which should be fed to the rolls? If the actual capacity of the machine is 12% of the theoretical, calculate the throughput in tons per hour when running at 100 rpm, if the working face of the rolls is 41 cm long and the feed weighs 2355 kg/rrr'. [3] 5. 1.28 g of a powder of particle density 2500 kg.m" are charged into the cell of an apparatus for measurement of particle size and specific surface area by permeametry method. The cylindrical cell has a diameter of 1.14 ern and the powder forms a bed of depth 1 ern. Dry air of density 1.2 kg.m" and viscosity 18.4 x 10-6Pa.s, flows at a rate of 36 cm3.min-'through the powder (in a direction parallel to the axis of the cylindrical cell) and producing a pressure difference of 100 mm of water across the bed. Assuming laminar flow condition in the cell, determine the surface-volume mean diameter, Reynolds number, and the specific surface of the powder sample. [5] 6. (a) Summarize three different models for predicting the energy requirement associated with particle size reduction. Over what size ranges might each model be most appropriately applied? (b) Describe six material properties that would influence selection of a crusher/mill type. [(3+3) = 6] 7. The resistance F of a sphere of diameter x, due to its motion with velocity u through a fluid of density p and viscosity p, varies with Reynolds number (Re) as given below: 2.0 2.5 3.0 3.5 4.0 1.05 0.63 0.441 0.3R5 0.39 Find the mass ofa sphere of 0.013 m diameter which falls with a steady velocity of 0.6 m.s-J in a large deep tank of water of density 1000 kg.rn" and viscosity 0.0015 Pa.s.[4]