A Project Report on

PRODUCTION OF ACETALDEHYDE

Submitted in partial fulfillment of the requirements for the award of the degree of

BACHELOR OF TECHNOLOGY IN

CHEMICAL ENGINEERING

Submitted By:

Table of Contents

Acknowledgement ................................................................ Ошибка! Закладка не определена.

Table of Contents .............................................................................................................................. i

List of Figures .................................................................................................................................. iv

List of Tables .................................................................................................................................... v

List of Symbols and abbreviations used .......................................................................................... vi

Abstract ......................................................................................................................................... viii

Chapter 1 .......................................................................................................................................... 1

1

Introduction .............................................................................................................................. 1

1.1

Overview ............................................................................................................................ 1

1.2

Occurrence ......................................................................................................................... 1

1.3

Environmental Aspect ........................................................................................................ 2

Chapter 2 .......................................................................................................................................... 3

2

Market Survey .......................................................................................................................... 3

2.1

Global Consumption and demand of Acetaldehyde: ......................................................... 3

2.2

Demand for acetaldehyde in Western Europe and China .................................................. 5

2.3 Demand for acetaldehyde in Japan ......................................................................................... 7

2.4

Indian market for acetaldehyde .......................................................................................... 8

2.5

Present and future condition of demand for acetaldehyde ................................................. 8

Chapter 3 ........................................................................................................................................ 11

3

Literature Survey .................................................................................................................... 11

Chapter 4 ........................................................................................................................................ 12

4

Physical Properties and Uses .................................................................................................. 12

i

4.1 Properties .............................................................................................................................. 12

4.2 Uses ...................................................................................................................................... 19

Chapter 5 ........................................................................................................................................ 20

5

Different Manufacturing Processes ........................................................................................ 20

5.1

Oxidation of Ethylene ...................................................................................................... 20

5.1.1

Two stage process developed by Wacker Chemie ................................................... 21

5.1.2

One stage process developed by Farbwerke Hoechst ............................................... 21

5.2

By Oxidation of ethyl alcohol .......................................................................................... 22

5.3

By Dehydrogenation of ethyl alcohol .............................................................................. 22

5.4

Preparation method of acetaldehyde from acetylene ....................................................... 23

5.5

From synthesis Gas .......................................................................................................... 24

5.6

From acetic acid ............................................................................................................... 24

5.7

From Saturated Hydrocarbons: ........................................................................................ 25

6

Selection of Process with Justification ................................................................................... 26

7

Description of the Process ...................................................................................................... 27

8

Material and Energy Balance ................................................................................................. 29

Chapter 9 ........................................................................................................................................ 45

9

DESIGN OF EQUIPMENT ................................................................................................... 45

9.1

DESIGN OF DISTILLATION COLUMN: ..................................................................... 45

9.2

Design of Heat exchanger ................................................................................................ 88

9.3

Design of Reactor ............................................................................................................ 99

9.4

Design of Condenser ...................................................................................................... 105

Chapter 10 .................................................................................................................................... 109

10 COST ESTIMATION .......................................................................................................... 109

10.1

Estimation of Total Capital Investment: .................................................................... 109

ii

10.2

Estimation of Total Product cost: ............................................................................... 112

11 Profitability Analysis ............................................................................................................ 116

11.1

Gross Earnings/Income: ............................................................................................. 116

11.2

Rate of Return: ........................................................................................................... 116

11.3

Payback Period ........................................................................................................... 116

11.4

Break-Even Analysis .................................................................................................. 117

12 Chapter ................................................................................................................................. 118

PLANT LOCATION AND LAYOUT ......................................................................................... 118

Chapter 13 .................................................................................................................................... 126

13 Pollution and Safety in Process Industries ........................................................................... 126

References .................................................................................................................................... 129

iii

List of Figures

Figure 2.1 The following Pie chart shows the Global Consumption in the year 2012 ..................... 4

Figure 2.2 China's Demand for Acetaldehyde Since 2002 ............................................................... 5

Figure 2.3 Western Europe's Demand for Acetaldehyde Since 2003 .............................................. 6

Figure 2.4 Graph of Japan's Annual import of Acetaldehyde .......................................................... 7

Figure 2.5 India's Acetaldehyde Trade Statistics ( demand and supply) .......................................... 8

Figure 2.6 Chart Showing Major Importers of Acetaldehyde ........................................................ 10

Figure 7.1 Flowsheet ...................................................................................................................... 28

Figure 12.1 Plant Layout .............................................................................................................. 125

iv

List of Tables

Table 2-1 Consumption of Acetaldehyde in Kg ............................................................................... 9

Table 2-2 Some Leading Producers of Acetaldehyde and their Production Capacities ................. 10

Table 4-1 Physical Properties of Acetaldehyde .............................................................................. 13

8-1 Values of constants for calculating Cp ..................................................................................... 31

8-2 Values of CP for different temperature range (kcal/Kg.C) ...................................................... 31

8-3 Mass Balance Table for Vaporizer ........................................................................................... 33

8-4 Energy Balance Table for Vaporizer ........................................................................................ 33

8-5 Mass Balance Table for Reactor .............................................................................................. 34

8-6 Energy Balance Table for Reactor ........................................................................................... 35

8-7 Mass Balance Table for Heat Exchanger ................................................................................. 36

8-8 Energy Balance Table for Heat Exchanger .............................................................................. 36

8-9 Mass Balance Table for Condenser 1 ....................................................................................... 38

8-10 Energy Balance for Condenser 1 ............................................................................................ 38

8-11 Mass Balance Table for Condenser 2 ..................................................................................... 40

8-12 Energy Balance for Condenser 2 ............................................................................................ 40

8-13 Mass Balance for Preheater .................................................................................................... 41

8-14 Energy Balance Table for Preheater....................................................................................... 41

9-1 T-x-y data for ethanol-acetaldehyde ........................................................................................ 46

9-2 List of Parameters used in calculation...................................................................................... 49

9-9-3 Conditions of fluidization ................................................................................................... 103

v

List of Symbols and abbreviations used

Msteam

Mass flow rate of steam.

∆Hsteam

Enthalpy of steam.

E

Mass flow rate of ethanol.

A

Mass flow rate of acetaldehyde.

H

Mass flow rate of hydrogen.

Cp

Specific heat capacity.

λ

Latent heat of vaporization.

F

Molar flow rate of Feed, kmol/hr.

D

Molar flow rate of Distillate, kmol/hr.

W

Molar flow rate of Residue, kmol/hr.

XF

Mole fraction of Acetaldehyde in liquid/Feed.

YD

Mole fraction of Acetaldehyde in Distillate.

XW

Mole fraction of Acetaldehyde in Residue.

MF

Average Molecular weight of Feed, kg/kmol

MD

Average Molecular weight of Distillate, kg/kmol

MW

Average Molecular weight of Residue, kg/kmol

Rm

Minimum Reflux ratio

R

Actual Reflux ratio

L

Molar flow rate of Liquid in the Enriching Section, kmol/hr.

G

Molar flow rate of Vapor in the Enriching Section, kmol/hr.

L

Molar flow rate of Liquid in Stripping Section, kmol/hr.

G

Molar flow rate of Vapor in Stripping Section, kmol/hr.

Q

Thermal condition of Feed

ρL

Density of Liquid, kg/m3.

ρV

Density of Vapor, kg/m3.

qL

Volumetric flow rate of Liquid, m3/s

qV

Volumetric flow rate of Vapor, m3/s

μL

Viscosity of Liquid, cP.

vi

TL

Temperature of Liquid, K.

TV

Temperature of Vapor, K

vii

Abstract

The present work illustrates the production of acetaldehyde by different production methods, market

survey, literature survey and selection of an appropriate method. The method of production we have

chosen is dehydrogenation of ethyl alcohol. In this process, hydrogen is taken out as a by-product

which can be used elsewhere or which can be used to generate heat. In dehydrogenation process more

conversion-taking place compared to other processes. The mass balance is being performed for the

various units involved in the production of acetaldehyde by dehydrogenation of ethyl alcohol method.

We have also done energy balance for each unit to find out heat utility and amount of auxiliary fluids

required for the heat supply. In design section we have designed a distillation column, heat exchanger,

condenser and packed bed reactor which matches the design specifications required for given plant.

Cost estimation is also done along with profitability studies to show the investment required, rate of

return and payback period. The last sections consists of plant layout, pollution control and safety

measures which are very much essential for and process industry.

viii

Chapter 1

1

Introduction

1.1 Overview

Acetaldehyde, CH3CHO is an important intermediate in industrial organic synthesis with IUPAC

name ethanal. It is one of the most important aldehydes, occurring widely in nature and

being produced on a large scale in industry . In acetaldehyde carbon atom shares a double

bond with an oxygen atom, a single bond with a hydrogen atom, and a single bond with another

atom of carbon. The double bond between carbon and oxygen is characteristic of all aldehydes

and is known as the carbonyl group.

