Uploaded by

Martin Piskulov

TRNSYS 18 Mathematical Reference: Simulation Software Components

advertisement

TRNSYS 18

a TRaNsient SYstem Simulation program

Volume 4

Mathematical Reference

Solar Energy Laboratory, Univ. of Wisconsin-Madison

http://sel.me.wisc.edu/trnsys

TRANSSOLAR Energietechnik GmbH

http://www.trnsys.de

CSTB – Centre Scientifique et Technique du Bâtiment

http://software.cstb.fr

TESS – Thermal Energy Systems Specialists

http://www.tess-inc.com

TRNSYS 18 – Mathematical Reference

About This Manual

The information presented in this manual is intended to provide a detailed mathematical reference for the

Standard Component Library in TRNSYS 18. This manual is not intended to provide detailed reference

information about the TRNSYS simulation software and its utility programs. More details can be found in

other parts of the TRNSYS documentation set. The latest version of this manual is always available for

registered users on the TRNSYS website (see here below).

Revision history

2004-09

For TRNSYS 16.00.0000

2010-11

For TRNSYS 17.00.0019

2005-02

For TRNSYS 16.00.0037

2012-03

For TRNSYS 17.01.0000

2006-03

For TRNSYS 16.01.0000

2014-05

For TRNSYS 17.02.0000

2007-03

For TRNSYS 16.01.0003

2017-04

For TRNSYS 18.00.0000

2009-11

For TRNSYS 17.00.0006

2017-10

For TRNSYS 18.00.0015

2010-04

For TRNSYS 17.00.0013

2018-05

For TRNSYS 18.00.0018

2010-08

For TRNSYS 17.00.0018

2018-10

For TRNSYS 18.01.0000

Where to find more information

Further information about the program and its availability can be obtained from the TRNSYS website

or from the TRNSYS coordinator at the Solar Energy Lab:

TRNSYS Coordinator

Thermal Energy System Specialists, LLC

3 North Pinckney Street – suite 202

Madison, WI 53703 – U.S.A.

Email: TechSupport@tess-inc.com

TRNSYS website: http://sel.me.wisc.edu/trnsys

Notice

This report was prepared as an account of work partially sponsored by the United States Government.

Neither the United States or the United States Department of Energy, nor any of their employees, nor any

of their contractors, subcontractors, or employees, including but not limited to the University of Wisconsin

Solar Energy Laboratory, makes any warranty, expressed or implied, or assumes any liability or

responsibility for the accuracy, completeness or usefulness of any information, apparatus, product or

process disclosed, or represents that its use would not infringe privately owned rights.

© 2018 by the Solar Energy Laboratory, University of Wisconsin-Madison and Thermal Energy

System Specialists, LLC

The software described in this document is furnished under a license agreement. This manual and the

software may be used or copied only under the terms of the license agreement. Except as permitted by any

such license, no part of this manual may be copied or reproduced in any form or by any means without prior

written consent from the Solar Energy Laboratory, University of Wisconsin-Madison or Thermal Energy

System Specialists, LLC

4–2

TRNSYS 18 – Mathematical Reference

TRNSYS Contributors

S.A. Klein

W.A. Beckman

J.W. Mitchell

J.A. Duffie

N.A. Duffie

T.L. Freeman

J.C. Mitchell

J.E. Braun

B.L. Evans

J.P. Kummer

R.E. Urban

A. Fiksel

J.W. Thornton

N.J. Blair

P.M. Williams

D.E. Bradley

T.P. McDowell

M. Kummert

D.A. Arias

M.J. Duffy

A.M. Weiss

Additional contributors who developed components that have been included in the Standard Library are

listed in their respective section.

Contributors to the building model (Type 56) and its interface (TRNBuild) are listed in Volume 5.

Contributors to the TRNSYS Simulation Studio are listed in Volume 2.

