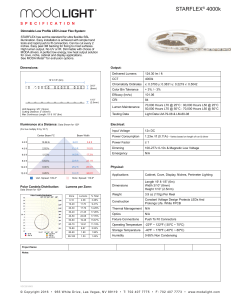

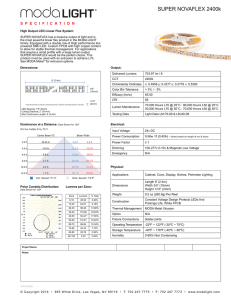

Pharma&Biotech MODA™ Solution Informatics for QC Micro Automated QC Microbiology Processes for Regulated Manufacturing Fully Equipped « The MODA™ Solution is equipped with hardware, software, and implementation services required to get you into production quickly – allowing time and resources to be directed toward higher value initiatives and paths to operational excellence. » Featured: MODA-FDC® Platform – – – – – – – – Stainless steel cart Ergonomic tablet PC Docking station Thermal label printer Barcode scanner gun Proximity reader for RF badges Space for equipment Space for growth media « Mobile, field data capture for all critical areas. » Pharma&Biotech – MODA-EM – Informatics for QC Micro « Eliminate unnecessary time and cost associated with paper-based QC methods. » Capture » Track » MODA™ Solution Mobile Data Acquisition The MODA™ Solution delivers a comprehensive informatics platform that automates quality control (QC) processes for all regulated manufacturing in the Life Sciences industry. As a user of the MODA™ Solution, Lonza has direct experience with its value – providing improved decision making, regulatory compliance, and productivity across our own global manufacturing facilities. The MODA™ Solution integrates with Laboratory Information Management Systems (LIMS) to bridge the communication gap between QC and production. A comprehensive Solution The MODA™ Solution encompasses automation of the full spectrum of QC activities including environmental monitoring (EM), utility testing, and product testing. MODA™ Software easily integrates with commonly used instrumentation and media found in manufacturing facilities, specifically production and laboratory areas. Organizations gain timely and accurate QC monitoring by utilizing locationbased scheduling, mobile data collection, and paperless lab processing. MODA™ Software also delivers on-demand reporting, trending, and visualization capabilities to allow in-depth process analysis and ad hoc queries by decision makers. Pharma&Biotech – MODA-EM – Informatics for QC Micro Components Include MODA-EM® — Lonza’s flagship software for paperless EM automates your QC Micro data collection and management (EM, utility, and product testing). MODA-VIP® — Visual Intelligence Portal provides improved insight into your manufacturing operation and testing data. MODA-FDC® — Field Data Capture lets you quickly collect, label (barcode) and track test samples for EM, utilities, and products at points of sampling within all critical areas. Sample Collection Time Reduced 50 % The typical paper-based process for a sample collection regiment is roughly about 8 hours per person, per shift. Using the MODA™ Solution for sample collection, your process time is cut in half to roughly 4 hours per person, per shift. This savings has significant implications when it is applied to multi technician, multi-shift operation for a one year period. 70 70 Number of IDs Results Trend » 60 50 5 4 40 3 30 25 20 15 16 15 2 10 0 8 6 00 0 0 0 0 0 0 0 6 23 0 0 0 0 0 0 0 00 0 0 00 0 0 0 00 0 0 0 0 0 0 0 00 00 0 0 00 0 0 0 0 00 00 00 0 0 0 0 0 M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M 1P 5A 8A 2P 0P 9P 2A 3P 2P 5P 1A 9P 8A 9A 5P 6P 8P 1P 0A 6A 0P 4P 7A 1P 1P 7P 5A 2P 4A 5P 3P 1A 1P 4A 4P 7P 8P 1P 1P 2A 9P 4P 1P 7A 1A 8A 4A 4P 5A 5A 6P 4A 9A 5P 5A 6A 1A 6P 3P 1P 8P 7A 9A 0P 6P 8:2 :2 :3 :1 :1 :0 :4 7:4 :1 :0 4:2 :2 :4 7:2 7:4 :4 :4 :3 :0 :5 :0 :3 :5 :0 :0 4:1 :4 :0 :5 :2 :1 8:4 :4 4:1 7:1 :4 :3 7:5 7:5 :5 :2 :2 :3 7:5 :1 :4 0:1 :5 :4 :0 :0 9:1 :3 :1 :2 :2 :3 :0 :2 2:2 :0 :2 :5 :2 :3 :0 :29 :53 :24 :25 :05 :52 :0 :38 :28 :1 :26 :11 :1 :1 :39 :09 :40 :30 :38 :10 :46 :32 :59 :59 :1 :01 :28 :01 :49 :23 :4 :48 :1 :0 :05 :33 :2 :2 :04 :05 :13 :03 :2 :38 :16 :2 :16 :51 :26 :54 :2 :23 :52 :51 :08 :03 :52 :41 :0 :12 :29 :25 :14 :22 12 9 8 9 5 9 3 9 5 11 10 12 9 8 9 9 10 11 10 10 0 4 0 1 0 6 0 2 0 9 0 9 0 2 0 8 06 0 1 0 1 0 3 11 0 5 11 0 2 0 5 10 10 0 1 0 1 0 8 0 4 0 4 0 4 11 0 4 0 2 0 3 10 0 5 0 9 0 9 12 11 10 11 0 1 0 7 0 9 12 0 8 10 1 8 1 5 1 6 2 1 2 6 10 2 3 2 7 09 200 200 200 200 009 009 009 200 200 009 010 010 010/201 201201 201 201 201 201 201 010 201 201 201 010 201 010 201 201 010 010 /201/201 201 201 201 201 010 201 201 201 010 201 201 201 010 010 010 010 201 201 201 010 201 011 201 201 201 201 201 012 201 201 0 / / / / 2 / / / 2 / / / 2 2 2 2 / / / 2 / 2 / / / / / 2 / / / / / / / / / / 2 / / / 2 / 2 / / 2 2 / 2 / / 2 2 / / 2 2 2 /2 7/ 6 9 2 8 /2 / 8/ 9 9 0/ 1/ 2/ 2 22 15 15 18 3 23 16 8 2/ 13 13 13 3/ 17 8/ 21 23 4/ 3/ 21 22 23 8 03 03 4/ 0 08 27 4/ 18 19 21 8/ 9/ 0/ / 07 08 08 9/ 14 2/ 3 20 14 17 29 6/ 09 13 /1 9/2 9/2 0/2 0/2 /29 /18 /0 2/0 2/0 /1 /1 /1 /2 1/ 2/ 2/ 2/ 2/2 2/ 3/ 3/1 /2 4/ 4/ 1/ /1 5/ /1 5/ 6/ /2 /1 7/ 7/ 7/ 7/2 8/ 8/ /2 8/3 