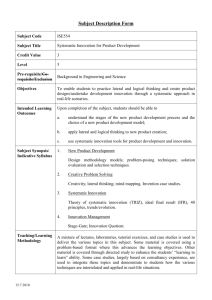

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/272748157 Innovative Cases of TRIZ Application in the Automotive Industry Article in Applied Mechanics and Materials · December 2014 DOI: 10.4028/www.scientific.net/AMM.735.326 CITATIONS READS 8 806 2 authors: Zulhasni abdul rahim Nooh abu Bakar Universiti Teknologi Malaysia Universiti Teknologi Malaysia 22 PUBLICATIONS 76 CITATIONS 43 PUBLICATIONS 555 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Physical Asset Management in MJIIT Lab View project All content following this page was uploaded by Zulhasni abdul rahim on 27 March 2015. The user has requested enhancement of the downloaded file. SEE PROFILE Applied Mechanics and Materials Vol. 735 (2015) pp 326-330 © (2015) Trans Tech Publications, Switzerland doi:10.4028/www.scientific.net/AMM.735.326 Submitted: 29.08.2014 Revised: 21.11.2014 Accepted: 01.12.2014 Innovative Cases of TRIZ Application in the Automotive Industry A. R. Zulhasni1, a and A. B. Nooh2,b 1 Razak School of Engineering and Advanced Technology, Universiti Teknologi Malaysia, Kuala Lumpur, MALAYSIA 2 Malaysia-Japan International Institute of Technology, Universiti Teknologi Malaysia, Kuala Lumpur, MALAYSIA a b zulhasni@gmail.com, noohab@gmail.com Keywords: TRIZ; Automotive; Design to Cost; Optimization; Patent. Abstract. It is becoming increasingly difficult to ignore that cost reduction in the product system does not support the development of innovation. This contradiction becomes a great challenge for any type of industry in order to improve the competitive level. This research focused on the mechanism of cost reduction using Design to Cost (DTC) strategy to achieve cost improvement and innovation. The contradiction was solved using the Theory of Inventive Problem Solving (TRIZ) that was integrated into the Design to Cost Innovation framework. Two types of cases were introduced in this research that highlighted the application and the outcome of TRIZ in DTC framework. From the case studies, the results show that the magnitude of cost improvement and innovation achieved is more than the application of conventional tools in the DTC strategy. These change the limitation of mindset in cost reduction without compromise or trade-off, and open up new possibility of research for reducing cost in processes and services for various industries. Introduction In the world of automotive industries, the competition focuses critically on product cost and technology advancement. The biggest challenge is the contradiction to achieve a win-win situation for the product manufacturer and the customer. It is common conflict in producing cost effective product and provides the highest satisfaction to the target customer at the same time. The conventional approach to balance-up between the new technology for customer and the incurred cost from the manufacturer is known as trade-off. TRIZ methodology is proposed to bring higher value to the customer by engaging neither trade-off nor compromise. TRIZ methodology already adopted in the automotive industry in various areas such as product design [1], product performance [2] and technology management [3]. However, every industry will always relate improvement activity with cost impact in business processes. Using other research on Design-To-Cost (DTC) framework integrated with TRIZ [4], cost improvement and reduction able to achieve further compared to conventional approach. This research presents several innovative cases, applying TRIZ in automotive industry to generate innovative solutions. From the literature, there are a lot of tools that are currently being used in the DTC program [5] [6]. The most commonly used tools are Brainstorming, Value Analysis, Trade-off, Pareto analysis and others [7]. Those tools are applied in specific phases throughout the DTC processes and activities. The common four phases of the DTC program are ‘Prioritization Phase’, ‘Idea Generation Phase’, ‘Idea Evaluation Phase’ and ‘Implementation Phase’. Each of the DTC phase requires a systematic approach to ensure that the innovation in the product design can be executed and simultaneously achieving cost reduction. An implementation framework is proposed to synergize the TRIZ methodology as a systematic innovation in order to develop DTC Innovation framework as shown in Fig. 1. All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of TTP, www.ttp.net. (ID: 175.143.45.253-03/02/15,10:03:56) Applied Mechanics and Materials Vol. 735 327 Fig. 1 The proposed Design-To-Cost Innovation (DTCI) framework [4] Case project for the DTCI framework using TRIZ The implementation of the proposed framework has been executed upon several breakthrough cases in the automotive industry. Previously, there was a research on complexity planning for automotive components through this framework [8]. In this study, another two case projects were presented. The first case project is about