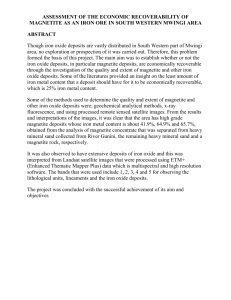

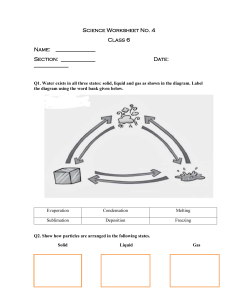

Separation and Purification Technology 247 (2020) 116975 Contents lists available at ScienceDirect Separation and Purification Technology journal homepage: www.elsevier.com/locate/seppur Recovery of magnetite from fluidized-bed homogeneous crystallization of iron-containing solution as photocatalyst for Fenton-like degradation of RB5 azo dye under UVA irradiation Nicolaus N.N. Mahastia, Yu-Jen Shihb, Yao-Hui Huanga, a b T ⁎ Department of Chemical Engineering, National Cheng Kung University, Tainan, Taiwan Institute of Environmental Engineering, National Sun Yat-Sen University, Kaohsiung, Taiwan A R T I C LE I N FO A B S T R A C T Keywords: Decolorization Mineralization Fluidized-bed homogeneous crystallization Supersaturation Superparamagnetic Iron recovery from wastewater as magnetite (Fe3O4) pellets was performed in a fluidized-bed homogeneous crystallization (FBHC) process. The catalytic effectiveness of magnetite in the heterogeneous degradation of RB5 azo dye was evaluated. The key parameters of FBHC, including effluent pH, cross-section loading (L, kg/m2.h), initial iron concentration ([Fe(II)], mg/L), and inlet supersaturation (S), were optimized to maximize the total iron removal (TR, %) and crystallization ratio (CR, %) from a fluidized-bed reactor. Under the conditions of pH = 8.5–9.5 and [Fe(II)]in = 100 – 500 mg/L, the TR and CR values reached 99% and 77%, respectively. The magnetization and coercivity of the recovered Fe3O4 pellets were analyzed to confirm the magnetic characteristic. A Fenton-like degradation of RB5 azo dye was activated using the Fe3O4 pellets under UVA irradiation, pH = 2.75 – 3.0, initial peroxide concentration of 10 mM, and catalyst loading of 2 g/L. The efficiencies of decolorization and mineralization reached about 98 – 99% and 60 – 68%, respectively. FBHC method benefited the recovery of high-purity metal oxides and the production of a low quantity of sludge. Magnetic pellets transformed from the dissolved iron in wastewater were promising materials to reuse as a photochemical reactant for organic pollutant degradation. 1. Introduction Iron (Fe) is abundant in surface waters due to the leaching of ironcontaining rocks by rain [1]. The dumping of domestic and industrial waste has polluted water with a significant level of iron. The iron and steel industries, mining, and metal corrosion are the main activities that discharge iron-containing wastewater [2]. Iron concentrations of 0.3 and 5 mg/L are recommended for drinking water and irrigation water, respectively, according to the World Health Organization and the Food and Agriculture Organization [3,4]. Excess ferrous ions can reduce light intensity underwater and disturb the photosynthesis of aquatic plants. Chemical oxidation followed by precipitation is applied to remove iron from wastewater. An increase in pH stimulates iron oxidation and precipitation, which can yield 1.2 m3 of iron sludge from 10 m3 of wastewater. The purity of iron in waste sludge can be as low as 2 wt% [5]. A large amount of the sludge was also produced from the heavy metal removal in the wastewater treatment facilities. Waste sludge is considered a secondary pollutant that increases the cost of waste disposal [6].Fluidized-bed crystallization (FBC) has been ⁎ developed to solve the problem of sludge production in the removal of heavy metals and inorganic acids processes. The inert seeds such as silica sand was applied to collect the precipitation of the target pollutant. The low degree of supersaturation was set to initiate the heterogeneous nucleation from the reaction between target pollutant and precipitant, and to grow the metal salt crystal [7,8]. However, the seed material as an impurity of the crystal significantly limited the reusability of the product. Fluidized-bed homogeneous crystallization (FBHC) has been developed to remove various kinds of metal pollutant from wastewater and recover high purity metal-salt or metal-oxide granules with low water content [9–12]. The pellets collected from FBHC in the removal of metal ions or anions pollutants could be valuable products, such as calcium carbonate and hydroxyapatite from the water softening and phosphate removal, respectively [10]; nickel carbonate hydroxide [12] and lead carbonate [13] from heavy metal removal. The authors have previously studied FBHC for the recovery of FeOOH crystals from iron-contaminated solution [14]. In addition, Bailey (1992) reported the adsorption of Cr(IV) using iron oxide coatedsand product from batch co-precipitation method in a packed column Corresponding author. E-mail address: yhhuang@mail.ncku.edu.tw (Y.-H. Huang). https://doi.org/10.1016/j.seppur.2020.116975 Received 30 December 2019; Received in revised form 23 March 2020; Accepted 23 March 2020 Available online 29 April 2020 1383-5866/ © 2020 Elsevier B.V. All rights reserved. Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. and solute-poor liquid phases occurs. With increasing supersaturation degree, the nucleation of amorphous nanoclusters within the solute-rich liquid phase occurs, followed by the crystallization of the amorphous clusters [27]. In one study, after a sufficient number of nuclei formed, the recirculation stream was increased to reduce the supersaturation condition and increase the collision chance among the small particles to make them grow. The aggregation of molecules followed by structural modification on the surface of the existing particles led to crystal growth [28]. The magnetite nanoparticles have been utilized to catalytically oxidize some organic pollutants, such as hexabromocyclododecane [29], dichlorophenol [30], triethylenetetramine [31], and azo dye [32]. Magnetite can induce the Fenton-like process due to its spinel structure. The Fe(II) in the tetrahedral site is an electron donor for activating H2O2 to create %OH and various reactive oxygen species (ROS) such as superoxide radicals and singlet oxygen. Then, the octahedral site accommodates the oxidized Fe(II) [33,34]. The degradation of RB5 azo dye was initiated by breaking the azo bonding (ReN]NeR), followed by the cleavage of the benzenic and napthalenic cycle, which resulted in a reduction of