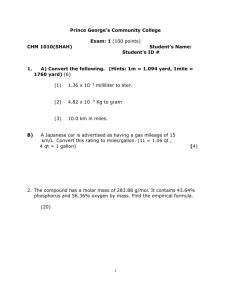

Available online at www.sciencedirect.com ScienceDirect Procedia Materials Science 6 (2014) 1658 – 1667 3rd International Conference on Materials processing and Characterization (ICMPC 2014) Preparation of 6061Al-Al2O3 MMC’s by Stir Casting and Evaluation of Mechanical and Wear Properties Bharath Va, Madev Nagaralb, V Auradib* and S. A. Koric a Department of Mechanical Engineering, Brindavan College of Engineering, Bangalore-560063, Karnataka, India b R & D Centre, Department of Mechanical Engineering, Siddaganga Institute of Technology, Tumkur-572103, Karnataka, India b *Department of Mechanical Engineering, Siddaganga Institute of Technology, Tumkur-572103, Karnataka, India c R & D Centre, Department of Mechanical Engineering, Basaveshwar Engineering College, Bagalkot-587102, Karnataka, India Abstract Aluminum MMCs are preferred to other conventional materials in the fields of aerospace, automotive and marine applications owing to their improved properties like high strength to weight ratio, good wear resistance etc. In the present work an attempt has been made to synthesize metal matrix composite using 6061Al as matrix material reinforced with ceramic Al2O3 particulates using liquid metallurgy route in particular stir casting technique. The addition level of reinforcement is being varied from 6 12wt% in steps of 3wt%. For each composite, reinforcement particles were preheated to a temperature of 200 0C and then dispersed in steps of three into the vortex of molten Al6061 alloy to improve wettability and distribution. Microstructural characterization was carried out for the above prepared composites by taking specimens from central portion of the casting to ensure homogeneous distribution of particles. Hardness and tensile properties of the prepared composite were determined before and after addition of Al2O3 particulates to note the extent of improvement. Microstructural characterization of the composites has revealed fairly uniform distribution and some amount of grain refinement in the specimens. Further, the hardness and tensile properties are higher in case of composites when compared to unreinforced 6061Al matrix, also increasing addition level of reinforcement has resulted in further increase in both hardness and tensile strength. © 2014 Elsevier Ltd. This is an open access article under the CC BY-NC-ND license © 2014 The Authors. Published by Elsevier Ltd. (http://creativecommons.org/licenses/by-nc-nd/3.0/). Selection and peer-review under responsibility of Organizing Committee of AMME 2014. Selection and peer review under responsibility of the Gokaraju Rangaraju Institute of Engineering and Technology (GRIET) Keywords:MMC’s; Al2O3 particulates;6061Al; stir-casting * Corresponding author. Tel.: +91-9742707854;+91-9844386037 E-mail address:vsauradi@gmail.com;madev.nagaral@gmail.com;bharathv88@gmail.com: 2211-8128 © 2014 Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/3.0/). Selection and peer review under responsibility of the Gokaraju Rangaraju Institute of Engineering and Technology (GRIET) doi:10.1016/j.mspro.2014.07.151 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 1. Introduction Metal–matrix composites (MMCs) are most promising materials in achieving enhanced mechanical properties such as: hardness, Young’s modulus, yield strength and ultimate tensile strength due to the presence of micro-sized reinforcement particles into the matrix[Vencl A et al.,(2010) and Yung C.K et al.,(2004)] and Aluminum-matrix composites (AMCs) reinforced with discontinuous reinforcements are finding increased use in automotive, military, aerospace and electricity industries because of their improved physical and mechanical properties [Sajjadi SAet al., (2010), A.R.K.Swamy et al., (2011)and Ceschini L et al., (2006)]. Among Al-alloys, 6061Al-alloy is widely used in engineering applications such as transport and construction sectors where superior mechanical properties like tensile strength, hardness etc., are essentially required [Vencl A et al., (2010) and Chawla Net al., (2001)]. A number of materials such as SiC, Al2O3, B4C, TiB2, ZrO2, SiO2 and graphite are being used as reinforcements to improve the properties of 6061Al alloy. However, the applications of Al 2O3 or SiC particle reinforced aluminum alloy matrix composites in the automotive and aircraft industries is gradually increasing for pistons, cylinder heads, connecting rods etc. where the tribological properties of the materials are very important [Vencl A et al.,(2010) and Sajjadi SA et al., (2011)and C.S. Ramesh et al., (2005)] The mechanical properties of MMCs are very sensitive to the method of processing being used. Considerable improvements may be achieved by applying science-based modelling techniques to optimize the processing procedure. Several techniques have been employed to prepare the composites including powder metallurgy, melt techniques and squeeze casting [Yung C.K et al.,(2004), Sajjadi SA et al., (2010), and Sajjadi SA et al., (2010)]. However, powder metallurgy appears to be the preferred process in view of its ability to give more uniform dispersions. Hot extrusion is generally used as post-treatment to take the advantages of applying compressive forces and high temperatures, simultaneously[Mazahery A et al., (2011)]. Although powder metallurgy produces better mechanical properties in MMCs, liquid state processing has some important advantages. They are as: better matrix-particle bonding, easier control of matrix structure, simplicity, low cost of processing, nearer net shape and the wide selection of materials [Vencl A et al., (2010) and Chawla N et al., (2001)]. Liquid state fabrication of MMC’s includes two methods which depend on the temperature at which the particles are introduced into the melt. In melt stirring process, the particles are incorporated above the liquidus temperature of the molten alloy, while in compo-casting method the particles are incorporated at the semi-solid slurry temperature of the alloy. In both processes, the vortex is used for introducing reinforcement particles. However, the melting process has two major problems firstly, the ceramic particles are generally not wetted by the liquid metal matrix, and secondly, the particles tend to sink or float according to their density relative to the liquid metal. Wettability can be defined as the ability of a liquid to spread on a solid surface and it represents the extent of intimate contact between liquid and solid [A.R.I. Kheder et al., (2011)]. Consequently, it results in poor dispersion of the ceramic particles, high porosity and low mechanical properties of the composite. This represents a great challenge of synthesizing cast MMC’s. Poor wettability means the molten matrix cannot wet the surface of reinforcement particles as a result they simply float on the surface owing to surface tension, large surface area, high interfacial energy and presence of oxide film on the melt surface. Improvement in wettability to certain extent can be achieved by several methods like mechanical stirring, preheating the particles to remove adsorbed gases from particle surface [S.A. Sajjadi et al.,(2011)],addition of alloying elements, use of surface coatings on reinforcement particle etc [Zhiqiang.Y U, (2005)]. Another problem is distribution of reinforcement particles in molten matrix. Due to density difference between matrix and reinforcement, these particles tend to float or settle in the molten matrix as a result agglomeration and clustering of the particles will occur [S.A. Sajjadi et al., (2011)]. It has been reported that injection of particles with inert carrier gas is helpful in improving the distribution [S.A. Sajjadi et al., (2011)]. Therefore, it is essential to develop a method for producing Al-MMC’s taking account of incorporation and distribution reinforcing particles in the molten matrix. The aim of present study is to synthesize 6061Al-Al2O3 particulate MMC by stir casting method. In order to improve wettability and distribution of reinforcing particles a novel three stage mixing combined with preheating of the reinforcing particles is being adopted. 1659 1660 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 2. Experimental Details The matrix material used for the present study is 6061Al-alloy. The chemical composition of matrix material is as shown in Table1 determined using Atomic Absorption Spectrophotometer (model AA-670, Varian, The Netherlands). Al2O3 particles with size of 125μm and with varying amounts of 6, 9 and 12wt% are being used as reinforcing material in the preparation of composites. Stir casting technique has been used for the preparation of composites. Initially calculated amount of 6061Al alloy was charged into SiC crucible and superheated to a temperature of 8000C in an electrical resistance furnace. The furnace temperature was controlled to an accuracy of r500C using a digital temperature controller. A novel three stage mixing combined with preheating of the reinforcing particles is followed. Ceramic Al2O3 particulates were preheated to a temperature of 200 0C in an oven to remove the adsorbed gases from the particle surface and to avoid high drop of temperature after addition of particulates. Preheated Al2O3 particles were introduced into the vortex of the molten alloy after effective degassing using solid hexachloroethane (C2Cl6). Vortex is generated with the help of a zirconia coated steel impeller. The extent of incorporation of Al 2O3 particles in the matrix alloy was achieved in steps of 3. i.e. Total amount of reinforcement required was calculated and is being introduced into the melt 3 times rather than introducing all at once. At every stage before and after introduction of reinforcement, mechanical stirring is carried out for a period of 10 min. The stirrer was preheated before immersing into the melt, and is located approximately to a depth of 2/3 height of the molten metal from the bottom and run at a speed of 200 rpm. Composite mixture was poured into permanent cast iron moulds having diameter 12.5mm and length of 125mm at a pouring temperature of 750 0C. The prepared composites were characterized by microscopic studies. Specimens of 12mm diameter and thickness of 10mm were cut from the central portion of the casting for microstructural studies conducted using Optical microscopy(model DS X100,Olympus).SEM photographs were obtained using Scanning Electron Microscope (make-Joel, Japan).For XRD (Philips analytical) analysis, a plot of 2-theta verses intensity could be analyzed using origin plus software. The density of the samples were measured by Archimedes’s method while theoretical density is computed by taking densities of 6061Al matrix and Al2O3 particles as 2.7 and 3.9gm/cm3 respectively. To investigate the mechanical behaviour of the composites the hardness and tensile tests were carried out using Zwick and computerized uni-axial tensile testing machine. Fig.1. Shows the dimensions of the mould and specimen used for tensile studies. The Micro-Vickers hardness values of the composites before and after addition of Al2O3 particles were measured with a load of 20N using MVH-II digital micro hardness tester (Zwick/Roell indentec). The hardness value reported is the average value of 100 readings taken at various locations on the polished specimen. Similarly tensile tests were carried out before and after addition of Al2O3 particles and for each of the composite three tests were conducted and average value is reported. Table.1 Shows the Chemical Composition of Al6061 alloy assessed using Atomic Absorption Spectrophotometer (Model AA-670, Varian, the Netherlands) Elements Si Fe Cu Mn Ni Pb Zn Ti Sn Mg Cr Al Percentage 0.43 0.7 0.24 0.139 0.05 0.24 0.25 0.15 0.001 0.802 0.25 Balance . (a) (b) Figure.1 showing the details of (a) Permanent mould for producing composites (b) Dimensions of the tensile specimen 1661 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 3. Results And Discussions 3.1 Microstructural studies Fabrication of metal–matrix composites with alumina particles by casting processes is usually difficult because of the very low wettability of alumina particles and agglomeration phenomena which results in non-uniform distribution and poor mechanical properties. In the current work, an attempt has been made to prepare Al6061 aluminum alloy matrix composites with micro size alumina particles by stir casting method with a novel three stages mixing combined with preheating of the reinforcing particles. The magnitude of alumina powder used in the composites was 6, 9 and 12wt. %. The optical micrographs of the 6061Al alloy with 0, 6, 9 and 12wt. % Al 2O3 particulates were shown in Fig 2(a-h). Fig. 2a-h shows microstructure of as cast 6061Al and 6061Al with 6 wt% (Fig. 2c-d), 9wt% (Fig. 2e-f) and 12wt% (Fig. 2g-h) Al2O3 particulates. The microstructure of the prepared composites contains primary D-Al dendrites and eutectic silicon, while Al2O3 particles are separated at inter-dendritic regions and in eutectic silicon. The stirring of melt before and after introducing particles has resulted in breaking of dendrite shaped structure into equiaxed form, it improves the wettability and incorporation of particles within the melt and also it causes to disperse the particles more uniformly in the matrix. Fig. 2c-h reveals the distribution of alumina particles in different specimens and it can be observed that there is fairly uniform distribution of particles and also agglomeration of particles at few places were observed in the composites reinforced with 6wt%, 9wt% and12wt% Al 2O3. The microphotographs also indicate that the Al2O3 particles have tendency to segregate and cluster at inter-dendritic regions which are surrounded by eutectic silicon (Fig. 2c–h). Further, the micrographs show that grain size of the reinforced composite (Fig.2.a-h) is smaller than the alloy without alumina particles (Fig. 2a-b) because, Al2O3 particles added to melt also act as heterogeneous nucleating sites during solidification. SEM photographs were obtained using Scanning Electron Microscope (make-Joel, Japan).Fig. 3(a-c) shows the SEM photographs of 6061Al with 6 wt %( Fig.3a), 9 wt %( Fig.3b) and 12wt %( Fig.3c) Al2O3 particulates. Fig. 3c (12wt %) reveals good distribution of particles and very low agglomeration compare to 9 wt %( Fig.3b) and 12wt%(Fig.3c) Al2O3 particulates.Moreover, the figure indicates that the Al 2O3 particles have tendency to segregate and cluster at inter-dendritic regions which are surrounded by eutectic silicon (Fig.3a–c). (b) (a) 100X 50X (c) (d) Al2O3 Porosities 50X 100X 1662 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 (e) (f) Al2O3 100X 50x (h) (g) Al2O3 100X 50X Fig.2-a-h Showing the optical microphotographs of 6061Al with and without Al 2O3 particulates at 50X & 100X (a-b) as-cast, (c-d) with 6wt% of Al2O3p, (e-f) with 9wt% of Al2O3p & (g-h) with 12wt% of Al2O3p at 100X. (b) (a) (c) Fig.3-a-cshowing the SEMphotographs of 6061Al with Al2O3 particulates (a) with 6wt% of Al2O3p, (b) with 9wt% of Al2O3p & (c) with 12wt% of Al2O3p 1663 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 3.2 X-Ray Diffraction Analysis Fig.3.1 (a-b) shows the XRD analyses were conducted on 6061Al based composites reinforced with 9 and 12wt% of Al2O3particles in order to confirm the presence of Al2O3as to identify other phases formed. Fig.3.1.a.Shows the X-ray diffraction pattern and results of 6061Al alloy with 9 wt% Al2O3 MMC’s.In X-ray diffraction pattern (Fig. 3.1.a), ninepeaks have been obtained in the 2 span ranging from 20 to 100 and the peaks at 2Ө of 38.44°, 44.7°, 65.32° and 77.2°belongs to Pure Al andthe peaks at 2Ө of 42.23°, 51.46°, 57.56° and 75.42° belongs to Al2O3 andother remaining minor peaks attributed toimpurity. Fig.3.1.b.Shows the X-ray diffraction pattern and results of 6061Al alloy with 12 wt% Al2O3 MMC’s. In X-ray diffraction (Figure 3.1.b), Ten peaks have been obtained in the 2 span ranging from 20 to 100 and the peaks at 2Ө of 38.44 °,44.7°, 65.32°belongs to Pure Al andthe peaks at 2Ө 26.23°, 37.46°, 44.67°, 58.2° and 66.2°belongs to Al2O3 and other remaining minor peaksattributed toimpurity. 