4–3

TRNSYS 18 – Mathematical Reference

TABLE OF CONTENTS

4. M ATHEMATICAL REFERENCE

4–8

4.1. Controllers

4–9

4.1.1. Type 2: Differential Controller

4–10

4.1.2. Type 22: Iterative Feedback Controller

4–13

4.1.3. Type 23: PID Controller

4–17

4.1.4. Type 40: Microprocessor Controller

4–23

4.1.5. Type 82: Simple Thermostat

4–29

4.1.6. Type 85: Simple Humidistat

4–31

4.1.7. Type 104: Simple Dehumidistat

4–33

4.1.8. Type 106: Aquastat (Heating Applications)

4–35

4.1.9. Type 108: Five Stage Room Thermostat

4–37

4.1.10. Type 113: Aquastat (Cooling Applications)

4–41

4.1.11. Type 115: Tempering Valve (Prevents Overheating)

4–43

4.1.12. Type 116: Tempering Valve (Prevents Undercooling)

4–45

4.1.13. Type 150: Delayed Inputs

4–47

4.1.14. Type 165: Differential Controller

4–49

4.2. Electrical

4–52

4.2.1. Type 47: Simple Lead Acid Battery

4–53

4.2.2. Type 48: PV Charge Controller/Inverter

4–60

4.2.3. Type 90: Wind Turbine

4–67

4.2.4. Type 102: Internal Combustion Engine / Generator Set Controller

4–84

4.2.5. Type 103: Simple Photovoltaic

4–87

4.2.6. Type 105: MiniGrid Controller

4–96

4.2.7. Type 120: Internal Combustion Engine / Generator

4–100

4.2.8. Type 175: Power Conditioning

4–105

4.2.9. Type 185: Advanced Lead Acid Battery with Gassing Effects

4–109

4.2.10. Type 188: AC Busbar (MiniGrid Energy Balance)

4–116

4.2.11. Type 190: Advanced Photovoltaic

4–119

4.3. HVAC

4–133

4.3.1. Type 42: Generic Conditioning Equipment

4–134

4.3.2. Type 43: Generic PLR Curve

4–138

4.3.3. Type 52: Detailed Cooling Coil

4–141

4.3.4. Type 107: Singe-Effect Hot-Water Fired Absorption Chiller

4–149

4.3.5. Type 117: Air Heater

4–157

4.3.6. Type 118: Air Cooled Chiller

4–160

4.3.7. Type 119: Air-to-Air Heat Pump

4–165

4.3.8. Type 122: Boiler

4–176

4.3.9. Type 123: Chilled Water Coil (Wet or Dry)

4–180

4.3.10. Type 124: Chilled Water Coil (Partially Wet)

4–187

4–4

TRNSYS 18 – Mathematical Reference

4.3.11. Type 126: Basic Cooling Tower (Single Speed, Control Signal)

4–192

4.3.12. Type 128: Cooling Tower (Two Speed, External Control)

4–195

4.3.13. Type 129: Cooling Tower (Two Speed, Internal Controls)

4–198

4.3.14. Type 136: Direct Expansion Coil

4–201

4.3.15. Type 137: Fan Coil

4–207

4.3.16. Type 138: Fluid Heater

4–215

4.3.17. Type 139: Furnace

4–217

4.3.18. Type 140: Hot Water Coil (constant UA)

4–220

4.3.19. Type 141: Hot Water Coil (varying UA)

4–223

4.3.20. Type 142: Water Cooled Chiller

4–227

4.3.21. Type 143: Water-to-Air Heat Pump

4–232

4.3.22. Type 144: Packaged Terminal Air Condition/Split System Air Conditioner

4–240

4.3.23. Type 151: Variable Air Volume (VAV) Air Handler

4–245

4.3.24. Type 152: Variable Air Volume (VAV) Air Handler with Parallel Fan Powered (PFP) Boxes4–257

4.3.25. Type 161: Cooling Tower (Single Speed, Internal Control)

4–269

4.3.26. Type 162: Detailed Cooling Tower (Variable speed, Internal or External Control)

4–272

4.4. Hydrogen

4–281

4.4.1. Type 100: Electrolyzer Controls

4–282

4.4.2. Type 160: Alkaline Electrolyzer

4–285

4.4.3. Type 164: Compressed Gas Storage

4–294

4.4.4. Type 167: Gas Compressor

4–297

4.4.5. Type 170: Proton Exchange Membrane (PEM) Fuel Cell

4–300

4.4.6. Type 173: Alkaline Fuel Cell

4–312

4.5. Hydronics

4–316

4.5.1. Type 5: Heat Exchanger

4–317

4.5.2. Type 11: Tee Piece, Flow Diverter, Flow Mixer, Tempering Valve

4–322

4.5.3. Type 31: Pipe

4–329

4.5.4. Type 91: Effectiveness Heat Exchanger

4–333

4.5.5. Type 110: Variable Speed Pump

4–337

4.5.6. Type 114: Constant Speed Pump

4–341

4.5.7. Type 145: Air Duct

4–345

4.5.8. Type 146: Single-Speed Fan

4–349

4.5.9. Type 147: Variable-Speed Fan

4–352

4.5.10. Type 148: Air Flow Diverter/Mixer

4–356

4.6. Loads and Structures

4–359

4.6.1. Type 19: Detailed Single Zone (Transfer Function)

4–360

4.6.2. Type 34: Overhang and Wingwall Shading

4–372

4.6.3. Type 36: Glazed Trombe (Thermal Storage) Wall

4–379

4.6.4. Type 49: Slab on Grade

4–389

4.6.5. Type 56: Detailed Multizone Building (Transfer Function)

4–401

4.6.6. Type 75: Sherman Grimsrud Simple Infiltration

4–402

4–5

TRNSYS 18 – Mathematical Reference

4.6.7. Type 88: Single Zone (Lumped Capacitance)

4–406

4.6.8. Type 149: National Institute of Standards and Technology (NIST) Simple Infiltration

4–410

4.6.9. Type 168: Simple Natural Ventilation Model

4–412

4.7. Output

4–417

4.7.1. Type 25: Output Printer

4–418

4.7.2. Type 28: Simulation Summary

4–421

4.7.3. Type 46: Printegrator (Combined Integrator and Printer)

4–426

4.7.4. Type 65: Online Plotter

4–429

4.7.5. Type 76: Scopes

4–434

4.7.6. Type 125: Trnsys3D Result Visualizer for SketchUp™

4–436

4.8. Physical Phenomena

4–441

4.8.1. Type 16: Solar Radiation Processing

4–442

4.8.2. Type 30: Thermal Solar Collector Array Shading

4–446

4.8.3. Type 33: Thermodynamic Properties of Wet Air (Psychrometrics)

4–453

4.8.4. Type 54: Weather Data Generator

4–456

4.8.5. Type 58: Thermodynamic Properties of Refrigerants (including steam)

4–463

4.8.6. Type 59: General Lumped Capacitance

4–466

4.8.7. Type 64: Simple Horizon Shading Mask

4–469

4.8.8. Type 67: Detailed Horizon Shading Mask

4–473

4.8.9. Type 69: Sky Temperature

4–481

4.8.10. Type 77: Simple Ground Temperature Model

4–484

4.8.11. Type 80: Convection Coefficient Calculator

4–488

4.9. Solar (Thermal)

4–492

4.9.1. Type 1: Flat Plate Collector, Quadratic Efficiency Performance Model

4–493

4.9.2. Type 45: Thermosyphon Collector with Integral Collector Storage

4–503

4.9.3. Type 50: Photovoltaic-Thermal Collector

4–515

4.9.4. Type 71: Evacuated Tube Solar Collector

4–525

4.9.5. Type 72: Performance Map Solar Collector

4–533

4.9.6. Type 73: Theoretical Flat-Plate Collector

4–541

4.9.7. Type 74: Compound Parabolic Concentrating Collector

4–546

4.10. Storage (Thermal)

4–555

4.10.1. Type 10: Gravel Bed Thermal Storage

4–556

4.10.2. Type 38: Plug Flow Vertical Cylindrical Storage Tank

4–562

4.10.3. Type 39: Variable Volume Liquid Storage

4–570

4.10.4. Type 153: Gas Water Heater with Integrated Controls

4–575

4.10.5. Type 154: Dual-Element Electric Water Heater with Integrated Controls

4–584

4.10.6. Type 156: Constant Volume Liquid Storage Tank with Immersed Heat Exchanger

4–594

4.10.7. Type 158: Constant Volume Liquid Storage Tank (no Heat Exchanger)

4–607

4.11. Utility

4–615

4.11.1. Type 9: Data Reader (Generic Data Files)

4–616

4.11.2. Type 14: Time Dependent Forcing Functions

4–626

4–6

TRNSYS 18 – Mathematical Reference

4.11.3. Type 21: Time Values

4–628

4.11.4. Type 24: Quantity Integrator

4–629

4.11.5. Type 41: Forcing Function Sequencer

4–631

4.11.6. Type 42: Linear Interpolation

4–634

4.11.7. Type 55: Periodic Integrator and Statistics

4–638

4.11.8. Type 57: Unit Conversion

4–643

4.11.9. Type 62: Calling External Programs: Excel™

4–649

4.11.10. Type 66: Calling External Programs: Engineering Equation Solver (EES)

4–651

4.11.11. Type 82: Pacemaker (Simulation Speed Control)

4–656

4.11.12. Type 83: Differentiation

4–657

4.11.13. Type 84: Moving Average

4–658

4.11.14. Type 95: Holiday Calculator

4–659

4.11.15. Type 96: Utility Bill Generator

4–663

4.11.16. Type 97: Calling External Programs: CONTAM

4–671

4.11.17. Type 98: Calling External Programs: CONTAM-W

4–674

4.11.18. Type127: Floating Mean Temperature Based On EN 15251:2007

4–675

4.11.19. Type 130: Calling External Programs: ESP-r

4–677

4.11.20. Type 155: Calling External Programs: Matlab™

4–678

4.11.21. Type 159: Calling External Programs: MATHIS

4–684

4.11.22. Type 163: Calling External Programs: Python – using I/O files

4–685

4.11.23. Type 169: Calling External Programs: Python – direct calling Python

4–687

4.12. Weather

4–689

4.12.1. Type 15: Standard File Format Weather Data Processor

4–690

4.12.2. Type 99: User-Defined File Format Data Reader / Processor

4–699

4–7

TRNSYS 18 – Mathematical Reference

4. MATHEMATICAL REFERENCE

This manual provides a detailed reference on each component model (Type) in TRNSYS. The information

includes the mathematical basis of the model, as well as other elements that the user should take into

consideration when using the model (e.g. data file format, etc.).

This guide is organized in 14 component categories that match the upper level directories in the Simulation

Studio proformas. Those categories are:

Controllers

Electrical

Heat Exchangers

HVAC

Hydrogen Systems

Hydronics

Loads and Structures

Obsolete

Output

Physical Phenomena

Solar Thermal Collectors

Thermal Storage

Utility

Weather Data Reading and Processing

Within the categories, components are organized according to the models implemented in each component.

This is different from the Simulation Studio structure, where components are first organized according to

the function they perform, then according to the operation modes. An example is the mathematical model

known as Type 1 (Solar Collector), which is the first component in the "Solar Thermal collectors" category

in this manual. Type 1 is the underlying model for 5 different proformas listed in the "Solar Thermal

Collectors\Quadratic Efficiency" category in the Simulation Studio. It is very frequent for one Type listed in

this manual to be associated with several proformas which correspond to different modes of operation for

the component.

Users looking for information on which components are included in those categories or which component

to use have two sources of information:

Each section starts with a short introduction that briefly explains the features of all components in that

category

Volume 03 of the documentation (Standard Component Library Overview) also has a list of available

components (based on the Studio's organization)

4–8

TRNSYS 18 – Mathematical Reference

4.1. Controllers

Controller Basics

Number of Oscillations permitted and controller stickiness:

When the difference between the setpoint and the monitored temperature nears the dead band in the

normal mode of operation, the control signal may sometimes oscillate between ON and OFF for successive

iterations at a given time step. This happens because the setpoint and the monitored temperature change

slightly at each iteration, alternately satisfying and not satisfying the conditions for switching the controller.

The value of parameter 1 in this model is the number of oscillations of the control signal that are permitted

in the time step before the component “sticks” the output signal at one value so that the calculations at this

time step may be solved. It is recommended that the value of this first parameter be set to an odd number

to avoid biasing short-term results.

Dead band:

Controllers do not typically make the on/off decisions directly at the setpoint. Instead they make them for

a specified difference above and below the setpoint. For instance, a controller will turn heating on when

the temperature gets below the setpoint temperature minus half the dead band temperature difference and

turn of heating once the temperature has risen to the setpoint plus half the dead band temperature. This

prevents the equipment from cycling on and off quickly.

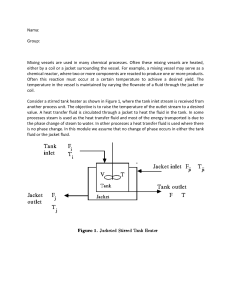

Figure 4.1.1–1: Dead band example for a heating thermostat

4–9

TRNSYS 18 – Mathematical Reference

4.1.1.

