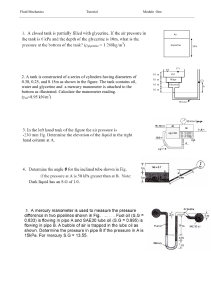

Nama: Group: Mixing vessels are used in many chemical processes. Often these mixing vessels are heated, either by a coil or a jacket surrounding the vessel. For example, a mixing vessel may serve as a chemical reactor, where two or more components are reacted to produce one or more products. Often this reaction must occur at a certain temperature to achieve a desired yield. The temperature in the vessel is maintained by varying the flowrate of a fluid through the jacket or coil. Consider a stirred tank heater as shown in Figure 1, where the tank inlet stream is received from another process unit. The objective is to raise the temperature of the outlet stream to a desired value. A heat transfer fluid is circulated through a jacket to heat the fluid in the tank. In some processes steam is used as the heat transfer fluid and most of the energy transported is due to the phase change of steam to water. In other processes a heat transfer fluid is used where there is no phase change. In this module we assume that no change of phase occurs in either the tank fluid or the jacket fluid. 1) State all the assumptions 2) Develop the dynamic models for the tank and jacket temperatures. 3) What happen to the development of energy balance when the thermal capacitances of the steam and the heating coil wall are negligible compared to the thermal capacitance of the liquid in the tank? The notations used are