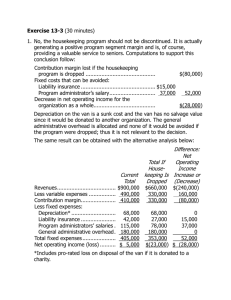

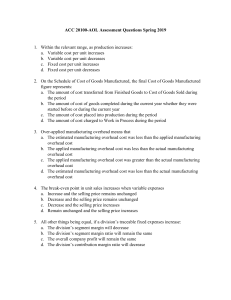

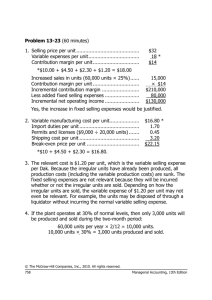

Relevant Costs for Decision Making: Managerial Accounting Chapter

advertisement