Type 2: Differential Controller

This controller generates a control function 𝛾0 that can have a value of 0 or 1. The value of𝛾0 is chosen as

a function of the difference between upper and lower temperatures (𝑇𝐻 and 𝑇𝐿 ) compared with two dead

band temperature differences (∆𝑇𝐻 and ∆𝑇𝐿 ). The new value of 𝛾0 is dependent on whether the input control

signal is on or off (𝛾𝑖 = 0 or 1). The controller is normally used with the output control signal (𝛾0 )connected

to to the inlet control signal (𝛾𝑖 ) giving a hysteresis effect. A high limit cut-out is included with the Type 2

controller. Regardless of the dead band conditions, the control function will be set to zero if the high limit

condition is exceeded. Note that this controller is not restricted to sensing temperatures, even though

temperature notation is used throughout the documentation.

4.1.1.2.

Parameter/Input/Output Reference

PARAMETERS

1

Number of Oscillations

[-]

The number of control oscillations allowed in one timestep

before the controller is "stuck" so that the calculations can be

solved. This parameter should be set to an odd number so that

short-term results are not biased. NOTE: Setting the number of

oscillations to 0 to use solver 1 (Powell's method).

2

High Limit Cut-Out

[C]

The controller will set the controller to the OFF position,

regardless of the dead bands, if the temperature being

monitored exceeds the high limit cut-out. The controller will

remain OFF until the monitored temperature falls below the high

limit cut-out temperature.

INPUTS

1

Upper Input

Temperature

[delta C]

The temperature difference that will be compared to the dead

bands is this input (𝑇𝐻 ) minus input 2 (𝑇𝐿 ).

2

Lower Input

Temperature

[delta C]

The temperature difference that will be compared to the dead

bands is input 1 (𝑇𝐻 ) minus this input (𝑇𝐿 ).

3

Monitoring

Temperature

[C]

Temperature to monitor for high-limit cut-out checking. The

controller signal will be set to OFF if this input exceeds the high

limit cut-out temperature. The controller will remain OFF until

this input falls below the high limit cut-out.

4

Input Control Function

[-]

The input control function is used to promote controller stability

by the use of hysteresis. The control decision will be based on

the dead band conditions and this input controller state. In most

applications, the output control signal from this component is

hooked up to this input.

5

Upper Dead Band

[delta C]

The dead band used when the controller is in the ON state.

6

Lower Dead Band

[delta C]

The dead band used when the controller is in the OFF state.

[-]

The output control function may be ON (=1) or OFF (=0).

OUTPUTS

1

Output Control

Function

4–10

TRNSYS 18 – Mathematical Reference

4.1.1.3.

Simulation Summary Report Contents

TEXT FIELDS

Control

[-]

States whether the Successive Substitution or Powell’s Method mode is

used.

MINIMUM/MAXIMUM VALUE FIELDS

Upper Input Value

[-]

The minimum and maximum of input 1

Lower Input Value

[-]

The minimum and maximum of input 2

Upper Dead Band

[-]

The minimum and maximum of input 5

Lower Dead Band

[-]

The minimum and maximum of input 6

4.1.1.4.

Hints and Tips

With the default TRNSYS solver (SOLVER 0, successive substitution), when (𝑇𝐻 − 𝑇𝐿 ) nears the upper or

lower dead band, 𝛾0 may sometimes oscillate between 1 and 0 for successive iterations at a given time

step. This happens because 𝑇𝐻 and 𝑇𝐿 change slightly during each iteration, alternately satisfying and not

satisfying the conditions for switching the controller. The value of the first parameter (Number of

Oscillations) is the number of oscillations permitted within a time step before the control function (𝛾0 ) ceases

to change. In general, it is recommended that the number of oscillations be set to an odd number, typically

five, in order to encourage the controller to come to rest at a state different than at the previous time step.

{The Powell’s Method control strategy is more robust in certain situations than successive substitution,

solving the system of equations by not permitting the control variable to change during the iteration process.

Upon convergence, the controller state is compared to the desired controller state at the converged solution

and the calculations repeated if necessary. The use of Powell’s Method requires other changes to the

simulation and the documentation should be read for more information. It is important to note that if you

use the Powell’s Method control strategy, you must also use SOLVER 1 in your system. – NOTE – for

version 18 the Powell’s Method (SOLVER 1) has been deactivated. If you wish to make use of this solver

please contact your TRNSYS distributor.}

For most simulations, use of the two control strategies will yield similar results. However, in short term

simulations with unstable control behavior, the Successive Substitution (SOLVER 0) control strategy with

an odd value of Number of Oscillations may yield quite different results from the Powell’s Method control

strategy.

An example set-up for Type 2: If you have a SDHW system and want to control the collector loop pump to

be on when the temperature of the fluid leaving the collector is 10 degrees C higher than the fluid coming

from the tank to the collector, turn off when the temperature of the fluid leaving the collector is less than 2

degrees C below the fluid coming from the tank to the collector, and turn off if the fluid supplying the hot

water is higher than 90 degrees C; the Upper Dead band should be 10 degrees C, the Lower Dead band

should be 2 degrees C, the upper input temperature should be the collector outlet temperature, the lower

input temperature should be the temperature at the tank outlet connected to the collector, the high-limit

cutoff should be 90 and the monitoring temperature should be the tank outlet connected to the hot water

system.

4.1.1.5.

Nomenclature

∆𝑇𝐻

[C]

upper dead band temperature difference

∆𝑇𝐿

[C]

lower dead band temperature difference

4–11

TRNSYS 18 – Mathematical Reference

𝑇𝐻

[C]

upper Input temperature

𝑇𝑖𝑛

[C]

temperature for high limit monitoring

𝑇𝐿

[C]

lower Input temperature

𝑇𝑚𝑎𝑥

[C]

maximum Input temperature

𝛾𝑖

[0..1]

input control function

𝛾0

[0..1]

output control function

4.1.1.6.

Detailed Description

Mathematically, the control function is expressed as follows:

If the controller was previously ON (𝛾𝑖 = 1):

𝑖𝑓 Δ𝑇𝐿 ≤ (𝑇𝐻 − 𝑇𝐿 ) then 𝛾0 = 1

Eq. 4.1.1-1

𝑖𝑓 Δ𝑇𝐿 > (𝑇𝐻 − 𝑇𝐿 ) then 𝛾0 = 0

Eq. 4.1.1-2

If the controller was previously OFF (𝛾𝑖 = 0):

𝑖𝑓 Δ𝑇𝐻 ≤ (𝑇𝐻 − 𝑇𝐿 ) then 𝛾0 = 1

Eq. 4.1.1-3

𝑖𝑓 Δ𝑇𝐻 > (𝑇𝐻 − 𝑇𝐿 ) then 𝛾0 = 0

Eq. 4.1.1-4

However, the control function is set to zero, regardless of the upper and lower dead band conditions, if

𝑇𝑖𝑛 > 𝑇𝑚𝑎𝑥 . This situation is often encountered in domestic hot water systems where the pump is not

allowed to run if the tank temperature is above some prescribed limit.

The controller function is shown graphically as follows.

=1

i

1

o

=0

i

0

L

(TH - T L )

H

Figure 4.1.1–1: Controller Function

4–12

TRNSYS 18 – Mathematical Reference

4.1.2.

Type 22: Iterative Feedback Controller

The iterative feedback controller calculates the control signal (u) required to maintain the controlled variable

(y) at the setpoint (ySet). It uses TRNSYS iterations to provide accurate setpoint tracking. This controller can

be used to model a real feedback controller (e.g. PID) that would adapt its control signal continuously or

using a discrete timestep much shorter than the TRNSYS simulation timestep. The controller has an

ON/OFF signal and bounds can be fixed for the control signal.

4.1.2.1.

Parameter/Input/Output Reference

PARAMETERS

1

Mode

[-]

Controller mode (not used)

2

Number of Oscillations

Permitted

[-]

The number of oscillations of the controller state allowed in one

timestep before the output will be fixed and the solution found.

Set to an odd number to allow the controller to bounce between

two control states for successive timesteps. (See Control Basics

for a more complete discussion of controller oscillations.)

INPUTS

1

Setpoint

[-]

ySet is the setpoint for the controlled variable. The controller will

calculate the control signal that zeroes (or minimizes) the

tracking error (e = y-ySet).

2

Controlled Variable

[-]

y is the controlled variable that will track the setpoint (ySet).

3

On/Off Signal

[-]

The control signal is always zero if the On/Off Signal = 0.