1.2 Occurrence

Acetaldehyde is used in the production of perfumes, polyester resins, and basic

dyes. Acetaldehyde is also used as a fruit and fish preservative, as a flavouring agent, and as a

denaturant for alcohol, in fuel compositions, for hardening gelatin, and as a solvent in the rubber,

tanning, and paper industries. Acetaldehyde is a normal intermediate product in the respiration of

higher plants. It occurs in traces in all ripe fruits that have a tart taste before ripening; the

aldehyde content of the volatiles has been suggested as a chemical index of ripening during cold

storage of apples. Acetaldehyde is an intermediate product of alcoholic fermentation but it is

reduced almost immediately to ethanol. It may form in wine and other alcoholic beverages after

exposure to air, and imparts an unpleasant taste; the aldehyde ordinarily reacts to form diethyl

acetal and ethyl acetate. Acetaldehyde is an intermediate product in the decomposition of sugars

in the body and, hence, occurs in traces in blood. Acetaldehyde is a product of most hydrocarbon

oxidations.

1

1.3 Environmental Aspect

Acetaldehyde is toxic when applied externally for prolonged periods, an irritant, and a probable

carcinogen. It is an air pollutant resulting from combustion, such as automotive exhaust

and tobacco smoke. Acetaldehyde is an important intermediate in the production of acetic acid,

acetic anhydride, ethyl acetate, peracetic acid, pentaerythritol, chloral, glyoxal, alkyl amines, and

pyridines. Acetaldehyde was first used extensively during World War I as an intermediate for

making acetone from acetic acid.

2

Chapter 2

2

Market Survey

2.1 Global Consumption and demand of Acetaldehyde:

The global market for acetaldehyde has been trending downward for the past twenty years as a

result of the commercialization of more efficient technologies to produce those products formerly

based on acetaldehyde. For example, the production of plasticizer alcohols has totally switched

from N-butyraldehyde based on acetaldehyde to the oxonation of propylene, while acetic acid is

now made predominantly by the lower-cost methanol carbonylation process.

With acetic acid manufacturing processes migrating from acetaldehyde based production

techniques towards carbonylation-of-methanol, the world acetaldehyde market are projected to

witness a steady deterioration in consumption. But acetic acid facilities based on acetaldehyde

continue to operate in Asia and South America, although these will eventually be phased out in

favour of methanol carbonylation. In addition to these structural changes, acetaldehyde demand

has also declined in the last few years because of mature end-use markets and the effects of the

economic downturn on these acetaldehyde-derived products.

3

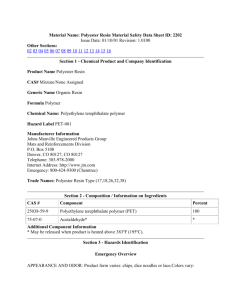

Figure 2.1 The following Pie chart shows the Global Consumption in the year 2012[23]

Sales

1st Qtr

2nd Qtr

3rd Qtr

4th Qtr

.

Production of pyridine and pyridine bases, pentaerythritol, and acetate esters accounted for 16%,

16%, and 14%, respectively, of 2012 global acetaldehyde consumption. Pyridine and pyridine

bases are important raw materials in the production of agricultural chemicals. Pentaerythritol and

acetate esters (mainly ethyl acetate, but also some isobutyl acetate) are both used heavily in

surface coatings. The other uses of acetaldehyde accounted for the remaining global consumption

of acetaldehyde in 2012. This category includes 1, 3-butylene glycol, crotonaldehyde and glyoxal,

along with some smaller-volume derivatives.

As the chart shows, China is the largest consumer of acetaldehyde in the world, accounting for

almost half of global consumption in 2012. Chinese consumption is heavily weighted toward the

production of acetic acid. However, the growth of acetaldehyde in this end use will be limited in

the future because any new acetic acid plants will be based on the methanol carbonylation

process. Other uses such as pyridines and pentaerythritol will grow faster than acetic acid, but the

volumes are not large enough to offset the decline in acetic acid. Consequently, overall Chinese

acetaldehyde consumption will grow only slightly at 1.6% per year through 2018.

4

2.2 Demand for acetaldehyde in Western Europe and China

Western Europe is the second-largest consumer of acetaldehyde worldwide after China,

accounting for 20% of world consumption in 2012. As with China, the Western European

acetaldehyde market is expected to increase only very slightly at 1% per year during 2012 to

2018.

China’s acetaldehyde imports decreased gradually from 2003 and there is a sudden increase in the

value in the year 2010

Figure 2.2 China's Demand for Acetaldehyde Since 2002[23]

Year

5

Figure 2.3 Western Europe's Demand for Acetaldehyde Since 2003[23]

We can see France and Germany are the leading importers of acetaldehyde which shows that they

have a huge demand since 2003.

The US acetaldehyde market will also rise only minimally, at 1–2% per year during 2012–2018.

Acetaldehyde is not consumed for acetic acid and the rest of the markets will experience GDPlike growth in the next five years.

6

2.3 Demand for acetaldehyde in Japan

In contrast, Japan could very well be the brightest spot for acetaldehyde consumption in the next

five years and this hinges upon the on-purpose production of butadiene from acetaldehyde. The

supply of butadiene has been volatile in Japan and the rest of Asia because of the limited

availability of naphtha feedstock. Typically, butadiene and other C4hydrocarbons are coproduced

when naphtha is used as a feedstock for ethylene manufacture. However, the increased production

of natural gas from shale gas, particularly in the United States, has caused many ethylene crackers

to switch feedstock from naphtha to ethane, which yields lower volumes of co product butadiene

and other C4hydrocarbons. This has spurred the revival of on-purpose production for butadiene

and Japan certainly has enough sources of acetaldehyde to support such a project. This new end

use should provide a much needed boost to an otherwise flat acetaldehyde market. If Showa

Denko starts up its butadiene plant as scheduled, acetaldehyde consumption in Japan should

exhibit close to 4% per year growth through 2018.

.

Figure 2.4 Graph of Japan's Annual import of Acetaldehyde[23]

Year

7

2.4 Indian market for acetaldehyde

Indian consumption is anticipated to have moderate growth rate of nearly 3% for the next several

years and demand for acetaldehyde use in acetic acid production will grow 3-4% annually.

Figure 2.5 India's Acetaldehyde Trade Statistics ( demand and supply)[23]

2.5 Present and future condition of demand for acetaldehyde

Overall, the global market for acetaldehyde has grown 2-3% annually during 2009-2014.

However, some of this growth is actually a recovery from the significant decline experienced in

2009(for example, China’s use in acetic acid market). Major regions including Western Europe,

United States of America will have low growth than that of global consumption’s rate. However,

the demand for acetaldehyde worldwide has continued to decrease primarily as a result of less

consumption for acetic acid manufacture, as the industry continues to move toward more efficient

methanol carbonylation process. Its production in North America and Western Europe has

8

decreased but its manufacture in Asia continues and new acetaldehyde capacity has been installed

in china, but this is the only area where new capacity has been added.

Traditionally, acetaldehyde was mainly used as a precursor to acetic acid. In terms of

condensation reactions, acetaldehyde is an important precursor to pyridine derivatives,

pentaerythritol, and crotonaldehyde. Urea and acetaldehyde combine to give a useful resin. Acetic

anhydride reacts with acetaldehyde to give ethylidene diacetate, a precursor to vinyl acetate,

which is used to produce polyvinyl acetate.

China is the largest consumer of acetaldehyde in the world, accounting for almost half of global

consumption in 2012. Major use has been the production of acetic acid. Other uses such

as pyridines and pentaerythritol are expected to grow faster than acetic acid, but the volumes are

not large enough to offset the decline in acetic acid. As a consequence, overall acetaldehyde

consumption in China may grow slightly at 1.6% per year through 2018. Western Europe is the

second-largest consumer of acetaldehyde worldwide, accounting for 20% of world consumption

in 2012. As with China, the Western European acetaldehyde market is expected to increase only

very slightly at 1% per year during 2012–2018. However, Japan could emerge as a potential

consumer for acetaldehyde in next five years due to newfound use in commercial production

of butadiene. The supply of butadiene has been volatile in Japan and the rest of Asia. This should

provide the much needed boost to the flat market, as of 2013

Table 2-1 Consumption of Acetaldehyde in Kg[23]

9

Table 2-2 Some Leading Producers of Acetaldehyde and their Production Capacities[5]

COMPANY

Production ( in 103 t)

Celanese Chemicals Europe, Germany

120

Eastman chemical company

225

ECROS,SA, Spain

90

Japan aldehyde company Ltd, Japan

69

Jilin chemical industrial company, China

180

Kyowa Yuka Company Ltd, Japan

61

Wacker chemie AG, Germany

65

Figure 2.6 Pie Chart Showing Major Importers of Acetaldehyde[5]

10

Chapter 3

3

Literature Survey

Acetaldehyde was first prepared by Scheele in 1774, by the action of manganese dioxide and

sulphuric acid on ethanol[1]. Liebig established the structure of acetaldehyde in 1835 when he

prepared a pure sample by oxidizing ethyl alcohol with chromic acid [2]. Liebig named the

compound “aldehyde” from the Latin words translated as al (cohol) dehyd (rogenated).

