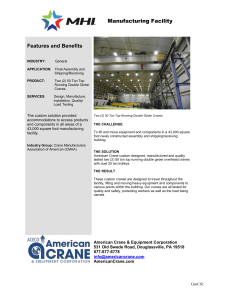

Overhead cranes ABUS cranes make light work of lifting. ABUS travelling cranes ABUS is one of Europe’s leading tory shape or application condi- crane manufacturers, offering tions. The wide range of acces­ customers tailor-made solutions for sories available means that ABUS for handling loads up to 120 tonnes, efficient material handling and indi- cranes are ideally suited for special are the ideal solution for heavy vidual service from design through applications. ABUS cranes are lifting and wide spans. The ABUS to maintenance. ABUS has been highly versatile and extremely travelling crane range includes five ensuring high quality and precision reliable and have a number of series designed for different appli- right down to the smallest compo- features which by no means all cations and operating conditions: nent for more than four decades manufacturers offer as standard single girder, double girder, under­ now. equipment. Whether you need slung and single girder wall travelling ABUS crane systems cover the lifting, lowering, linear handling or cranes and single girder semi-goli- entire load range up to 120 t and area coverage, ABUS cranes help ath cranes. can easily be adapted to any fac- you keep everything under control. ABUS travelling cranes, designed ABUS underslung travelling ABUS single girder travelling ABUS double girder travelling mounted tracks rather than free handling even where very little capacity of up to 120 tonnes. standing or building columns. space is available in production They are available in various confi­ Advantageous side approach halls or warehouses. ABUS single gurations and feature the versatility dimensions allow the optimum girder travelling cranes are available required for additional requirements. use of the entire width of the with rolled section or box girders. For example, higher crane travel production. Each model is available in different speeds, maintenance walkways, girder connection versions to allow trolleys with service platforms and a space-saving configuration and auxiliary hoists are all features an optimised highest hook position. which can easily be implemented. ABUS single girder wall travelling The ABUS single girder semi­ semi-goliath cranes are installed on spans up to 15 m and Safe Working a seperate track below other types Loads up to 10 tonnes. cranes are installed on ceiling cranes ensure efficient material cranes and ABUS single girder cranes achieve the maximum load goliath crane is designed for of travelling crane. They are the ideal solution for serving several working areas at the same time. The ABUS single girder wall travelling crane is designed for spans up to 12 m and load capacities up to 5 tonnes. 2 3 ABUS ELV, ELK and ELS single girder travelling cranes: a high-profile solution for low buildings Model ELV single girder travelling crane with rolled section girder ELK single girder travelling crane with welded box girder ELS single girder torsion box crane with side-mounted trolley ABUS single girder travelling The ABUS range of single girder ABUS ELV travelling cranes are cranes allow efficient material travelling cranes includes a variety equipped with sturdy section handling with load capacities up of girder connection versions for girders while ELK and ELS cranes to 16 t and spans up to 39 m even highly versatile adaptation to the feature torsionally rigid welded box in halls with low ceilings. space and dimensions available. girders. In addition, side-mounted With a minimal safety clearance The compact design of these units trolleys on ABUS ELS single girder between top of crane and factory allows very high hook positions. travelling cranes allow maximum roof, and the compact dimensions For new buildings, version 3 is the use of the available lifting height. of ABUS crane girders, it is ideal solution, offering the smallest possible to make full use of the side approach. In addition, the available height and to reduce ABUS range includes a wide variety the cost of a new building. of accessories for many different special applications. Max. span [m] up to 5 18,5 17,5 up to 6,3 17 up to 8 up to 10 15 29,5 up to 5 27,5 up to 10 22 up to 16 39 up to 6,3 35 up to 8 34 up to 10 Main girder connection versions to suit factory conditions – for ELV and ELK 3,2 t Stooled down configuration Version 1 3,2 t Stooled down configuration Version 2 for ELS 5t Stooled down configuration Version 1 4 Load capacity [t] 5t Stooled down configuration Version 2 3,2 t Standard main girder connection configuration Version 3 5t Standard main girder connection configuration Version 3 3,2 t Stooled up configuration Version 4 3,2 t Stooled up configuration Version 5 5t Stooled up configuration Version 4 5 ABUS single girder travelling cranes can be equipped with identical but also with differing girder connection versions for each track. In this way, you can divide a wide factory into two sections, allowing highly flexible material handling. The ideal solution for a new factory: the ABUS ELK single girder travelling crane with long angle chamfer adapted to suit the building haunch (version 3), optimising available height. Optional: thruster rollers offer an even more exact method of crane travel guidance, reducing skewing forces. 