4

Minimum Control

Signal

[-]

Minimum value of the control signal. The controller will minimize

the tracking error for uMin <= u <= uMax. uMin and uMax can be

variable but you should always ensure that some values of u are

acceptable. In other words, do not set uMin > uMax to switch the

controller Off. You can use the On/Off input for that purpose.

uMin and uMax are used in the numerical algorithm and using

realistic values rather than arbitrarily large numbers will improve

the controller stability and speed.

5

Maximum Control

Signal

[-]

Maximum value of the control signal. The controller will minimize

the tracking error for uMin <= u <= uMax. uMin and uMax can be

variable but you should always ensure that some values of u are

acceptable. In other words, do not set uMin > uMax to switch the

controller Off. You can use the On/Off input for that purpose.

uMin and uMax are used in the numerical algorithm and using

realistic values rather than arbitrarily large numbers will improve

the controller stability and speed.

6

Threshold for NonZero Output

[-]

This is the minimum control signal (absolute value) for which a

non-zero output will be set. It is different from uMin. Control

values lower than uThreshold in absolute value will be zeroed.

This can be used for example to model a pump that has a

minimum operating flowrate: in that case uThreshold should be

set to the minimum flowrate and uMin should be set to 0.

Another example is a control signal where uMin = -100, uMax =

100 and uThreshold = 10. This means that values between -100

4–13

TRNSYS 18 – Mathematical Reference

and 100 are acceptable but outputs lower than 10 in absolute

value will be set to zero.

7

Tolerance on Tracking

Error

[-]

The controller will stick to its current value (i.e. not attempt to

further reduce the tracking error) if the tracking error is within this

tolerance. Positive numbers are interpreted as a relative

tolerance on y, negative numbers are interpreted as an absolute

tolerance. 0 is acceptable.

OUTPUTS

1

Control Signal

[-]

This is the controller output

2

Tracking Error

[-]

Tracking error (ySet-y).

3

Controller Status

[-]

Controller status. 0 means the controller is OFF. The following

values are added to status to indicate the controller status: 1 if

the controller is ON, 2 if the control signal is set to 0 because of

the threshold value, 4 if it is constrained by the minimum value,

8 if it is constrained by the maximum value, 16 if it is stuck to its

previous value, 32 if the tracking error is within the tolerance,

and 64 if the slope of the (control signal, tracking error) curve is

too steep and steps are cut in order to promote numerical

convergence. All flags are summed so that the status for "ON, at

the maximum value and within tolerance" is 1+8+32=41.

4

Unsaturated Control

Signal

[-]

Unsaturated control signal: calculated value before taking the

minimum and maximum boundaries into account. This output is

mostly used for debugging purposes, the control signal (u) that

should be connected to the controlled system is output 1.

4.1.2.2.

Simulation Summary Report Contents

MINIMUM/MAXIMUM VALUE FIELDS

Controller Setpoint

[-]

Minimum and maximum of Input 1

Tracking Error

[-]

Minimum and maximum of Output 2

4.1.2.3.

Hints and Tips

Type 22 uses TRNSYS iterations to adjust the control signal. Its performance may be affected by different

factors:

Time step: Type 22 "solves" the control problem by attempting to zero the tracking error. It has no

knowledge at all about the process dynamics, which may lead to oscillations. Changing the timestep

will have a strong influence on those oscillations. If you notice an "On-Off" behavior with poor setpoint

tracking, you can try to adjust the simulation timestep.

Order of components in the Input file: it is recommended to start with the controller before the

component(s) it controls and to keep components in a logical order. This will minimize the risk that

TRNSYS "skips" timesteps because the simulation appears to be converging. You can usually facilitate

convergence and minimize simulation time by grouping all the controlled components and place them

just after the controller. Please note that this is not an absolute rule and that we recommend that you

experiment with different component sequences, especially if the controller appears to be

unresponsive.

4–14

TRNSYS 18 – Mathematical Reference

Simulation tolerances: often, small variations in a control signal have a very small effect on a controlled

system, but users are expecting the controlled variable to follow the setpoint accurately. It is

recommended to use stricter tolerances than the usual default values in simulations that make use of

Type 22. Reducing tolerances usually minimizes the impact of component order.

TRNSYS solver: when using Solver 0 (successive substitution) with numerical relaxation, the

convergence promotion algorithm may interact with the oscillations caused by Type 22. It is

recommended to use Solver 0 without numerical relaxation (i.e. with a minimum and maximum

relaxation factors equal to 1) with Type 22.

Equation Solver: EQSolver 1 and above have been designed to speed up simulations by removing

unnecessary calls to equations. If equations are used in an information loop that includes an iterative

controller, those equations should always be called as soon as their Inputs have changed (as normal

components are). This is the solving mode used by EQSolver 0 (the default), and Type 22 should be

used with that equation solver

The factors discussed here above are the most likely causes of "unresponsive" iterative controllers.

4.1.2.4.

Nomenclature

ySet

[any]

Setpoint for the controlled variable

y

[any]

Controlled variable that tracks the setpoint

u

[any]

Control signal (controller's output)

umin

[any]

Minimum value of the control signal

umax

[any]

Maximum value of the control signal

uthreshold

[any]

Threshold value for non-zero output (see text)

tol

[any]

Tolerance on tracking error

e

[any]

Tracking error

4.1.2.5.

Detailed Description

The iterative feedback controller uses a secant method to calculate the control signal that zeroes (or

minimizes) the tracking error e (e = ySet-y). The principle of operation is as follows:

At the first 2 iterations in a timestep, the controller outputs a control signal that is selected in order to

provide a suitable starting point for the secant method search. The value used is different from the

value at the previous call in order to prevent TRNSYS from considering that the simulation has

converged, but not too far from that previous value in order to keep the system in a stable state.

The controller stores the values of u it outputs and records the values of e that are measured when

that control signal is applied. The controller operation can be interpreted in a (u,e) plane, where the

solution is the value of u that zeroes e. Once the two initial points are obtained, the controller uses a

secant method to search for the solution

The secant method is best described by an example (see Figure 4.1.2–1). The system's trajectory in the

(u,e) plane is the gray dotted line. The controller first outputs a control signal u 1. The system is then

simulated using that value, which gives point 1. The controller then outputs signal u2, which is chosen to be

different but not too far apart from u1. The system now outputs an error signal (e) that corresponds to point

2. The controller extrapolates the line between points 1 and 2 and calculates the u value that zeroes e. In

this example, this value is outside the allowed range, so umin is used. This gives point 3. A linear interpolation

between points 2 and 3 gives point 4. Points 5 and 6 are obtained in a similar way and the controller stops

iterating when the tolerance (tol) is reached or when TRNSYS stops iterating because the variation in the

controller's output is within the global tolerances.

4–15

TRNSYS 18 – Mathematical Reference

1

e

2

4

umin

umax

u3

5

6

u6 u5

u4

u2

u1

u

3

Figure 4.1.2–1: Secant method used in Type 22

The controller will also stop iterating when the number of iterations at a given timestep reaches the

maximum set by the number of oscillations parameter. If you set this parameter to 0, the controller will stick

a few iterations before the maximum number of iterations set in the general simulation parameters, so

TRNSYS gets a chance to converge at the current timestep.

CONSTRAINTS ON THE CONTROL SIGNAL

You can impose different constraints on the control signal:

umin

Minimum value (see Figure 4.1.2–1)

umax

Maximum value (see Figure 4.1.2–1)

uthreshold

Threshold value for non-zero output. This input tells the controller that all calculated

values that are less than uthreshold (in absolute value) should be forced to zero. It is

different from umin. This can be used for example to model a pump that has a minimum

operating flowrate: in that case uthreshold should be set to the minimum flowrate and umin

should be set to 0. Another example is a control signal where u min = -100, umax = 100

and uthreshold = 10. This means that values between -100 and 100 are acceptable but

outputs lower than 10 (in absolute value) will be set to zero.

4–16

TRNSYS 18 – Mathematical Reference

4.1.3.

Type 23: PID Controller

Type 23 implements a Proportional, Integral and Derivative (PID) controller. Type 23 calculates the control

signal required to maintain the controlled variable at the setpoint. This control signal is proportional to the

tracking error, as well as to the integral and the derivative of that tracking error. Type 23 implements a stateof-the-art discrete algorithm with anti-windup.

4.1.3.1.

Parameter/Input/Output Reference

PARAMETERS

1

Mode

[-]

Controller's operation mode. Mode 0 implements a "real-life" (i.e.

non-iterative) controller which performs its calculations after

"measuring" the system's outputs (i.e. after convergence in

TRNSYS) and maintains its outputs at a constant level until the

end of the next timestep. Mode 1 implements an iterative

controller that uses TRNSYS iterations to adjust its outputs.