Kutscherow observed the formation of acetaldehyde by the addition of water to acetylene in

1881[3]. Commercial processes for the production of acetaldehyde include: the oxidation or

dehydrogenation of ethanol, the addition of water to acetylene, partial oxidation of hydrocarbons,

and the direct oxidation of ethylene. It is estimated that in 1976, 29 companies with more than

82% of the world’s 2.3 megaton per year plant capacity use the Wacker Hoechst processes for the

direct oxidation of ethylene[5].

11

Chapter 4

4

Physical Properties and Uses

4.1 Properties

Chemical name: Acetaldehyde

Othername:Ethanal

Chemical formula CH3CHO

Molecular mass 44.05 g/mol

Appearance: Colourless liquid and Etherial odour

Structure:

12

Physical properties

Acetaldehyde is a colorless, mobile liquid having a pungent suffocating odour that is somewhat

fruity and pleasant in dilute concentrations. Some physical properties of acetaldehyde are given in

Table 4.1.

The freezing points of aqueous solutions of acetaldehyde are as follows: 4.8 wt %, -2.50C; 13.5

wt %, - 7.80 C, and 31.0 wt %, - 23.00 C. Acetaldehyde is miscible in all proportions with water

and most common organic solvents: acetone, benzene, ethyl alcohol, ethyl ether, gasoline,

paraldehyde, toluene, xylenes, turpentine, and acetic acid.

Table 4-1 Physical Properties of Acetaldehyde[5]

Properties

Values

Formula weight g/mol

44.053

Melting point °C

-123.5

Boiling point at 101.3 kPa (1 atm), °C

20.16

Specific Density

0.8045

Coefficient of expansion per °C (0-30 °C)

0.00169

Refractive index

1.33113

Vapor density (air = 1 )

1.52

Absolute viscosity at 15 °CmPa.s b

0.02456

Specific heat at 0 °C,J/(g.K)

2.18

At 25 °C

1.41

α = Cp / Cv at 30 °C and 101.3 kPa

1.145

13

Latent heat of fusion, kJ/mol

3.24

Latent heat of vaporization, kJ/mol

25.71

Heat of solution in water at 0 °C, kJ/mol

- 8.20

At 25 °C

- 6.82

Heat of combustion of liquid at constant

11867.9

pressure, kJ/mol

Heat of formation at 273 K, kJ/mol

-165.48

Free energy of formation at 273 K, kJ/mol

-136.40

Critical temperature, °C

181.5

Critical pressure, MΡa (atm)

6.40(63.2)

Dipole moment, C-m (debyes )

9.04 x 10 – 30

(2.69)

Ionization potential, Ev

10.50

Dissociation constant at 0 °C, K

0.7 x 10 – 14

Flash point, closed cup, °C

-38

Ignition temperature in air, °C

165

14

Chemical Properties

Acetaldehyde is a highly reactive compound exhibiting the general reactions of aldehydes;

under suitable conditions, the oxygen or any hydrogen can be replaced. Acetaldehyde

undergoes numerous condensation, addition, and polymerization reactions.

Decomposition Reaction of Acetaldehyde

Acetaldehyde decomposes at temperatures above 400°C, forming principally methane and

carbon monoxide. The activation energy of the pyrolysis reaction is 97.7 kJ/mol

(408.8kcal/mol).

The Hydrate and Enol Form of Acetaldehyde

In aqueous solutions, acetaldehyde exists in equilibrium with the hydrate, CH3CH(OH)2. The

degree of hydration can be computed from an equation derived by Bell and Clunie. The mean

heat of hydration is –21.34 kJ/mol (89.29kcal/mol); hydration has been attributed to hyper

conjugation. The enol form, vinyl alcohol (CH2 = CHOH) exists in equilibrium with

acetaldehyde to the extent of approximately one molecule per 30,000. Acetaldehyde enol has

been acetylated with ketene to form vinyl acetate.

Reduction Reaction of Acetaldehyde

Acetaldehyde is readily reduced to ethanol. Suitable catalysts for vapor-phase hydrogenation

are supported nickel and copper oxide.

15

Oxidation Reactions of Acetaldehyde

Acetaldehyde is readily oxidized with oxygen or air to acetic acid, acetic anhydride, and

peracetic acid. The principal product isolated depends on reaction conditions. Acetic acid is

produced commercially by the liquid – phase oxidation of acetaldehyde at 65°C with cobalt or

manganese acetate dissolved in acetic acid as a catalyst. Liquid – phase oxidation of

acetaldehyde in the presence of mixed acetates of copper and cobalt yields acetic anhydride.

Peroxyacetic acid or a perester is believed to be the precursor of acetic acid and acetic

anhydride. There are two commercial processes for the production of peracetic acid. Low

temperature oxidation of acetaldehyde in the presence of metal salts, ultraviolet irradiation, or

ozone yields acetaldehyde monoperacetate, which can be decomposed to peracetic acid and

acetaldehyde. Peracetic acid can also be formed directly by liquid phase oxidation at 5 - 50°C

with a cobalt salt catalyst. The nitric acid oxidation of acetaldehyde yields glyoxal. Oxidations

of para xylene to terephthalic acid and of ethanol to acetic acid are activated by acetaldehyde.

Polymerization Reactions of Acetaldehyde

Paraldehyde, 2, 4, 6- trimethyl–1,3,5–trioxan, a cyclic trimer of acetaldehyde is formed when a

mineral acid, such as sulfuric, phosphoric, or hydrochloric acid, is added to acetaldehyde.

Paraldehyde can also be formed continuously by feeding acetaldehyde as a liquid at 15 - 20°C

over an acid ion – exchange resin. Depolymerization of paraldehyde occurs in the presence of

acid catalysts.

Metaldehyde, a cyclic tetramer of acetaldehyde, is formed at temperatures below 0°C in the

presence of dry hydrogen chloride or pyridine hydrogen bromide. The metaldehyde crystallizes

from solution and is separated from the paraldehyde by filtration. Metaldehyde melts in a

sealed tube at 246.2°C and sublimes at 115 °C with partial depolymerization.

More recently, it has been shown that white, nontacky, and highly elastic polymer can be

formed by cationic polymerization with BF3 in liquid ethylene. At temperatures below

-75°C with anionic initiators, such as metal alkyls in a hydrocarbon solvent, a crystalline,

isotactic polymer is obtained.

16

This polymer also has an acetal structure [poly (oxymethylene) structure]. Molecular weights

in the range of 800,000 – 3,000,000 have been reported.

Reactions with aldehydes and ketones

The base catalyzed condensation of acetaldehyde leads to the dimmer, acetaldol, which can be

hydrogenated to form 1,3 butandiol or dehydrated to form crotonaldehyde. Crotonaldehyde can

also be made directly by the vapor-phase condensation of acetaldehyde over a catalyst.

Crotonaldehyde was formerly an important intermediate in the production of butyraldehyde,

butanol, and 2-ethylhexanol.

Acetaldehyde forms aldols with other carbonyl compounds containing active hydrogen atoms.

Kinetic studies of the aldol condensation of acetaldehyde and deuterated acetaldehydes have

shown that only the hydrogen atoms bound to the carbon adjacent to the –CHO group takes

part in the condensation reactions and hydrogen exchange. A hexyl alcohol, 2-ethyl-1 butanol,

is produced, industrially by the condensation of acetaldehyde and butaraldehyde in dilute

caustic solution followed by hydrogenation of the acrolein intermediate. condensation of

acetaldehyde in the presence of dimethylamine hydrochloride yields polyenals which can be

hydrogenated to a mixture of alcohols containing from 4 to 22 carbon atoms.

The base catalyzed reaction of acetaldehyde with excess formaldehyde is the commercial route

to pentaerythritol. The aldol condensation of three moles of form aldehyde with one mole of

acetaldehyde is followed by a crossed cannizzaro reaction between pentaerythrose, the

intermediate product, and formaldehyde to give pentaerythritol. The process proceeds to

completion without isolation of the intermediate. Pantaerythrose has been made by condensing

acetaldehyde and formaldehyde at 450 C using magnesium oxide as a catalyst. The vapor-phase

reaction of acetaldehyde and formaldehyde at 450C over a catalyst composed of lanthanum

oxide on silica gel gives acrolein. Ethyl acetate is produced commercially by the Tischenko

condensation of acetaldehyde with an aluminum ethoxide catalyst. The Tischenko reaction of

acetaldehyde with isobutyraldehyde yields a mixture of ethyl acetate, isobutyl acetate, and

isobutyl isobutyrate.

17

Reactions with Ammonia and Amines

Acetaldehyde readily adds ammonia to form acetaldehyde ammonia. Diethyl amine is obtained

when acetaldehyde is added to a saturated aqueous or alcoholic solution of ammonia and the

mixture is heated to 50-750C in the presence of a nickel catalyst and hydrogen at 1.2 MPa

(12atm). Pyridine and pyridine derivates are made from paraldehyde and aqueous ammonia in

the presence of a catalyst at elevated temperatures; acetaldehyde may also be used by the yields

of pyridine are generally lower than when paraldehyde is the staring material.

Reactions with Alcohols and Phenols

Alcohols add readily to acetaldehyde in the presence of a trace of mineral acid to form acetals;

eg, ethanol and acetaldehyde form diethyl acetal. Similarly, cyclic acetals are formed by the

reactions with glycols and other polyhydroxy compounds; eg, the reaction of ethylene glycol

and acetaldehyde gives 2 – methyl – 1,3 – dioxolane.

