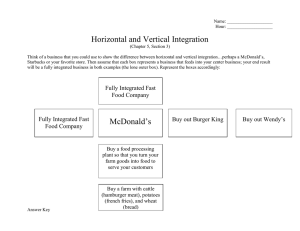

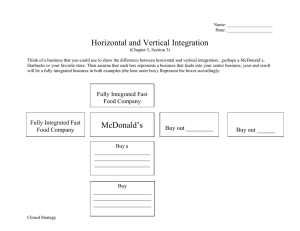

McDonalds 1 Prof. Bin Jiang, Ph.D MGT501 03/17/2020 Final Project: Supply Chain Management – McDonald’s French Fries McDonald’s brand is recognized globally. Its golden arches can be found in large cities, rural communities and over-seas. McDonald’s is known for their Big Macs and Happy Meals, but its all-time best seller has been their french fries. This report provides analysis of McDonald’s french fry supply chain. is ar stu ed d vi y re aC s o ou urc rs e eH w er as o. co m French Fry Architecture: From Potato to Restaurant Th It is important to note that McDonald’s does not own any of its supply chain. McDonald’s does not own farms, freight transportation, nor distribution centers. Ready to serve McDonald’s french fries consist of 19 different ingredients. The architecture above only represents the potatoes flow process. sh Potato Farms: McDonald’s purchased 1.35 billion pounds of potatoes in 2015. They use three potato suppliers for its french fries. “They get supplied by 100 Circle Farm, farmer Frank Martinez, and farmer Jenn Bunger. 100 Circle Farm is a huge farm that grows potatoes in circles that you can see from space and has a high standard of quality and production, pumping out 24 hundred tons of potatoes per day. The two other farms are family farms run by two people whose family line has been in the business for generations.” (arcgis.com) It’s important to note that all three potato suppliers are in the state of Washington and in relatively close proximity to each other. This may pose a risk to McDonald’s french fry supply chain if unforeseen circumstances should occur like a natural disaster or drought in the region. I’d hope that McDonald’s would have a contingency plan in place in the event that the Washington potato supply be disrupted. This study source was downloaded by 100000795058236 from CourseHero.com on 12-08-2021 12:31:32 GMT -06:00 https://www.coursehero.com/file/104161423/Final-Project-Supply-Chain-Management-at-McDonalds-MGT-501docx/ McDonalds 2 Idaho has plenty of potato farms but too close in proximity to Washington. Wisconsin also has a large potato farm presence in the U.S. and far away enough from the Pacific Northwest to be impacted from the hypothetical natural disaster/drought. I’d recommend McDonald’s establish a relationship with Wisconsin potato suppliers as a back-up to their Washington Suppliers. Potato Processing: McDonald’s processing suppliers are Lamb Weston and Simplot. These firms receive the potatoes from the potato farms and proceed to peel and precision cut them. They then apply an ingredient dip, partially fry them, and freeze the fries. These processing plants are able to process potatoes at high volume. “We can dig anywhere from a thousand to twenty-four hundred tons of potatoes per day…and the majority of these will go into McDonald’s Fries”. - Troy Grimes, Director of Farm & Dairy Operations, Lamb Weston. Both Lamb Weston and Simplot have their manufacturing plants located in the Pacific Northwest. is ar stu ed d vi y re aC s o ou urc rs e eH w er as o. co m Transportation/Distribution Centers: “The Martin-Brower Company is the largest supplier of food and materials to McDonald's restaurants worldwide. The company delivers more than 510 million cases of its products to about 20,000 Golden Arches locations each year. MartinBrower supplies such items as frozen, refrigerated, and dry food, and bakery and paper products. In addition to its food-distribution services, Martin-Brower provides global logistics management services to other food and beverage suppliers through its MBX Logistics unit.” (dnb.com) The shipping containers that Martin-Brower uses demonstrates efficiency in its transportation. McDonald’s requires supplies stored at various temperatures. Rather than transporting an entire container of items of one temperature, its containers have the ability to customize the temperature in different sections. This flexibility benefits the supply chain as quantities of various supplies fluctuate per order. Martin-Brower has distribution centers throughout the U.S. and delivers supplies to almost all the company’s 15,000 locations in North America. sh Th McDonald’s Restaurant: The final location the french fries arrive at before being sold to customers is the restaurant. At the restaurant, french fries are fully cooked/fried and salted before they’re ready to be served. A bottleneck in this process is when customers request their fries not to be salted. When this request occurs, employees must wipe down the station, clean the scoop, and then clean out the entire area. This is particularly problematic during busy lunch and dinner times. Customers often request no salt simply because they want a fresh batch of fries and request salt packets instead. It would be much more efficient for McDonald’s employees to simply fry a new batch and avoid the time cost of thoroughly cleaning out the entire area. I’d recommend McDonald’s to enforce a policy where customers requesting nonsalted fries will not receive salt packets. Perhaps even displaying a notice that fresh fries are available upon request might reduce this bottleneck, though may increase costs if too many customers begin to take advantage. Capacity This study source was downloaded by 100000795058236 from CourseHero.com on 12-08-2021 12:31:32 GMT -06:00 https://www.coursehero.com/file/104161423/Final-Project-Supply-Chain-Management-at-McDonalds-MGT-501docx/ McDonalds 3 Capacity management can be very challenging to any company as this refers to the act of ensuring a business maximizes its potential activities and production output taking into consideration all conditions over a period of time. McDonald in this instance would be asking: 1. What is the number of fries that McDonald’s should order to meet customer demand without ordering too much where it would increase