Mode 1 will usually provide a faster response at the expense of

more iterations and the optimal parameters may be far from realworld values for a similar system. Mode 0 does not cause more

TRNSYS iterations but it may require that you reduce the time

step in order to obtain a satisfactory closed-loop response. Note

that Type 22 (Iterative feedback controller) offers an alternative

to mode 1 and is easier to configure).

2

Number of Oscillations

Permitted

[-]

The number of oscillations of the controller state allowed in one

timestep before the output will be fixed and the solution found.

Set to an odd number to allow the controller to bounce between

two control states for successive timesteps. (See Control Basics

for a more complete discussion of controller oscillations.)

INPUTS

1

Setpoint

[-]

ySet is the setpoint for the controlled variable. The controller will

calculate the control signal that zeroes (or minimizes) the

tracking error (e = ySet-y).

2

Controlled Variable

[-]

y is the controlled variable that will track the setpoint (ySet).

3

On/Off Signal

[-]

The control signal is always zero if On/Off = 0.

4

Minimum Control

Signal

[-]

The controller saturates the calculated control signal to have

uMin <= u <= uMax.

5

Maximum Control

Signal

[-]

The controller saturates the calculated control signal to have

uMin <= u <= uMax.

6

Threshold for NonZero Output

[-]

This is the minimum control signal (absolute value) for which a

non-zero output will be set. It is different from uMin. Control

values lower than uThreshold in absolute value will be zeroed.

For example, this can be used to model a pump that has a

minimum operating flowrate: in that case uThreshold should be

set to the minimum flowrate and uMin should be set to 0.

Another example is a control signal where uMin = -100, uMax =

100 and uThreshold = 10. This means that values between -100

and 100 are acceptable but values lower than 10 in absolute

value will be set to zero.

4–17

TRNSYS 18 – Mathematical Reference

7

Gain Constant

[-]

This is the gain of the PID controller (acts on the 3 parts of the

signal: proportional, integral and derivative).

8

Integral Time

[h]

This is Ti, the integral (or reset) time of the controller. You can

set Ti to 0 to disable integral control.

9

Derivative Time

[h]

This is Td, the derivative time of the controller. You can set Td to

0 to disable the derivative control.

10

Tracking Time for AntiWindup

[h]

The tracking (anti-windup) time constant is used to de-saturate

the integrator in case the control signal is saturated by the

minimum, maximum or threshold values. 0 means no antiwindup (not recommended) and -1 means "use default value" (Tt

= Ti). It is generally recommended to set Tt to 0.1 .. 1 Ti.

11

Fraction of ySet for

Proportional Effect

[-]

b is the fraction of ySet used in the proportional effect: vp = Kc *

(b*ySet-y). This parameter should be set between 0 and 1. Using

values less than 1 allows for smoother transitions in case of fast

setpoint changes but it will lead to a more sluggish response to

such a setpoint change.

12

Fraction of ySet for

Derivative Effect

[-]

g is the fraction of ySet used in the derivative effect, which is

proportional to the derivative of (g*ySet-y). This parameter

should be set to a value between 0 and 1. Using values less

than 1 allows for smoother transitions in case of fast setpoint

changes but it will lead to a more sluggish response to such a

setpoint change. Often in servo control g is 1 while in process

control g is 0.

13

High-Frequency Limit

of Derivative

[-]

N is the high-frequency limit of the derivative gain. The derivative

effect is basically multiplied by (Td/(Td+N delta_t)). N should be

a positive number. N is usually set in the range [3 ; 20]. The

default value is N=10.

OUTPUTS

1

Control Signal

[-]

This is the controller output.

2

Tracking Error

[-]

ySet-y

3

Unsaturated Control

Signal

[-]

Calculated value before taking the minimum, maximum and

threshold values into account. This output is mostly used for

debugging purposes, the control signal (u) that should be

connected to the controlled system is output 1.

4

Proportional Action

[-]

This is the part of the control signal that is proportional to the

tracking error (before saturation).

5

Integral Action

[-]

This is the part of the control signal that is proportional to the

integral of the tracking error (before saturation). Note that antiwindup has not been applied to this value.

6

Derivative Action

[-]

This is the part of the control signal that is proportional to the

derivative of the tracking error (before saturation).

7

Controller Status

[-]

0 means the controller is OFF. The following values are added to

status to indicate the controller status: 1 if the controller is ON, 2

if the control signal is set to 0 because of the threshold value, 4 if

4–18

TRNSYS 18 – Mathematical Reference

it is constrained by the minimum value, 8 if it is constrained by

the maximum value. All flags are summed so that the status for

"ON, at the maximum value" is 1+8=9.

4.1.3.2.

Simulation Summary Report Contents

MINIMUM/MAXIMUM VALUE FIELDS

Controller Setpoint

[-]

Minimum and maximum of Input 1

Tracking Error

[-]

Minimum and maximum of Output 2

4.1.3.3.

Hints and Tips

TYPE 23 MODES

The PID controller can operate in two Modes: Mode 0 implements a "real life" (non-iterative) controller, and

Mode 1 implements an iterative controller.

In Mode 0, Type 23 is only called after other TRNSYS components have converged. It then calculates the

control variable based on the converged outputs, which is applied at the next simulation timestep. This

mimics the behavior of a real-life controller which uses the measured outputs at one point in time and

calculates a control variable that is applied during the next timestep. Mode 0 typically requires short

timesteps (usually less than 1/10th of the dominant time constant in the system, although this is certainly

not an absolute rule).

Mode 1 uses TRNSYS iterations to correct the control signal. It may lead to a faster response without

requiring a short timestep, but it is less stable and will generate more TRNSYS iterations. Please also note

that Type 22 implements a generic feedback controller that is an alternative to Type 23 in Mode 1.

TIMESTEPS AND OTHER SETTINGS THAT MAY AFFECT TYPE 23'S PERFORMANCE

Type 23's performance depends on the simulation timestep. It is generally recommended to keep the

sampling time smaller than 10% of the dominant time constant of the process. Real-world controllers

typically use very short timesteps, which is not always practical in simulation studies. For that reason, it is

not always possible to transfer the optimal parameters of a PID to a real application. Using Type 23 in Mode

1 (iterative) can improve the performance for relatively long timesteps.

CHOOSING THE PID PARAMETERS

A discussion of PID parameters tuning is beyond the scope of this manual. The listed references are good

examples of information sources on that topic.

It should be noted that the usual timesteps used in TRNSYS simulations are typically much larger than the

sampling time of commercial digital controllers (which are usually in the order of 200 ms). It may still be

possible to achieve a satisfactory feedback control with a "typical" TRNSYS timestep, but this might require

some trial and error for parameter tuning. It is also likely that the optimal controller settings will be dependent

on the simulation timestep.

A final note on the transposition of parameter tuning to real-world controllers: even if your simulation uses

a very short timestep and if you use Mode 0, the tuned parameters may be different from the ones you

would need to use in a real controller applied to the simulated system. Optimal parameters depend on the

algorithm used in the PID, for which different implementations are available.

USING TYPE 23 IN HEATING ONLY, COOLING ONLY AND COMBINED HEATING AND COOLING

APPLICATIONS

4–19

TRNSYS 18 – Mathematical Reference

Unlike many of TRNSYS’s controller components, Type 23 may be used in heating, cooling, and combined

heating and cooling applications. Depending on the nature of the controlled variable (energy addition rate,

mass flow rate, fraction), it may be appropriate to set up the controller with a negative proportional gain for

cooling-only or combined heating and cooling applications. The examples here below illustrate a few typical

uses of Type 23 for heating and cooling. The reader is also invited to refer to the corresponding standard

examples (in Examples\Feedback Control).

Heating and/or cooling power (where heating power is positive, cooling power is negative)

When Type 23 is used to control the heating or cooling power that is provided to a room, a storage tank or

any other device, the control signal must have the same sign as the tracking error (difference between the

setpoint and the controlled variable): if the controlled temperature is below the setpoint, a positive power

must be applied and if the temperature is above the setpoint a negative power must be applied. In such

cases, users should select a positive gain constant for the PID controller and set the minimum and

maximum values to -(maximum cooling power) and +(maximum heating power) respectively.

Cooling power only (cooling power is positive)

If cooling only is required, the components or equations using the output of Type 23 might require positive

values for cooling power. In that case the power should increase when the tracking error (difference

between the setpoint and the controlled variable) decreases, i.e. more cooling should be provided when

the temperature rises above the setpoint. Users should then use a negative gain constant and set the

minimum and maximum control values to 0 and +(maximum heating power) respectively.