6 7 Stooled up crane bridge configurati­ons are the ideal solution for speci­al situations and buildings with diffi­cult conditions. The LED matrix display is available as a special option and informs about the current load in the hook even from distance. The tandem operation of travelling cranes makes it easier to handle bulky loads. ABUS radio remote control gives and for lifting heavy loads or con­ crane operators maximum freedom trolling travelling cranes on different of movement, which is especially levels. important where visibility is poor 8 9 ABUS ZLK double girder travelling cranes: the heavy brigade Model ZLK double girder travelling crane with welded box girder Load capacity [t] Max. span [m] 40 up to 40 37 up to 50 up to 100 30 Main girder connection versions to suit individual factory conditions Two girders are simply stronger than ABUS range includes a wide variety spans of up to 40 m and feature one, making ABUS double girder of accessories for many different the versatility needed for special travelling cranes the ideal solution special applications. ABUS ZLK requirements. For example, higher for the area coverage handling of double girder cranes feature welded crane travel speeds, service plat- heavy loads up to 120 t. Like all box beams. All the sections used for forms, trolleys with walkways and ABUS factory cranes, these units main girders and end carriages are auxiliary hoists are all features that are available with a number of main computer-optimised for high perfor­ can easily be implemented. girder connection versions to best mance and low weight, benefits that suit new or existing buildings and pay in terms of strength and cost the best in functionality, versatility efficiency. ABUS double girder and convenience. In addition, the travelling cranes are available for Stooled down configuration* Standard main girder connection configuration – Version 1 Stooled up configuration Version 2 Stooled up configuration Version 3 Stooled up configuration Version 4 Stooled up configuration Version 5 * Shown in combination with a stooled down law headroom hoist. 10 11 In the photographed application shown, the ABUS overhead travelling crane operates the crane flap, allowing the crane to travel back inside. Lowered trolleys allow double-girder travelling cranes to be installed even where there is little space above the crane track. The higher position of the crane bridge with a lowered trolley may be a decisive advantage, for example when handling bulky machines or large tanks. The electronic synchronisation control system allows synchronised lifting with several hoists, ensuring secure and precise load positioning at all times, even with minimal hook spacing. 12 The end carriage may be mounted on eight wheels for even load distribution. Heavier loads can then be carried on a smaller crane track and the reinforcement otherwise needed in existing buildings may not be required. 13 When transporting long and bulky goods, two adjacent cranes work in parallel to provide one risk-free load movement. With maintenance walkways and crab unit with service platforms, all the components of the crane system are easily accessible, a crucial advantage for maintenance work. ABUS two fall wire rope hoists are designed for high lifting speeds and load capacities up to 20 t. If a certain lifting height is only girder travelling crane with a DQA required in part of a hall, ABUS ultra low headroom hoist on the travelling cranes can be installed lower level. This configuration on different levels. In this example, ensures the safety distance required an ABUS ELS single girder torsion and maximises the available lifting box crane is used on the higher height. level, with an ABUS ZLK double 14 15 ABUS DLVM, EDL and EDK underslung travelling cranes High performance under special circumstances Model Load capacity [t] DLVM underslung travelling crane with rolled section girder and welded main girder connection EDL underslung travelling crane with rolled section girder and bolted main girder connection EDK underslung travelling crane with box girder and bolted main girder connection Max. span [m] up to 3,2 14 up to 5 17,5 up to 6,3 up to 8 17 9 up to 6,3 25 up to 8 13 Main girder connection versions to suit individual factory conditions – for EDL and EDK Complex factory configurations With minimum side approach DLVM and EDL travelling cranes are pose special problems, but they dimension and cantilevers