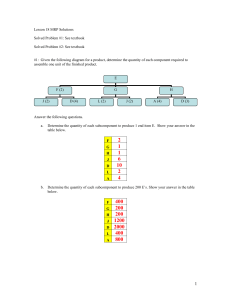

Chapter 12 - MRP and ERP CHAPTER 12 MRP AND ERP Solutions 1. a. Each E requires 2 F + 1 G + 1 H. Each F requires 2 J + 4 D. Each G requires 2 L + 2 J. Each H requires 4 A + 2 D. Total J required = (2 F * 2 J) + (1 G * 2 J) = 4 + 2 = 6. Total D required = (2 F * 4 D) + (1 H * 2 D) = 8 + 2 = 10. Total L required = 1 G * 2 L = 2. Total A required = 1 H * 4 A = 4. Total required of each: F = 2, G = 1, H =1. J = 6, D = 10, L = 2, A = 4. b. Product structure tree (tree diagram) for stapler: Stapler Top Assembly Cover Spring Base Assembly Slide Assembly Base Slide Strike Pad Rubber Pad(2) Spring 12-1 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 2. Given: We have the following information: End Item B(2) E(2) C D(3) F(3) G(2) End B C D E F G H LT (wk) 1 2 3 3 1 2 1 2 Amount on hand 0 10 10 25 12 30 5 0 Item E(2) H(4) E(2) a. If 20 units of the end item are to be assembled, how many additional units of E are needed? Step 1: Determine the gross requirements and the net requirements for the End Item: Item Gross Requirements – On Hand = Net Requirements End Item 20 – 0 = 20 Step 2: Determine the gross requirements and the net requirements for B, C, & D. Multiply the net requirements for the end item by the usage quantities of B, C, & D to determine the gross requirements for B, C, & D. Item Gross Requirements – On Hand = Net Requirements B (20 * 2) = 40 – 10 = 30 C (20 * 1) = 20 – 10 = 10 D (20 * 3) = 60 – 25 = 35 Step 3: Determine the gross requirements and net requirements for E. Multiply the net requirements for B, C, & D by the usage quantities of E to determine gross requirements for E. Item Gross Requirements – On Hand = Net Requirements E [(30 B * 2) + (10 C * 2) + (35 D * 2)] = 150 – 12 = 138 12-2 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP b. Given: An order for the end item is to be shipped at the start of week 11. Determine the latest week that the order could be started. To solve this, we need to determine the longest sequence through the product structure tree moving from the end item down to the lowest items. The lead time for each item is indicated in bold to the left of each item in the product structure tree shown below. 1 wk End Item 2 wk B(2) 1 wk E(2) 1 wk 3 wk C 2 wk F(3) 1 wk G(2) 1 wk Total LT = 4 wk 3 wk D(3) 1 wk E(2) 2 wk H(4) 1 wk 5 wk 1 wk 5 wk 5 wk 1 wk E(2) 1 wk 6 wk 5 wk The longest sequence is 6 weeks (End Item – D – H). 11 – 6 weeks = start of week 5. 3. Given: We have the following information: Item End L C K B J G H LT (wk) 1 2 3 3 2 3 3 2 Amount on hand 0 10 15 20 30 30 5 0 Item End L C K Direct Components L(2), C(1), K(3) B(2), J(3) G(2), B(2) H(4), B(2) Using the information above, we can construct a product structure tree as shown below: End Item L(2) B(2) C J(3) G(2) K(3) B(2) H(4) B(2) 12-3 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP a. If 40 units of the end item are to be assembled, how many additional units of B are needed? Step 1: Determine the gross requirements and the net requirements for the end item: Item Gross Requirements – On Hand = Net Requirements End Item 40 – 0 = 40 Step 2: Determine the gross requirements and the net requirements for L, C, & K. Multiply the net requirements for the end item by the usage quantities of L, C, & K to determine the gross requirements for L, C, & K. Item Gross Requirements – On Hand = Net Requirements L (40 * 2) = 80 – 10 = 70 C (40 * 1) = 40 – 15 = 25 K (40 * 3) = 120 – 20 = 100 Step 3: Determine the gross requirements and net requirements for B. Multiply the net requirements for L, C, & K by the usage quantities of B to determine gross requirements for B. Item Gross Requirements – On Hand = Net Requirements B [(70 L * 2) + (25 C * 2) + (100 K * 2)] = 390 – 30 = 360 b. Given: An order for the end item is to be shipped at the start of week 8. Determine the latest week that the order could be started. To solve this, we need to determine the longest sequence through the product structure tree moving from the end item down to the lowest items. The lead time for each item is indicated in bold to the left of each item in the product structure tree shown below. 1 wk End Item 2 wk L(2) 2 wk B(2) Total LT = 5 wk 3 wk C 3 wk J(3) 6 wk 3 wk G(2) 7 wk 3 wk K(3) 2 wk B(2) 2 wk H(4) 6 wk 6 wk 2 wk B(2) 6 wk The longest sequence is 7 weeks (End Item – C – G). 8 – 7 weeks = start of week 1. 