Heating flow rate

In this application, it is presupposed that a hot source is available and that heating is accomplished by

increasing the flow rate from this hot source. The control signal must increase when the tracking error

(setpoint – controlled temperature) increases, i.e. more heating should be provided when the temperature

is below the setpoint. Users should then use a positive gain constant and set the minimum and maximum

control values to 0 and (maximum flow rate) respectively.

Cooling flow rate

For this cooling application, it is presupposed that a cold source is available and that cooling is

accomplished by increasing the flow rate from this cold source. The control signal must increase when the

tracking error (setpoint – controlled temperature) decreases, i.e. more cooling should be provided when the

temperature is above the setpoint. Users should then use a negative gain constant and set the minimum

and maximum control values to 0 and (maximum flow rate) respectively.

4.1.3.4.

Nomenclature

ySet

[any]

Setpoint for the controlled variable

y

[any]

Controlled variable (tracks the setpoint)

u

[any]

Control variable (controller's output)

v

[any]

Unsaturated control variable (before applying constraints)

umin

[any]

Minimum value of the control variable

umax

[any]

Maximum value of the control variable

uthreshold

[any]

Threshold value for non-zero output (see text)

e

[any]

Tracking error

K

[any]

Controller gain

Ti

[h]

Integral time (also called reset time)

Td

[h]

Derivative time

4–20

TRNSYS 18 – Mathematical Reference

b

[any]

Setpoint weighting factor in Proportional action

c

[any]

Setpoint weighting factor in Derivative action

N

[-]

High frequency limit for derivative action

Tt

[h]

Tracking time for integrator desaturation (anti wind-up)

h

[h]

TRNSYS timestep

4.1.3.5.

Detailed Description

This section is a short description of the algorithm implemented in Type 23. The algorithm is presented in

(Aström and Wittenmark, 1990) and (Aström and Hägglund, 1994).

The "textbook" PID algorithm is:

𝑣(𝑡) = 𝐾 [𝑒(𝑡) +

1 𝑡

𝑑𝑒(𝑡)

∫ 𝑒(𝜏)𝑑𝜏 + 𝑇𝑑

]=𝑃+𝐼+𝐷

𝑇𝑖 𝑜

𝑑𝑡

Eq. 4.1.3-1

There are 3 terms in the equation which can easily be identified as the P-term (proportional to the error),

the I-term (proportional to the integral of the error) and the D-term (proportional to the derivative of the

error). This equatoin is sometimes referred to as the non-interacting PID algorithm, or series PID algorithm.

There are many forms of the PID algorithm, and the optimal settings are different for the

different algorithms. This should be kept in mind when transferring the parameters tuned

in a simulation into a real-life controller. More information on the different algorithms and

conversion factors between their parameters can be found in (Aström and Hägglund, 1994)

Several modifications have been made to the original algorithm in order to improve its performance and

operability:

SETPOINT WEIGHTING

It is sometimes advisable to replace the tracking error (e) with a more general expression in both the PTerm and the D-term:

𝑣(𝑡) = 𝐾 [𝑒𝑝 (𝑡) +

1 𝑡

𝑑𝑒𝑑 (𝑡)

∫ 𝑒(𝜏)𝑑𝜏 + 𝑇𝑑

]

𝑇𝑖 𝑜

𝑑𝑡

Eq. 4.1.3-2

where

𝑒𝑝 = 𝑏𝑦𝑠𝑒𝑡 − 𝑦 (0 ≤ 𝑏 ≤ 1)

Eq. 4.1.3-3

𝑒𝑑 = 𝑐𝑦𝑠𝑒𝑡 − 𝑦 (0 ≤ 𝑐 ≤ 1)

Eq. 4.1.3-4

Using b<1 reduces overshoot during fast setpoint changes and, in a similar way, using c<1 will avoid large

transients in the control variable due to sudden changes in the setpoint. In servo control (where the

controller is supposed to respond quickly to changes in setpoint) b and c are usually close or equal to 1. In

regulatory control (where one is more interested in responding to input variations to bring the system back

to a steady state), b and c are usually small (close or equal to 0).

LIMITATION OF THE DERIVATIVE GAIN

The derivative action may result is very large variation in the control variable and it is most often advisable

to limit the high frequency gain of the derivative term. This can be done by replacing the D-term with the

following:

𝐷 = 𝐾𝑇𝑑

𝑑𝑒𝑑 (𝑡) 𝑇𝑑 𝑑𝐷

−

𝑑𝑡

𝑁 𝑑𝑡

Eq. 4.1.3-5

This can be interpreted as the ideal derivative term, filtered by a first-order system with the time constant

Td/N. N is usually between 3 and 20, a value of 10 is usually a good compromise.

4–21

TRNSYS 18 – Mathematical Reference

INTEGRATOR WINDUP

Control variables are usually limited by an upper and a lower bound that represent physical actuator limits.

When the control variable reaches one of those limits, the feedback loop is broken because the actuator

will remain at its limit independently of the system's output. A controller with integrating action will continue

to integrate the error. In such a situation, the integral term may become very large (it "winds-up"). It is then

necessary that the tracking error has an opposite sign for a very long time before the controller returns to a

"normal" status.

Integrator wind-up can be prevented by back-calculating the integral value that would give a control variable

exactly at the saturation limit. It is also advantageous to reset the integrator towards that back-calculated

value not instantaneously but with a time constant (T t):

𝑣(𝑡) = 𝑃 + 𝐼 + 𝐷

𝑢(𝑡) = 𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑒(𝑣(𝑡))

1 𝑡

𝐼 = 𝐼 − ∫ (𝑢(𝜏) − 𝑣(𝜏)) 𝑑𝜏

𝑇𝑡 0

Eq. 4.1.3-6

Where the saturate() function applies minimum and maximum values and other constraints. It is generally

recommended to have Tt [0.1 Ti ; Ti].

DISCRETIZATION

The Proportional term is straightforward:

𝑃(𝑡𝑘 ) = 𝐾𝑒𝑝 (𝑡𝑘 ) = 𝐾(𝑏𝑦𝑠𝑒𝑡 (𝑡𝑘 ) − 𝑦(𝑡𝑘 ))

Eq. 4.1.3-7

The Integral term is calculated using the backward difference approximation, which is consistent with the

TRNSYS definition of variables (any variable reported at time t is the average between

tk-1 and tk):

𝐼(𝑡𝑘 ) = 𝐼(𝑡𝑘−1 ) +

𝐾ℎ

𝑒(𝑡𝑘 )

𝑇𝑖

Eq. 4.1.3-8

The Derivative term is approximated by a backwards difference:

𝐷(𝑡𝑘 ) =

𝑇𝑑

𝐾𝑇𝑑 𝑁

𝐷(𝑡𝑘−1 ) +

(𝑒 (𝑡 ) − 𝑒𝑑 (𝑡𝑘−1 ))

𝑇𝑑 + 𝑁ℎ

𝑇𝑑 + 𝑁ℎ 𝑑 𝑘

Eq. 4.1.3-9

Finally, anti-windup desaturation is applied after calculating the saturated control variable by correcting the

integral term as follows:

𝐼(𝑡𝑘 ) = 𝐼(𝑡𝑘 ) −

ℎ

(𝑢(𝑡𝑘 ) − 𝑣(𝑡𝑘 ))

𝑇𝑡

4.1.3.6.

Eq. 4.1.3-10

References

Aström, K.J. and Wittenmark, B. – Computer controlled Systems, 2nd Edition. Prentice Hall, Englewood

Cliffs, NJ – 1990. ISBN 0-13-168600-3

Aström, K.J. and Hägglund, T. – PID Controllers: Theory, Design and Tuning, 2nd Edition. International

Society for Measurement and Control – 1994. ISBN 1-55617-516-7

4–22

TRNSYS 18 – Mathematical Reference

4.1.4.

Type 40: Microprocessor Controller

The Microprocessor Controller component combines five differential comparators with a logic array to allow

simulation of certain types of programmed controllers.

4.1.4.1.

Parameter/Input/Output Reference

Type 40's flexibility results in a tremendous complexity in the cycles involving parameters.

For that reason, Type 40 is recommended for advanced users only.

PARAMETERS

The parameters used to describe the functions of the four internal parts of the controller are listed

separately. Since this component may use more than 200 parameters, care must be used in constructing

and documenting the parameter list used.

The first set of parameters, designated section A, relate to the number of comparators to be used and their

on and off dead bands. This section may contain from three to eleven parameters. This number is

represented in the following section by NPARS(A).