to suit equipped with rolled section girders are easy to solve with ABUS under­ individual conditions, ABUS under­ while EDK cranes feature torsionally slung travelling cranes. The crane slung travelling cranes make full rigid welded box girders. A full track is mounted directly on the use of the space available. range of accessories is available. factory ceiling and not on free stan- The highest hook position can also ding structural or building columns, be raised by installing the main gir­ allowing efficient material handling der up between the end carriages. solutions even in tight spaces with These cranes are designed for load difficult design conditions. capacities up to 8 t and spans up to 25 m. 16 3,2 t 3,2 t Standard main girder connec­tion configuration – Version 1 (variable cantilever for minimum side approach dimension) 3,2 t Standard main girder connection configuration Version 1, “angled” (variable overhang for minimum side approach dimension) Stooled up configuration Version 2 (optimised hook height with­out crane girder cantilevers) 17 The ABUS EWL single girder wall travelling crane: a high-profile solution for the lower working level. Model EWL single girder wall travelling crane with welded box girder The ABUS single girder wall A wall travelling crane installed at travelling crane is designed for right angles across the hall can operation on a lower level beneath serve several working stations. a large travelling crane system. ABUS single girder wall travelling These cranes provide additional cranes are available for load handling possibilities and ensure capacities up to 5 t with jib lengths smooth and troublefree material up to 12 m. Load capacity [t] up to 5 Max. jib length [m] 12 handling between different working areas. With two hoists in tandem operation, ABUS single girder wall travelling cranes can also be used for the precise positioning of long loads. 18 19 ABUS EHPK single girder semi-goliath crane: a powerful partner on more than one level. Model Safe Working Loads [t] EHPK single girder semi-goliath crane with welded box beam 20 The ABUS single girder semi- goliath crane is available with Safe higher wheel loads, on a suitable goliath crane is the ideal solution Working Loads of up to 10 to and steel plate mounted flush to the for operation in the areas beneath a spans up to 15 m. plant floor. A raised or countersunk large travelling crane system. The torsion resistant and sturdy guide rail with the consequent trip Similar to the ABUS single girder box girder construction allows cra- hazards are avoided. The EHPK is wall travelling crane, due to its ne travel without any lateral guidan- fitted with lift-off prevention devices configuration at right angles to the ce of the portal leg at floor level. on the high level end carriage as downshop tracks, this crane can The lower end carriage travels eit­ well as obstacle detection and serve several adjacent work stati- her directly on the even and load clearly visible rotating lights at floor ons. The ABUS single girder semi- bearing shopfloor, or in the case of level. Max. spans [m] up to 5 up to 10 15 10 Guide rollers on the high level end Obstacle detection on the floor carriage as standard. level end carriage as standard and no guide rail on the floor required. 21 Standard equipment on ABUS travelling cranes – setting an example ABUS quality – right down to the ABUCommander are suitable ABUS travelling cranes are supplied cranes and are made to an ergo- for control of all ABUS overhead last detail nomic design. They ensure safe with comprehensive high perfor- activation of all crane functions mance standard equipment and have a slightly angled con- including many features often only offered as accessories. These fea­ Motor circuit breakers tures make ABUS cranes especially offer additional safety for cranes safe and reliable and allow precise with ABUS wire rope hoists by adaptation to the customer’s limiting the thermal load on crane individual needs. Like the cranes and hoist trolley travel motors themselves, each of these com­ in two-phase and severe inching ponents items meets stringent operation and when the drive quality requirements and has been system is blocked. After the circuit thoroughly tested. breaker has been tripped, there is no need to replace a fuse before figuration for holding in a natural, low-fatigue position. ABUCommanders feature non­ageing rugged plastic housings that are corrosion and weather proof. The connection between handset and control cable is designed with bayonet connections, making it possible for the handset to be released and removed, if required. restarting the hoist or crane. ABUS clamping buffers can be used for a variety of functions: for limiting crane travel, fixing hoists at specific positions, absorbing impact energy or securing trolleys against rolling away. They are