waste resulting in increase of cost. To understand the Capacity strategy that McDonald’s has implemented it is important that we understand how capacity was managed in the past and how technology and data has increased the accuracy & efficiency of this process. Old Inventory Management System Order of Inventory based on Manager is ar stu ed d vi y re aC s o ou urc rs e eH w er as o. co m Regional Planner Restaurant Manager In the past McDonald’s relied too much on their store managers to order the correct amount of inventory that the restaurants needed. However, this process caused problems as managers made their inventory orders based only on sales not taking into consideration other factors such as seasons, promotions and even holidays. As such, McDonald’s decided to implement the a new system which integrated technology and data analysis to increase accuracy and efficiency which would result in reduction of waste and continuing to meet customer demands. New Inventory Management System Restaurant Manager Inv. Control System Regional Planner Warehouse, Plant, Farm sh Th The new inventory system was introduced in 2004. In addition to the technology added, McDonald’s also implemented a new team whose responsibilities were to help manage inventory at the restaurants. The new inventory supply chain management system consisted in restaurant managers communication with the planning and forecasting team regarding local events or any other factors that would need to be taken into consideration that would have an inventory effect. To dive into how this system affects the orders of fries it is important to understand the types of inventory that McDonald’s manages. Mcdonald’s has broken down inventory into 3 categories; 1. Raw materials, WIP ( work-in- progress) and Finished goods. These can be frozen, chilled or ambient which is room temperature. Also, McDonald’s uses FIFO for their inventory; this means first in first out. This study source was downloaded by 100000795058236 from CourseHero.com on 12-08-2021 12:31:32 GMT -06:00 https://www.coursehero.com/file/104161423/Final-Project-Supply-Chain-Management-at-McDonalds-MGT-501docx/ McDonalds 4 Engagement Potato farmers for McDonald’s. McDonald’s is company which is able to build a great relationship with its suppliers. McDonald’s is able to engage them to be part of the complete supply chain management. As an example, McDonald’s lists some of its main food suppliers on its website in order to give them recognition of the great products they offer. By accessing this URL https://www.mcdonalds.com/us/en-us/about-our-food/meet-our-suppliers.html, users can identify the different food suppliers. For the potato farmers, McDonald’s has listed these 3 different potato suppliers: A potato farmer, Frank Martinez A potato farmer, Jenn Bunger A potato farmer, 100 Circle Farms is ar stu ed d vi y re aC s o ou urc rs e eH w er as o. co m - McDonald’s create a deep business connection with the potato farmers by making them part of the whole food business. Then, McDonald’s shares with them information in respect to the French fries inventory level, making them part of the whole business model. Collaboration is a key factor that makes its supply chain a success, and that is the reason McDonald’s tracks its inventory at every stage of the supply chain by using different technologies such us RFID or barcoding. In addition, McDonald’s consolidates all of its data in a centralized location using a cloud-based system. So, with all those tools, the potato farmers are able to enter into its system and they have access to the potato inventory information accurately and on a real time. However, McDonald’s only grants access to identify inventory levels based on the role of the supplier. So, for instance, McDonald’s will not share any information in respect to the amount of tomatoes needed or the inventory levels with the potato farmers, only the information in regards to the potatoes needed. sh Th The potato farmers and McDonald’s always maintain a good communication and it makes the supply chain more transparent. Furthermore, being transparent means that both parties are sharing the correct information and they are following a code of conduct in respect to the whole product itself, from its initiation process of harvesting, picking, cleaning, and sorting to the end consumer who is consuming the final product, the French fries. By doing that, McDonald’s will make sure that they are not out of French fries which it is one the most important product of its restaurants, and most important, it makes sure that suppliers will have a long-lasting relationship with them. As a result, the potato suppliers will be able to run the business for many years without worrying about the fact of losing market share and to always maintain a constant income stream. This study source was downloaded by 100000795058236 from CourseHero.com on 12-08-2021 12:31:32 GMT -06:00 https://www.coursehero.com/file/104161423/Final-Project-Supply-Chain-Management-at-McDonalds-MGT-501docx/ McDonalds 5 REFERENCE PAGE - ClearSpider (Top 3 Supply Chains of 2017: McDonald’s) Retrieved from https://clearspider.net/blog/mcdonalds-supplychain/ - McDonald’s (McDonald’s Food Suppliers) - is ar stu ed d vi y re aC s o ou urc rs e eH w er as o. co m https://www.mcdonalds.com/us/en-us/about-our-food/meet-our-suppliers.html Mapping McDonald’s Ingredients https://www.arcgis.com/apps/MapJournal/index.html? appid=36977f8b4f9d4320a159283fb192ad2a - Dun & Bradstreet, The Martin-Brower Company LLC - Company Profile sh Th https://www.dnb.com/business-directory/company-profiles.the_martinbrower_company_l_l_c.cad03437ad4f823b60c1ed909a6f3695.html This study source was downloaded by 100000795058236 from CourseHero.com on 12-08-2021 12:31:32 GMT -06:00 https://www.coursehero.com/file/104161423/Final-Project-Supply-Chain-Management-at-McDonalds-MGT-501docx/ Powered by TCPDF (www.tcpdf.org)