absorption intesity at 597 nm and 310 nm, respectively, on the UV–vis spectrum. The final products dissociated from dye molecules would be nontoxic CO2, H2O, NO3−, and SO42− [35]. In this work, the iron removal from the iron-containing solution was recovered as photocatalyst for the degradation of organic pollutant. The unseeded crystallization of magnetite was evaluated in FBHC process in terms of optimizing experimental parameters, including effluent pH and cross-sectional loading, to maximize the crystallization ratio (CR) and total iron removal (TR). RB5 azo dye was utilized as a model contaminant to assess the effectiveness of magnetically separable magnetite pellets in activating the UVA photo-assisted Fenton-like reaction. [15]. Magnetite (Fe3O4) was applied in wastewater treatment, such as, adsorbent for arsenic and other various heavy metal such as Pb2+, Zn2+, Cd2+, and Cu2+ [16–18] or catalyst for photochemical degradation of organic pollutants [19,20]. Accordingly, an increase in solution pH ferrous ion would be hydrolyzed as different Fe(II) species, which leads to the partial oxidation to Fe(OH)2 with different rates to Fe(III). The formation of Fe3+ strongly depends on the dissolved oxygen, which is subject to partial pressure of oxygen gas [21]. (Detailed derivatives are added in supporting materials) −d [Fe 2 +] dt −d [Fe 2 +] dt = k [Fe 2 +][OH−]2 PO2 (1) = (k 0 [Fe 2 +] + k1 [Fe (OH )+] + k2 [Fe (OH )20] + k3 [Fe (OH )3]) D (2) O The hydrolysis of Fe(II) produces the Fe3O4 phase: O2 + 4H+ + 4e− ⇄ 2H2 O ; K O = 1083.14 (E 0 = 1.23 V ) (3) Fe3 O4 + 8H+ + 2e− ⇄ 3Fe 2 + + 4H2 O ; KM = 1033.84 (E 0 = 1.001 V ) (4) The spontaneous oxidation of ferrous ions results in their precipitation as magnetite. Near the thermodynamic equilibrium, the solubility of total iron is affected by the atmospheric oxygen pressure [22,23]. 2Fe3 O4(s) + 12H+(aq) ⇄ 6Fe 2 +(aq) + O2(aq) + 6H2 O(l) ; Ksp1 = KM 2/ K O = 10−15.46 (5) The solubility of magnetite therefore strongly depends on the dissolved oxygen (Eq. (5)). Ksp1 = 6 [FeT ]6 αFe [Fe 2 +]6 [O2] (II ) [O2] = + 12 [H ] [H+]12 2. Materials and methods (6) The degree of supersaturation can be determined as: S= 2.1. Chemicals αFe Sat αFe All chemicals were laboratory-grade and used without any further purification. The iron-containing solution was prepared by dissolving FeSO4·7H2O (99%, Panreac, Germany) in deionized water. Na2CO3 (99.2% Sesoda, China) was applied as a feed to condition the buffering of pH change during precipitation. Sodium hydroxide (97%, Showa, Japan) and sulfuric acid (95 – 97%, Merck, Germany) were applied to adjust the pH in the inlet tank. The azo dye solution was prepared by dissolving Reactive Black 5 (RB5, 55%, Sigma-Aldrich, Germany) in deionized water·H2O2 (50%, Chang Chun Petrochemical, Taiwan) was applied as oxidant. For the quenching experiment, Tert-butanol ((CH3)3COH, 99.5%, Merck, Germany) and furfuryl alcohol (C5H6O2, 98%, Acros Organics, Belgium) were prepared as hydroxyl radical and singlet oxygen scavengers respectively. The water was deionized using a reverse osmosis ultrapure water system (resistance > 18.3 MΩ·cm). (7) where sat sat aFe = γFe ∗ [Fe]T and aFe = γFe ∗ [Fe]Tsat (8) In the presence of carbonate, however, the precipitation of ferrous carbonate competes with that of hydroxides, in which both phases are transformed to magnetite by dissolved oxygen [24]. FeCO3(s) + H+ ⇄ Fe 2 + + HCO3−; Ksp2 = 10−0.18 Fe (OH )2(s) + 2H+ ⇄ Fe 2 + + 2H2 O ; Ksp3 = 1011.69 (9) (10) 6FeCO3(s) + O2 + 6H2 O ⇄ 2Fe3 O4(s) + 6H+ + 6HCO3− ; K = 1022.55 (11) 6Fe (OH )2(s) + O2 ⇄ 2Fe3 O4(s) + 6H2 O ; K = 1093.78 (12) 2.2. Fe3O4 synthesis via FBHC The speciation of ferrous and ferric ions as hydroxyl ions depends on pH [25,26]. The theoretical solubility of total iron (FeT) can be estimated from the solubility products of the two main precursor phases, i.e., Eqs. (11) and (12): K Sp2 = K Sp3 = [FeT ] αFe (II ) CT αHCO3− [Fe 2 +][HCO3−] = + [H ] [H+] [Fe 2 +] [H+]2 = [FeT ] αFe (II ) [H+]2 Iron recovery (as magnetite) from the iron-containing solution was conducted in a cylindrical FBHC reactor (450 ml) made of Pyrex, as shown in Fig. 1. The FBHC reactor had two cross-sectional areas, one each for the upper (diameter: 4 cm; height: 15 cm) and lower (diameter: 2 cm; height: 80 cm) parts. The upflow velocity suddenly dropped when the solution was uplifted to the upper region, thus increasing the collision chance among the formed primary crystals. The flow rates of the stock solutions, namely 3.5 mM FeSO4·7H2O (pH 2.8) and 4.2 mM Na2CO3 (pH 11.6), pumped into the reactor were 5 ml/min. At effluent pH 8.5 – 9.5, small black particles formed. The rate of recirculation was increased to 90 ml/min to reduce the degree of supersaturation and grow particles. (13) (14) where CT is the total carbonate, and αHCO3- and αFe(II) are fractionation of HCO3− and Fe2+ species, respectively. Once the concentration of the solute exceeds the solubility (i.e., supersaturation is reached), spinodal decomposition into solute-rich 2 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. Fig. 2. Configuration of three-phase fluidized-bed Fenton reactor. of RB5 and H2O2 were 50 mg/L and 10 mM, respectively. During the chemical reaction, 98% H2SO4 was dropwise added to maintain pH at 2.75 – 3. The ranges of pH and initial H2O2 concentration have been tested in the preliminary experiment (supporting material) under constant temperature (25 – 30 °C) using a water bath. A UVA lamp (15 W, UVP BL-15 365 nm, Philips, Poland) was turned on to activate the catalytic reaction. The chemical reaction was stopped by adding 1 M NaOH to the sample before total organic carbon (TOC) analysis. Fig. 1. Fluidized-bed crystallization apparatus. 