adjustable and can be installed as required. In particular, they can be used ABUS plug-in connectors make ABUS contactor-type control temporarily, offering considerable control signals from the crane hoist trolleys, ABUS offers clamping versatility. Especially for monorail systems bring together all the contact easily and reliably. They are system. These systems feature already preassembled and reduce modular design for maximum repair and maintenance times to a versatility and easy adaptation minimum. Using these connectors, to customers’ requirements. hoists, geared motors and control Interfaces to the main items of units can be connected up quickly optional equipment (radio remote and easily without the assistance of control, signal horn, limit switches, an electrician. anti-collision devices, etc.) are pre­ installed ready for connection. The clear configuration with ducted wiring makes maintenance work easier. Timers prevent excessive inching and power contactors are generously sized for long service lives. buffers designed for adaptation to current conditions. The ABUS LIS-SE load indicator The main functions include: system features a comprehensive - overload protection range of switching and monitoring - part-load switches functions. The system offers an - operating hours meter extremely short load detection - current monitoring for time of only a few hundredths of a second, effectively protecting ABUS wire rope hoists against motor protection - redundant circuitry for additional safety overloading. The measurement - mains power and fault diagnostic principle allows the load on the - braking with use of motor as a hoist to be limited without reducing the lifting height available. generator to reduce wear on brakes - load population recorder (optional) 22 23 ABUS accessories: Just what you need for individual solutions The ABUS synchronization con­ With the comprehensive range ABUS cross-type limit switches trol system ensures that even of accessories offered by ABUS, limit long travel and cross travel, minor differences in lifting speed every ABUS travelling crane can be automatically slowing or stopping caused for example by different precisely adapted to the customer’s the crane or the hoist at the end of loads on the hooks are evened out requirements, ensuring optimum the track. These limit switches may when several hoists with the same performance. The range includes also be applied for crane zoning if rated lifting speed are operated in additional safety devices and it is necessary to divert a hoist on parallel. In this way, differences in equipment for additional functions a crane around a prohibited area. the levels of hooks with the same such as electric limit switches, The switch is operated by a or different loads can be kept within integrated load analysis systems, switching lug installed on the defined limits. The ABUS synchro- crane lighting and maintenance walkways. The ABULiner is an effective solution when precise positioning is required with variable speed hoists. This frequency converter also allows the maximum speed to be increased above the rated crane track or on the crane bridge. nization control system is an electronic system which can be retrofitted cost-effectively to pole­ changing standard hoist motors without mechanical modifications or electronic switches. speed when lifting part / reduced loads. ABULiners are also available for crane and trolley travel. Load measurement systems LIS-SE: Load measurement and evaluation system that measures the voltage and current on all three phases of the hoist motor. Radio remote control Optional functions: load population Radio remote controls give crane recorder. operators greater freedom of move­ ment, allowing them to choose the LIS-SV: this load indicator system position which gives the best view offers all the functions of the LIS- of their working area and effectively SE system, but uses load measure­ saving time. ABUS offers radio remote controls with joystick or the ABUS radio remote control sys- compact push-button hand held tem should be used in combination transmitter. ABUS radio remote with the tandem control system. controls are also suitable for multi­ With this control configuration, two user operation, with parallel access crane operators can control the two to several cranes. cranes separately, or one operator can control both cranes, either The ABUS tandem control system allows the crane operator to control two electrically coupled travelling separately or together. ment sensors in addition to motor current measurements. This system is an attractive proposition for systems with several hoists where the overall total load of all hoists needs to be limited. Measurement LED matrix display accuracy increases systemically, with the resultant load able to be shown on the pendant handset display or LED matrix