9/ 9/ /0 0/ 0/ 0/ /2 /0 /3 /05 2/ 2/ 2/ /0 2/ /1 5/2 9/ 2/ 4/ 5/ /0 8/ 8/ 09 0 0 1 1 10 10 12 1 1 12 01 01 01 0 0 0 0 0 0 0 0 03 0 0 0 05 0 05 0 0 06 07 0 0 0 0 0 0 08 0 0 0 10 1 1 1 10 11 11 12 1 1 1 12 1 01 0 0 1 0 0 08 0 0 Result Action Level Alert Level 95th Percentile 99th Percentile Min. Result Max. Result Avg. Result Sample Data 2 1 1 0 1 Acinetobacter Aspergillus genomospecies candidus 9 2 1 Aspergillus glaucus Aspergillus parasiticus 2 1 Bacillus cereus Enterococcus Escherichia casselifavus coli 1 Gram-Cocci 1 Gram-Rods Visualization Mapping Tool On-demand Analytics Enable a correlation of test results with floor plans of your physical facility. This can be easily configured to match the zone classifications on the processing plant floor. MODA™ Solution is compatible with facility maps developed with industry standard drawing packages such as AutoCAD® and Visio®. Tabular Views such as a Deviation Summary report. « Gain complete insight into your manufacturing operations. » 2 Gram + Cocci Micrococcus luteus Species Trend Reports for user-selected tests and timeframes. « Quickly access reports and trends on your quality data – at the click of a button. » Visualize » Featured: MODA-VIP® module More Science. Less Paper.™ Without MODA™ Solution By combining automated scheduling, workflows, mobile data acquisition, device integration, and advanced analytics, the MODA™ Solution delivers efficiencies across your organization. Manual, paper-based process steps burden QC Micro programs with paper scheduling, marker labeling of sample media, manual reconciliation, paper log book entry, and manual notification of deviations. Test results are stored in shelves of paper binders – a challenge to quickly navigate during an audit. QC Departments Are Able To: – – – – – – – Automate data collection from devices and people Eliminate redundant data entry and transcription errors Gain direct traceability of QC Micro programs Increase worker efficiency Improve regulatory compliance Make sound product quality and release decisions Quickly advance Green initiatives Measurable Benefits: – QC Technicians quickly and accurately collect data in critical areas – Lab Managers improve process efficiency for scheduling and tracking. – Supervisors gain immediate, detailed reporting on the production area to enable sound product release decisions, effective investigations, and quick response to audits. – Executive Management can access longer term trend reports to assess overall program effectiveness. For Corrective and Preventative Action (CAPA) purposes, building a set of trend reports can require more than eight weeks. By the time a trend of activity is developed and recognized, the condition causing the trend is likely to have changed – making it difficult to support corrective action activities – and nearly impossible to perform meaningful preventative actions. www.lonza.com www.lonza.com/moda A Life Sciences Focus Across the pharmaceutical industry, problems with product safety and efficacy due to contamination issues make the front page headlines all too often. The cost of a recall due to real or even a suspected contamination event is incalculable when one factors in the risk to consumers and the loss of brand confidence. Lonza is dedicated to helping our clients prevent incidents like this from ever occurring. Regulating agencies require comprehensive QC Micro programs to demonstrate that processing areas are under control for potential viable and non-viable contamination. However, the traditional paper-based QC Micro processes can be expensive, error-prone, and time and labor-intensive regardless if they are managed by small biotech companies or large pharmaceutical manufacturers. Lonza Walkersville, Inc. – Walkersville, MD 21793 Visio is a registered trademark of Microsoft. AutoCAD is a registered trademarks of Autodesk, Inc. All other trademarks belong to Lonza or its affiliates or to their respective third party owners. The information contained herein is believed to be correct and corresponds to the latest state of scientific and technical knowledge. However, no warranty is made, either expressed or implied, regarding its accuracy or the results to be obtained from the use of such information and no warranty is expressed or implied concerning the use of these products. The buyer assumes all risks of use and/or handling. Any user must make his own determination and satisfy himself that the products supplied by Lonza Group Ltd or its affiliates and the information and recommendations given by Lonza Group Ltd or its affiliates are (i) suitable for intended process or purpose, (ii) in compliance with environmental, health and safety regulations, and (iii) will not infringe any third party’s intellectual property rights. © 2016 Lonza. All rights reserved. RT-BR013 01/16