Mercaptals, CH3CH(SR)2, are formed in a like manner by the addition of mercaptans. The

formation of acetals by a noncatalytic vapor – phase reactions of acetaldehyde and various

alcohols at 3500C has been reported. Butadiene can be made by the reaction of acetaldehyde

and ethyl alcohol at temperature s above 3000C over a tantala – silica catalyst. Aldol and

crotonaldehyde are believed to be intermediates. Butyl acetate has been prepared by the

catalytic reaction of acetaldehyde with butanol at 3000C.

Reactions with Halogens and Halogen compounds

Halogens readily replace the hydrogen atoms of the methyl group. eg, chlorine reacts with

acetaldehyde or paraldehyde at room temperature to give chloroacetaldehyde; increasing the

temperature to 700-800C gives dichloroacetaldehyde; and at a temperature of 80-900C chloral

is formed.

18

4.2 Uses

The manufacturers use about 95% of the acetaldehyde produced internally as an intermediate

for the production of other organic chemicals. Acetic acid and acetic anhydride are the

derivatives of acetaldehyde followed by n-butanol and 2-ethylhexanol. Twenty percent of the

acetaldehyde is consumed in variety of other products, the most important being

pentaerythritol, trimethylolpropane, pyridines, peraceticacid, crotonaldehyde, chloral, lactic

acid. Acetaldehyde is used in the production of perfumes, polyester resins, and basic

dyes. Acetaldehyde is also used as a fruit and fish preservative, as a flavoring agent, and as a

denaturant for alcohol, in fuel compositions, for hardening gelatin, and as a solvent in the

rubber, tanning, and paper industries.

19

Chapter 5

5

Different Manufacturing Processes

The economics of the various processes for the manufacture of acetaldehyde are strongly

dependent on the price of the feedstock used.

5.1 Oxidation of Ethylene [1]

Reactions:

C2H4+PdCl2 + H2O

CH3CHO +Pd +2HCl

Pd + 2CuCl2

PdCl2 +2CuCl

2CuCl+1/2 O2 + 2HCl

2CuCl2 + H2O

The catalyst is an aqueous solution of PdCl2 and CuCl2. In 1894, F.C. Phillips observed the

reaction of ethylene with an aqueous palladium chloride solution to form acetaldehyde. The net

result is a process in which ethylene is oxidized continuously through a series of oxidation –

reduction reactions.

Overall Reaction:

C2H4 + ½ O2

CH3CHO

There are two processes for the production of acetaldehyde by the oxidation of Ethylene.

20

5.1.1 Two stage process developed by Wacker Chemie[5]

In the two – stage process ethylene and oxygen (air) react in the liquid phase in two stages. In

the first stage ethylene is almost completely converted to acetaldehyde in one pass in a tubular

plug-flow reactor made of titanium. The reaction is conducted at 125-1300C and 1.13 Mpa (150

psig) palladium and cupric chloride catalysts. Acetaldehyde produced in the first reactor is

removed from the reaction loop by adiabatic flashing in a tower. The flash step also removes

the heat of reaction. The catalyst solution is recycled from the flash – tower base to the second

stage (or oxidation) reactor where the cuprous salt is oxidized to the cupric state with air. The

high pressure off – gas from the oxidation reactor, mostly nitrogen, is separated from the liquid

– catalyst solution and scrubbed to remove acetaldehyde before venting. The flasher overhead

is fed to a distillation system where water is removed for recycle to the reactor system and

organic impurities, including chlorinated aldehydes, are separated from the purified

acetaldehyde product.

5.1.2 One stage process developed by Farbwerke Hoechst[5]

In the one-stage process ethylene, oxygen, and recycle gas are directed to a vertical reactor for

contact with the catalyst solution under slight pressure. The water evaporated during the

reaction absorbs the heat evolved, and make – up water is fed as necessary to maintain the

catalytic solution concentration. The gases are water –scrubbed and the resulting acetaldehyde

solution is fed to a distillation column and thus acetaldehyde is obtained.

21

5.2 By Oxidation of ethyl alcohol [1,2]

Reaction:

CH3CH2OH + ½ O2

CH3CHO + H2O, ΔH = 242 kJ/mol (57.84 kcal / mol)

Temperature: 4800C

Catalyst: silver

Passing alcohol vapours and preheated air over a silver catalyst at 4800C carries out the

oxidation. With a multi tubular reactor, conversions of 74-82% per pass can be obtained while

generating steam which can be used elsewhere in the process.

5.3 By Dehydrogenation of ethyl alcohol[1]

Reaction:

C2H5OH → CH3CHO + H2

Catalyst: Cu -Co-Cr2O3

Temperature: 280 – 350 0C.

Process description

The raw material i.e., ethanol is vaporized and the vapours so generated are heated in a heat

exchanger to the reaction temperature by hot product stream. The product stream is cooled to –

100C and in doing it; all unreacted ethanol and acetaldehyde are condensed. The outgoing

gaseous stream, containing hydrogen mainly, is scrubbed with dilute alcohol (alcohol + water)

to remove uncondensed products and the undissolved gas. The remaining pure hydrogen (98%)

is burnt in stack. Ethanol is vaporized in vaporizer and heated to the reactor temperature in heat

exchanger. The heated vapours are passed through the converter. The product stream is first

cooled in heat exchanger and then in condensers using water and liquid ammonia. This

condenses most of the unreacted ethanol and the acetaldehyde formed in reactor.

22

The escaping gas, which is almost pure hydrogen, is scrubbed by ethanol to remove all the

traces of the product. The liquid stream consisting of mainly ethanol and acetaldehyde is

distilled in distillation column to get acetaldehyde.

5.4 Preparation method of acetaldehyde from acetylene [2,3]

Reaction:

H2C = CH2 + H2O

CH3CHO

Temperature: 70-900C

Pressure: 103.4 KPa

Process description

Fresh catalyst is fed to the reactor periodically; the catalyst may be added in the mercurous

form. The excess acetylene sweeps out the dissolved acetaldehyde which is condensed by water

and refrigerated brine and scrubbed with water; the crude acetaldehyde is purified by

distillation and the unreacted acetylene is recycled. The catalytic mercuric ion is reduced to

catalytically inactive mercurous sulfate and metallic mercury; this sludge, consisting of reduced

catalyst and tars, is drained from the reactor at intervals and resulfated. Adding ferric or other

salts to the reaction solution can reduce the rate of catalyst depletion. In one variation,

acetylene is completely hydrated with water in a single operation at 68-730C using the

mercuric iron salt catalyst. The acetaldehyde is partially removed by vacuum distillation and

the mother liquor recycled to the reactor. The aldehyde vapors are cooled to about 350C,

compressed to 253 KPa and condensed. It is claimed that this combination of vacuum and

pressure operations substantially reduces heating and refrigeration costs.

23

5.5 From synthesis Gas[2]

Reaction:

CO + H2 → CH3CHO + other products

Catalyst: Rhodium

Temperature: 3000C

The process is a single step comprises passing synthesis gas over 5% rhodium on SiO2 at

3000C and 2.0 Mpa (20 atm). The principal co products are acetaldehyde, 24% acetic acid,

20%; and ethanol, 16%.

5.6 From acetic acid[4]

Reaction:

CH3 COOH + H2 → CH3 CHO + H2 O ΔG300° C. = +0.8 kcal/mole

Catalyst: Iron oxide containing 2.5-90 wt% Pd

Temperature: 250-400 0C

Procedure:

Hydrogen and acetic acid are fed to a reactor in hydrogen to acetic acid ratio of 2:1 to 25:1. The

hydrogenation of acetic acid produces a partially gaseous product, and acetaldehyde is

absorbed from the partially gaseous product with a solvent containing acetic acid. The gas

remaining after the absorption step contains hydrogen, and this gas is recycled for the

hydrogenation of acetic acid. The absorbed acetaldehyde is distilled. After acetaldehyde is

isolated from unreacted acetic acid and the other products via distillation, the unreacted acetic

acid is separated from the other products using azeotropic distillation. Water is contained in the

other products, and the azeotrope is an azeotrope of ethyl acetate and water. The unreacted

24

acetic acid is separated in a column, and the column is controlled to contain an ethyl acetate

rich azeotrope of ethyl acetate and water.

5.7 From Saturated Hydrocarbons:

Acetaldehyde is formed as a co product in the vapour – phase oxidation of saturated

hydrocarbons, such as butane or mixtures containing butane, with air or in higher yield oxygen.

Oxidation of butane yields acetaldehyde, formaldehyde, methanol, acetone, and mixed solvents

as major products; other aldehydes, alcohols, ketones, glycols, acetals, epoxides, and organic

acids are formed in smaller concentrations. It has almost no chance to be used as a major

process.

25

Chapter 6

6

Selection of Process with Justification

Here, ethyl alcohol dehydrogenation is selected for the production of acetaldehyde. Because, in

this process, hydrogen is taken out as a by-product which can be used elsewhere or which can

be used to generate heat. In dehydrogenation process more conversion-taking place compared

to other processes. The dehydrogenation catalyst has a life of several years but requires

periodic reactivation. In dehydrogenation process, number of products is less, so separation of

acetaldehyde from other product is not a difficult problem.