display. cranes at the same time. Ideally, 24 25 ABUS accessories: Just what you need for individual solutions ABUS crane lighting systems effectively illuminate the working space under a crane, avoiding the shadows normally cast by crane Load suspension devices Anti-collision device can be used with ABUS cranes The ABUS anti-collision device pro­ designed to maintain a specified for special material handling tasks. tects cranes, preventing accidental minimum spacing and other special For example, ABUS cranes can be collision via photoelectric distance designs. equipped with vacuum lifting units measurement. Automatic switch­ Important: Not suitable to be used for lifting plates or with C-hooks for over to a lower speed as the two for distancing required because of handling coils. AZS smooth starting units and hoists approach each other is a structural reasons. In such cases standard feature. the light barrier system may be are the ideal accessories for the A shut-down function can be composed of fail-safe components incorporated. ABUS can also and check and malfunction indica- supply collision prevention devices tors. SU-2 smooth switching relays girders working beneath normal factory lighting. ABUS uses highly smooth handling of sensitive loads efficient energy-saving LED lights. and goods using pole-changing The number of lights, as well as drive systems. These electronic their light intensity reflect systems allow the crane operator customer requirements. to control crane and trolley travel sensitively, with adjustable acceleration and improved deceleration behaviour. Depending on individual ABUS spring reels keep push button pendants at the height required. Normally, the bottom of the push button pendant is positioned one metre above the operating level. Using the spring reel, the length of the control cable can be individually adapted. This is especially important when operating a crane from a mezzanine floor or an assembly pit. The ABUS requirements, the system can also be used separately for crane or trolley travel. ABUS maintenance walkways allow access to the entire length of the crane girder, bringing all the main components of the crane system within easy reach, a major prerequisite for safe and efficient maintenance work. Option: Hook block scale Further information is available on the website spring- reels are available with cable lengths of 3 and 4.5 m. 26 27 ABUControl: lifts cranes to a new level Travel profiles can be used to adapt ABUS cranes to your circumstances. Cranes with two fixed speeds move in a completely different way to cranes controlled by frequency converter, for example. Travel and hoist profiles allow cranes to be adapted to your current or required situation. This means your crane operators no longer have to adjust existing cranes and perceive the increased productivity of an additional crane system. Operating data, settings, service information. By means of the modern KranOS interface, you can keep tabs on the crane. For wireless use with any laptop or tablet with browser. Speeding up regular annual inspections into the bargain. ABUControl relies on tried-and- The ABUS sway control increases operate cranes can transport loads rope hoists are used. This requires trusted freely available components safety and convenience during safely with the aid of the sway the crane to be equipped with from renowned electronics transportation of goods in sensitive control feature. a frequency converter for lifting. manufacturers. Replacement or areas. Sway control is based on repair requires neither ‘specialist mathematical calculations. Travel The ABUS synchronisation control on cranes which run in tandem. knowledge’ nor ‘software licences’. speeds, acceleration and decelera­ of two hoists on one crane enables Two cranes, maximum of four You remain in complete control tion of crane and hoist, the hook the safe handling of long products. hoists and their hoisting motions, of the crane at all times and have position and length of the load Divergence of lifting speeds is pre- all regulated. a free choice of service partner. lifting attachment are taken into vented effectively through constant ABUControl - a unique promise for account. Even people who rarely regulation even where different wire Travel speeds are regulated even simple maintenance and repairs. 