2.3. Iron removal experiments The FBHC process was initiated at a bed height of about 25–30 cm. Stock solutions of Fe(II) at various concentrations (100, 300, 500 mg/L) and CO32–, which was adjusted to yield a molar ratio of [total carbonate]/[Fe(II)] = 1.2, were pumped into the reactor at 50 ml/min. In the real case, iron pollution level in the water existed in a very wide range depends on the area and the pollution source, such as: 1.5 – 80 mg/L and 15 mg/L in the groundwater in Denmark and China respectively [36,37], 25 – 55 mg/L in the fracking wastewater from natural gas refinery [38], and 500 – 700 mg/L in the acid mine drainage [5]. The initial iron concentration was set at 100 – 500 mg/L to represent the effect of the different inlet iron concentration and the process limitation for the certain iron loading. The recirculation at 50 ml/min was set to maintain the upflow velocity in the lower part of FBHC at 28.6 m/h. The effluent pH (5 – 12) was conditioned by adjusting the pH of the stock solution using NaOH (40%) and H2SO4 (98%). For each variable adjustment, the FBHC reaction lasted at least 40 times the hydraulic retention time (HRT) to obtain steady-state effluent quality. Two samples were taken at specific intervals; one was filtered using a filter with a 0.45-μm pore size and the other was unfiltered and digested using 1 N H2SO4. The filtered sample was used to estimate TR, which was in the form of either fine nuclei that had drained out or coarse pellets that had fluidized in the reactor. The aciddigested sample was used to calculate the CR, which reflects the quantity of iron crystallized on the surface of the particles. CR% = 1 − [Fe]T × Qt CFe × QFe (15) TR% = 1 − [Fe]s × Qt CFe × QFe (16) 2.5. Analytical methods The total iron concentration in the samples was measured using inductively coupled plasma-optical emission spectrometry (ICP-OES ULTIMA 2000, HORIBA Ltd., Japan). The carbonate and TOC were determined using a TOC/inorganic carbon analyzer (Sievers Innovox Laboratory, USA). The dissolved oxygen was measured using a WTW ProfiLine Oxi 3210 Portable DO meter. Absorbance of RB-5 at 310 and 597 nm was analyzed using a diode array UV–Vis spectrometer (Agilent 8453, USA). The magnetite crystal product was taken after draining out the solution in FBHC reactor. The collected crystals were dried at 30–35 °C overnight in an oven. The crystalline phases were characterized using X-ray diffraction (XRD, DX III, Rigaku Co., Japan) (diffraction angles: 10° − 90°; scan step: 0.02°; scan rate: 10°/s). The morphology was observed using scanning electron microscopy (SEM, JEOL JSM-6700F, HITACHI, Japan) at 10 kV and 7 mA. The magnetic properties of the magnetite product were analyzed using a superconducting quantum interference device vibrating sample magnetometer (SQUID VSM, MPMS-3, American Quantum Design, USA) in the magnetization range of ± 10000 gauss. The surface compound were determined using Fourier-transform infra-red (FT-IR, Thermo Scientific Nicolet 6700, USA) and X-ray photoelectron spectroscopy (XPS, British Thermo VG-Scientific / Sigma Probe, UK) 3. Results and discussion 2.4. Fenton-like degradation of RB5 azo dye 3.1. Iron recovery as Fe3O4 pellets via FBHC The magnetite pellets recovered from the FBHC process were applied as a heterogeneous catalyst to remove RB5 azo dye under UVA irradiation. A glass cylindrical reactor (diameter: 8 cm; height: 44 cm) with a membrane diffuser was applied in this experiment, as shown in Fig. 2. The 2 g/L of magnetite added in the solution was fluidized by pumping homogeneous air at the bottom of the reactor at a flow rate of 6 sL/min (standard liter for air per minute). The initial concentrations The FBHC process for the removal of iron was optimized using the bed of magnetite pellets produced in the preceding step as the fluidized medium. The flow rates of the FeSO4 and Na2CO3 streams fed into the reactor were both 50 ml/min. The recirculation rate was adjusted at 50 ml/min to create a bed expansion of 25%, corresponding to an upflow velocity of 28.6 m/h, which was greater than the minimum fluidization velocity Umf based on the Ergun equation [39]: 3 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. 2 Δp (1 − εm)2 μu 0 1 − εm ρf μ0 = 150 + 1.75 2 2 3 L εm εm (Φs dp) Φs dp 5Fe (OH )2 + Fe 2 + + CO32 − + (17) [CO3. H2 O] For the minimum fluidization condition: g Δp = (1 − εmf )(ρs − ρf ) gc Lmf 1 O2 + 3H2 → [Fe4(II ) Fe2(III ) (OH )12 ] 2 [Fe4(II ) Fe2(III ) (OH )12 ][CO3. H2 O] + O2 → 6α − FeOOH + H2 CO3 + 4H2 O (24) (18) 2α − FeOOH + Fe (OH )2 → Fe3 O4 + H2 O Combining Eqs. (17) and (18) yields: 2 dp3ρf (ρs − ρf ) g 150(1 − εmf ) ⎛ dp umf ρf ⎞ 1.75 ⎛ dp umf ρf ⎞ ⎜ ⎟ + ⎜ ⎟ = Φs εmf 3 ⎝ μ Φs 2εmf 3 ⎝ μ μ2 ⎠ ⎠ (23) (25) Cross-sectional loading represents the fluidized-bed capacity in the removal of a unit weight of iron per square meter and time as plots in Fig. 4. The degree of supersaturation increases with increasing iron loading (Eqs. (6) and (7)). The supersaturation is related to the Gibbs free energy that drives the saturated solute to precipitate. When the loading to supersaturation in the region of homogeneous nucleation is increased, the solute is converted to fine particles that are easily drained out from the reactor by the upflow, leading to an increase in the total iron concentration in the effluent. However, the soluble iron level in the effluent stream remains low under high supersaturation. As a result, the CR decreases as the loading increases, while the TR remains constant when the cross-sectional loading increases to beyond 1.5 kg/ m2·h. (19) where dp = particle diameter Φs = sphericity εmf = porosity μ = viscosity ρf = fluid density ρs = particle density umf = up-flow velocity g = gravity acceleration 3.2. Characterization of FBHC pellets For small particles: Re < 20 umf = (Φs dp)2 ρs − ρf ⎛ εmf 3 ⎞ . g⎜ ⎟ 150 μ ⎝ 1 − εmf ⎠ Re > 1000 umf 2 = Re = Φs dp ρs − ρf . . gεmf 3 1.75 ρf The XRD peaks of the FBHC particles indicate a mineral composition of magnetite (JCPDS standard #19-0629), as shown in Fig. 5c. Two samples were taken, respectively from the top and bottom parts of the particle bed; the sample collected from the upper region consisted of the initial particles, whereas that taken from the bottom region consisted of coarse crystals [45,46]. Fig. 5a–b show the SEM micromorphology of an FBHC pellet. The particles grew up to 1.5–2 mm in diameter. Under high magnification, the surface of the pellet is relatively smooth because of the collisions and abrasion between particles promoted by the up flow of the solution [47]. The primary particles of Fe3O4, which are around 100 nm in diameter and irregularly aggregated, constitute the core of the pellet (Fig. 5b). There are two steps in the crystal growth: initiation by the solute