26

Chapter 7

7

Description of the Process

Production of Acetaldehyde by Dehydrogenation of Ethyl alcohol

Reaction:

C2H5OH → CH3CHO + H2

Catalyst

: Cu -Co-Cr2O3

Temperature: 280 – 350 0C.

Process description:

The raw material i.e., ethanol is vaporized and the vapours so generated are heated in a

heat exchanger to the reaction temperature by hot product stream. The product stream is

cooled to –100C and in doing it; all unreacted ethanol and acetaldehyde are condensed.

The outgoing gaseous stream, containing hydrogen mainly, is scrubbed with dilute

alcohol (alcohol + water) to remove uncondensed products and the undissolved gas. The

remaining pure hydrogen (98%) is burnt in stack. Ethanol is vaporized in vaporizer and

heated to the reactor temperature in heat exchanger. The heated vapours are passed

through the converter. The product stream is first cooled in heat exchanger and then in

condensers using water and liquid ammonia. This condenses most of the unreacted

ethanol and the acetaldehyde formed in reactor. The escaping gas, which is almost pure

hydrogen, is scrubbed by ethanol to remove all the traces of the product. The liquid

stream consisting of mainly ethanol and acetaldehyde is distilled in distillation column to

get acetaldehyde.

27

Figure 7.1 Flowsheet

28

Chapter 8

8

Material and Energy Balance

8.1 Reaction

C2H5OH → CH3CHO + H2

Catalyst

: Cu -Co-Cr2O3

Temperature: 280 – 3500 C.

Process

The raw material i.e., ethanol is vaporized and the vapors, so generated, are heated in a

heat exchanger to the reaction temperature by hot product stream. The product stream is

cooled to –100 C and in doing it, all unreacted ethanol and acetaldehyde are condensed.

The outgoing gaseous stream, containing hydrogen mainly, is scrubbed with dilute

alcohol (alcohol + water) to remove uncondensed products and the undissolved gas. The

remaining pure hydrogen (98%) is burnt in stack.

The material and energy balance in a plant design is necessary because this fixes the

relative flow rates of different flow streams and temperatures in the flow sheet.

29

Notations used

Msteam = Mass flow rate of steam.

∆Hsteam = enthalpy of steam.

E = Mass flow rate of ethanol.

A = Mass flow rate of acetaldehyde.

H = Mass flow rate of hydrogen.

Cp = specific heat capacity.

λ = Latent heat of vaporization.

Assumptions :

Let us assume an annual production of acetaldehyde 54000 tons per year.

It is assumed that the plant works for 300 days in a year.

Amount of acetaldehyde produced per day =180 tons per day

Basis: One hour of operation.

Amount of acetaldehyde to be produced = 180 TPD = 7500kg/h.

Molecular weight of ethanol = 46 kg/kmol.

Molecular weight of acetaldehyde = 44 kg/kmol.

Molecular weight of hydrogen = 2 kg/kmol.

Therefore, amount of acetaldehyde to be produced = 170.45kmol/h.

Let conversion be 90%.

Taking into account the losses let, the acetaldehyde produced to be some extra.

Let acetaldehyde to be produced = 8000 kg/h.

Amount of ethanol required for 100% conversion = 8363.63 kg/h.

Therefore, ethanol required for 90% conversion = 9292.92 kg/h.

Temperature dependency of Cp with temperature is given as

30

𝑇

∫

𝑇0

𝐶𝑝

𝑇 2 − 𝑇02

𝑇 3 − 𝑇03

𝑇 4 − 𝑇04

𝑇 5 − 𝑇05

𝑑𝑇 = 𝐴(𝑇 − 𝑇0 ) + 𝐵

+𝐶

+𝐷

+𝐸

𝑅

2

3

4

5

8-1 Values of constants for calculating Cp[22]

Component

A

B*103

C*106

D*10-5

Ethanol

3.518

20.001

-6.002

0

Hydrogen

3.249

0.422

0

0.083

Acetaldehyde

1.693

17.978

-6.158

0

Water

3.470

1.450

0

0.121

8-2 Values of CP for different temperature range (kcal/Kg.C)

Component

-25

40 oC

to 25 to

78.4 oC

78.4

to 100

100 oC

to 200

200 oC

to 40

310 oC

232.36

to 310

o

C

o

C

Ethanol

0.616

0.587

0.4382

0.471

0.539

0.5415

0.549

Acetaldehyde 0.347

-----

------

-----

------

0.417

0.528

Hydrogen

3.399

-----

-----

-----

------

2.485

2.485

Water

---

------

-----

-----

------

------

----

31

8.2 Vaporizer

As shown in the figure,

Ethanol liquid inlet temperature = Ti=25oC.

Ethanol leaves as superheated steam at 1000C = To

Heating fluid is assumed to be saturated steam here and to provide sufficient temperature

gradient; it is taken to be at about 3 atmospheric pressure. At this pressure it condenses at

133.890 C and because process streams are normally available at this pressure.

Condensing temperature of water = 133.890 C.

From steam table enthalpy of steam at this temperature = ∆Hsteam =514.9kcal/kg. [6]

Boiling point of ethanol = Tb = 78.40 C. [6]

Latent heat of vaporization of ethanol= λ ethanol = 200.6 kcal/kg [6]

From heat balance we have,

Msteam = E*[Cpi*(Tb-Ti) + λ ethanol + Cpo*(To-Tb)]

Msteam = 9292.92* [0.5876 * (78.4 – 25) + 200.6 + 0.4382 * (100 – 78.4)]/514.9

= 4357.56 kg.

32

8-3 Mass Balance Table for Vaporizer

Component

Input Feed Stream

Output Feed Stream

(Kg)

(Kg)

Ethanol

9292.92

9292.92

Water

4357.56

4357.56

Total

13650.48

13650.48

For Water

𝑇

Heat in = (𝑚 ∫𝑇 𝐷 𝐶𝑃 𝑑𝑇)

𝑜

𝑊𝑎𝑡𝑒𝑟

+ m ∗ λ𝑤𝑎𝑡𝑒𝑟 = 2714324.124kcal

Where To=298.15 K and TD=406.15K

406.15

Heat out=(𝑚 ∫298.15 𝐶𝑃 𝑑𝑇)

𝑊𝑎𝑡𝑒𝑟

=2714324.124 kcal

For ethanol (Tref= 298.15 K)

Heat in= 0 kcal

Heat out=470616.48kcal

8-4 Energy Balance Table for Vaporizer

Component

Stream In kcal

Stream Out kcal

Ethanol

0

2243710.112

Water

2714324.124

470616.48

Total

2714324.124

2714326.592

8.3 Reactor

33

The reaction in the reactor:

C2H5OH → CH3CHO + H2

Optimum reaction temperature = 3100C.

Conversion = 90%.

From material balance we have,

Amount of acetaldehyde produced = .90 * 44* 9292.92 / 46 =8000 kg.

=181.81kmol

Amount of hydrogen produced = .90 * 2* 9292.92 / 46 = 363.63 kg.

Amount of ethanol unreacted = 9292.92 – (8000 + 363.63)

= 929.28kg =20.20 kmol

8-5 Mass Balance Table for Reactor

Component

Input Feed stream (Kg)

Output feed stream (kg)

Ethanol

9292.92

929.28

Acetaldehyde

0

8000

Hydrogen

0

363.64

Dowtherm

32447.6042

32447.6042

Total

41740.5252

41740.5252

It is decided to use saturated vapours of dowtherm, at 3200 C, for cooling purposes

λ dowtherm = 56.5 kcal / kg.

Heat of reaction = ∆Hrxn = 332.64 kcal / kg. [6]

Assuming ethanol vapors enter the reactor at 2000 C.

From heat balance we can found amount of dowtherm required = Md.

Specific heat capacity of ethanol = 0.549 kcal / kg 0C.

Energy in by ethanol =929.28*[0.5876*(98.2-25)+200.6+0.549*(310-98.2)]

=334439.0624 kcal/kg

Energy in by hydrogen=363.63*2.485*(310-25)=257531.8568 kcal/kg

34

Energy in by acetaldehyde

=8000*0.528*(310-25)

=1203840 kcal/kg

Energy required for the reaction

=0.90*9292.92*332.64

=2782077.218 kcal/kg

Q= Amount of heat supplied by dowtherm

Q={Energy out from the reactor+ Heat of reaction }-{Energy entering into the reactor}

= 1833289.639 kcal

Md *λdowtherm=Q

Md=1833289.639 /56.5=32447.6042Kg

8-6 Energy Balance Table for Reactor

Component

Stream In (kcal)

Stream Out(kcal)

Ethanol

2744598.5

334439.0624

Hydrogen

0

257531.8568

Acetaldehyde

0

1203840

Heat Exchanger

This is used only for heat recovery. Since it is assumed vapor is heated up to 200 0 C by

the product stream of the reactor at 3100 C.

Let outlet temperature = T0 C.

Cp of ethanol at 3100 C = 0.549 kcal / kg 0C.