28 29 ABUS through and through: advanced production, typical precision The high quality standards achieved weld sequences through to the can rely on rapid completion to Plates of the lengths required for by ABUS crane systems are only application of the high-quality paint schedule and just in time delivery. box girders are welded together on possible because of the extreme system. Highly automated, highly They can also be sure that all the a PLC-controlled welding machine. care taken in production at the versatile production facilities ensure mechanical, electrical and electronic The butt welding machine can pro- ABUS plants in Lantenbach and an ideal combination of precision, components of an ABUS crane cess plates of different thicknesses Herreshagen. Our production cost-effectiveness and constant have been thoroughly tested prior and the automatic weld sequence facilities represent the state of the high quality levels. Highly special- to shipment and that any item of control system ensures the highest art, from the preparation of steel ised machines developed in-house, equipment bearing the ABUS name welding quality possible. plate using high-performance blast such as the mobile portal welding represents ABUS quality through cleaning systems and welding unit, ensure smooth and troublefree and through. using machinery with automated production at all times; customers Before the next processing stage, web plates are stabilised with welded on buckling stiffeners. A picture of quality: ABUS welded box girders Following assembly on the box girder line, the box girder is ready Depending on the individual model, capacities (up to 120 t) and the sion of the production process. If for processing by the portal weld- ABUS travelling cranes are either widest spans (up to 40 m). Every you would like more evi­dence of ing unit. fitted with rolled section girders or ABUS box girder is tailored from the efficiency of material flow and welded box girders. While rolled high quality steel sheets to ensure the performance of our production section girders are mainly used for that these units are a unique combi- facilities, the best way is to see for low to medium load capacities and nation of strength, size, quality, relia- yourself during a visit to our plants narrow spans, welded box girders bility and precision. In this brochure, in Lantenbach and Herreshagen. are designed for the highest load we can only give you a first impres- We look forward to seeing you. Following thorough inspection, the steel plates are derusted and descaled to ensure excellent weld and paint finish quality. The shotblasting unit is equipped with four high-perfor­mance turbines and can produce surfaces to DIN 55928, Grade SA 2 /2. It can be adjusted 1 to any steel grade and plate thickness. The moving portal welding unit designed in-house by ABUS personnel welds the web plates to the upper and bottom flanges and the rails on the top of the girder. The welding unit can complete up to eight welds simultaneously. The high-performance burners are automatically controlled by a PLC. Following the welding of the closure plates and the installation of the end carriages, the paintwork required for the specific application is applied. 30 31 ABUS for quality that stands out – the ABUS service The ABUS service begins with ABUS for service without frontiers. comprehensive advice for custo- ABUS experts offer comprehensive good service mers. If you wish, we will be only service not only in Europe but ABUS sales and estimating engi­ too pleased to assist you in the throughout the world. ABUS subsi- neers and service operatives planning process before you take a diaries and international partners receive thorough training at the decision on the system you intend ensure that your crane system is ABUS training centre in Gummers­ to purchase. ABUS prepares quota­ ideally adapted to your technical bach and their theoretical and tion precisely in accordance with requirements and complies with all practical training is continually your requirements using computer­ the applicable national legislation updated to maintain the high aided systems and you can be sure and regulations. ABUS and its standards of our global service. of ABUS competence and commit- partners operate spare parts stock Our product range, our develop- ment right through to the commis- holding in a number of countries. ment activities, our computer pro- sioning of your crane system. After You can also rely on the support of grams and our production facilities commissioning, our world-wide our central spare parts depot and are also adapted continuously to service network ensures optimum our unique service at ABUS head­ meet the requirements of our inter- availability. quarters. national customers. ABUS training – designed for ABUS is represented in more than 50 countries throughout the world. A convincing service in all respects. 