Sphere Fluid Dynamics Lab Results: Viscosity & Reynolds Number

advertisement

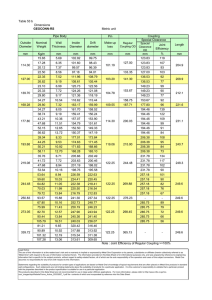

Results: Diameter Sphere reading for a (mm) reading for b (mm) Average (mm) Average (m) Large metal 10.04 10.04 10.04 Small metal 5.01 5.00 5.005 Large white 9.97 9.96 9.965 Small white 4.98 4.98 4.980 Off white 10.00 9.98 9.990 Sphere A (s) Large metal Small metal Large white Small white Off white Time B (s) 4.51 12.41 13.80 44.93 24.87 Type of Oil Hydraulic Oild Average (s) 4.00 12.26 13.98 45.23 24.56 4.255 12.34 13.89 45.08 24.72 Volume Weight Density Average Volume (mm3) Average Volume (m3) Reading for a (g) Reading for b (g) Average (g) Average Density (g/mm3) Average Density (kg/m3) 0.01004 529.9 5.299E-07 1.487 1.486 1.4865 0.0002861 286.1 0.005005 65.65 6.565E-08 0.176 0.176 0.1760 0.0002734 273.4 0.009965 518.1 5.181E-07 0.698 0.697 0.6975 0.0001373 137.3 0.004980 64.67 6.467E-08 0.086 0.087 0.08650 0.0001364 136.4 0.009990 522.0 5.220E-07 0.595 0.594 0.5945 0.0001161 116.1 Termial Velocity (m/s) Dynamic Viscosity (mPa.s) Reynold's Number 0.1880 -174.1 -3.102 0.06486 -128.1 -0.6929 0.05760 -699.5 -0.1126 0.01775 -567.7 -0.0212 0.03237 -1286 -0.0292 Specific Gravity Density (kg/m3) Density (g/mm3) 0.882 882 0.000882 Discussion: 1. All the calculated Reynold’s numbers are below 1 so the use of the Stokes equation is justified. Possible errors: measuring diameter not exactly due to the tool, measuring weight not exactly due to the tool, specific gravity not being exact due to the tool being used, measuring 80 cm was not exact due to the tool used, and time spheres took to travel 80 cm was not exact as a human was handling the stopwatch. All these possible sources of error would have resulted in accuracy lost. 2. The most reliable measurements are the diameter, volume, weight, and density because all measurements were done with tools that are very accurate.