35

Cp of acetaldehyde at 3100 C = 0.528 kcal / kg 0C.

Cp of hydrogen at 3100 C = 2.485 kcal / kg 0C.

8-7 Mass Balance Table for Heat Exchanger

Component

Ethanol

Acetaldehyde

Water

Total

Shell in (kg)

929.28

8000

363.63

9292.91

Tube in (kg)

9292.92

9292.92

Shell out (Kg)

929.28

8000

363.63

9292.91

Tube out (kg)

9292.92

9292.92

From heat balance we can find the outlet temperature.

E*Cp,ethanol*(200–100)=E*Cp,ethanol*(310–T) +H*Cp,hydrogen*(310–T)+ A*Cp,acet*(310-T)

9292.92*0.471*(200-100)=929.92*0.549*(310-T)+363.63*2.485*(310T)+8000*0.528*(310-T)

Therefore, T = 232.360 C.

8-8 Energy Balance Table for Heat Exchanger

Component

Shell side(kcal)

Tube side(kcal)

Ethanol

437696

39637.24

Hydrogen

-

70157.099

Acetaldehyde

-

327951.36

Total

437696

437745.699

8.4 Condenser C1

In condenser 1 it is decided to use cooling water at 300 C. the outlet temperature of

cooling water is not allowed to go above 500C, because above this temperature, there is a

problem of vaporization. Normally the approach temp difference is about 100C. Since the

product can at best be cooled to 400C, at this temperature the product stream would be a

two-phase mixture and the mixture composition can be found out from VLE data.

We make an approximate that; the information given at 699 mmHg is taken.

36

At 4000C, ethanol in vapor phase = 4.1 mol%.[6]

Ethanol in liquid phase = 55 mol%.[6]

Let, ml = moles of liquid consisting of ethanol and acetaldehyde.

mv = moles of vapor consisting of ethanol and acetaldehyde.

Therefore from mole balance we have

0.55 * ml + 0.041 * mv = 20.20

0.45 * ml + 0.959 * mv = 181.81

On solving above two equations we get, ml = 23.413 kmol.

mv = 178.596 kmol.

Vapor phase composition,

Acetaldehyde = 171.27 kmol = 7536.03 kg.

Ethanol = 7.32 kmol = 336.83 kg.

Liquid phase composition,

Acetaldehyde = 10.535 kmol = 463.57 kg.

Ethanol = 12.977 kmol = 592.348 kg

Heat Balance

At 232.690C,

Cp, hydrogen = 2.485 kcal / kg 0C.

Cp, acetaldehyde = 0.417 kcal / kg 0C.

Cp, ethanol = 0.5415 kcal / kg 0C.

λ acetaldehyde = 139.5 kcal / kg.

λ ethanol = 200.6 kcal / kg.

Heat given out by hydrogen = 363.636 * 2.485 * (232.69 – 40) = 173.823 * 103 kcal.

Heat given out by acetaldehyde = 8000* 0.417 * (232.69 – 40) + 463.57 * 139.5

= 706.38 * 103 kcal.

Heat given out by ethanol = 929.92* 0.5415 * (232.69 – 40) + 592.348 *200.6

= 215.621 * 103 kcal.

Total heat given out = 1095.82 * 103 kcal.

Let, Mw = mass flow rate of cooling water

Cp of water = 1 kcal / kg 0C.

37

Therefore, Mw = 1095.8 * 103 / (1 * (5030)). = 54.79 * 103 kg.

8-9 Mass Balance Table for Condenser 1

Component

In (Kg)

Vapor

Phase

Out (Kg)

Liquid phase out (Kg)

Ethanol

929.28

336.83

592.348

Acetaldehyde

8000

7536.03

463.57

Hydrogen

363.64

363.636

--------

Water

54791.29

----------

54791.29

Total

64084.21

64083.704

8-10 Energy Balance for Condenser 1

Component

Tube side (kcal)

Shell side (kcal)

Ethanol

215621

------

Hydrogen

173823

------

Acetaldehyde

706380

------

Water

--------

1095800

Total

1095824

1095800

Condenser C2

In condenser c2, it is desired to condense all ethanol and acetaldehyde. If the working

38

pressure is 1 atm. From the equilibrium data it is seen that for temperatures below 300C,

there is going to be no ethanol in vapor phase and acetaldehyde would exert its vapor

pressure at that temperature. If it is desired to achieve about 97% recovery of

acetaldehyde, the outlet temperature of the product stream should be about –250C.This is

because at –22.60C, its vapor pressure is 100 mmHg and the vapor phase will consists of

13.15 mol%. In view of this, the cooling fluid chosen is saturated NH3 at 1 atm. At which

it boils at –33.60C[6].

Heat balance:

At 400C,

Cp, hydrogen = 3.399 kcal / kg 0C.

Cp, acetaldehyde = 0.347 kcal / kg 0C.

Cp, ethanol = 0.616 kcal / kg 0C.

λ acetaldehyde = 139.5 kcal / kg.

λ ethanol = 200.6 kcal / kg.

λ ammonia = 590 kcal / kg.

Heat given out by hydrogen = 363.64 * 3.399 * (40 + 25) = 80.339 * 103 kcal.

Heat given out by acetaldehyde = 7536.03* 0.347 * (40+ 25) + 7309.95 * 139.5

= 1189.182 * 103 kcal.

Heat given out by ethanol = 336.83* 0.616 * (40+25) + 336.83 * 200.6

39

= 81.054 * 103 kcal.

Total heat given out = 1350.575 * 103 kcal.

Let Mammonia = mass flow rate of ammonia.

Therefore, Mammonia = 1350.575 * 103 / 590.= 2289.11 kg.

8-11 Mass Balance Table for Condenser 2

Component

Feed In (Kg)

Vapor Phase Out (Kg)

Liquid Phase out (Kg)

Ethanol

336.83

--------

336.83

Acetaldehyde

7536.03

226.10

7309.95

Hydrogen

363.64

363.64

----------

NH3

2289.11

2289.11

----------

Total

10525.61

10525.63

8-12 Energy Balance for Condenser 2

Component

Tube side (kcal)

Shell side (kcal)

Ethanol

81.054*103

------

Hydrogen

80.339*103

------

Acetaldehyde

1189.182*103

------

Ammonia

--------

1350574.9

Total

1350.575*103

1350.5749*103

Preheater

The preheater to the distillation column is necessary because the feed plate will be

completely chilled if the feed is not heated. The water stream from condenser c1 is

40

available at 500C and is used in the preheater. If the maximum approach temperature

difference is 100C, the product stream can at best be heated to 400C. the distillation

column pressure is chosen to be 1158 mmHg so that pure acetaldehyde is obtained as

liquid product at 400C. In view of this, the stream coming out of the preheater is liquid.

Heat balance

At 40 oC

Cp, acetaldehyde = 0.347 kcal / kg 0C.

Cp, ethanol = 0.616 kcal / kg 0C.

Let, Mw = mass flow rate of cooling water.

Mw * (50-30) = 929.178 * (40 + 14.54872)* 0.616 + 7773.52*(40+14.54872)*0.347

Therefore, Mw = 8918.1296 kg

8-13 Mass Balance for Preheater

Component

Input (Kg)

Out(Kg)

Ethanol

929.178

929.178

Acetaldehyde

7773.52

7773.52

Water

10626.80

10626.80

Total

19329.498

19329.498

8-14 Energy Balance Table for Preheater

component

Tube side (kcal)

Shell side (kcal)

Ethanol

31222.249

0

Acetaldehyde

147140.3414

0

Water

0

178362.59

Total

178362.5904

178362.59

8.7 Distillation column

In distillation column acetaldehyde condenses at 400C. since vapor pressure data’s of

pure gas is not available, it is estimated using Antoine’s equation.

41

ln P = A + B/T

Where, A and B are constants, they can be determined from boiling point data

at, Pressures 760 mmHg and 400 mmHg.

At 760 mmHg T = 20.20C= 293.20K. [6]

400 mmHg T = 4.90C = 277.90K. [6]

Therefore, ln 760 = A + B/293.2

ln 760 = A + B/277.9

On solving above two equations we get,

A = 18.29 and B = -3418.2[6]

Therefore, ln P = 18.29 – 3418.2/T

Therefore at 400C, P = 1586.41 mmHg.

Assume 99% acetaldehyde recovery in overhead product and ethanol recovery

as 10%.

In overhead:

Acetaldehyde = 7695.78 kg.

Ethanol = 92.917 kg.

Total D = 7788.69 kg.

In bottom:

Acetaldehyde = 77.73 kg. Ethanol = 836.26 kg. Total W = 913.99 kg.

42

F=D+W

xd = .989

F * xf = D * xd + W * x w

Therefore, xw = F * xf – D * xd

W

Therefore, xw = .0815

Assume reflux ratio = 0.3

Therefore L / D = 0.3

L = 0.3 * 7788.69 = 2336.60 kg.

Vapor going to the condenser = L + D = 2336.60 + 7788.69

=10125.30 kg.

Of this 98.9% is acetylaldehyde

Therefore, vapor composition going to the condenser:

Acetaldehyde = 10013.92 kg, Ethanol = 111.37 kg.

