Kemper Arena Roof Collapse Analysis: Structural Failure Report

advertisement

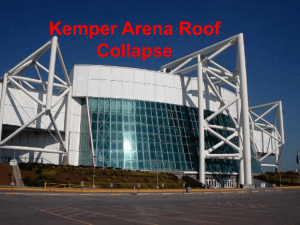

KEMPER ARENA ROOF COLLAPSE GROUP 5 Introduction: The Kemper Arena was built in 1973 for the Kansas basketball and hockey teams. The arena was designed by the German architect Helmuth Jahn to sit 17,000 people. The project was completed over 18 months and was built on the site of the old Royals baseball stadium. The building was revolutionary in its simplicity and the fact that it did not have interior columns obstructing views. The 22 million dollar project was hailed as a work of art and engineering feat. Three years prior to the Kemper Arena collapse received an ‘Honour’ award by this American Institute of Architects Convention. Figure 1. Scenario: On the evening of June 4th 1979, Kansas City was subject to a downpour of rainfall and winds of up to 112kph. At this time only one person was present in the arena and 25 minutes after the initial downpour he heard odd noises. Only minutes later, one acre of the roof collapsed and he barely got out of the arena on time. Upon analysis of the failed structure, it was determined that 4,000m2 of the roof collapsed. The rapidly falling roof increased the air pressure in the arena and thus some of the walls blew out. The portals however remained undamaged. Ironically, less than 24 hours before the collapse, thousands of architects were in the arena for the American Institute of Architects Convention. Structure: The arena’s structural system consisted of a reinforced concrete roof supported by steel trusses hanging from three enormous portals. The basic structural elements supporting the loads of the roof itself and those acting on it, as well as the weight of the upper part of the walls of the arena, were three external space frames spaced at 46m in the north-south direction in the shape of rectangular portals 108m long in the east-west direction and 24m high as shown in figure 1. The structure of the hanger assemblies is very import in understanding the actual failure of the Kemper Arena roof since their design was the primary cause of the collapse. Six hangers had hinges at both the top and half way down the shaft while the other 36 had hinges at the top only. This insured rigidity as well as flexibility. The hanger system consisted of four vertical stiffeners, a base plate, and plastic composite plate (called Micarta), and four high strength bolts that connected the hangers and the trusses as seen in figure 2. Figure 2. The hanger assembly because of the large load it had to resist was not a simple rod as the word hanger might suggest (as seen above). The hangers had to take the weight of the roof itself 1.3 KN/m2, another 1.25 KN/m2 due to additional load caused by rain, the load of the mechanical systems and other hanger loads accounting for another 1.3KN/m2 which would leave each of the 42 hangers to support 622KN in tension. In addition to this the hangers had to resist the horizontal variable wind force which tended to move the roof horizontally as a gigantic pendulum. It has been estimated that during the six years preceding the failure these connections were subjected to at least twenty-four thousand oscillations. Steel subject to stress oscillations suffers from fatigue and fails at lower load values than under steady loads. The high-strength steel bolts (called A490) used in the arena had warnings against their use in variable loading condition however this may have been ignored because of the coefficient of safety of the bolts under the design loads appeared to be sufficiently high. Explanation: Due to Kansas City inadequate sewer system the Kemper arena roof was designed to hold water and act like a reservoir and slowly release the water into the sewers system during heavy storms. This was achieved by having only 8 drains at 5 inches in diameter, placed 2 inches above the base of the roof. This restricted drainage to only 0.9 cubic foot of the water per second. The maximum downpour codes (for one in ten year storm) for Kansas City required 55 of these drains. Also that night a phenomenon known as the Bernoulli Effect occurred. This happened as the water was acted upon by two wind actions. There were 112km/hr winds that pushed the water from the northern section to the southern section and an upward suction which decreased from the north to the south. These two winds actions combined to create the Bernoulli suction which moved the water from the north to the south section of the roof. Therefore on the night of the collapse, this caused the downpour to "pond" in the south end of the roof, adding weight and causing it to sag. Ponding was the main cause of the collapse, it occurs when water covers stiff horizontal surfaces. It depends on the stiffness of the structure as well as the unit weight g of the liquid accumulation on the structure. If the critical g caused by ponding is greater than the unit weight of the liquid (usually water, and taken as 1) the roof is stable, and when it is less than 1 is it unstable. In the case of Kemper Arena g = 0.627. This meant that roof was unstable and allowed increasing amounts of water to accumulate up to a depth of at least 9 inches deep. When water accumulates over the stiff horizontal structure, its elastic deflections are negligible, but in the case of the Kemper Arena, the roof was made as a flexible structure. Therefore the water that ponded added to the deflection of the roof, which in turn allowed more water to pond which increased the deflection. This ferocious circle of increasing loads and deflection caused the roof to become unstable. Conclusions: The arena collapse shocked the engineering world. Even a layman could understand that the arena’s collapse was not the result of just that one storm as the media had suggested as for six years, it had withstood harder winds and downpours than that night. The reasons for the collapse are many and complex but in order to move forward and learn something from the collapse we need to full understand these reasons. So what happened two major oversights: The bolts used in the stadium roof where A490. They are a high strength fastener used only for tensile strength. However these bolts had dynamic loading on them form the gusting wind. It has been report since that the A490 high strength steel bolts lack ductility and only maintain tensile strength for static conditions. Tests have shown that the bolts fail at only one third of their capacity after tightening and loosening (simulation dynamic stress). The other major error was the number of assembly hangers used. The 42 hangers had to support 3,000 tons of weight and a wind displacement. The pooling effect and the metal fatigue of the bolts caused the bolts one hanger to fail due to fatigue. Then, this caused the surrounding hangers to fail because they were unable to carry the extra weight of the roof as a result of lack of redundancy. This inevitably caused a domino effect across all of the hangers on the south end of the roof leading to the complete collapse of 4,000m2 of the roof. If they had used more hangers there would not have been such stresses placed on the bolts or the hangers and the domino effect could have been avoid however the design lacked redundancy. The collapse of the Kemper Arena cannot be explained by a single cause the intensity of rain downpour, drainage deficiencies, wind effects, fatigue of bolts and lack of redundancy in the design all contributed to the catastrophe. The arena has been rebuild and redesigned to take into account these defects. References: http://aurora.wells.edu/ http://en.wikipedia.org/wiki/Kemper_Arena Why Building Fall Down Matthys Levy &Mario Salvador