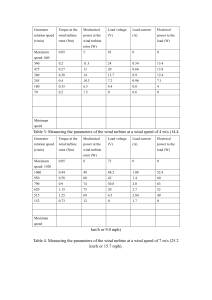

Wind Turbine Conclusion This project looked into designing a rotor to perform in a wind tunnel at varying wind speeds. Data was collected and the non-dimensional power coefficient and speed were calculated and plotted against each other on a graph. From this we were able to scale up our model to generate a power of 10kW, mimicking a large rotor. Our results which allowed us to calculate Cp produced the desired trend as shown on the graph. However, as the tip speed ratio drops below 10 no data points were determined from the results, this could be due to the minimum wind speed we tested at was 4ms-1 or the angular velocity being too large, both of which would result in a larger value for the tip speed. Upon scaling up our design to generate a larger power output of 10kW, our value of approximately 10m in diameter seems reasonable when we take our peak Cp value. To improve on the results we obtained I would retest with a broader range of wind speeds starting lower than 4 and increasing with smaller increments to produce more data points. This would improve the accuracy of Cp and make any pieces of anomalous data more clear to see, as this is hard to notice when only 3 data points were collected. In addition to this using smaller masses when stalling the wind turbine would produce more accurate values for the torque. As when we were stopping the rotor it was hard to get the blade to the point where it just stopped. It is possible that we added too much weight which may have skewed our values for the torque. Throughout the project we worked well as a team and all contributed to the labs and calculation of the results. It aided my understanding of the fluid calculations and gave some practice when producing the results sheet.