32 ■ advice in the planning phase ■ installation, dismantling and modification of crane systems ■ inspection and overhaul of crane systems by local partners ■ repair and maintenance ■ upgrading and modernisation ■ personnel training 33 Fax form The ABUS range at a glance Overhead travelling cranes: Load capacity: up to 120 t Span: up to 40 m (depending on load capacity) Applications: area coverage Features: comprehensive standard equipment and wide range of accessories to suit individual requirements HB systems: Load capacity: up to 2 t Crane girder length: up to 22 m (depending on load capacity) Applications: area coverage and linear handling Features: highly versatile for adaptation to individual requirements, designed for modular extension, wide range of suspension hangers, low headroom wide range of accessories Load capacity: up to 6.3 t Jib length: up to 10 m (depending on load capacity) Applications: swept area coverage, mainly for use in loading Just copy this form, complete it and fax it to us for an initial quotation without obligation. Company: Postcode / place: Name: Phone / extension: PO Box / address e-mail: Details of Overhead Travelling Crane required Type/load capacity options, comprehensive standard equipment and Jib cranes: The first step to your Overhead Travelling Crane 2t Single girder overhead travelling crane Double girder overhead travelling crane Underslung overhead Single girder travelling crane wall travelling crane Single girder semi-goliath crane _______________ kg ______________ kg ______________ kg ______________ kg ______________ kg or workbench applications Features: Clear width inside hall, mm 2 Finished floor level to top of crane track, mm 3 Height to lowest obstruction, mm 4 Span, mm,. if a crane track is available slewing range up to 360° depending on model Electric wire rope hoists: Load capacity: up to 120 t Features: compact dimensions, two lifting and travel speeds 4 as standard feature, comprehensive standard 2 equipment and wide range of accessories 3 The planning sketch for overhead travelling cranes is intended to assist you in determining the dimensions needed. 1 Electric chain hoists: Load capacity: up to 4 t Features: low headroom configuration, two lifting speeds as standard feature, comprehensive standard equipment, ready for installation, wide range of accessories Lightweight portal cranes: Load capacity: up to 2 t Features: with four stop rollers, easy to move, height and width individually adaptable 34 1 Building data: 1 Clear width inside hall mm 2 Finished floor level to top of crane track mm 3 Height to lowest obstruction mm 4 Span mm Crane track length m Crane track required (to be installed on existing supports): Crane track length m Support spacing m 35 KranHaus: Fascinating insights into the world of cranes Enjoy a ride on a crane 8 m high Feel the different drive concepts for yourself Transport loads single-handedly as an exciting insight into real-life tenance, repair and servicing take Contact: with a powerful overhead travelling working situations in a building that place in the modern training rooms Phone: +49 2261 37-3700 crane, experience the ease of our has 1,600 m2 of space. In the crane that are equipped with special E-mail: anmeldung@kranhaus.com crane systems yourself, ride on a workshop above the crane build- technology. You are also warmly 8-metre-high crane – the KranHaus ing, service technicians, installation welcome to get to know the Kran- at our company headquarters in engineers, service engineers and Haus yourself, and to optimise your Gummersbach offers an overview crane operators are trained. Semi- particular material handling applica- of current crane technology as well nars on the themes of crane main- tion requirements with us. Address: Archimedesstraße 1 D-51647 Gummersbach SatNav: Martin-Siebert-Straße 51647 Gummersbach, Germany 36 On 3 levels, different crane systems are waiting to be tested at length by visitors like you. 37 Notes 38 Notes 39 Further product information... …on our entire product range will be gladly forwarded to you. You can also view these directly and download them from our homepage. CRANES AT A HIGH LEVEL Flexible modular principle for individual solutions Overhead travelling cranes HB light crane systems Jib cranes Electric wire rope hoists Electric chain hoists Lightweight mobile gantries Monorail trolley track for linear material flow ☐ The Product Overview ☐ HB-System The complete range of pillar and wall jib cranes for loads up to 6.3 tonnes. ☐ Jib cranes ABUS LPK mobile gantry Electric chain hoists Electric wire rope hoists ☐ ABUS Image brochure Jib Cranes HB light crane track systems The Product Overview Strong and versatile kg up to 2 t up to 5 m up to 7,9 m short delivery time ABUCompact Product information / Technical data ABUS Kransysteme GmbH - P. O. 10 01 62 - 51601 Gummersbach - Germany - Phone +49 2261 37-7200 - e-mail: info@abuscranes.com www.abuscranes.com ☐ Electric wire rope hoists Please send your request by fax to: +49 2261 37-90165 ☐ Electric chain hoists ☐ Mobile gantries by email to: info@abuscranes.com Name: Company: Street: Postal code/City/Country: Telephone: Date ABUS Kransysteme GmbH P.O. Box 100162 · 51601 Gummersbach · Germany Phone +49 2261 37-0 · Fax +49 2261 37-130 e-mail: info@abuscranes.com · www.abuscranes.com Signature AN 12282 2.20 E-mail: