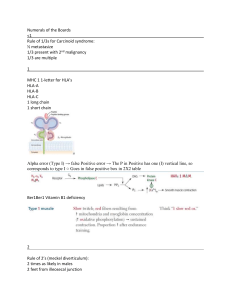

Received: 27 June 2020 Revised: 8 August 2020 Accepted: 10 August 2020 DOI: 10.1002/qre.2752 RESEARCH ARTICLE A mixed HWMA-CUSUM mean chart with an application to manufacturing process Muhammad Abid1,2 Sun Mei1 Hafiz Zafar Nazir3 Muhammad Riaz4 Shahid Hussain1,5 1 Institute of Applied Systems Analysis Jiangsu University, Zhenjiang, Jiangsu, P.R. China 2 Department of Statistics, Government College University, Faisalabad, Pakistan 3 Department of Statistics, University of Sargodha, Sargodha, Pakistan 4 Department of Mathematics and Statistics, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia 5 Department of Mathematics, COMSATS University Islamabad, Attock Campus, Attock, Pakistan Correspondence Dr. Muhammad Abid, Institute of Applied Systems Analysis, Jiangsu University, Zhenjiang, Jiangsu 212013, P.R. China. Email: mabid@gcuf.edu.pk Funding information National Science Foundation of China, Grant/Award Number: 71774070 Abstract Memory-type control charts play a significant role to identify slight changes in the parameters of the production process. In this article, we have proposed a new cumulative sum chart that utilizes the statistic of the homogeneously weighted moving average chart. The performance of the proposed chart is studied using Monte Carlo simulations. The proposed chart is compared with some existing charts under different run length profiles. The run length profile comparisons reveal that the proposed chart performs superior as compared to the existing control charts. A real-life application using a manufacturing process dataset is also part of this study. KEYWORDS average run length, CUSUM, HWMA, manufacturing processes, mixed control chart, run length profiles 1 INTRODUCTION The control chart is one of the core techniques from all other techniques of the statistical process control and monitoring (SPCM). The basic purpose of the control chart is to detect the slight changes in the process production, which occur due to the special cause variation. Memoryless and memory-type charts are two main branches of the control chart. The memoryless charts like Shewhart1 charts are popular to identify larger shifts, while the memory-type charts like the cumulative sum (CUSUM) and the exponentially weighted moving average (EWMA) charts proposed by Page2 and Roberts,3 respectively, are famous to identify the smaller shifts in the process parameter(s) (cf. Montgomery4 ). Nowadays, several types of amendments (such as combining and mixing the design structure of the control charts) have been recommended in the SPCM literature. Lucas5 suggested the combined Shewhart-CUSUM chart. On the lines of Lucas,5 Lucas and Saccucci6 developed a combined Shewhart-EWMA chart. A double EWMA chart was suggested by Shamma and Shamma.7 Abbas et al8 developed a mixed EWMA-CUSUM (MEC) chart and in this chart, they involved the EWMA statistic in the design structure of the CUSUM chart. Zaman et al9 reversed the design structure of the MEC chart Qual Reliab Engng Int. 2020;1–14. wileyonlinelibrary.com/journal/qre © 2020 John Wiley & Sons Ltd. 1 2 ABID et al. and suggested a mixed CUSUM-EWMA (MCE). Zaman et al10 offered the design structure of some mixed charts. The incontrol (IC) robustness behavior of the MEC mean and dispersion charts were studied by Abid et al,11,12 respectively. Ali and Haq13 introduced a mixed GWMA-CUSUM chart, where GWMA is labeled as a generally weighted moving average. A new adaptive EWMA chart was suggested by Haq.14 A multivariate version of the MEC chart was introduced by Ajadi and Riaz.15 Haq and Bibi16 proposed a new dual CUSUM (DCUSUM) chart. Haq et al17 suggested the multivariate DCUSUM mean charts. Recently, the double progressive mean chart was suggested by Abbas et al18 In the SPCM literature, the homogeneously weighted moving average (HWMA) chart proposed by Abbas19 became well known. The interested readers can see the work of the following researchers: Adegoke et al,20,21 Nawaz and Han,22 Abid et al,23 and Abbas et al24 on the HWMA chart under various directions. So, taking motivation from the structures of the HWMA chart, this article suggests a new CUSUM chart by using the statistic of the HWMA chart and from now labeled as the MHC chart. The contents of this paper are as follows:to give the design structure of the existing and proposed MHC charts in Sections 2 and 3, respectively; the ARL and graphical comparisons between proposed and existing charts are offered in Section 4; we provide the real-life application in Section 5; and in Section 6, we make some conclusions and recommendations of this paper. 2 SOME EXISTING CHARTS This section presents the design structure of some existing charts. 2.1 The CUSUM chart Let 𝑌𝑡 be the quality characteristic of interest, which follows a normal distribution with mean 𝜇 and variance 𝜎2 , that is, 𝑌𝑡 ∼ 𝑁(𝜇, 𝜎2 ) for 𝑡 > 1. The known mean and variance for the IC process are 𝜇 = 𝜇0 and 𝜎2 = 𝜎02 . The CUSUM chart was first suggested by Page.2 As the CUSUM plotting-statistics denoted by 𝐶𝑡+ and 𝐶𝑡− depend both on the present and past information, that is why it is relatively better to monitor infrequently small variations. The 𝐶𝑡+ and 𝐶𝑡− based on the sample mean of 𝑌𝑡 , that is., 𝑌̄ 𝑡 are defined as: ] ] [ + 𝐶𝑡+ = max 0, (𝑌̄ 𝑡 − 𝜇0 ) − K + 𝐶𝑡−1 ] [ − 𝐶𝑡− = 𝑚𝑎𝑥 0, − (𝑌̄ 𝑡 − 𝜇0 ) − K + 𝐶𝑡−1 (1) √ where 𝐶𝑡+ = 𝐶𝑡− = 0, K = k 𝑉𝑎𝑟(𝑌̄ 𝑡 ) is the reference value for k > 0 and where 𝑉𝑎𝑟 (𝑌̄ 𝑡 ) = shows an out-of-control (OOC) signal when 𝐶𝑡+ √ or 𝐶𝑡− 2 𝜎𝑌 𝑛 . The CUSUM chart >𝐻 > 𝐻, else, it is IC. The 𝐻 is called the control limit or decision ̄ interval and it is defined as 𝐻 = ℎ 𝑉𝑎𝑟(𝑌𝑡 ). The values of k and ℎ are selected carefully because the average run length (𝐴𝑅𝐿) performance of the CUSUM chart is influenced due to these values. We refer Hawkins and Olwell25 for further details on the CUSUM chart. 2.2 The HWMA chart The HWMA chart was proposed by Abbas19 which is performed superior to other memory-type charts to monitor the infrequent variation in the process mean. The plotting-statistic of the HWMA chart is: 𝐻𝑊𝑡 = 𝜑𝑌̄ 𝑡 + (1 − 𝜑) 𝑌̄ 𝑡−1 where 𝜑 ∈ (0, 1], 𝑌̄ 0 = 𝜇𝑜 , and 𝑌̄ 𝑡−1 = ∑𝑡−1 𝑖=1 [( 𝐻𝑊𝑡 = 𝜑𝑌̄ 𝑡 + 𝑌̄ 𝑖 𝑡−1 (2) . The statistic in (2) can also be written as (cf. Abbas et al19 ): 1−𝜑 𝑡−1 ) ( 𝑌̄ 𝑡−1 + 1−𝜑 𝑡−1 ) ( 𝑌̄ 𝑡−2 + ⋯ + 1−𝜑 𝑡−1 ] ) 𝑌̄ 1 (3) ABID et al. 3 where 𝜑 denoted the current sample weight and 1 − 𝜑 represented the previous sample weights. The statistic given in (3) has the following mean and variance for IC process (cf. Abbas19 ): 𝐸 (𝐻𝑊𝑡 ) = 𝜇0 𝑉𝑎𝑟 (𝐻𝑊𝑡 ) = 𝜑2 𝜎02 𝑖𝑓 𝑡 = 1) and 𝑛 𝐸 (𝐻𝑊𝑡 ) = 𝜇0 𝑉𝑎𝑟 (𝐻𝑊𝑡 ) = 𝜑2 𝜎02 𝑛 + (1 − 𝜑) 𝜎02 2 𝑖𝑓 𝑡 > 1) 𝑛(𝑡−1) Using 𝐸 (𝐻𝑊𝑡 ) = 𝜇0 and 𝑉𝑎𝑟(𝐻𝑊𝑡 ), the control limits of the HWMA chart are: √ ⎤ 𝑖𝑓 𝑡 = 1 ⎥ 𝑛 ⎥ 𝐿𝐶𝐿𝑡 = √ ⎥ 2 𝜑2 𝜎02 𝜎 2 0 𝜇0 − 𝐶 + (1 − 𝜑) , 𝑖𝑓 𝑡 > 1 ⎥ 𝑛 𝑛(𝑡−1) ⎥ ⎥ ⎥ 𝐶𝐿 = 𝜇0 ⎥ ⎥ √ ⎥ 𝜑2 𝜎02 𝑖𝑓 𝑡 = 1 ⎥ 𝜇0 + 𝐶 𝑛 ⎥ 𝑈𝐶𝐿𝑡 = √ ⎥ 2 𝜑2 𝜎02 2 𝜎0 𝜇0 + 𝐶 + (1 − 𝜑) , 𝑖𝑓 𝑡 > 1 ⎥⎦ 𝜇0 − 𝐶 𝜑2 𝜎02 𝑛 (4) 𝑛(𝑡−1) where 𝐶 is nominated to achieve the preferred IC 𝐴𝑅𝐿 and it is represented the width of the control limits. 3 THE PROPOSED CHART In this study, we attach the HWMA statistic in the design structure of the CUSUM chart. The upper and lower plottingstatistics, that is, 𝐻𝐶𝑡+ and 𝐻𝐶𝑡− , respectively, of the MHC chart are: ] ] [ + 𝐻𝐶𝑡+ = max 0, (𝐻𝑊𝑡 − 𝜇0 ) − K𝑡 + 𝐻𝐶𝑡−1 ] [ − 𝐻𝐶𝑡− = 𝑚𝑎𝑥 0, − (𝐻𝑊𝑡 − 𝜇0 ) − K𝑡 + 𝐻𝐶𝑡−1 (5) where 𝐻𝑊𝑡 is given in (3) and 𝐻𝐶𝑡+ = 𝐻𝐶𝑡− = 0. The K𝑡 and H𝑡 are two design parameters of the MHC chart. The 𝐻𝐶𝑡+ and 𝐻𝐶𝑡− are plotted against H𝑡 . The process is stated to be OOC if either 𝐻𝐶𝑡+ or 𝐻𝐶𝑡− exceeds than H𝑡 , otherwise, it is stated to be IC. The K𝑡 and H𝑡 for the MHC chart are defined as: √ k𝑡 √ K𝑡 = k𝑡 𝑉𝑎𝑟 (𝐻𝑊𝑡 ) = √ k𝑡 𝑛 𝜑2 𝜎02 𝑛 √ H𝑡 = h𝑡 √ h𝑡 √ 𝑉𝑎𝑟 (𝐻𝑊𝑡 ) = h𝑡 𝜑2 𝜎02 + (1 − 𝜑) 2 𝜎02 𝑛(𝑡−1) , 𝜑2 𝜎02 𝑛 𝜑2 𝜎02 𝑛 + (1 − 𝜑) 2 𝜎02 𝑛(𝑡−1) , ⎤ 𝑖𝑓 𝑡 = 1 ⎥ ⎥ ⎥ 𝑖𝑓 𝑡 > 1⎥ ⎦ (6) ⎤ 𝑖𝑓 𝑡 = 1 ⎥ ⎥ ⎥ 𝑖𝑓 𝑡 > 1⎥ ⎦ (7) We select the value of k𝑡 = 0.50 by following Abbas et al.8 The value of h𝑡 is selected in such a way that it is reached to the desired IC 𝐴𝑅𝐿. In SPCM literature, so many techniques are available to compute the 𝑅𝐿 profiles of a control chart. In this study, we prefer Monte Carlo simulations due to the complex design structure of the MHC chart. Ali and Haq13 investigated that the 𝐴𝑅𝐿 results computed through Monte Carlo simulations are found to be more accurate as compared with other techniques, that is, Markov chain and integral equations. 4 ABID et al. TA B L E 1 Values of ℎ for MHC chart for several combinations of 𝜑 and 𝐴𝑅𝐿𝑜 when k𝑡 = 0.5 𝑨𝑹𝑳𝟎 𝝋 0.1 0.25 0.5 0.75 100 6.47 4.87 4.01 3.71 200 7.401 5.66 4.679 4.32 300 7.95 6.102 5.06 4.7 400 8.303 6.32 5.333 5.04 500 8.575 6.625 5.536 5.187 We select various combinations of 𝜑 and find the values of h𝑡 for different selections of the IC 𝐴𝑅𝐿 (Table 1). In Table 2, we report the 𝑅𝐿 profile values of the MHC chart using different selections of 𝜑, h𝑡 when the IC 𝐴𝑅𝐿 ≈ 500. We also |𝜇 −𝜇 | consider different choices of 𝛿, that is, the amount of shift in the process mean and it is defined as = 1 0 , where 𝜎0 𝜇1 is the out of control (OOC) process mean. The value of h𝑡 is decreased as 𝜑 increases for a fixed value of k𝑡 (like IC 𝐴𝑅𝐿 = 300, h𝑡 = 7.95, 𝜑 = 0.1, and h𝑡 = 5.06, 𝜑 = 0.5) (Table 1). The OOC 𝐴𝑅𝐿 values of the MHC chart are decreased with the decrease of 𝜑 (like k𝑡 = 0.5, 𝜑 = 0.25, 𝛿 = 0.1, OOC ARL = 112, and k𝑡 = 0.5, 𝜑 = 0.1, 𝛿 = 0.1, OOC ARL = 62 [Table 2]). For fixed k𝑡 and 𝜑, the OOC 𝐴𝑅𝐿 values of the MHC chart are decreased as 𝛿 increases (Table 2). The IC standard deviation of the RL (SDRL) and OOC SDRL values are decreased as the value of 𝜑 increases (Table 2). We have also made the IC RL curve of the MHC chart against various choices of 𝜑 (Figure 1). From Figure 1, it is seen that there is a decrease in the IC RL values of the MHC chart as the value of 𝜑 is increased. 4 PERFORMANCE COMPARISONS The performance comparisons between MHC and existing charts (such as CUSUM, EWMA, MEC, MCE, and HWMA) based on 𝐴𝑅𝐿 are performed in this section. A chart is considered to be an efficient chart if its IC 𝐴𝑅𝐿 is adequately large and if its OOC 𝐴𝑅𝐿 is adequately small. Another measure called the percentage decrease in 𝐴𝑅𝐿 is also used for compari𝐼𝐶 𝐴𝑅𝐿−𝑂𝑂𝐶 𝐴𝑅𝐿 ) × 100. son and is labeled as the 𝑃𝐷𝐴𝑅𝐿 (cf. Abbas et al18 and Abid et al23 ). The 𝑃𝐷𝐴𝑅𝐿 is calculated as ( 𝐼𝐶 𝐴𝑅𝐿 4.1 MHC versus CUSUM The MHC chart with all selected values of 𝜑 and 𝛿 detects the shifts quickly against the CUSUM chart (like in CSUUM chart at 𝑘 = 0.5, 𝛿 = 0.1, 0.15, 0.2, 0.5, OOC 𝐴𝑅𝐿 = 369, 271, 201, 39 and in MHC chart at k𝑡 = 0.5, 𝜑 = 0.1, 𝛿 = 0.1, 0.15, 0.2, 0.5, OOC 𝐴𝑅𝐿 = 62, 41, 32, 13, also in MHC chart at k𝑡 = 0.5, 𝜑 = 0.75, 𝛿 = 0.1, 0.15, 0.2, 0.5, OOC 𝐴𝑅𝐿 = 310, 204, 133, 24 [Table 2 vs Table 3]). At 𝛿 = 20%, the 𝑃𝐷𝐴𝑅𝐿 in CUSUM chart is 45.8% but in MHC, the 𝑃𝐷𝐴𝑅𝐿 is 93.6% and 73.4%, when 𝜑 = 0.1 and 𝜑 = 0.75, respectively. 4.2 MHC versus EWMA It is noted that the MHC chart performs superior to the EWMA chart (like in EWMA chart at 𝜑 = 0.1, 𝛿 = 0.10, .15, 0.2, 0.5, OOC 𝐴𝑅𝐿 = 62, 41, 32, 13 and in MHC chart OOC 𝐴𝑅𝐿 = 316, 218, 146, 29 [Tables 2 and 4]). Also, with 𝛿 = 15% and 𝜑 = 0.1, the 𝑃𝐷𝐴𝑅𝐿 in MHC and EWMA charts is 91.8% and 57.4%, respectively. 4.3 MHC versus MEC From Tables 2 and 5, it is revealed that the MHC chart indicates improved performance against the MEC chart (like in MHC chart at 𝜑 = 0.1 and 𝛿 = 0.1, 0.15, 0.2, 0.5, OOC 𝐴𝑅𝐿 = 62, 41, 32, 13 and in MEC chart OOC 𝐴𝑅𝐿 = 243, 156, 107, 35). The MHC chart also performs better for larger values of 𝜑 over the MEC chart (Tables 2 and 5). Furthermore, at 𝛿 = 10% and 𝜑 = 0.1, the 𝑃𝐷𝐴𝑅𝐿 in the MHC chart is 87.6%, while in the MEC chart is 51.6%. ABID et al. 5 TA B L E 2 The 𝑅𝐿 profiles for MHC chart at 𝐴𝑅𝐿𝑜 ≅ 500 𝝋 𝐤𝒕 𝐡𝒕 𝜹 Profiles 𝑨𝑹𝑳 𝑺𝑫𝑹𝑳 𝑷𝟓 𝑷𝟐𝟓 𝑷𝟓𝟎 𝑷𝟕𝟓 𝑷𝟗𝟓 0.1 0.5 8.575 0 501 3016 6 12 27 87 1382 0.1 62 107 24 6 11 63 244 0.15 41 57 21 6 11 47 148 0.2 32 35 19 6 10 39 100 0.25 25 25 17 6 10 31 75 0.5 13 8 10 5 7 16 30 0.75 9 4 8 4 6 11 17 1 7 3 6 4 5 8 12 1.5 5 1 5 4 4 6 8 0.25 0.5 0.75 0.5 0.5 0.5 6.625 5.536 5.187 2 4 1 4 3 4 5 6 0 499 1145 5 11 37 265 2636 0.1 112 211 29 5 11 112 508 0.15 65 101 25 5 10 74 266 0.2 41 55 21 5 9 49 145 0.25 31 36 17 5 9 37 103 0.5 12 9 9 4 6 15 30 0.75 8 4 7 4 5 10 16 1 6 3 6 3 4 7 11 1.5 4 1 4 3 4 5 7 2 4 1 4 3 3 4 5 0 501 710 6 30 211 689 1959 0.1 222 302 103 6 23 306 825 0.15 128 166 63 6 18 175 477 0.2 79 96 43 5 15 107 274 0.25 52 60 30 5 13 70 174 0.5 16 13 12 4 7 20 42 0.75 9 5 7 3 5 11 20 1 6 3 5 3 4 8 12 1.5 4 1 4 3 3 5 7 2 3 1 3 2 3 4 5 0 502 544 14 112 322 689 1622 0.1 310 338 199 12 71 430 974 0.15 204 214 133 11 50 282 650 0.2 133 142 86 9 34 186 416 0.25 94 95 62 8 26 129 284 0.5 24 20 18 5 10 31 63 0.75 12 8 10 4 7 15 27 8 4 7 3 5 10 15 1.5 5 2 4 3 3 6 8 2 3 1 3 2 3 4 5 1 4.4 MHC versus MCE It is observed that the MHC chart shows improved performance than the MEC chart (like in MHC chart at = 0.1, 𝛿 = 0.1, 0.15, 0.25, 0.5, OOC 𝐴𝑅𝐿 = 62, 41, 25, 13 and in MCE chart OOC 𝐴𝑅𝐿 = 350, 244, 126, 36, also, in MHC chart at 𝜑 = 0.75, 𝛿 = 0.1, 0.15, 0.25, 0.5, 𝑂𝑂𝐶 𝐴𝑅𝐿 = 310, 204, 94, 24 and in MCE chart OOC 𝐴𝑅𝐿 = 369, 269, 144, 37 [Tables 2 and 6]). The 𝑃𝐷𝐴𝑅𝐿 in MHC and MCE charts is 91.8% and 51.2%, respectively, at 𝛿 = 15% and 𝜑 = 0.1. 6 ABID et al. FIGURE 1 4.5 The IC RL curve of the proposed chart for various choices of φ MHC versus HWMA The MHC chart performs efficiently well than to the HWMA chart against all 𝜑 and 𝛿 values (like in MHC chart at 𝜑 = 0.1, 𝛿 = 0.1, 0.15, 0.25, 0.5, OOC 𝐴𝑅𝐿 = 62, 41, 25, 13 and in HWMA chart OOC 𝐴𝑅𝐿 = 250, 161, 81, 29, also, in MHC chart at 𝜑 = 0.75, 𝛿 = 0.1, 0.15, 0.5, OOC 𝐴𝑅𝐿 = 310, 204, 24 and in HWMA chart OOC 𝐴𝑅𝐿 = 462, 414, 131 [Tables 2 and 7]). Moreover, at 𝛿 = 15% and 𝜑 = 0.1, the PDARL in MHC and HWMA charts is 91.8% and 50%, respectively. We have also computed the OOC 𝑆𝐷𝑅𝐿 and OOC percentile point (like 𝑃5 , 𝑃25 , 𝑃50 , 𝑃75 , and 𝑃95 ) values of the proposed and existing charts (Tables 2–7). The main reason to compute these measures is the skewed distributional behavior of the 𝑅𝐿. From Tables 2–7, it is noted that the MHC chart has a smaller 𝑆𝐷𝑅𝐿, 𝑃5 , 𝑃25 , 𝑃50 , 𝑃75 , and 𝑃95 values as compared to the CUSUM, EWMA, MEC, MCE, and HWMA charts (like at 𝜑 = 0.1, k𝑡 = 0.5, 𝛿 = 0.1, the values of 𝑆𝐷𝑅𝐿 and 𝑃50 in MHC chart are 107 and 11 [Table 2]; in CUSUM chart are 363 and 259 [Table 3]; in EWMA chart are 317 and 220 [Table 4]; in MEC chart are 205 and 181 [Table 5]; respectively, in MCE chart are 340 and 246 [Table 6]; and in HWMA chart are 198 and 204 [Table 7]). As the value of 𝑃50 is smaller than the value of 𝐴𝑅𝐿, it indicates that the distribution of the 𝑅𝐿 is positively skewed. TA B L E 3 The 𝑅𝐿 profiles for CUSUM chart at 𝐴𝑅𝐿𝑜 ≅ 500 𝒌 𝒉 0.5 5.072 𝜹 Profiles 𝑨𝑹𝑳 𝑺𝑫𝑹𝑳 0 499 0.1 369 𝑷𝟓 𝑷𝟐𝟓 𝑷𝟓𝟎 𝑷𝟕𝟓 𝑷𝟗𝟓 485 31 148 346 681 1467 363 26 112 259 511 1070 0.15 271 264 20 84 189 372 797 0.2 201 193 17 64 142 278 586 0.25 147 139 15 49 105 203 426 0.5 39 31 7 16 29 52 102 0.75 17 11 5 9 14 22 39 1 10 5 4 7 9 13 21 1.5 6 2 3 4 5 7 10 2 4 1 2 3 4 5 6 ABID et al. 7 TA B L E 4 The 𝑅𝐿 profiles for EWMA chart at 𝐴𝑅𝐿𝑜 ≅ 500 𝝋 𝑪 𝜹 Profiles 𝑨𝑹𝑳 𝑺𝑫𝑹𝑳 0.1 2.824 0 499 503 20 0.1 316 317 0.15 218 213 0.2 146 0.25 103 0.5 0.75 0.25 0.5 0.75 3 3.072 3.088 𝑷𝟐𝟓 𝑷𝟓𝟎 𝑷𝟕𝟓 𝑷𝟗𝟓 138 343 694 1519 16 92 220 436 942 12 66 153 298 644 140 11 45 101 204 422 97 8 35 74 138 298 29 23 4 13 23 39 73 14 10 3 7 12 18 32 1 8 5 2 4 7 11 18 1.5 4 2 1 2 4 5 9 2 3 1 1 2 2 3 5 0 498 497 24 144 345 687 1484 0.1 386 385 21 110 269 532 1149 0.15 296 293 16 87 208 409 877 0.2 226 222 14 66 158 317 673 0.25 168 164 12 52 118 232 501 0.5 48 44 5 16 34 65 135 0.75 19 16 3 8 15 25 51 1 10 8 2 5 8 14 25 1.5 5 3 1 3 4 6 10 2 3 2 1 2 3 4 6 0 502 501 26 145 353 695 1510 0.1 437 441 23 123 302 608 1297 0.15 377 372 21 110 259 524 1122 0.2 311 315 17 91 216 425 929 0.25 254 248 14 74 179 356 743 0.5 88 87 6 26 62 121 261 0.75 35 34 3 11 25 48 104 1 17 15 2 6 13 23 47 1.5 6 5 1 3 5 8 15 2 3 2 1 2 3 4 7 0 501 500 26 144 347 699 1508 0.1 465 465 322 24 133 645 1393 0.15 418 419 290 22 121 582 1241 0.2 372 373 259 20 109 514 1114 0.25 320 317 222 17 92 443 956 0.5 140 139 97 8 41 194 417 0.75 63 62 44 4 19 85 186 1 30 29 21 3 10 42 90 1.5 10 9 7 1 4 13 27 4 3 3 1 2 6 11 2 4.6 𝑷𝟓 Graphical comparisons In this section, we present the graphical comparisons between the MHC and existing charts based on OOC 𝐴𝑅𝐿 value curves for various choices of 𝜑. It is found that the MEC chart shows enhanced performance against the EWMA, MCE, and HWMA charts for larger values of 𝜑 and 𝛿 < 1.5 (Figure 2C,D). The HWMA has a better shift detection ability than 8 ABID et al. TA B L E 5 The 𝑅𝐿 profiles for MEC chart at 𝐴𝑅𝐿𝑜 ≅ 500 𝝋 𝐤𝒕 𝐡𝒕 𝜹 Profiles 𝑨𝑹𝑳 𝑺𝑫𝑹𝑳 𝑷𝟓 𝑷𝟐𝟓 𝑷𝟓𝟎 𝑷𝟕𝟓 𝑷𝟗𝟓 0.1 0.5 37.43 0 501 466 62 171 359 681 1452 0.1 243 205 46 97 181 324 646 0.15 156 121 38 71 120 203 391 0.2 107 74 32 55 86 135 254 0.25 79 48 28 45 66 100 173 0.5 35 13 20 26 33 41 60 0.75 24 6 16 20 23 27 36 1 19 4 14 16 18 21 26 1.5 14 2 11 12 14 15 17 0.25 0.5 0.75 0.5 0.5 0.5 20.19 11.2 7.33 2 11 1 9 10 11 12 14 0 502 480 47 154 357 688 1472 0.1 272 250 35 94 197 372 758 0.15 177 154 29 68 128 236 491 0.2 115 93 23 50 88 154 299 0.25 83 63 21 40 65 108 209 0.5 31 15 14 20 27 38 61 0.75 19 7 11 14 17 22 32 1 14 4 9 11 13 16 21 1.5 10 2 7 8 9 11 13 2 8 1 6 7 7 8 10 0 503 490 37 152 354 705 1509 0.1 312 301 29 99 219 430 910 0.15 208 194 24 70 147 280 603 0.2 139 126 20 50 99 189 392 0.25 100 85 17 40 74 133 265 0.5 30 19 10 17 26 38 68 0.75 17 8 8 11 15 20 31 1 12 4 6 8 11 14 20 1.5 7 2 5 6 7 8 11 2 6 1 4 5 5 6 8 0 499 494 32 150 359 697 1480 0.1 350 340 27 107 249 482 1029 0.15 238 227 22 77 170 322 699 0.2 169 160 18 56 120 232 496 0.25 120 110 15 42 87 161 340 0.5 34 24 9 16 26 44 82 0.75 17 9 6 10 14 21 34 1 11 5 5 7 10 13 20 1.5 6 2 4 5 6 7 10 2 5 1 3 4 4 5 7 EWMA and MCE chart for smaller values of 𝜑 and 𝛿 < 0.75 (Figure 2A,B). Moreover, the MHC chart performs comparatively superior as compared to EWMA, MEC, MCE, and HWMA charts under for all 𝜑 and 𝛿 values (Figure 2A,D). The dominance zone of the MHC chart becomes closer to the existing charts with an increase in the value of 𝜑 (Figure 2C,D). From tabulated and graphical comparisons, it is concluded that the MHC shows superior performance against EWMA, MEC, MCE, and HWMA charts. ABID et al. TA B L E 6 9 The 𝑅𝐿 profiles for MCE chart at 𝐴𝑅𝐿𝑜 ≅ 500 𝝋 𝒌 𝑪 𝜹 0.1 0.5 9.66 0 𝑺𝑫𝑹𝑳 𝑷𝟓 𝑷𝟐𝟓 𝑷𝟓𝟎 𝑷𝟕𝟓 𝑷𝟗𝟓 499 482 35 150 352 691 1441 0.1 350 340 27 108 246 482 1026 0.15 244 232 22 78 174 333 708 0.2 177 168 19 59 125 239 514 0.25 126 115 16 44 92 171 355 0.5 36 27 9 17 28 47 90 0.75 18 10 7 11 15 22 37 1 12 5 6 8 11 14 21 7 2 4 6 7 8 11 1.5 0.25 0.5 0.75 0.5 0.5 0.5 9.1 7.42 6.09 2 5 1 3 4 5 6 8 0 500 497 31 149 352 689 1475 0.1 366 359 25 112 255 509 1070 0.15 261 252 20 82 183 355 767 0.2 191 185 17 61 134 262 557 0.25 137 128 14 46 98 189 396 0.5 37 30 8 16 28 49 96 0.75 17 11 6 9 14 21 38 1 10 5 5 7 9 13 20 1.5 6 2 3 5 6 7 10 2 4 1 3 3 4 5 7 0 503 509 26 146 356 699 1505 0.1 371 365 23 112 261 515 1079 0.15 272 265 19 83 191 375 795 0.2 198 193 15 62 139 271 584 0.25 144 138 13 47 102 199 418 0.5 38 32 6 15 28 51 101 0.75 17 11 4 8 14 22 39 1 10 5 3 6 9 12 20 1.5 5 2 2 4 5 6 10 2 4 1 2 3 3 4 6 0 499 498 23 139 347 684 1472 0.1 369 368 21 108 258 511 1072 0.15 269 266 17 81 187 372 797 0.2 198 196 13 60 137 272 588 0.25 144 140 11 46 101 199 422 0.5 37 32 5 14 28 50 101 0.75 16 11 3 8 13 21 38 9 6 2 5 8 12 20 1.5 5 2 2 3 4 6 9 2 3 1 1 2 3 4 6 1 5 Profiles 𝑨𝑹𝑳 A REAL-LIFE APPLICATION OF EXISTING AND PROPOSED CHARTS This section offers the real-life application of the existing and proposed charts based on the dataset related to the semiconductor manufacturing process (cf. Montgomery4 ). For phase-I analysis, the 25 subgroups each of size 5 have been taken at every hour to measure the “flow width of the resist,” which is the variable under study. Twenty more subgroups have 10 TA B L E 7 ABID et al. The 𝑅𝐿 profiles for HWMA chart at 𝐴𝑅𝐿𝑜 ≅ 500 𝝋 𝑪 𝜹 Profiles 𝑨𝑹𝑳 𝑺𝑫𝑹𝑳 𝑷𝟓 𝑷𝟐𝟓 𝑷𝟓𝟎 𝑷𝟕𝟓 𝑷𝟗𝟓 0.1 2.938 0 499 402 44 200 401 696 1274 0.1 250 198 29 105 201 341 633 0.15 161 123 21 71 131 219 403 0.2 110 81 16 51 92 149 266 0.25 81 57 13 40 68 108 193 0.5 29 18 6 15 25 38 61 0.75 15 9 4 8 13 19 31 0.25 0.5 0.75 3.075 3.089 3.09 1 9 5 3 6 8 12 19 1.5 5 2 1 3 5 6 10 2 3 2 1 3 3 4 6 0 500 483 31 151 354 691 1469 0.1 322 305 24 105 231 437 946 0.15 229 213 20 77 167 312 657 0.2 156 140 16 55 117 212 431 0.25 113 98 12 43 86 153 306 0.5 33 25 6 16 27 45 84 0.75 16 11 4 9 14 22 37 1 10 6 3 6 9 13 21 1.5 5 2 1 3 4 6 10 2 3 1 1 2 3 4 6 0 501 500 28 143 343 687 1504 0.1 420 415 23 123 294 582 1224 0.15 351 350 19.95 101 246 484 1049 0.2 280 276 17 85 197 386 828 0.25 217 213 14 65 151 300 645 0.5 68 65 6 23 49 94 194 0.75 28 25 3 10 21 38 78 1 14 12 2 6 11 19 37 1.5 6 4 1 3 5 7 13 2 3 2 1 2 3 4 7 0 502 504 26 146 346 696 1540 0.1 462 462 23 133 320 641 1373 0.15 414 416 23 119 289 575 1216 0.2 369 366 20 107 255 512 1100 0.25 312 314 16 90 213 433 926 0.5 131 129 8 39 92 183 388 0.75 58 58 4 18 41 81 173 1 28 27 2 9 20 38 83 1.5 9 8 1 3 7 12 25 2 4 3 1 2 3 6 10 been taken for phase-II analysis and these subgroups are considered to make the real-life application of the existing and proposed MHC charts. The scatter plot of these 45 subgroups is provided in Figure 3 and this plot shows a rising drift after 30 subgroups. To investigate this drift, the values of the selected design parameters are presented in Table 8 by fixing ̂ and standard deviation (𝜎) ̂ for monitoring of the Phase-I 𝐼𝐶 𝐴𝑅𝐿 ≈ 500. The unknown values of the population mean (𝜇) ABID et al. 11 FIGURE 2 OOC ARL comparisons between proposed and existing charts when (A) φ = 0.1, (B) φ = 0.25, (C) φ = 0.5, and (D) φ = 0.75 FIGURE 3 The scatter plot for all subgroups TA B L E 8 Design parameter values for the existing and proposed charts 𝐂𝐡𝐚𝐫𝐭𝐬 𝐃𝐞𝐬𝐢𝐠𝐧 𝐩𝐚𝐫𝐚𝐦𝐞𝐭𝐞𝐫𝐬 𝐶𝑈𝑆𝑈𝑀 𝑘 = 0.75, ℎ = 3.538 𝐸𝑊𝑀𝐴 𝜑 = 0.25, 𝐶 = 3 𝑀𝐸𝐶 𝜑 = 0.25, k𝑡 = 0.75, h𝑡 = 13.44 𝐻𝑊𝑀𝐴 𝜑 = 0.75, 𝐶 = 3.09 𝑀𝐻𝐶 𝜑 = 0.25, k𝑡 = 0.75, h𝑡 = 4.125 12 ABID et al. FIGURE 4 A real-life application of (A) CUSUM, (B) EWMA, (C) MEC, (D) HWMA, and (E) MHC charts analysis are calculated using the following formulas: 1 𝜇̂ = 𝑙 √ 𝑙 ∑ 𝑌̄ 𝑡 = 𝑡=1 ∑𝑙 ∑𝑚 𝑠𝑝 = 𝑡=1 1 25 (37.6403) = 1.5056, ̄ 2 𝑗=1 (𝑌𝑖𝑗 −𝑌𝑖 ) 𝑙(𝑚−1) √ = 1.93424 25(5−1) = 0.01391 and 𝜎̂ = 𝑠𝑝 𝑐4,𝑙 = 0.019308 0.997503 = 0.13943. The diagram outputs of the existing and proposed charts are shown in Figure 4A-E. From Figures 4A and 4C, it is seen that there is no OOC point in the CUSUM and MEC charts because the plotting-statistics of these charts stayed inside the control limits. From Figures 4B and 4D, it can be noticed that the EWMA and HWMA charts spot shifts at the 20th sample. On the other hand, the proposed MHC chart spot shifts at the 19th sample (Figure 4E). Hence, the proposed MHC chart triggers an earlier OOC signal in the process mean over the existing charts included in this section. 6 CONCLUSIONS AND RECOMMENDATIONS In this study, we have suggested a new CUSUM chart that utilizes the statistic of the HWMA chart and named as the MHC chart. The 𝑅𝐿 profile comparisons of the MHC chart have been performed with existing charts. From tabular and graphical comparisons, we have found that the MHC chart offers superior performance than the existing charts under ABID et al. 13 study. Hence, we suggest the practice of the MHC chart to the SPCM experts for evaluating infrequent changes in the process mean. The scope of this study may also be extended to assess variations in the process dispersion. Moreover, the MHC chart might be used to develop efficient nonparametric and multivariate charts. AC K N OW L E D G M E N T S The authors are grateful to the editor and referees for their constructive comments that led to substantial improvements in the article. This research fund was supported by the National Science Foundation of China through project number 71774070. ORCID Muhammad Abid https://orcid.org/0000-0001-8996-1120 Sun Mei https://orcid.org/0000-0003-0276-0612 Muhammad Riaz https://orcid.org/0000-0002-7599-6928 Shahid Hussain https://orcid.org/0000-0003-2206-1739 REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. Shewhart WA. Economic control of quality of manufactured product. Van Nostrand, New York. 1932;27(178):217-215. Page ES. Continuous inspection schemes. Biometric. 1954;41(1-2):100-115. Roberts SW. Control chart tests based on geometric moving averages. Technometrics. 1959;1(3):239–250. Montgomery DC. Introduction to Statistical Quality Control. 7th ed. New York: John Wiley & Sons;2012. Lucas JM. Combined Shewhart-CUSUM quality control schemes. J Qual Technol. 1982;14(2):51–59. Lucas JM, Saccucci MS. Exponentially weighted moving average control schemes: properties and enhancements. Technometrics. 1990;32(1):1–12. Shamma SE, Shamma AK. Development and evaluation of control charts using double exponentially weighted moving averages. Int J Qual Reliabil Manage. 1992;9(6):18–25. Abbas N, Riaz M, Does RJMM. Mixed exponentially weighted moving average-cumulative sum charts for process monitoring. Qual Reliab Eng Int. 2013;29(3):345–356. Zaman B, Abbas N, Does RJ. Mixed cumulative sum exponentially weighted moving average control charts. Qual Reliab Eng Int. 2014;31(1):1407–1421. Zaman B, Abbas N, Lee MH. On the performance of control charts for simultaneous monitorring of location and dispersion parameters. Qual Reliab Eng Int. 2017;33(1):37–56. Abid M, Nazir HZ, Riaz M, Lin Z. In-control robustness comparison of different control charts. Trans Inst Meas Control. 2018;40(13):3860– 3871. Abid M, Nazir HZ, Tahir M, Riaz M, Abbas T. A comparative analysis of robust dispersion control charts with application related to health care data. J Test Eval. 2020;48(1):247–259. Ali R, Haq A. A mixed GWMA-CUSUM control chart for monitoring the process mean. Commun Statist Theory Methods. 2018;47(15):3779– 3801. Haq A. A new adaptive EWMA control chart using auxiliary information for monitoring the process mean. Commun Statist Theory Methods. 2018;47(19):4840–4858. Ajadi JO, Riaz M. Mixed multivariate EWMA-CUSUM control charts for an improved process monitoring. Commun Statist Theory Methods. 2017;46(14):6980–6993. Haq A, Bibi L. A new dual CUSUM mean chart. Qual Reliab Eng Int. 2019;35(4):1245–1262. Haq A, Munir T, Khoo MBC. Dual multivariate CUSUM mean charts. Comput Ind Eng. 2019;137:106028. Abbas Z, Nazir HZ, Akhtar N, Riaz M, Abid M. An enhanced approach for the progressive mean control charts. Qual Reliab Eng Int. 2019;35(4):1046–1060. Abbas N. Homogeneously weighted moving average control chart with an application in substrate manufacturing process. Comput Ind Eng. 2018;120(6):460–470. Adegoke NA, Abbasi SA, Smith ANH, Anderson MJ, Pawley MDM. A multivariate homogeneously weighted moving average control chart. IEEE Access. 2019;7:9586–9597. Adegoke NA, Smith ANH, Anderson MJ, Sanusi RA, Pawley MDM. Efficient homogeneously weighted moving average chart for monitoring process mean using an auxiliary variable. IEEE Access. 2019;7:94021–94032. Nawaz T, Han D. Monitoring the process location by using new ranked set sampling based memory control charts. Qual Technol Quant Manage. 2020;17(3):255–284. Abid M, Shabbir A, Nazir HZ, Sherwani RAK, Riaz M. A double homogeneously weighted moving average control chart for monitoring of the process mean. Qual Reliab Eng Int. 2020;36(5):1513–1527. Abbas N, Riaz M, Shabbir A, Abid M, Zaman B. On the efficient monitoring of multivariate processes with unknown parameters. Mathematics. 2020;8:823. Hawkins DM, Olwell DH. Cumulative Sum Charts and Charting Improvement. New York: Springer: 1998. 14 ABID et al. AU T H O R B I O G R A P H I E S Muhammad Abid obtained his MSc and MPhil degrees in statistics from Quaid-i-Azam University, Islamabad, Pakistan, in 2008 and 2010, respectively. He did his PhD in statistics from the Institute of Statistics, Zhejiang University, Hangzhou, China, in 2017. He served as a statistical officer in National Accounts Wing, Pakistan Bureau of Statistics (PBS) during 2010-2011. He is now serving as an Assistant Professor in the Department of Statistics, Government College University, Faisalabad, Pakistan, from 2017 to present. His research interests include statistical quality control, Bayesian statistics, nonparametric techniques, and survey sampling. His e-mail address is: mabid@gcuf.edu.pk. Sun Mei received her B.S. degree in Mathematics from Yangzhou University and the Ph.D. degree in System Engineering from Jiangsu University, respectively. She is currently a Professor in the School of Mathematical Science, Jiangsu University, China. She was the recipient of the Excellent Ph.D. Thesis Award of Jiangsu province of China and the Teaching Achievement Award of Ministry of Education of China. She has published over 50 peer-reviewed journal papers and four books. Her research interest includes the theory and application of nonlinear systems, and the modeling and analysis of complex systems. Hafiz Zafar Nazir obtained his MSc and M.Phil degrees in Statistics from the Department of Statistics, QuaidiAzam University, Islamabad, Pakistan, in 2006 and 2008, respectively. He did his PhD in statistics from the Institute of Business and Industrial Statistics University of Amsterdam, The Netherlands, in 2014. He served as a lecturer in the Department of Statistics, University of Sargodha, Pakistan, during 2009-2014. He is now serving as an assistant professor in the Department of Statistics, University of Sargodha, Pakistan, from 2015 to date. His current research interests include statistical process control, nonparametric techniques, and robust methods. His e-mail address is: hafizzafarnazir@yahoo.com. Muhammad Riaz obtained his PhD in statistics from the Institute for Business and Industrial Statistics, University of Amsterdam, The Netherlands, in 2008. He holds the position of professor in the Department of Mathematics and Statistics, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia. His current research interests include statistical process control, nonparametric techniques, and experimental design. Shahid Hussain obtained his Ph.D. degree in Probability Theory and Mathematical Statistics from the School of Mathematical Sciences, Dalian University of Technology, Dalian, China in 2018. He obtained his M.Sc. in statistics (2006) and M.Phil. in statistics (2008) from the Department of Statistics, Quaid-i-Azam University, Islamabad, Pakistan. He served as a Lecturer during 20062011 and as an Assistant Professor from 2011 to date at the Department of Mathematics, COMSATS University Islamabad, Attock Campus. Currently, he is serving as a post-doctorate researcher at the Institute of Applied Systems Analysis, Faculty of Science, Jiangsu University, Zhenjiang, P. R. China. His current research interests include Statistical Process Control and Application of Sampling Techniques. His email is: shahid_libra82@hotmail.com How to cite this article: Abid M, Mei S, Nazir HZ, Riaz M, Hussain S. A mixed HWMA-CUSUM mean chart with an application to manufacturing process. Qual Reliab Engng Int. 2020;1–14. https://doi.org/10.1002/qre.2752