diffusion from the bulk liquid to the solid-liquid interface, followed by the integration of the solute into the crystal lattice on the surface [48]. The growth of small crystals was driven by a lowering of the surface energy in the total interfacial area, resulting in an increase in the size of aggregated pellets [49]. FTIR analysis also introduced to the magnetite product as depicted in Fig. 5d. A dominated peak appeared at 584 cm−1 indicated the existence of Fe-O stretching in Fe3O4 [50]. Two additional peaks also appear at 796 and 890 cm−1 show the deformational (δ) modes of hydroxyl group [51].Three similar peaks could be observed in the commercial Fe3O4 indicated the similar surface structure between the magnetite from FBHC product to the standard commercial magnetite. The surface analysis of the magnetite product was determined by XPS to verify the existence of Fe(II) and Fe (III). As shown in Fig. 6, the peaks at 711.6 and 724.9 eV represented the binding energies of Fe2p1/2 and Fe2p3/2 on the Fe3O4 structure, which evidenced FBHC product consitsted of the crystal phase of Fe3O4 [52,53]. Fig. 7 plots the effect of the degree of supersaturation on the CR at various input iron concentrations. The supersaturation (log S) was defined as the difference between the measured iron activity at the effluent (aFe) and the thermodynamically determined solubility of a specific precipitate (aFeSat). The magnetite was a much stable material, which should be phase-transformed from Fe(II) species at long-term operation, compared to carbonate and hydroxide phase. Since Fe (OH)2(s) or FeCO3(s) precipitated at very early stage, the supersaturation was estimated based on solubility products of Fe(II) species. The ideal solubility was obtained from eq. (13) and (14), which gave (20) (21) ρUmf D μ (22) As a result, the Umf is 11.40 m/h when the density of water (ρf) is 1 g/cm3, solution viscosity (μ) is 1 cp, and measured particle density (ρs) is 2.66 g/cm3, and void ratio (ε) is 0.44, resulting in a Re number of 1.58 (Re < 20). Fig. 3a shows that both CR and TR increase with increasing pH for pH values of 6 to about 8.5; at pH beyond 8.5, TR remains constant and CR drops. The ability of FBHC to remove iron in crystal form depends on the degree of supersaturation, which is affected by pH (Eqs. (13) and (14)). Under low supersaturation, the particles grow via the assembly of nuclei onto the existing surface of seeds [7,40]. In contrast, the high Gibbs energy of the system that results from high supersaturation (ΔG = −RTlnS) drives new nuclei to form homogeneously in bulk solution [41]. The TR of iron was ascribed to precipitation in the form of either small particles or crystallized pellets. The generation of fine particles, which were drained out from the reactor by the upstream, increased the total iron level in the effluent, and thus the CR declined significantly. Fig. 3b shows the dissolved oxygen consumption as a function of pH for the precipitation of magnetite. The oxygen consumption is related to the formation of Fe(II) precipitate, followed by the oxidative transformation into Fe3O4. As shown in Fig. 3c, with increasing pH, Fe(II) consumption increases, reaching a maximum at pH above 9 for the selected range of initial concentrations of 100 – 500 ppm, at which the solubility of Fe(II) is minimized. However, the residual inorganic carbon as carbonate species increases with increasing pH during the FBHC process, as shown in Fig. 3d. Accordingly, Fe(OH)2 became predominant in the removal of Fe(II) as the solubility of FeCO3 increased at pH greater than 10 (Ksp2 vs. Ksp3) (Fig. 7c). The carbonate ligand acts as a buffer that prevents Fe(OH)3 acute precipitation in the presence of dissolved oxygen; the green rust of ferrous carbonate as the intermediate transform to magnetite in alternative pathways [42–44]. [Fe 2 +] = K Sp2 [H +] CT αFe (II ) αHCO − 3 , and [Fe 2 +] = K Sp3 [H +]2 αFe (II ) for precipitation of ferrous carbonate and hydroxide, respectively. S is strongly related to the bulk 4 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. Fig. 3. Effect of input Fe concentration on (a) effluent total removal (TR) and crystallization ratio (CR) of Fe, (b) dissolved oxygen (DO) removal, (c) ferrous removal, and (d) inorganic carbon (C) residual as a function of pH (flow rates QFe = QCO3 = QR = 50 ml/min; U = 28.6 m/h; HRT = 3 min; molar ratio of [carbonate]/[Fe (II)] = 1.2). (v). The value of rC can be determined as the bulk energy is balanced out by the surface energy (γ). The energy gap (ΔG*) that has to be overcame to form a new nucleus should be: ΔG∗ = Gibbs free energy (ΔGb) for the formation of crystals with a critical radius rC [54,55]: and rC = − (26) 3.3. Magnetite product application for treating azo-dye-containing wastewater 2γv aFe ⎞ kT ln ⎛ Sat ⎝ aFe ⎠ (28) At a specific S, the deposition of iron onto the seed surface increases. However, once S reaches a level where the nucleus can be created homogeneously, the iron in the FBHC system prefers to precipitate as sludge [56,57]. As indicated in Fig. 7, the FBHC should operate at relatively low supersaturation for Fe(OH)2 compared to FeCO3, namely pH around 9 that FeCO3 is the predominant phase to oxidatively transform as Fe3O4 (Eq. (11)). In addition, the FBHC was optimized at around 80% of CR under a supersaturation degree range of 0.28 – 2.15. Fig. 8 plots the magnetization curve of Fe3O4 pellets obtained from the FBHC process in a size range of 25–35 mesh against the magnetic field, revealing that the magnetization and coercivity are about 79.45 emu/g and 5.60 Oe, respectively, at room temperature. The magnetization of FBHC product was similar to that of the commercial magnet sample; the FBHC pellets are magnetically soft possibly due to their relatively low coercivity. The low magnetization is ascribed to a decrease in crystalline size and crystallinity. Further, coercivity is proportional to the number of crystal defects [58–61]. The high magnetization and low coercivity confirm the super paramagnetism of the FBHC pellets in this work [59–62]. Fig. 4. Effect of cross-sectional surface loading on total removal (TR) and crystallization ratio (CR) of iron at total flow rate Q = 150 ml/min, U = 28.6 m/h, HRT = 3 min and molar ratio of [carbonate]/[Fe(II)] = 1.2. aFe ⎞ ΔGb = −RT ln S = −jkT ln ⎜⎛ Sat ⎟, ⎝ aFe ⎠ 16πγ 3v 2 3(kT ln S )2 (27) A photo-assisted Fenton-like reaction was carried out to demonstrate the ability of FBHC pellets to degrade RB5 azo dye solution. The where j is the ratio of the particle volume to the molar volume of nuclei 5 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. Fig. 5. XRD analysis and SEM image of magnetite crystal product: (a) SEM image of magnetite whole particle, (b) inner structure of magnetite particle, and (c) XRD patterns for magnetite product, (d) FTIR analysis for magnetite product. about 82%; whereas the efficiencies without magnetite catalyst could achieve 66% and 47%, respectively (Fig. 9a). In the dark reaction, the removal rate was 14% in 6 h, which represented the specific adsorption of dye molecules onto the catalyst surface. As shown in Fig. 9b, the TOC removal which represents the mineralization of RB5 into carbon dioxide and water reaches less than 40% without magnetite catalyst at the end of the reaction. By contrast, with the aid of the magnetite catalyst, the efficiency of TOC removal increases up to 68%. The hydroxyl radicals %OH are produced through either the Fenton-like reaction, in which the adsorbed H2O2 is activated with the surface oxidation of Fe(II) to Fe(III) on the iron oxide particles [63], or the homogeneous Fenton reaction, which is induced by the dissolved iron and H2O2 [64,65]. Another ROS (such as HO2%, O2%−, and O21) also produced by the chain reaction of radicals or stimulated by the dissolved oxygen experimental conditions were controlled at 2 g/L Fe3O4 pellets, 10 mM H2O2, and UVA irradiation for treating 50 mg/L RB5. The particles were fluidized by pumping the air at a flow rate of 6 sL/min through the glass membrane at the bottom of the reactor. The Fenton-like reaction was performed for 360 min. Afterwards, the UVA light was turned off, and the solution pH was adjusted to 12 to desorb the organic residues on the magnetite surface. The desorption step (for 60 min) can verify whether TOC removal was overestimated due to adsorption. Fig. 9 plots the degradation and mineralization of RB5 azo dye. The degradation is represented by the decolorization (i.e., breaking of azo compound at 597 nm) and the breaking of aromatic ring (310 nm) of azo-dye molecular structure. Under UVA irradiation, the Fenton reaction catalyzed with magnetite pellets decolorized the RB5 solution completely in 60 min, but the aromatic ring cleavage only reached Fig. 6. XPS analysis for magnetite product: (a) Survey XPS pattern, (b) The details of the Fe2p1/2 and Fe2p3/2. 6 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. Fig. 7. Effect of supersaturation degree (S) on crystallization ratio (CR) of FBHC for precipitates of (a) Fe(OH)2; (b) FeCO3 at various input Fe concentrations; and (c) Solubility curve of FeCO3 and Fe(OH)2 (QFe = QCO3 = QR = 50 ml/min; U = 28.6 m/h; HRT = 3 min; molar ratio of [carbonate]/[Fe(II)] = 1.2). degraded by photolysis to produce %OH radicals [66]. Because of the lack of active radicals in the absence of UVA irradiation or H2O2, the decolorization and TOC removal were substantially lowered. In other words, photolysis was required to activate the Fenton-like reaction in the formation of radicals from H2O2. Because the Fe(II)/Fe(III) redox in the spinel structure of Fe3O4 mediates the photo-assisted Fenton-like reaction, at low pH, the lattice Fe(II) may dissolve into the solution after transferring the electron for ROS generation. Fig. 10 shows the amount of iron dissolved from magnetite particles during RB5 degradation. Two conditions produced soluble Fe accounting for homogeneous Fenton reaction. First, in the dark experiment, the leached iron increased up to 0.8 mg/L due to the Fenton reaction between H2O2 and surface Fe(II) species at low pH (2.8). Second, with UVA irradiation, the photolysis of surface metalligand complex may release Fe(II), which reached above 1 mg/L. Accordingly, the photolysis of H2O2 reduced the concentration of free Fe (II) to around 0.5 mg/L, and thus limited the effectiveness of the homogeneous Fenton reaction. Quenching experiment was conducted to evaluate the predominance of reactive oxygen species (ROS) in the photo-fenton like reaction, as depicted in Fig. 11. Tert-butyl alcohol (TBA) and furfuryl alcohol (FA) were chosen as the %OH radical and singlet oxygen scavengers, respectively [67,68]; Fenton reaction was performed for two hours, followed by 30 min of desorption process. Since the signal at 310 nm as representing aromatic ring may be inferred by furfuryl alcohol, the data of decolorization at 579 nm were compared. Accordingly, both of %OH radical and singlet oxygen oxidized RB5. In the absence of singlet oxygen (FA system), %OH removed the color of RB5 Fig. 8. Magnetization curve of Fe3O4 pellets from FBHC. from the air bubbling. However, in this work, the ineffectiveness of Fenton-like reaction (black full and empty symbols) suggested that Fe (II)/Fe(III) are less active to H2O2. In the photo-assisted Fenton-like process, the surface sites on existing magnetite pellets induced the catalytic reaction that converted the adsorbed H2O2 to %OH radicals. The UVA light irradiation accounted for the metal–ligand charge transfer, which mediated the reduction of the Fe(III)-organic complex to Fe(II) for the reproducibility of the Fenton reaction·H2O2 was also 7 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. Fig. 9. (a) Decolorization (Color, reduction in 597 nm band) and breaking of aromatic ring (AR, reduction in 310 nm band), and (b) TOC removal of RB5 (initial RB5 = 50 mg/L; [H2O2] = 10 mM; Fe3O4 dosage = 2 g/L; air flow = 6 sL·min; pH = 2.8; photocatalytic reaction for 360 min, followed by desorption for 60 min). (UVA) [69]: DOM1 + hv → DOM1 ∗ (29) DOM1 ∗ → DOM 3 ∗ (30) DOM 3 ∗ + O2 → DOM1 + O21 (31) The yield of singlet oxygen also resulted from the side reactions of hydroxyl and superoxide radical evolved from Fenton-like process. The heterogeneous redox reaction can be predicted as following equations [65,70,71]. H2 O2 + s → H2 O2 − s (32) ≡ Fe (II ) + H2 O2 − s → ≡Fe (III ) − OH + ∙OH (33) ≡ Fe (II ) + O2 + H2 O → ≡Fe (III ) − OH + HO2 ∙ (34) HO2 ∙ ⇄ Fig. 10. Leached iron from magnetite particles (RB5 = 50 mg/L; [H2O2] = 10 mM; Fe3O4 dosage = 2 g/L; air flow = 6 sL/min; pH = 2.8). H+ + ∙O2− (35) ∙OH + H2 O2 → HO2 ∙ + H2 O (36) ∙OH + O2∙− → O21 + OH− (37) HO2 ∙ + O2∙− → O21 + HO2− (38) HO2 ∙ + HO2 ∙ → O21 + H2 O2 ≡ Fe (III ) − OH + HO2 ∙/ ∙O2− (39) → ≡Fe (II ) + H2 O/OH− + O2 ≡ Fe (III ) − OH + hv → ≡Fe (II ) + ∙OH (40) (41) The reaction kinetics of RB5 decolorization and mineralization are shown in Fig. 12. The experimental data were fitted with pseudo-first and second-order rate models, given by the following equations [72–74]: s + R ↔ sR ; K1 (adsorption) sH2 O2 + sFe (II ) → s∙OH + sOH− (42) + sFe (III ) ; k2 (Fenton − like ) (43) s + O21 → sO21 By using the total ROS attached on the catalyst surface sROS = s∙OH + sO21 sR + sROS → sR∙ or sR + sROS → sCO2 + sH2 O ; k3 Fig. 11. Quenching experiment of RB5 decolorization ([RB5] = 50 mg/L, [H2O2] = 10 mM, pH = 2.5 – 3.0, tert-butyl alcohol [TBA] = 20 mM, furfuryl alcohol [FA] = 20 mM, air flow = 6 sL/min). (44) The component sR, which denotes surface-adsorbed RB5, is supposed to be a steady-state species; the concentration of sR approaches a constant because the adsorption rate is balanced by the consumption rate. about 60%. By contrast, singlet oxygen could decolorize RB5 up to 88%. Singlet oxygen may derived from the reactions of dissolved organic matter (which was the intermediate of RB5 degradation), dissolved oxygen (from the air bubble as fluidization media), and light irradiation d [sR] = k1+ [s][R] − k1− [sR] − k3 [sR][sROS ] = 0 dt 8 (45) Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. Fig. 12. Linear regression of decolorization and mineralization of RB5 using (a) pseudo first-order and (b) pseudo second-order rate models (RB5 = 50 mg/L; [H2O2] = 10 mM; Fe3O4 dosage = 2 g/L; air flow = 6 sL/min; pH = 2.8). conventional chemical precipitation was solved by FBHC. Meanwhile, the reuse of iron from the wastewater as granular catalysts of metal salt or oxide for further application in treatment of organic pollutants was also demonstrated. Then, the rate of R removal in the bulk solution is related to the adsorption-desorption equilibrium. − k +k3 [s][sROS ][R] d [R] = k1+ [s][R] − k1− [sR] − k3 [sR][sROS ] = 1 − k1 + k3 [sROS ] dt (46) CRediT authorship contribution statement By assuming an excess of surface sites (s) and radicals (s•ROS), the concentration profile of R should be: − d [R] = k1+ [s][R] = kapp [R] dt Nicolaus N.N. Mahasti: Methodology, Formal analysis, Investigation, Writing - original draft, Visualization. Yu-Jen Shih: Validation, Writing - review & editing. Yao-Hui Huang: Conceptualization, Resources, Supervision, Project administration, Funding acquisition. (47) For the pseudo first-order rate model: ln [R] = −kapp1 t [R]0 Declaration of interests (48) The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. For the pseudo second-order rate model: 1 1 − = −kapp2 t [R]0 [R] (49) Acknowledgement The constant kapp represents the apparent rate of RB5 removal. Fig. 12a and b summarize the fitting of experimental data with the pseudo first- and second-order rate models, respectively. The pseudo first-order reaction better described the decolorization and mineralization of RB5 than second-order reaction, according to its relatively high R2 value. As shown in Fig. 12a, the rate constants of decolorization and mineralization with the aid of Fe3O4 are about two times (from k = 0.0197 to k = 0.0248 min−1) and five times larger (from k = 0.001 to k = 0.005 min−1), respectively, than those without Fe3O4, which is mainly attributable to the effective production of the ROS under UVA irradiation. The authors would like to thank to the Ministry of Science and Technology, Taiwan, for the financial support under contract no. MOST 107-2221-E-006-004-MY3. Appendix A. Supplementary material Supplementary data to this article can be found online at https:// doi.org/10.1016/j.seppur.2020.116975. References 4. Conclusions [1] N. Khatri, S. Tyagi, Influences of natural and anthropogenic factors on surface and groundwater quality in rural and urban areas, Front. Life Sci. 8 (2015) 23–39. [2] N. Khatri, S. Tyagi, D. Rawtani, Recent strategies for the removal of iron from water: A review, J. Water Process Eng. 19 (2017) 291–304. [3] World Health Organization. Iron in drinking water: background document for development of WHO guidelines for drinking water quality. Proceedings of the kinetics and metabolism in humans. 2003. Geneva. WHO/SDE/WSH/03.04/08. [4] World Health Organization. A Compendium of standards for wastewater reuse in the eastern Mediterranian Region, in: FAO Guidelines for trace metals in irrigation water. World Health Organization Regional Office for the Eastern Mediterranian. 2006. Cairo. WHO-EM/CEH/142/E. [5] Z. Chen, X. Wang, Q. Ge, G. Guo, Iron oxide red wastewater treatment and recycling of iron-containing sludge, J. Cleaner Prod. 87 (2015) 558–566. [6] A. Stoica, M. Sandberg, O. Holby, Energy use and recovery strategies within wastewater treatment and sludge handling at pulp and paper mills, Bioresour. Technol. 100 (2009) 3497–3505. [7] M.D.G. de Luna, D.P.M. Rance, L.M. Bellotindos, M.C. Lu, Removal of sulfate by fluidized bed crystallization process, J. Environ. Chem. Eng. 5 (2017) 2431–2439. Fluidized-bed homogeneous crystallization (FBHC) was performed to treat iron-containing solution by recovering iron as magnetite pellets (Fe3O4). The efficiency of iron removal from FBHC attained 77% and 98.5% for CR and TR, respectively, under pH 8.5 – 9.5. The crystallization ratio was highly dependent on effluent pH, carbonate, and residual iron, which were determining factors of solubility of iron hydroxide and carbonate. The catalytic properties of the FBHC Fe3O4 pellets were evaluated in terms of photo-assisted Fenton-like degradation of RB5. The efficiencies of RB5 decolorization and mineralization reached about 98 – 99% and 60 – 68%, respectively, at pH 2.75 – 3 (10 mM H2O2, 2 g/L of magnetite particles), confirming the treatability of dye solution using the recycled iron as catalyst. This research evidenced that the generation of low-purity sludge as by-product in 9 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. [39] D. Kunii, O. Levenspiel, Fluidization Engineering, Butterworth-Heinemann, United States of America, 1991. [40] N. Boonrattanakij, M.C. Lu, J. Anotai, Iron crystallization in a fluidized-bed Fenton process, Water Res. 45 (2011) 3255–3262. [41] C.Y. Tai, Crystal growth kinetics of two-step growth process in liquid fluidized-bed crystallizers, J. Cryst. Growth 206 (2019) 109–118. [42] S.H. Drissi, P. Refait, M. Abdelmoula, J.M.R. Genin, The preparation and thermodynamic properties of Fe(II)-Fe(III) hydroxide-carbonate (green rust 1); Pourbaix diagram of iron in carbonate-containing aqueous media, Corros. Sci. 37 (2025–2041) (1995) 37. [43] T. Iwasaki, N. Sato, K. Kosaka, S. Watano, T. Yanagida, T. Kawai, Direct transformation from goethite to magnetite nanoparticles by mechanochemical reduction, J. Alloy. Compd. 