7000 [Group:Standard, Data : 12%_Al2O3] 12% Al2O3 Al [Group:Standard, Data : 9 %_Al2O3] 9%Al2O3 Al 6000 6000 5000 5000 I(CPS) 4000 3000 Al 2000 3000 Al Al 1000 0 20 30 40 50 Theta-2Theta (deg) (a) 60 70 Al Al2O3 Al2O3 Al2O3 Al2O3 Al2O3 Al2O3 Al2O3 1000 Al2O3 Al 2000 Al2O3 I(CPS) 4000 0 80 20 30 40 50 60 70 80 Theta- 2Theta(deg) (b) Fig.3.1 showing the X-ray diffraction pattern of the 6061Al alloy with (a) 9 wt. %Al2O3 and(b) 12 wt. %Al2O3 3.2 Density measurements Table.2. is presented with the comparison of theoretical density obtained by rule of mixture and measured density values by experiment for both the composites studied for different wt% of reinforcements. Experimentally, the density of a composite is obtained by displacement techniques [B.K. Prasad, (2007)] using a physical balance with density measuring kit as per ASTM: D 792-66 test method. Further, the density can also be calculated from porosity and apparent density values (sample mass and dimensions). [M.D. Bermudez et al., (2001)]. From the table.2. It can be concluded that the experimental density of composite containing 6, 9 and 12 wt% Al2O3p is less when compared to the theoretical density. Further, measured density of composites is lesser than theoretical density, could be due to the presence of porosity. The porosity is probably due to i) increase in surface area in contact with air (ii) gas entrapment during stirring; (iii) gas injection of particles introduces a quantity of gas into the melt; (iv) hydrogen evolution; (v) the pouring distance from the crucible to the mold and (vi) shrinkage during solidification [J. Hashim et al.,(1999)]. 3.3 Hardness measurements Fig.3.2 shows the results of micro hardness tests conducted on Al6061 alloy and the 6061Al composite containing different weight percentage of Al2O3particles. The Micro-Vickers hardness were measured on the 1664 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 Table .2: showing the theoretical and measured densities of as cast 6061Al and with 6 wt% of Al2O3p respectively Composition Theoretical Density (g/cm3) Measured Density(g/cm3) 6061Al+6% Al2O3p 2.74 2.57 6061Al+9% Al2O3p 2.76 2.58 6061Al+12% Al2O3p 2.79 2.35 polished samples using diamond cone indentor with a load of 20N and the value reported is average of 100 readings taken at different locations. A significant increase in hardness of the alloy matrix can be seen with addition of Al 2O3 particles. Higher value of hardness is clear indication of the fact that the presences of particulates in the matrix have improved the overall hardness of the composites. This is true due to the fact that aluminium is a soft material and the reinforced particle especially ceramics material being hard, contributes positively to the hardness of the composites. The presence of stiffer and harder Al2O3 reinforcement leads to the increase in constraint to plastic deformation of the matrix during the hardness test. Thus increase of hardness of composites could be attributed to the relatively high hardness of Al2O3 itself. 200 180 Hardness (VHN) 160 140 120 100 80 0 3 6 9 12 Wt% of Al2O3 particulates Fig. 3.2 Graph showing the variations in hardness of 6061Al before and after addition of different wt% of Al 2O3 particulates 3.4 Tensile Properties To investigate the mechanical behaviour of the composites the tensile tests were carried out using computerized uni-axial tensile testing machine as per ASTM standards. Three specimens were used for each test and average value is reported. The tensile properties, such as, tensile strength, yield strength and % elongation were extracted from the stress-strain curves and are represented in Table 3.2. and Fig. 3.3a-b. From fig. it is clear that fracture strength of composites (6, 9 and 12wt %) is higher when compared to as cast 6061Al, while ductility of composite is lesser that unreinforced alloy. It is also clear from fig. that the tensile strength increases with increase in amount of reinforcement, while there is decrease in ductility with increasing amount of reinforcement. Increase in strength is possibly due to the thermal mismatch between the metallic matrix and the reinforcement, which is a major mechanism for increasing the dislocation density of the matrix and therefore, increasing the composite strength. However, the composite materials exhibited lower elongation than that of unreinforced specimens. It is obvious that plastic deformation of the mixed soft metal matrix and the non-deformable reinforcement is more difficult than the base metal itself. As a result, the ductility of the composite drops down when compared to that of unreinforced material. 1665 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 Sl No Weight percentage of Al2O3 particles (%) Ultimate Tensile strength (MPa) 0 Yield Stress (MPa) 138.06 149.76 Extent of Improvement in UTS Value (%) - 1 2 6 145.51 167.93 12.12 3 9 155.94 173.61 15.92 4 12 178.91 193.47 29.18 200 16 190 14 180 12 % Elongation Tensile Strength (MPa) Table. 3. showing the tensile test results of as cast 6061Al, with addition of 6, 9 and 12 wt% of Al 2O3 particulates to 6061Al 170 160 10 8 6 150 0 3 6 9 Wt% of Al2O3 particulates (a) 12 0 3 6 9 12 Wt% of Al2O3 particualtes (b) Fig. 3.3 Graphs showing the tensile test results of 6061Al-alloy before and after addition of Al2O3 particulates(a) Variation in ultimate tensile strength (b) Variation in % elongation 3.5 Wear properties A pin-on-disc tribometer is used to perform the wear experiment. The wear track, alloy and composite specimens are cleaned thoroughly with acetone prior to test. Each specimen is then weighed using a digital balance having an accuracy of ±0.0001 gm. After that the specimen is mounted on the pin holder of the tribometer ready for wear test. For all experiments, the sliding speed is adjusted to 1.256 m/s, track diameter 80mm, load 19.62N and total time is 40 minute under room temperature. Fig.3.4 shows the results of the weight loss conducted on 6061 Al alloy and the 6061Al composite containing 0, 6, 9 and 12wt. % ofAl2O3 particles at a constant load of 19.62N. From Fig.3.4 it is clear that weight loss in case of composites is decreased as compared to the base alloy (6061 Al alloy).This is due to the particle pull out, in the case of composite reinforced alumina particles during wear test. Further increase in addition level of wt% of reinforcement which decreases the weight loss of the composites.It is clear from Fig.3.4 the maximum weight loss was observed in as cast 6061Al alloy and minimum weight loss was observed for (6061Al alloy +12%Al2O3).Fig.3.5 shows the results of wear rate (weight loss) as a function of sliding distance for the 6061 Al alloy and 6061Al composite containing 0, 6, 9 and 12wt. % Al2O3 of particles at a constant load of 19.62N and speed of 300 rpm. It is seen from the Fig.3.5 that wear rate of composites (6, 9 and 12wt %) decreases after addition of Al2O3 particles compared to base alloy (6061 Al alloy). This is due to the incorporation of hard Al2O3 particles in the 6061 Al alloy restricts such ploughing action of hard steel counterpart and improves the wear resistance.The results as indicated from Fig.3.5 shows the decreasing trend of wear rate with increase in weight percentage of Al2O3 up to 12% weight fraction. 