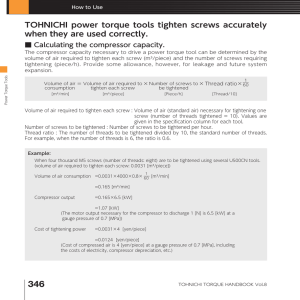

Assignment on Turbocharger removing and installing (ABB A175-M) Present by Ariful Islam Id: DECPCL9149 Weights of Assemblies Position 01 02 03 04 05 06 07 08 09 Component Radial air suction branch Wall insert Diffuser Compressor casing Cartridge group Turbine diffuser Cover ring Nozzle ring Gas inlet casing, radial A175-M [kg} 120 210 30 430 750 80 40 17 170 Part Number 27027 A 175-M M20 220Nm Axial clearance to a prior of assembly Product A175-M Axial clearance A [mm] 0.35 … 0.69 Removing the compressor casing Removing the cartridge group Removing the nozzle ring Installing nozzle ring Part number 56014 Table: Tightening torque (56014) A175-M M10 50 Nm Part number 57005 Table: Tightening torque (57005) A175-M M16 200 Nm Part number 61069 Table: Tightening torque (61069) 6. Coat threads of screws (61069) with high-temperature grease 7. Fit and tighten screws (61069) A175-M M16 200Nm Installing the cartridge group Part number 61059/42128 86505 25013 A175-M M24 490 Nm M18*1.5 150 Nm M10 40 Nm Table: Tightening torque (61059/42128/86505/25013) 1. 2. 3. 4. 5. 6. Coat thread of screw (61059) and two bolts for the nuts (42128) with high-temperature grease. Secure cartridge group with screw (61059) and nuts (42128). Fit spinner nose cone (25012) with screw (25013) and washer (25014) and tighten. Remove the lifting gear. Screw in and tighten speed sensor (86505) and new O-ring (86506). Insert cable connector (86515). Installing the compressor casing Part number 61037 61037 (nuts that are difficult to access) 61090 A175-M M24 490 Nm Pre-tightening torque 40 Nm Tightening angle 45 degree (-+ 5) M24 50 Nm Table: Tightening torque (61037/61090) 1. Distributed evenly around the circumference, screw the press-off nuts (61090) onto the studs of the bearing casing and turn them by hand until they are at the end of the thread. 2. Grease the new O-ring (42012) and fit it. 3. Fasten lifting device (90190/90195) to compressor casing (72000) and secure to crane. 4. Position compressor (72000). Tighten nuts (61037) crosswise. 5. Remove lifting device (90190/90195). 6. Tighten the three press-nuts (90190) against compressor casing (72000) by applying the corresponding tightening torque. Part number 77015 A175-M M6 10Nm Table: Tightening torque (77015) 1. Position diffuser (79000) with swivel lifting eye (90235) on wall inset (77000). 2. Attach diffuser with (77015). 3. Grease the new O-ring (77040) and fit it. Part number 72011 A175-M M24 1000 Nm Table: Tightening torque (72011) 1. Remove lifting device (90190/90195). 2. Slide wall inset (77000) onto compressor casing up to stop and remove guide stud (90329). 3. Secure wall inset with screws (72011) and washers (72008). Axial clearance after assembly Product A175-M Axial clearance A [mm] 0.35 … 0.69 Removing and installing turbine end nozzle ring Part number 61009 Tighten crosswise in stages Table: Tightening torque (56014/61009) A175-M M20 100 240 380 1. Coat threat of new screws (56014) with hight-temperature grease. Secure nozzle ring (56001) with screws (56014) and new locking washers (56015) at gas inlet casing (51001). 2. Fix new spiral-wound gasket (61014) in groove of gas casing (61001) at three evenly distributed points with a little superglue (such as “Loctite 454 Gel”). 3. Fit two guide studs (90321) in the upper part of the gas outlet casing (61001). 4. Coat threads of screws () with high-temperature grease. 5. Loop round inlet gas inlet casing (51001) and, using ligting gear, slide over guide studs until at the gas outlet casing (61001) and secure with screws (61009). 6. Remove the guide stud (90321). 7. Fit remaining scres (61009), then tighten all screws (61009). 8. If present: Fit conneting pipe for turbine cleaning. Refit dismantled insulation Table of tightening torque Thread size and tightening torque (Nm): Position Part number A175-M 1 82005 2 77015 3 61036 4 61037 5 61090 6 61059 7 61069 8 63001 9 56014 10 61009 11 57005 12 42059 13 72011 14 72027 15 72026 16 25013 17 86505 M22*1.5 80 M6 10 M24 80 M26 490 M24 50 M24 490 M16 200 M18 240 M10 50 M20 380 M16 200 M16 200 M24 1000 M20 220 M20 50 M10 40 M18*1.5 150