509 (2011) L34–L37. [44] S. Alibeigi, M.R. Vaezi, Phase Transformation of Iron Oxide Nanoparticles by Varying the Molar Ratio of Fe2+:Fe3+, Chem. Eng. Technol. 31 (2008) 1591–1596. [45] J. Xu, Q. Zhang, F. Guo, J. Hong, W. Chu, Effects of the crystallization time on the mesoporous structure, texture, morphology and styrene oxidation performances of V-MCM-41, J. Energy Chem. 25 (2016) 1058–1063. [46] V.I. Tkatch, S.V. Vasiliev, Svyrydova.K.A. Identification of the onset crystallization time in metallic glasses at isothermal conditions, J. Non-Cryst. Solids 463 (2017) 102–107. [47] B. Bellocq, B. Cuq, T. Ruiz, A. Duri, K. Cronin, D. Ring, Impact of fluidized bed granulation on structure and functional properties of the agglomerates based on the durum wheat semolina, Innovative Food Sci. Emerg. Technol. 45 (2018) 73–83. [48] Y. Qiu, A.C. Rasmuson, Crystal growth rate parameters from isothermal desupersaturation experiments, Chem. Eng. Sci. 46 (1991) 1659–1667. [49] P.W. Voorhees, The theory of Ostwald ripening, J. Stat. Phys. 38 (1985) 231–252. [50] T. Zeng, S. Li, J. Hua, Z. He, X. Zhang, H. Feng, S. Song, Synergistically enhancing Fenton-like degradation of organics by in situ transformation from Fe3O4 microspheres to mesoporous Fe, N-dual doped carbon, Sci. Total Environ. 645 (2018) 550–559. [51] P.S.R. Prasad, K.S. Prasad, V.K. Chaitanya, E.V.S.S.K. Babu, B. Sreedhar, S.R. Murthy, In situ FTIR study on the dehydration of natural goethite, J. Asian Earth Sci. 27 (2006) 503–511. [52] W. Lu, Y. Shen, A. Xie, W. Zhang, Green synthesis and characterization of superparamagnetic Fe3O4 nanoparticles, J. Magn. Magn. Mater. 322 (2010) 1828–1833. [53] J.F. Anderson, M. Kuhn, U. Dielbold, Epitaxially Grown Fe3O4 Thin Films: An XPS Study, Surf. Sci. Spectra 4 (1998) 266–272. [54] R. Priambodo, Y.L. Tan, Y.J. Shih, Y.H. Huang, Fluidized-bed crystallization of iron phosphate from solution containing phosphorus, J. Taiwan Inst. Chem. Eng. 80 (2017) 247–254. [55] S. Karthika, T.K. Radhakrishnan, P. Kalaichelvi, A Review of Classical and Nonclassical Nucleation Theories, Cryst. Growth Des. 16 (2016) 6663–6681. [56] H. Takiyama, Supersaturation operation for quality control of crystalline particles in solution crystallization, Adv. Powder Technol. 23 (2012) 273–278. [57] H. Cheap-Charpentier, O. Horner, J. Lédion, H. Perrot, Study of the influence of the supersaturation coefficient on scaling rate using the pre-calcified surface of a quartz crystal microbalance, Water Res. 142 (2018) 347–353. [58] E.S.D.T. de Mendonça, A.C.B. de Faria, S.C.L. Dias, F.F.H. Aragón, J.C. Mantilla, J.A.H. Coaquira, J.A. Dias, Effects of silica coating on the magnetic properties of magnetite nanoparticles, Surf. Interfaces 14 (2019) 34–43. [59] S.H. Gee, Y.K. Hong, D.W. Erickson, M.H. Park, J.C. Sur, Synthesis and aging effect of spherical magnetite (Fe3O4) nanoparticles for biosensor applications, J. Appl. Phys. 93 (2003) 7560–7562. [60] V.P. Ponomar, Synthesis and magnetic properties of magnetite prepared by chemical reduction from hematite of various particle sizes, J. Alloy. Compd. 741 (2018) 28–34. [61] H. Qi, J. Ye, N. Tao, M. Wen, Q. Chen, Synthesis of octahedral magnetite microcrystals with high crystallinity and low coercive field, J. Cryst. Growth 311 (2009) 394–398. [62] M. Ahmadzadeh, C. Romero, J. McCloy, Magnetic analysis of commercial hematite, magnetite, and their mixtures, AIP Adv. 8 (2017) 056807. [63] M.C. Lu, Oxidation of chlorophenols with hydrogen peroxide in the presence of goethite, Chemosphere 40 (2000) 125–130. [64] J. Shi, Z. Ai, L. Zhang, Fe@Fe2O3 core-shell nanowires enhanced Fenton oxidation by accelerating the Fe(III)/Fe(II) cycles, Water Res. 59 (2014) 145–153. [65] L. Zhao, Z.R. Lin, X.H. Ma, Y.H. Dong, Catalytic activity of different iron oxides: Insight from pollutant degradation and hydroxyl radical formation in heterogeneous Fenton-like systems, Chem. Eng. J. 352 (2018) 343–351. [66] R.G.L. Gonçalves, P.A. Lopes, J.A. Resende, F.G. Pinto, J. Tronto, M.C. Guerreiro, L.C.A. de Oliveira, W. de Castro Nunes, J.L. Neto, Performance of magnetite/ layered double hydroxide composite for dye removal via adsorption, Fenton and photo-Fenton processes, Appl. Clay Sci. 179 (2019) 105152. [67] S. Nasseri, A.H. Mahvi, M. Seyedsalehi, K. Yaghmaeian, R. Nabizadeh, M. Alimohammadi, G.H. Safari, Degradation kinetics of tetracycline in aqueous solutions using peroxydisulfate activated by ultrasound irradiation: Effect of radical scavenger and water matrix, J. Mol. Liq. 241 (2017) 704–714. [68] P.Z. Ray, M.A. Tarr, Solar production of singlet oxygen from crude oil films on water, J. Photochem. Photobiol., A 286 (2014) 22–28. [69] R.M. Dalrymple, A.K. Carfagno, C.M. Sharpless, Correlations between Dissolved Organic Matter Optical Properties and Quantum Yields of Singlet Oxygen and Hydrogen Peroxide, Environ. Sci. Technol. 44 (2010) 5824–5829. [70] S.S. Lin, M.D. Gurol, Catalytic Decomposition of Hydrogen Peroxide on Iron Oxide: Kinetics, Mechanism, and Implications, Environ. Sci. Technol. 32 (1998) 1417–1423. [71] X. Liang, Y. Zhong, S. Zhu, L. Ma, P. Yuan, J. Zhu, H. He, Z. Jiang, The contribution [8] P. Zhou, J.C. Huang, A.W.F. Li, S. Wei, Heavy metal removal from wastewater in fluidized bed reactor, Water Res. 33 (1999) 1918–1924. [9] Y.J. Shih, H.C. Chang, Y.H. Huang, Reclamation of phosphorus from aqueous solutions as alkaline earth metal phosphate in a fluidized-bed homogeneous crystallization (FBHC) process, J. Taiwan Inst. Chem. Eng. 62 (2016) 177–186. [10] N.N.N. Mahasti, Y.J. Shih, X.T. Vu, Y.H. Huang, Removal of calcium hardness from solution by fluidized-bed homogeneous crystallization (FBHC) process, J. Taiwan Inst. Chem. Eng. 78 (2017) 378–385. [11] P.S. Caddarao, S. Garcia-Segura, F.C. Ballesteros, Y.H. Huang, M.C. Lu, Phosphorous recovery by means of fluidized bed homogeneous crystallization of calcium phosphate. Influence of operational variables and electrolytes on brushite homogeneous crystallization, J. Taiwan Inst. Chem. Eng. 83 (2018) 124–132. [12] F.C. Ballesteros, A.F.S. Salcedo, A.C. Vilando, Y.H. Huang, M.C. Lu, Removal of nickel by homogeneous granulation in a fluidized-bed reactor, Chemosphere 164 (2016) 59–67. [13] C.S. Chen, Y.J. Shih, Y.H. Huang, Remediation of lead (Pb(II)) wastewater through recovery of lead carbonate in a fluidized-bed homogeneous crystallization (FBHC) system, Chem. Eng. J. 279 (2015) 120–128. [14] N.N.N. Mahasti, Y.J. Shih, Y.H. Huang, Removal of iron as oxyhydroxide (FeOOH) from aqueous solution by fluidized-bed homogeneous crystallization, J. Taiwan Inst. Chem. Eng. 96 (2019) 496–502. [15] R.P. Bailey, T. Bennett, M.M. Benjamin, Sorption onto and Recovery of Cr(VI) Using Iron-Oxide-Coated Sand, Water Sci. Technol. 26 (1992) 1239–1244. [16] S.E. Baltazar, A.H. Romero, M. Salgado, Adsorption of As(III) and As(V) compounds on Fe3O4(001) surfaces: A first principle study, Comput. Mater. Sci. 127 (2017) 110–120. [17] L. Feng, M. Cao, X. Ma, Y. Zhu, C. Hu, Superparamagnetic high-surface-area Fe3O4 nanoparticles as adsorbents for arsenic removal, J. Hazard. Mater. 217–218 (2012) 439–446. [18] H. Karami, Heavy metal removal from water by magnetite nanorods, Chem. Eng. J. 219 (2013) 209–216. [19] L. Yu, J. Chen, Z. Liang, W. Xu, L. Chen, D. Ye, Degradation of phenol using Fe3O4GO nanocomposite as a heterogeneous photo-Fenton catalyst, Sep. Purif. Technol. 171 (2016) 80–87. [20] S. Zhang, X. Zhao, H. Niu, Y. Shi, Y. Cai, G. Jiang, Superparamagnetic Fe3O4 nanoparticles as catalysts for the catalytic oxidation of phenolic and aniline compounds, J. Hazard. Mater. 167 (2009) 560–566. [21] B. Morgan, O. Lahav, The effect of pH on the kinetics of spontaneous Fe(II) oxidation by O2 in aqueous solution – basic principles and a simple heuristic description, Chemosphere 68 (2007) 2080–2084. [22] P. Vanysek, Electrochemical Series, CRC Handbook of Chemistry and Physics, CRC Press, Florida, United States of America, 2000. [23] G. Rocchini, Magnetite stability in aqueous solutions as a function of temperature, Corros. Sci. 36 (1994) 2043–2061. [24] J.A. Dean, Lange’s Handbook of Chemistry, McGraw-Hill, New York, United States of America, 1979. [25] W. Yu, Y.I. Peng, ZhengY.J. Effect of purification pretreatment on the recovery of magnetite from waste ferrous sulfate, Int. J. Miner. Metall. Mater. 23 (2016) 891–897. [26] M.M. Benjamin, Water Chemistry, Waveland Press, United States of America, 2010. [27] N.D. Loh, S. Sen, M. Bosman, S.F. Tan, J. Zhong, C.A. Nijhuis, P. Král, P.P. Matsudaira, U. Mirsaidov, Multistep nucleation of nanocrystals in aqueous solution, Nat. Chem. 9 (2016) 77–82. [28] C. Sun, D. Xue, Chemical bonding theory of single crystal growth and its application to crystal growth and design, CrystEngComm 18 (2016) 1262–1272. [29] M. Wu, Y. Zhao, Q. Li, G. Su, W. Liu, Q. Wang, C. Li, Thermal catalytic degradation of α-HBCD, β-HBCD and γ-HBCD over Fe3O4 micro/nanomaterial: Kinetic behavior, product analysis and mechanism hypothesis, Sci. Total Environ. 668 (2019) 1200–1212. [30] L. Xu, J. Wang, Fenton-like degradation of 2,4-dichlorophenol using Fe3O4 magnetic nanoparticles, Appl. Catal. B 123–124 (2012) 117–126. [31] X. Wang, B. Guo, W. Fu, H. Yang, Triethylenetetramine promoted rGO-Fe3O4 nanocomposites for highly efficient Fenton-like reaction, J. Water Process Eng. 31 (2019) 100814. [32] M. Farrokhi, S.C. Hosseini, J.K. Yang, M. Shirzad-Siboni, Application of ZnO–Fe3O4 Nanocomposite on the Removal of Azo Dye from Aqueous Solutions: Kinetics and Equilibrium Studies, Water Air Soil Pollut. 225 (2014) 2113. [33] R.C.C. Costa, F.C.C. Moura, J.D. Ardisson, J.D. Fabris, R.M. Lago, Highly active heterogeneous Fenton-like systems based on Fe0/Fe3O4 composites prepared by controlled reduction of iron oxides, Appl. Catal. B 83 (2008) 131–139. [34] P. Alimard, Fabrication and kinetic study of Nd-Ce doped Fe3O4-chitosan nanocomposite as catalyst in Fenton dye degradation, Polyhedron 171 (2019) 98–107. [35] K. Sahel, N. Perol, H. Chermette, C. Bordes, Z. Derriche, C. Guillard, Photocatalytic decolorization of Remazol Black 5 (RB5) and Procion Red MX-5B: Isotherm of adsorption, kinetic of decolorization and mineralization, Appl. Catal. B 77 (2007) 100–109. [36] G. Heron, T.H. Christensen, Impact of Sediment-Bound Iron on Redox Buffering in a Landfill Leachate Polluted Aquifer (Vejen, Denmark), Environ. Sci. Technol. 29 (1995) 187–192. [37] X. Du, G. Liu, F. Qu, K. Li, S. Shao, G. Li, H. Liang, Removal of iron, manganese and ammonia from groundwater using a PAC-MBR system: The anti-pollution ability, microbial population and membrane fouling, Desalination 403 (2017) 97–106. [38] A.R. Kaveeshwar, S.K. Ponnusamy, E.D. Revellame, D.D. Gang, M.E. Zappi, R. Subramaniam, Pecan shell based activated carbon for removal of iron(II) from fracking wastewater: Adsorption kinetics, isotherm and thermodynamic studies, Process Saf. Environ. Prot. 114 (2018) 107–122. 10 Separation and Purification Technology 247 (2020) 116975 N.N.N. Mahasti, et al. process for dye degradation in a fluidized-bed reactor: Kinetics and mass transfer, J. Cleaner Prod. 182 (2018) 644–653. [74] H.W. Chen, Y.L. Kuo, C.S. Chiou, S.W. You, C.M. Ma, C.T. Chang, Mineralization of reactive Black 5 in aqueous solution by ozone/H2O2 in the presence of a magnetic catalyst, J. Hazard. Mater. 174 (2010) 795–800. of vanadium and titanium on improving methylene blue decolorization through heterogeneous UV-Fenton reaction catalyzed by their co-doped magnetite, J. Hazard. Mater. 199–200 (2012) 247–254. [72] Y. Flores, R. Flores, A.A. Gallegos, Heterogeneous catalysis in the Fenton-type system reactive black 5/H2O2, J. Mol. Catal. A: Chem. 281 (2018) 184–191. [73] M.E. Farshchi, H. Aghdasinia, A. Khataee, Modeling of heterogeneous Fenton 11