Heat load to condenser

Let L/D=0.3

L=2336.60 kg

Vapor going to condenser = L+D =10125.30 kg

Out of this 98.9% is acetaldehyde

Acetaldehyde=10013.92 kg

Ethanol= 111.37 kg.

Heat load to the condenser = Methanol*λethanol + Macetaldehyde*λacetaldehyde

=111.37*200.6+10013.92*139.5 =1419282.662 Kcal

Reboiler load

Let “m” be the amount of liquid vaporized.

Let “L” be liquid going into the reboiler.

Let L/W = 10

43

L= 9139.9 kg

Therefore, m= L-W

m=9139.9-913.99=8225.91 kg

we know xw = .0815, so

Acetaldehyde=8225.91/45.976*.0815=14.581 kg

Ethanol=8211.32 kg

Heat load to the reboiler = Methanol*λethanol + Macetaldehyde*λacetaldehyde

=8211.32*200.6+14.581*139.5

=1649226.492 kcal.

44

Chapter 9

9

DESIGN OF EQUIPMENT

9.1 DESIGN OF DISTILLATION COLUMN:

Glossary of notations used:

F = molar flow rate of Feed, kmol/hr.

D = molar flow rate of Distillate, kmol/hr.

W = molar flow rate of Residue, kmol/hr.

XF = mole fraction of Acetaldehyde in liquid/Feed.

YD = mole fraction of Acetaldehyde in Distillate.

XW = mole fraction of Acetaldehyde in Residue.

MF = Average Molecular weight of Feed, kg/kmol

MD = Average Molecular weight of Distillate, kg/kmol

MW = Average Molecular weight of Residue, kg/kmol

Rm = Minimum Reflux ratio

R = Actual Reflux ratio

L = Molar flow rate of Liquid in the Enriching Section, kmol/hr.

G = Molar flow rate of Vapor in the Enriching Section, kmol/hr.

L = Molar flow rate of Liquid in Stripping Section, kmol/hr.

G = Molar flow rate of Vapor in Stripping Section, kmol/hr.

q = Thermal condition of Feed

ρL = Density of Liquid, kg/m3.

ρV = Density of Vapor, kg/m3.

qL = Volumetric flow rate of Liquid, m3/s

qV = Volumetric flow rate of Vapor, m3/s

μL = Viscosity of Liquid, cP.

45

TL = Temperature of Liquid, 0K.

TV = Temperature of Vapor, 0K

T – x- y data:

9-1 T-x-y data for ethanol-acetaldehyde[6]

T 0C

98.5

89.9

80

71

60.5

50

39

X

0.000

0.069

0.164

0.286

0.445

0.664

1.000

Y

0.000

0.317

0.578

0.761

0.879

0.954

1.000

Preliminary calculations:

F = 196.867 kmol/hr,

XF = 0.897,

MF = 44.123 kg/kmol.

D = 177.574 kmol/hr,

XD = 0.989,

MD = 44.022 kg/kmol.

W = 19.293 kmol/hr,

XW = 0.082,

MW = 45.976 kg/kmol.

Distillation column temperature = 40 0C.

Distillation column pressure = 2.08 atm. = 1586.41 mm Hg.

Basis: One-hour operation.

46

From graph

Figure 8: Calculating number of stages using Mc Cabe Thiele Method[9]

Number of stages = 5 (including the reboiler).

Reboiler is the last tray.

Feed tray = 3

Number of trays in Enriching Section = 3

Number of trays in Stripping Section = 2

Minimum Reflux ratio = ( xD-yF)/(yF-xF)=(.989-.976)/(.99-.897)=0.096643

Actual Reflux ratio

=1.5*.096643=.145

Now, we know that,

47

R = Lo/ D

=> Lo = R*D

i.e., Lo= .145*177.574

i.e., Lo =25.748 kmol/hr.

Therefore, Lo = 25.748 kmol/hr.

L= Liquid flow rate on the Top tray = 25.748 kmol/hr.

Since feed is Liquid, entering at bubble point,

q= (HV-HF) / (HV-HL) = 1

Now,

Slope of q-line = q/ (q-1)

= 1/ (1-1) = 1/0 = ∞

Now we know that,

(L̅ -L)/F = q = 1

(̅L - L) = F

L̅ = F + L

i.e., L̅ = 25.748 + 196.867

i.e., L̅ = 222.615 kmol/hr.

Therefore, liquid flow rate in the Stripping Section = 222.615 kmol/hr.

Also, we know that,

G̅ = [(q-1) ×F] + G

i.e., G̅ = [(1-1) ×F] + G

i.e., G̅ = [0×F] +G

i.e., G̅ = 0 +G

G̅ = G

Now, we know that,

G=L+D

i.e., G = Lo +D

i.e., G= 25.748 + 177.574

i.e., G= 203.322 kmol/hr.

Thus, the flow rate of Vapor in the Enriching Section = 203.322 kmol/hr.

Since G̅ =G

48

G̅ = G = 203.322 kmol/hr.

Therefore, the flow rate of Vapor in the Stripping Section = 203.322kmol/hr.

List of parameters used in calculation:

SECTION

ENRICHING SECTION

STRIPING SECTION

PROPERTY

TOP

BOTTOM

TOP

BOTTOM

X

.983

.719

.719

.102

Y

.999

.966

.966

.415

Liquid

L(kmol/hr)

25.748

25.748

222.615

222.615

Vapour

G(kmol/hr)

203.322

203.322

203.322

203.322

Tliquid 0C

41.93

51.56

51.56

85.70

Mavg Liquid(kg/kmol)

44.02

44.56

44.56

45.79

Mavg Vapour(kg/kmol)

44.01

44.07

44.07

44.17

Liquid,

L kg/hr.

1133.427

1147.331

9919.724

10193.541

Vapor,

G kg/hr

8948.201

8960.401

8960.401

8980.733

Density

ρ1(kg/m3)

784.69

774.50

774.50

747.87

Density

ρg(kg/m3)

3.4376

3.425

3.425

3.391

.008

.008

.073

.074

(L/G)( ρ1/ ρg).5

9-2 List of Parameters used in calculation

Design Specification[6]:

a) Design of Enriching Section:

Tray Hydraulics,

The design of a sieve plate tower is described below. The equations and correlations are

borrowed from the 6th and 7th editions of Perry’s Chemical Engineers’ Handbook.

1. Tray Spacing, (ts) :

Let ts = 18” = 457 mm. (range 0.15 – 1.0 m).

49

2. Hole Diameter, (dh):

Let dh = 5 mm. (range 2.5 – 12 mm).

3. Hole Pitch (lp):

Let lp = 3* dh (range 2.5 to 4.0 times dh).

i.e., lp = 3*5 = 15 mm.

4. Tray thickness (tT):

Let tT = 0.6* dh (range 0.4 to 0.7 times dh).

i.e., tT = 0.6*5 = 3 mm.

5. Ratio of hole area to perforated area (Ah/Ap):

Now, for a triangular pitch, we know that,

Ratio of hole area to perforated area (Ah/Ap) = ½ (π/4*dh2)/ [(√3/4) *lp2]

i.e., (Ah/Ap) = 0.90* (dh/lp)2

i.e., (Ah/Ap) = 0.90* (5/15)2

i.e., (Ah/Ap) = 0.1

Thus,

(Ah/Ap) = 0.1

6. Plate Diameter (Dc):

The plate diameter is calculated based on entrainment flooding considerations

L/G {ρg/ρl}0.5 = 0.008 ---------- (maximum value)

Now for,

L/G {ρg/ρl}0.5 = 0.008 and for a tray spacing of 500 mm.

We have,

From the flooding curve, ---------- (fig.18.10, page 18.7, 6th edition Perry.)

Flooding parameter, Csb, flood = 0.29 ft/s .

Now,

Unf = Csb, flood * (σ / 20) 0.2 [(ρl - ρg) / ρg]0.5

---- {eqn. 18.2, page 18.6, 6th edition Perry.}

Where,

Unf = gas velocity through the net area at flood, m/s (ft/s)

Csb, flood = capacity parameter, m/s (ft/s, as in fig.18.10)

σ = liquid surface tension, mN/m (dyne/cm.)

50

ρl = liquid density, kg/m3 (lb/ft3)

ρg = gas density, kg/m3 (lb/ft3)

Now, we have,

σ = 19.325 mN/m = 19.325 dyne/cm.

ρl = 774.50kg/m3.

ρg = 3.425 kg/m3.

Therefore,

Unf = 0.29*(19.325/20)0.2*[(774.50-3.4250)/ 3.4250]0.5

i.e.,Unf = 4.321 ft/s = 1.317 m/s.

Let,

Actual velocity, Un= 0.8*Unf

i.e., Un = 0.8∗1.317

i.e., Un = 1.054 m/s

It is desired to design with volumetric flow rate maximum (therefore, actual is less than

the maximum).

Volumetric flow rate of Vapor at the bottom of the Enriching Section

= qo = 8960.401/ (3600*3.4250) = 0.727 m3/s.

Now,

Net area available for gas flow (An)

Net area = (Column cross sectional area) - (Down comer area.)