1666 V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 0.21 0.036 0.20 Wear rate x 10 (mm /N-m) 0.034 0.030 -6 weight loss (gm) 3 0.032 0.028 0.026 0.024 0.022 Base Alloy 6% Al2O3 9% Al2O3 12% Al2O3 0.19 0.18 0.17 0.16 0.15 0.14 0.13 0.12 0.020 0.11 0.018 0 3 6 9 12 wt% of Al2O3 particulates Fig.3.4 showing the results of weight loss and different wt% of 6061Al-alloy before and after addition of Al2O3 particulates 500 1000 1500 2000 2500 3000 Sliding Distance (m) Fig. 3.5 showing the results of Wear rate and sliding distance of 6061Al- Alloy before and after addition of Al2O3 particulates 4. Conclusions The present work on preparation of 6061Al-Al2O3 metal matrix composite by stirr casting and evaluation of mechanical and wear properties has led to following conclusions x The composites containing 6061Al with 6, 9 and 12wt% of Al 2O3 particulates were successfully synthesized by melt stirring method using three stages mixing combined with preheating of the reinforcing particles. x The optical micrographs of composites produced by stir casting method shows fairly uniform distribution of Al2O3 particulates in the 6061Al metal matrix. The microstructure of the composites contained the primary D-Al dendrites and eutectic silicon. While Al2O3 particles were separated at interdendritic regions and in the eutectic silicon. x The hardness of the prepared composites increases withincreasingwt% ofAl2O3particulates and Strength of prepared composites both tensile and yield was higher in case of composites, while ductility of composites was less when compared to as cast 6061Al. Further, with increasing wt% of Al 2O3, the tensile strength shows an increasing trend. x Maximum weight loss was observed in as cast 6061Al alloy and minimum weight loss was observed in 6061Al+12%Al2O3 composites at a constant load of 19.62 N and speed of 300 rpm and higher wear rate was observed in as cast 6061Al alloy when compared to 6061Al-Al2O3 composites at a constant load of 19.62N and speed of 300 rpm. References A.R.I. Kheder et al., 2011, “Strengthening of Aluminium by SiC, Al2O3 and MgO”, Jordan Journal of Mechanical and IndustrialEngineering ISSN 1995-6665, 533 – 541 A.R.K.Swamy, A.Ramesha, G.B.Veeresh Kumar and J. N. Prakash, 2011 “Effect of Particulate Reinforcements on the Mechanical Properties of Al6061-WC and Al6061-Gr MMCs”,Journal of Minerals & Materials Characterization & Engineering, ,Vol.10, No.12, pp.11411152 B.K. Prasad, 2007, “Investigation into sliding wear performance of zinc-based alloy reinforced with SiC particles in dry and lubricated conditions”, Wear 262; 262–273 Chawla N and Shen Y.L, 2001, Mechanical Behaviour of Particle Reinforced Metal Matrix Composites, Advanced Engineering Materials, 3, 357370 C.S. Ramesh, A.R.Anwar Khan, N. Ravikumar, P. Savanprabhu, Prediction of wear coefficient of Al6061-TiO2 composites, Wear 259, 2005 602–608. J. Hashim et al., 1999, Journal of Materials Processing Technology; 92–93; 1–7. M.D. Bermudez et al., 2001, “Dry and lubricated wear resistance of mechanically-alloyed aluminium-base sintered composites” Wear 248; 178–186. Mazahery A et al., 2011, “Development of high-performance A356/nano-Al2O3 composites”, Mater Sci Eng; 518:61–4. V. Bharath et al. / Procedia Materials Science 6 (2014) 1658 – 1667 1667 Sajjadi SA, Ezatpour HR, Beygi H, 2010, “Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by Stir casting”, In: Proceedings of 14th national conference on Materials Science and Engineering, Tehran, Iran. 325. S.A. Sajjadi et al., 2011 “Microstructure and mechanical properties of Al– Al2O3 micro and nano composites fabricated by stir casting” Materials Science and Engineering A 528; 8765– 8771. Sajjadi SA et al., 2011, “Fabrication of A356 composites reinforced with micro and nano Al2O3 particles by a developed compo-casting method and study of their properties”, J Alloys Compd, accepted for publication S.K. Sajjadi and S.M. Zebarjad, 8, 2010, “Powder Metallurgy” 71–78. Vencl A et al., 2010, “Structural, mechanical and tribological properties of A356 aluminium alloy reinforced with Al2O3, SiC and SiC + Graphite particles”, J Alloys Compd 506:631–9. Yung C.K and Chan S.L.I. 2004, “Tensile Properties of Nanometric Al2O3 Particulate Reinforced Aluminium Matrix Composites”, Journal of Materials Chemistry and Physics, 85,438443. Zhiqiang. Y U, 2005, “Microstructure and Tensile Properties of Yttria coated-Alumina particulates Reinforced Aluminium Matrix Composites” J. Mater. Sci. Technol., Vol 21 No.1