pushing the boundary of component optimization using TRIZ to achieve weight and cost reduction. A wiper system was studied to explore the conventional and TRIZ methods to provide the best weight reduction idea and concept for the system. The second case project explored new tools from the TRIZ known as ‘Patent Circumvention’. In the automotive industry, patent plays a critical role in securing new findings and discovery that bring high impact to product competitiveness [9]. It aims to create an opportunity to develop own patent, alongside cost reduction on the benchmarked systems. An automotive OEM was selected where several case studies were developed by adopting the proposed framework. The company was selected because of their capability in conducting a full cycle product design process. 14 case studies were developed by utilizing the proposed framework, and involved both the OEM itself and several suppliers. The duration of each case study was around 1 to 3 months to be completed at the conceptual level, and it took further 6 to 12 months to actually implement the concept into the product for market. The cost improvement results were recorded after the case implementation was completed. Case project 1: Weight optimization on automotive components In the automotive industry, weight becomes a strong characteristic in the automotive design. Weight gives a significant impact on engine performance, stability and most importantly, fuel consumption. The team from the body equipment section chose wiper bracket component as shown in Fig. 2 for the comparison with the case study to identify the results of the conventional optimization process and the DTCI framework. The ultimate goal for this case study was to reduce the material used to manufacture the component. This indirectly reflects the cost reduction outcome on the material consumption related to the bracket design. The team started by optimizing the wiper bracket using special and expensive Computer Aided Engineering (CAE) software to assist them on identifying the area with high potential to be discarded through the stress-strain flow colored mapping analysis. Then, the engineer redesigned the 328 Technology and Engineering Reviews and Research Advances I bracket by excluding some portion of the component and re-ran the analysis to validate the modified component. The component was fabricated as a prototype and the data of weight reduction was measured. Fig. 2 The wiper bracket in a wiper system for automotive The same team member was trained and certified with TRIZ level 1 to ensure they have the competency to use certain type of tools such as the contradiction matrix. The team started to identify the contradiction parameters based on the function of the wiper bracket. By focusing to reduce the weight of the stationary object, the affected parameters were force, strength, stability, reliability and ease to manufacture. The contradiction matrix shows the recommended inventive principles to the engineers to develop a better concept of wiper bracket with better weight reduction. After the solution was analyzed and then adopted into the wiper design, a new wiper bracket was fabricated as a prototype and the weight was measured, similar to the previous one. The analysis of inventive principles was done based on the cost impact and the total concept feasibility level evaluated by the experts. Fig. 3 shows there are four inventive principles that have low cost impact and high feasibility to develop. The evaluation matrix filtered the recommended inventive principles specifically related to the project scope and budget. Those recommended concepts have been discussed and reviewed in detail by the designers. Fig. 3 TRIZ inventive principles in the technical and commercial evaluation matrix A new design was created based on the concept of inventive principles known as segmentation and change parameters. For detail design features, the designer changed the body of the wiper bracket into three parts, which are the main body as a hollow type shaft, and both mountings were smaller and used lightweight material, such as alloy. With both products were developed until the prototype level, the comparison could be simulated to identify the outcome of this project case. Fig. 4 shows the physical design for both wiper brackets to be analyzed. Applied Mechanics and Materials Vol. 735 329 Fig. 4 The optimized design concept modified with adopted Inventive Principles. As shown in Table 1, the result achieved using the current optimization method was 22.1% weight reduction against the existing design. Meanwhile, the optimization method using TRIZ achieved 75.3% of weight reduction against the existing design. This clearly shows that TRIZ gives a higher impact in component weight optimization than the existing method. Table 1 Weight comparison for optimized design and TRIZ design solution Level of bracket design Current design Optimized design Adopting TRIZ optimized design Weight improvement (kg) 1.504 1.172 0.371 % of weight reduction 22.1% 75.3% Case project 2: Patent development with cost reduction As we all know, patent brings a new level of competitiveness, especially in the automotive industry. Innovative Benchmarking may open up a new possibility to create another innovation. This can be achieved using Patent Circumvention. However, in the real situation, things may be more difficult when cost reduction is also a part of the target, which people normally compromises for the long-term goal. DTCI was used to explore this situation and to demonstrate how the results can be achieved, and later a comparison was made to the normal patent development process. A team that specialized in the automotive power-train and transmission explored the patent on a cylinder deactivation system. Four types on patents related to cylinder deactivation system were benchmarked by the team, which included patents filed by Bentley, Audi (cylinder on demand), Bosch and Volkswagen. The activity requires a strong teamwork between the group of designers and the group from the legal unit, from the very beginning of the project. For the mechanism of the selected system, the patent circumvention process used was trimmed out, and the secondary problem was solved using Technical Contradiction. Fig. 5(a) shows the process of TRIZ application for patent circumvention. Fig. 5 TRIZ trimming process (a) and patent circumvention (b) Using the feasible concept generated, a new system of cylinder deactivation was created as shown in Fig. 5(b). However, the concepts need to be further refined in terms of technical ground and also legal perspective. This creates a patentable solution that is different from others competing patents. 330 Technology and Engineering Reviews and Research Advances I Results and Discussions The result from both case projects shows that the application of TRIZ methodology in the DTC generates a significant impact towards cost reduction in the automotive components and enhance the innovation level of the existing system [10]. The application of TRIZ in the DTC program has achieved effective cost saving through product or component design improvement. TRIZ methods change the thinking process to extract more innovative ideas and expand new inventions that produce a significant impact on cost reduction. In the same financial year (2011/2012), the organization really shows significant results in cost reduction performance. Those initiatives are continued by adopting the proposed framework and eventually achieved further cost reduction in the following financial year. Conclusions These project cases explain the central importance of the DTCI framework that adopted TRIZ to enhance the result of cost improvement through innovation. The present study was designed to determine the effect of adopting TRIZ in cost strategy and compared to any existing available method. One of the more significant findings that emerges from this study is that all limitations and contradiction in reducing cost at the product design level can be solved using the DTCI. The result of this research supports the idea that the cost reduction achievement can be better enhanced using the TRIZ method [10]. The findings of this study have a number of important implications for future practice beyond product design, for example, process design or service design in cost reduction initiatives. References [1] M.R. Mansor, S.M. Sapuan, E.S. Zainudin, A.A. Nuraini, A. Hambali, Conceptual design of kenaf fiber polymer composite automotive parking brake lever using integrated TRIZ– Morphological Chart–Analytic Hierarchy Process method, Materials & Design (2014) 473-482. [2] M. Ishihama, Noise and vibration design by the TRIZ method, International Journal of Vehicle Noise and Vibration (2009) 219-237. [3] G. Schuh, C. Haag, J. Kreysa, TRIZ-based technology know-how protection - How to find protective mechanisms against product piracy with TRIZ, Procedia Engineering (2011) 611- 619. [4] A.R. Zulhasni, A.B. Nooh., Implementation Framework for Design-To-Cost Using TRIZ: Product Concept Design in Automotive Stamping Process, American Journal of Economics (2013) 100-107. [5] M. Esaki, T. Yamaguchi, New Thinking and Procedure of Design To Cost, Aircraft Division of Kawasaki Heavy Industries, Ltd. Kagamigahara City, Gifu, Japan. Society of American Value Engineering Proceedings (1979) 80- 100. [6] W. Schwint, Creative Design to Cost, SAVE Conference Proceedings, (1975) 89-95. [7] H. Sippel, E. Schelkle, Design-to-cost in Engineering, WOK Kreutzer (2009). [8] A.R. Zulhasni, A.B. Nooh., Complexity Planning for Product Design Using TRIZ, Advanced Materials Research (2014) 396-401. [9] S. Ikovenko, TRIZ Application for IP Strategies Development, TRIZ master thesis, MATRIZ, Boston, 2006. [10] E. Domb, T.J. Kling, How to Reduce Cost in Product and Process Using TRIZ, TRIZ Journal, 2006. View publication stats