Parameter No.

Description

1

NCOMPS

number of comparators (up to 5)

2

TON

on dead band, comp. 1 (° C)

3

TOFF

off dead band, comp. 1 (° C)

i*2

TON

on dead band comp. i (° C)

i * 2+1

TOFF

off dead band, comp. i (° C)

The second section of the parameter list, section B, contains parameters which relate to the determination

of the controller mode. This section will contain parameters NC*2+2 through NMODES*NC+2NC+2. The

number of parameters contained in this section is NPARS(B). All parameters in this section with the

exception of the first, NMODES, must be either 0, 1 or -1.

Parameter No.

Description

NPARS(A)+1

NPARS(A)+2

NPARS(A)+3

NPARS(A)+(k-1)*NCOMPS+i+1

NMODES, number of controller modes

Status of comparator 1 when in mode 1

Status of comparator 2 when in mode 1

Status of comparator i when in mode k

The third section of the parameter list, designated Section C, relates to the specific output values set by a

particular mode. This section contains NPARS(C) parameters.

Parameter No.

Description

NPARS(A)+NPARS(B)+1

NPARS(A)+NPARS(B)+2

NPARS(A)+NPARS(B)+(k-l)*NOUTS+i+1

NOUTS, number of outputs (1 ≤ NOUTS ≤ 18)

Output 1 of controller when in mode 1

Output i of controller when in mode k

4–23

TRNSYS 18 – Mathematical Reference

The final section of the parameter list contains parameters which relate to overall controller operation.

These include the values of NSTICK, HOLD, and MODE PRINT. Note that there must be NMODES HOLD

parameters specified, one for each mode.

Parameter No.

Description

NPARS(A)+NPARS(B)+NPARS(C)+1

NSTICK, number of times controller mode may

change in one timestep

NPARS(A)+NPARS(B)+NPARS(C)+2

HOLD1, number of timesteps before next mode

change in mode 1

NPARS(A)+NPARS(B)+NPARS(C)+1+k

HOLDk, number of timesteps before next mode

change when in mode k

NPARS(A)+NPARS(B)+NPARS(C)

MODE PRINT, number of times in a timestep

+NMODES+k+2

mode may change before mode trace is printed

INPUTS

Input No.

Description

1

2

2*(i-1)+1

2*(i-1)+2

Comparator 1 high Input

Comparator 1 low Input

Comparator i high Input

Comparator i low Input

OUTPUTS

Output No.

Description

1

…

N

…

19

20

4.1.4.2.

Control function output 1

Control function output N

Controller status, 0=free, 1=stuck, 2=hold

Current mode

Simulation Summary Report Contents

A Simulation Summary Report is not implemented for this component.

4.1.4.3.

Hints and Tips

EXAMPLE

The system to be controlled is shown in Error! Reference source not found.. Three comparators are

equired: one to decide whether the pump in the collector-storage loop (I) should be on or off, one to

determine whether useful energy is available in the storage tank, and one to determine whether heating is

required by the house. Note: The example provided in with the TRNSYS Simulation Studio is more detailed

and differs slightly from this figure.

4–24

TRNSYS 18 – Mathematical Reference

T

COL

TTOP

TB OTTOM

Auxilar y

( III)

T ROOM

Colle c tor

Pump (I)

Load

Pump (II)

Figure 4.1.4–1: Type 40 – Example system

The three comparators are shown schematically in Error! Reference source not found.. Six INPUTS are

equired: two for each comparator. The first group of 7 PARAMETERS specifies that 3 comparators are to

be used and gives on and off dead bands for each comparator. The very first PARAMETER (Number of

Comparators) is set to 3, which will create six INPUTS (a high and low input for each comparator) and also

a total of six PARAMETERS are displayed for the ON and OFF dead bands for each comparator, which

are set in the example according to Error! Reference source not found.. During the simulation, the

emperature inputs are compared to these dead bands set by the user, and the result is a comparator output

status (γ) of either a 0 or 1 for each comparator.

TCOL

TBOTTOM

C o m p a r a to r

1

1

TTOP

T ON = 1 0

T OF F = 1

TROOM

C o m p a r a to r

2

TSET TROOM

T ON = 2

T OF F = 0

C o m p a r a to r

3

2

T ON = 1

T OF F = 2

3

Figure 4.1.4–2: Type 40 – Example comparators

For example: In reference to comparator 1 with on and off dead bands of 10 and 1 degrees respectively,

this means if the collector temperature becomes 10 degrees higher than the bottom of the tank, the

comparator will output γ1 = 1. The comparator will not turn back to γ1 = 0 until the collector temperature

reaches within 1 degree of the bottom of the tank.

Whatever the actual comparator output states are for each comparator are compared to the “Comparator

Output Status” PARAMETERS set by the user, which determines what mode the system is currently

operating in.

Three OUTPUTS are also required: one to control the pump in the collector storage loop (I), one to control

the pump in the storage-load loop (II), and one to control the auxiliary heater (III).

Note: The number of OUTPUTS is not related to the number of comparators, it is merely a coincidence that

the outputs and comparator numbers are the same for this example. They can be different or the same for

any given system.

The values of the OUTPUTS will depend on the values of the comparator output states (γ1, γ2, and γ3)

generated by the 3 comparators.

The table below gives the possible output states of the comparators and the corresponding Type 40

Controller OUTPUTS desired. The left half of the table specifies that 6 possible output states are of interest.

4–25

TRNSYS 18 – Mathematical Reference

The right half of the table indicates how the controller will respond when the system is in each particular

mode determined by the comparator outputs.

Comparator outputs

Type 40 outputs

NMODE

1

2

3

I

II

III

1

2

3

4

5

6

0

0

0

1

1

1

(0 or 1)1

0

1

(0 or 1)

0

1

0

1

1

0

1

1

0

0

0

1

1

1

0

0

1

0

0

1

0

1

0

0

1

0

For example: In mode 2, γ1 = 0 and γ2 = 0, this means the collector cannot contribute any more heat to the

tank, and the tank cannot deliver any useful heat to the zone’s setpoint. However, γ3 = 1, which means the

setpoint is higher than the zone temperature. Since the solar side of the system is useless, the zone will

need auxiliary heat, therefore when looking across to the right half of the table on the same row, only output

(III) is turned on. So the controller will keep the collector and load pump off, but will turn on the auxiliary

pump.

Another example: In mode 4, γ1, = 1. This means the collector can supply energy to the tank so the Type

40 output (I) is turned on. But since γ3 = 0, this means the setpoint temperature has been reached and the

tank and auxiliary heater should remain off. Therefore no matter if the tank can supply energy to the room

or not (it doesn’t matter), outputs (II) and (III) are both turned off. Since it doesn’t matter if the tank can

supply energy or not, γ2 can be (0 or 1). This is simply a shortcut instead of using two separate modes to

create the same Type 40 output. More is explained on this in the next “note”.

As you can see, there is never a time all Type 40 output (II) and (III) are on. This is because the system

always relies on solar energy when it can, so the auxiliary heater should never be supplying energy at the

same time the tank is.

Note: With 3 comparators, there can be a maximum of be 8 modes (8 different binary combinations).

However, in our example there are only 6 modes. This is because there are two instances in which γ2 can

be (0 or 1) and the Type 40 output is the same (meaning the system behaves the same way). Another way

of saying this, is that, (0 or 1) means that comparator output does not matter.

This is essentially a time saver and allows for less parameter entries and also allows for less mode changes

in the simulation. If incorporating this shortcut by using a (0 or 1) as shown in this table, a value of -1 is

used in TRNSYS for the comparator output PARAMETER.

A final group of parameters is used to set NSTK = 3. HOLD-k = 0 (for k = 1 through 6) and MODE PRINT

= 4 (diagnostic printing turned on after four iterations for a given time step).

The following lines would be used in the Type 40 component description.

PARAMETERS 53

3

6

3

1

10 1

0 -1 0

0 0 0

2 0

0 0 1

0 0 1

1 2

0 1 1

0 1 0

0 -1 0

1 0 0

1 0 1

1 0 1

1 1 1

1 1 0

(0 or 1) indicates that the value does not matter.

4–26

TRNSYS 18 – Mathematical Reference

4.1.4.4.