An = Ac - Ad

Thus,

Net Active area, An = qo/ Un = 0.727/ 1.054 = 0.690 m2.

Let Lw / Dc = 0.77 (range 0.6 to 0.85 times Dc ).

Where, Lw = weir length, m

Dc = Column diameter, m

Now,

θc = 2*sin-1(Lw / Dc) = 2*sin-1 (0.77) = 100.70

Now,

Ac=(π /4)*Dc2= 0.785*Dc2 , m2

Ad = [(π/4) * Dc2 * (θc/3600)] - [(Lw/2) * (Dc/2) *cos (θc/2)]

i.e., Ad = [0.785*Dc2 *(100.70/3600)]-[(1/4)* (Lw / Dc) * Dc2 * cos(100.70)]

51

i.e., Ad = (0.2196* Dc2) - (0.1288* Dc2)

i.e., Ad = 0.0968*Dc2, m2

Since An = Ac -Ad

0.690 = (0.785*Dc2) - (0.0968* Dc2)

i.e., 0.6882* Dc2 = 0.690

⇒ Dc2 = 0.690/ 0.6882 = 1.003

⇒ Dc = √ 1.003

Dc = 1.001 m

Since Lw / Dc = 0.77,

⇒ Lw = 0.77* Dc = 0.77*1.001 = 0.771 m.

Therefore, Lw = 0.771 m.

Now,

Ac = 0.785*1.003 = 0.787 m2

Ad = 0.0968*Dc2 = 0.0968*1.003 = 0.097 m2

Aa = Ac –2* Ad

i.e., Aa = 0.787- 2*0.097 ⇒ Aa= 0.593 m2

7. Perforated plate area (Ap):

Now,

Lw / Dc = 0.771/ 1.001 = 0.7701

θc = 100.73 0

α = 180 0- θc

⇒ α = 79.27 0

Now,

Acz = 2* Lw* (thickness of distribution)

Where, Acz = area of calming zone, m2 (5 to 20% of Ac )

Acz = 2*0.771* (30×10-3) = 0.046 m2 -------- (which is 6.76% of Ac)

Also,

Awz= 2*{(π/4)*Dc2*(θc/3600)- (π/4)*(Dc-30*10-3)2*(θc/3600)}

Where, Awz = area of waste periphery, m2 (range 2 to 5% of Ac)

i.e., Awz = 2*{(π/4)*1.0012*(100.730/3600)- (π/4)*(1.001-30*10-3)2*(100.730/3600)}

i.e., Awz = 0.026 m2

--------- (which is 3.8% of Ac)

52

Now,

Ap = Ac - (2*Ad) - Acz - Awz

i.e., Ap = 0.787- (2*0.097) - 0.046 - 0.026

Thus, Ap = 0.521 m2.

8. Total Hole Area (Ah):

Since,

Ah / Ap = 0.1

⇒ Ah = 0.1* Ap

i.e., Ah = 0.1*0.521

⇒ Ah = 0.0521 m2

Thus, Total Hole Area = 0.0521 m2

Now we know that,

Ah = nh*(π/4)*dh2

Where, nh = number of holes.

⇒ nh = (4*Ah)/ (π*dh2) =2654(Aprox)

Therefore, Number of holes = 2654.

9. Weir Height (hw):

Let hw = 50 mm.

10. Weeping Check

The static pressure below the tray should be capable enough to hold the liquid

above the tray so that no liquid sweeps through the holes.

All the pressure drops calculated in this section are represented as mm head of

liquid on the plate. This serves as a common basis for evaluating the pressure

drops.

Notations used and their units:

hd = Pressure drop through the dry plate, mm of liquid on the plate

uh = Vapor velocity based on the hole area, m/s

how = Height of liquid over weir, mm of liquid on the plate

hσ = Pressure drop due to bubble formation, mm of liquid

53

hds= Dynamic seal of liquid, mm of liquid

hl = Pressure drop due to foaming, mm of liquid

hf = Pressure drop due to foaming, actual, mm of liquid

Df = Average flow length of the liquid, m

Rh = Hydraulic radius of liquid flow, m

uf = Velocity of foam, m/s

(NRe) = Reynolds number of flow

f = Friction factor

hhg = Hydraulic gradient, mm of liquid

hda = Loss under down comer apron, mm of liquid

Ads = Area under the down comer apron, m2

c = Down comer clearance, m

hdc = Down comer backup, mm of liquid

Calculations:

Head loss through dry hole

hd = head loss across the dry hole

hd = k1 + [k2* (ρg/ρl) *Uh2] --------- (eqn. 18.6, page 18.9, 6th edition Perry)

Where, Uh =gas velocity through hole area

k1, k2 are constants

For sieve plates,

k1 = 0 and

k2 = 50.8 / (Cv)2

Where, Cv=discharge coefficient, taken from fig 18.14, page 18.9 6th edition Perry.

Now,

(Ah /Aa) = 0.0521/ 0.593 = 0.088

Also, tT/dh = 3/5 = 0.60

Thus for (Ah/Aa) = 0.088 and tT/dh = 0.60

We have from fig. edition 18.14, page 18.9 6th Perry.

Cv = 0.74

54

⇒ k2 = 50.8 / 0.742 = 92.77

Volumetric flow rate of Vapor at the top of the Enriching Section

=qt = 8948.201/ (3.4376*3600) = 0.723 m3/s -------- (minimum at top)

Volumetric flow rate of Vapor at the bottom of the Enriching Section

= qo = 8960.401/(3.425*3600) = 0.727 m3/s. ---- (maximum at bottom)

Velocity through the hole area (Uh):

Now,

Velocity through the hole area at the top = Uh, top = qt /Ah

= 0.723/0.0521= 13.877 m/s

Also, Velocity through the hole area at the bottom= Uh, bottom = qo /Ah

= 0.727/0.0521 = 13.954 m/s

Now,

hd, top = k2 [ρg/ρl] (Uh,top)2

= 92.77∗(3.4376/784.69) ∗13.8772

⇒ hd, top = 78.263 mm clear liquid. -------- (minimum at top)

Also,

hd, bottom = k2 [ρg/ρl] (Uh, bottom)2

= 92.77∗(3.425/774.50)×13.9542

⇒ hd, bottom = 79.881 mm clear liquid ----- (maximum at bottom)

Head Loss Due to Bubble Formation

hσ = 409 [σ / ( ρL∗dh) ]

where σ =surface tension, mN/m (dyne/cm) = 19.325 dyne/cm.

dh =Hole diameter, mm

ρl = density of liquid in the section, kg/m3

= 784.69 kg/m3

hσ = 409 [ 19.325/(784.69 *5)]

hσ= 2.014 mm clear liquid

Height of Liquid Crest over Weir:

how = 664∗Fw [(q/Lw)2/3]

55

q = liquid flow rate at top, m3/s

= 1133.427/60* (784.69)

= 0.024 m3/min.

Thus, q’ = 6.339 gal/min.

Lw = weir length = 0.771 m = 2.530 ft

Now,

q’/Lw2.5 = 6.339/ (2.530)2.5 = 0.623

Now for q’/Lw2.5 = 0.623 and Lw /Dc =0.77

We have from fig.18.16, page 18.11, 6th edition Perry

Fw= correction factor =1.03

Thus,

how = 1.03∗664∗ [0.024/60*0.771] 2/3

⇒ how = 4.416 mm clear liquid.

Now,

(hd + hσ) = 78.263 + 2.014 = 80.227 mm ------ Design value

(hw + how) = 50 + 4.416 = 54.416 mm

For, Ah/Aa = 0.088 and (hw + how) = 54.416 mm

The minimum value of (hd + hσ) required is calculated from a graph given in

Perry,

plotted against Ah/Aa.

i.e., we have from fig. 18.11, page 18.7, 6th edition Perry

(hd + hσ)min = 13.0 mm ------- Theoretical value.

The minimum value as found is 13.0 mm.

Since the design value is greater than the minimum value, there is no

problem of

weeping.

Down comer Flooding:

hds =hw + how + (hhg /2) ------- (eqn 18.10, page 18.10, 6th edition Perry)

Where,

hw = weir height, mm

hds = static slot seal (weir height minus height of top of slot above plate floor,

56

height equivalent clear liquid, mm)

how = height of crest over weir, equivalent clear liquid, mm

hhg = hydraulic gradient across the plate, height of equivalent clear liquid, mm.

Hydraulic gradient, hhg

Let

hhg = 0.5 mm.

hds = hw + how + hhg/2

= 50 + 4.416 + 0.5/2 = 54.666 mm.

Now, Fga = Ua ∗ρg0.5

Where Fga = gas-phase kinetic energy factor,

Ua = superficial gas velocity, m/s (ft/s),

ρg = gas density, kg/m3 (lb/ft3)

Here Ua is calculated at the bottom of the section.

Thus, Ua = (Gb/ρg)/ Aa = 8960.401/(3600*3.425 * 0.593) = 1.225 m/s

Thus, Ua = 4.019 ft/s

ρg = 3.4250 kg/m3 = 0.209 lb/ft3

Therefore, Fga = 4.019∗(0.209) 0.5

Fga = 1.837