Nomenclature

NCOMPS

Number of comparators (1 < NCOMPS 5)

Ci

Output of comparator i

Ci-1

Output of comparator i on previous call to component number of controller

modes (1 < NMODE 12)

NMODES

Number of controller modes

NOUTS

Number of outputs of component (1 < NOUTS 18)

NPARS(A)

Number of parameters

(NPARS(A)=NC*2+1)

NPARS(B)

Number

of

parameters

(NPARS(B)=NMODES*NC+1)

used

to

describe

mode

array

NPARS(C)

Number

of

parameters

used

(NPARS(C)=NMODES*NOUTPUT+1)

to

describe

output

array

NSTK

Number of times mode may change in a time step before it is 'stuck' at its

current value.

HOLD

Number of time steps controller will remain in modeK before making next

control decision.

MODE PRINT

Number of times in a time step controller mode may change before diagnostic

mode trace is printed

4.1.4.5.

used

to

describe

comparator

functions

Detailed Description

The controller is logically divided into four parts. The first part is concerned with conversion of input

signals into binary logic levels and consists of up to five comparators. Each comparator incorporates

operational hysteresis based on user specified on and off dead bands. The state of comparator i at time t

is described by the following equation:

Ci ,t =

ON if (INhi-INlow) > Ton and Ci ,t-1 = OFF

OFF if (INhi-INlow) Toff and Ci ,t-1 = ON

Eq. 4.1.4-1

The output of this part of the component is a binary word NCOMPS bits long in which each bit corresponds

to a comparator state, 1 for on and 0 for off, with the least significant bit (LSB) corresponding to the first

comparator.

The second part of the controller is the mode array. This array consists of NCOMPS rows by NMODE

columns. Each element of the array may assume a value of 0, 1 or -1. The current operating mode is

determined by comparing the entries in each column with the word output by the comparator section. The

comparison is done on a bit-by-bit basis, with no comparison made if the mode array entry is -1.

The mode array output is a single decimal number indicating the column in the array which matches the

comparator output word. If no match is found, the output mode is set to -1. This is called the default mode

and results in all controller outputs being set to 0. At the end of the simulation a message is printed which

indicates the number of times the default mode occurred in the run.

The third part of the controller is the output array. This array consists of NOUTS rows by NMODES

columns. The number output by the mode array is used to point to a specific column of the output array.

The values contained in this column are transferred to the outputs of the controller, with the first value set

as the first output, the second value set as the second output, etc.

4–27

TRNSYS 18 – Mathematical Reference

The fourth part of this component is the control unit. This unit handles errors detected in other parts of the

component as well as implementing the NSTCK, HOLD, and MODE PRINT options described below.

CONTROLLER OPTIONS NSTCK, HOLD AND MODE PRINT

NSTCK

Since a TRNSYS simulation involves dead bands in time as well as in temperature, it is possible for a

system to experience instabilities that will result in a controller cycling between two or more different modes

continuously. To limit this type of cycling, a TRNSYS control component incorporates 'stickiness'. A sticky

controller is allowed to change state up to NSTK times in a given time step before its outputs are frozen in

the current state. A recommended value for NSTCK is 4 or 5 for most long-term simulations.

HOLD

This option is included to allow the simulation of time delays between control decisions. There are the

NMODES and HOLD parameters in the controller. The value of the HOLD parameter associated with a

particular mode specifies the number of timesteps that the controller will stay in that mode before another

control decision can be made.

MODE PRINT

This option allows the listing of successive controller modes in one time step after a specified number of

iterations have occurred. This is useful in situations where excessive controller cycling occurs. MODE

PRINT must be less than or equal to 40.

4.1.4.6.

1.

References

L.P. Piessens, "A Microprocessor Control

University of Wisconsin-Madison, 1980.

Component

for

TRNSYS",

M.S.

Thesis,

4–28

TRNSYS 18 – Mathematical Reference

4.1.5.

Type 82: Simple Thermostat

Type 82 models a basic thermostat that is similar to a thermostat that would be used in a residence. It

monitors a single temperature and returns a heating and cooling control signal depending on the monitored

temperature and the setpoints.

4.1.5.1.

Parameter/Input/Output Reference

PARAMETERS

1

Number of Oscillations

Permitted

[-]

The number of oscillations of the controller state allowed in one

timestep before the output will be fixed and the solution found. Set

to an odd number to allow the controller to bounce between two

control states for successive timesteps. (See Control Basics for a

more complete discussion of controller oscillations.)

2

Temperature Dead

Band

[delta C]

The dead band temperature difference of the controller. In this

model, hysteresis effects can be modeled by use of this

parameter. The setpoint temperature will be centered in the dead

band. If hysteresis is not desired for this controller, simply set this

parameter to 0.0. (See Control Basics for a more complete

discussion of controller hysteresis and dead bands.)

INPUTS

1

Monitoring

Temperature

[C]

The temperature being monitored by the controller. Typically this

input will be connected to a zone temperature where the

thermostat is located, but it could be any temperature being

sensed to control a heating and cooling system.

2

Heating Setpoint

[C]

The temperature below which heating is commanded. If a dead

band is specified, the heating signal will turn on when the

monitored temperature has dropped below this setpoint minus half

the dead band and turn off when the monitored temperature has

risen above this setpoint plus half the dead band.

3

Cooling Setpoint

[C]

The temperature above which cooling is commanded. If a dead

band is specified, the cooling signal will turn on when the

monitored temperature has risen above this setpoint plus half the

dead band and turn off when the monitored temperature has

dropped below this setpoint minus half the dead band.

OUTPUTS

1

Control Signal for

Heating

[-]

The control signal for heating. If heating is required then the

control signal will be 1. If no heating is required then the control

signal will be 0.

2

Control Signal for

Cooling

[-]

The control signal for cooling. If cooling is required then the

control signal will be 1. If no cooling is required then the control

signal will be 0.

4.1.5.2.

Simulation Summary Report Contents

VALUE FIELDS

4–29

TRNSYS 18 – Mathematical Reference

Dead band

[delta C]

Parameter 2

MINIMUM/MAXIMUM VALUE FIELDS

Heating Setpoint

[C]

Minimum and maximum values of Input 2

Cooling Setpoint

[C]

Minimum and maximum values of Input 3

4.1.5.3.

Hints and Tips

If you are seeing a high percentage of the simulation time that the controller is “stuck”, you can try

increasing the dead band, decreasing the timestep, or reducing the capacity of the equipment.

4.1.5.4.

Detailed Description

Type 82 uses the controller state at the previous timestep, the monitored temperature, the setpoints and

the dead band to determine the controller state at the current timestep.

If the control state was off at the previous timestep:

If the monitored temperature is less than the heating setpoint minus half the dead band, heating is on

If the monitored temperature is greater than the cooling setpoint plus half the dead band, cooling is on

Otherwise everything remains off

If heating was on at the previous timestep:

If the monitored temperature is greater than the heating setpoint plus half the dead band, heating is off

If the monitored temperature is greater than the cooling setpoint plus half the dead band, cooling is on

Otherwise heating remains on

If cooling was on at the previous timestep:

If the monitored temperature is less than the cooling setpoint minus half the dead band, cooling is off

If the monitored temperature is less than the heating setpoint minus half the dead band, heating is on

Otherwise cooling remains on

4–30

TRNSYS 18 – Mathematical Reference

4.1.6.

Type 85: Simple Humidistat

Type 85 models a simple humidistat that monitors a relative humidity and a setpoint and determines when

moisture should be added to air stream.

4.1.6.1.

Parameter/Input/Output Reference

PARAMETERS

1

Number of Oscillations

Permitted

[-]

The number of oscillations of the controller state allowed in one

timestep before the output will be fixed and the solution found.

Set to an odd number to allow the controller to bounce between

two control states for successive timesteps. (See Control Basics

for a more complete discussion of controller oscillations.)

2

Relative Humidity

Dead Band

[delta RH]

The dead band relative humidity difference of the controller. In

this model, hysteresis effects can be modeled by use of this

parameter. The setpoint relative humidity will be centered in the

dead band. If hysteresis is not desired for this controller, simply

set this parameter to 0.0. (See Control Basics for a more

complete discussion of controller hysteresis and dead bands.)

INPUTS

1

Monitoring Relative

Humidity

[RH]

The relative humidity that is monitored by the controller. Typically

this input will be connected to a zone relative humidity where the

humidistat is located, but it could be any relative humidity being

sensed to control a humidification system.

2

Humidity Setpoint

[RH]

The relative humidity below which humidification is commanded.

If a dead band is specified, the humidification signal will turn on

when the monitored relative humidity has dropped below this

setpoint minus half the dead band and turn off when the

monitored relative humidity has risen above this setpoint plus

half the dead band.

[-]

The control signal for humidification. If humidification is required

then the control signal will be 1. If no humidification is required

then the control signal will be 0.