12-4 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 4. Given: Eighty units of end item E are needed at the beginning of week 6. Three cases (30 units per case) of J have been ordered, and one case is scheduled to arrive in week 3, one in week 4, and one in week 5. Note: J must be ordered by the case, and B must be produced in multiples of 120 units. There are 60 units of B and 20 units of J on hand. Lead times are 2 weeks each for E and B, and 1 week for J. The product structure tree is shown below: E B(2) J(4) J(3) F(2) a. Determine a material requirements plan for J. We will need to prepare material plans for E, B, and J. All given information is highlighted in bold in the tables below. POH is the projected on hand inventory at the beginning of each period. All MRP problems below will use the following formula to determine POH: POH (Current Period) = [POH + Planned-Order Receipts – Gross Requirements (Prior Period)] + Scheduled Receipts (Current Period) or using subscripts, we have the following: POHt = [POHt-1 + Planned-Order Receiptst-1 – Gross Requirementst-1] + Scheduled Receiptst Net Requirements = Max[(Gross Requirements – POH), 0]. Note: This ensures that we have net requirements only when the Gross Requirements > POH. Master Schedule for: E Week 1 2 3 4 5 Quantity E LT = 2 Lot size: Lot-for-Lot Gross requirements 6 80 Beg. Inv. 1 2 3 4 5 6 80 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 Net requirements 80 Planned-order receipts 80 Planned-order releases 80 12-5 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP B(2) LT = 2 Lot size: Multiples of 120 Beg. Inv. 1 2 3 Gross requirements 4 5 6 20 20 160 Scheduled receipts Projected on hand 60 60 60 60 60 Net requirements 100 Planned-order receipts 120 Planned-order releases 120 Notes: Gross Requirements (week 4) = Planned-Order Releases of 80 E * 2 = 160. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [60 + 0 – 0] + 0 = 60. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [60 + 120 – 160] + 0 = 20. J(3) & J(4) LT = 1 Lot size: Multiples of 30 Gross requirements Beg. Inv. 1 2 480 Scheduled receipts Projected on hand 3 20 20 20 4 5 6 240 30 30 30 50 80 50 Net requirements 460 160 Planned-order receipts 480 180 50 Planned-order releases 480 180 Notes: Gross Requirements (week 2) = Planned-Order Releases of 120 B * 4 = 480. Gross Requirements (week 4) = Planned-Order Releases of 80 E * 3 = 240. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3. POH3 = [20 + 480 – 480] + 30 = 50. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4. POH4 = [50 + 0 – 0] + 30 = 80. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5. POH5 = [80 + 180 – 240] + 30 = 50. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6. POH6 = [50 + 0 – 0] + 0 = 50. Planned-Order Receipts (week 2) = 16 * 30 = 480 (must order in cases of 30). Planned-Order Receipts (week 4) = 6 * 30 = 180 (must order in cases of 30). 12-6 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP b. Suppose that in week 4 the quantity of E needed is changed from 80 to 70 units. The planned-order releases through week 3 have all been executed. How many more Bs and Js will be on hand in week 6? Note: We are now at the start of week 4. Step 1: Before we do the MRP processing, we list what changes have occurred: 1. All Planned-Order Releases in weeks 1 – 3 have been executed. B had Planned-Order Releases in week 2 (120) corresponding to Planned-Order Receipts (120) in week 4. Change the Planned-Order Receipts to Scheduled Receipts in week 4. J had Planned-Order Releases in week 1 (480) corresponding to Planned-Order Receipts (480) in week 2. The Planned-Order Receipts would have been changed to Scheduled Receipts and received in week 2 (this increases inventory). J had Planned-Order Releases in week 3 (180) corresponding to Planned-Order Receipts (180) in week 4. These will show up as Scheduled Receipts in week 4 and will be added to the original amount of Scheduled Receipts (30) in week 4. 2. Scheduled Receipts for J in week 3 (30) would have been received (this increases inventory). 3. Gross requirements for all items in weeks 1 – 3 would have been disbursed (these transactions decrease inventory). Step 2: Determine the ending inventory for each item at the end of week 3. These will become the beginning inventory balances in week 4. Remember: Scheduled receipts increase inventory while gross requirements decrease inventory. Ending Inventory = Beginning Inventory + Scheduled Receipts – Gross Requirements Item E Ending Inventory Week 1 0+0–0=0 Week 2 0+0–0=0 Week 3 0+0–0=0 Item B Ending Inventory Week 1 60 + 0 – 0 = 60 Week 2 60 + 0 – 0 = 60 Week 3 60 + 0 – 0 = 60 Item J Ending Inventory Week 1 20 + 0 – 0 = 20 Week 2 20 + 480 – 480 = 20 Week 3 20 + 30 – 0 = 50 12-7 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Step 3: Fill in all beginning inventory balances and scheduled receipts, and then change E to 70 units in week 6 of the master schedule. Our MRP tables are shown for weeks 4 – 6 only. Master Schedule for: E Week 4 5 Quantity E LT = 2 Lot size: Lot-for-Lot Gross requirements 6 70 Beg. Inv. 4 5 6 70 Scheduled receipts Projected on hand 0 0 0 0 Net requirements 70 Planned-order receipts 70 Planned-order releases B(2) LT = 2 Lot size: Multiples of 120 70 Beg. Inv. 4 Gross requirements 140 Scheduled receipts 120 Projected on hand 60 180 5 6 40 40 Net requirements Planned-order receipts Planned-order releases Notes: POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4. POH4 = [60 + 0 – 0] + 120 = 180. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5. POH5 = [180 + 0 – 140] + 0 = 40. 12-8 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP J(4) & J(3) LT = 1 Lot size: Multiples of 30 Gross requirements Beg. Inv. 5 6 210 Scheduled receipts Projected on hand 4 50 210 30 260 80 80 Net requirements Planned-order receipts Planned-order releases Notes: Scheduled Receipts (week 4) = Original amount of 30 + 180 = 210. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4. POH4 = [50 + 0 – 0] + 210 = 260. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5. POH5 = [260 + 0 – 210] + 30 = 80. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6. POH6 = [80 + 0 – 0] + 0 = 80. Original on hand amounts (week 6): B = 20 & J = 50. Revised on hand amounts (week 6): B = 40 & J = 80. There will be an additional 20 units of B & 30 units of J on hand. 12-9 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 5. a. Given: 120 units of end item Z are needed at the beginning of week 7. On hand balances: Z = 40, A 70, B = 100, and C = 30 units. There is a scheduled receipt of 20 units of C in week 4. Lead times are 2 weeks for Z and B, and 1 week for other items. Lot-for-lot ordering is used for all items. The product structure tree is shown below: Z A(2) C(3) B(4) D(2) E(2) C(2) Prepare a material requirements plan for component C: We will need to prepare material plans for Z, A, B, and C. Master Schedule for: Z Week 1 2 3 4 5 6 Quantity Z LT = 2 Lot size: Lot-for-Lot Gross requirements 7 120 Beg. Inv. 1 2 3 4 5 6 7 120 Scheduled receipts Projected on hand 40 40 40 40 40 40 40 40 Net requirements 80 Planned-order receipts 80 Planned-order releases 80 Notes: POH7 = [POH6 + Planned-Order Receipts6 – Gross Requirements6] + Scheduled Receipts7 POH7 = [40 + 0 – 0] + 0 = 40. A(2) LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 0 0 160 Scheduled receipts Projected on hand 70 70 70 70 70 70 Net requirements 90 Planned-order receipts 90 Planned-order releases 90 Notes: Gross Requirements (week 5) = Planned-Order Releases of 80 Z * 2 = 160. 12-10 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP B(4) LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 0 0 320 Scheduled receipts Projected on hand 100 100 100 100 100 100 Net requirements 220 Planned-order receipts 220 Planned-order releases 220 Notes: Gross Requirements (week 5) = Planned-Order Releases of 80 Z * 4 = 320. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [100 + 220 – 320] + 0 = 0. C(3) & C(2) LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 440 270 Scheduled receipts Projected on hand 5 6 7 0 0 0 20 30 20 Net requirements 410 250 Planned-order receipts 410 250 30 30 30 Planned-order releases 410 250 Notes: Gross Requirements (week 3) = Planned-Order Releases of 220 B * 2 = 440. Gross Requirements (week 4) = Planned-Order Releases of 90 A * 3 = 270. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [30 + 410 – 440] + 20 = 20. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [20 + 250 – 270] + 0 = 0. 12-11 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP b. Given: 95 units of end item E are needed at the beginning of week 7. On hand balances: E = 5, B = 50, C = 100, and D = 80 units. There is a scheduled receipt of 30 units of C in week 4. Lead times are 2 weeks for E and C, and 1 week for other items. Assume lot-for-lot ordering except for D, where multiples of 40 must be used. The product structure tree is shown below: E B(3) D(2) C(2) I(2) S(2) D(2) Prepare a material requirements plan for component D: We will need to prepare material plans for E, B, C, and D. Master Schedule for: E Week 1 2 3 4 5 6 Quantity E LT = 2 Lot size: Lot-for-Lot Gross requirements 7 95 Beg. Inv. 1 2 3 4 5 6 7 95 Scheduled receipts Projected on hand 5 5 5 5 5 5 5 5 Net requirements 90 Planned-order receipts 90 Planned-order releases B(3) LT = 1 Lot size: Lot-for-Lot Gross requirements 90 Beg. Inv. 1 2 3 4 5 6 7 0 0 270 Scheduled receipts Projected on hand 50 50 50 50 50 50 Net requirements 220 Planned-order receipts 220 Planned-order releases 220 Notes: Gross Requirements (week 5) = Planned-Order Releases of 90 E * 3 = 270. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [50 + 220 – 270] + 0 = 0. 12-12 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP C(2) LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 5 6 7 0 0 180 Scheduled receipts Projected on hand 4 30 100 100 100 100 130 130 Net requirements 50 Planned-order receipts 50 Planned-order releases 50 Notes: Gross Requirements (week 5) = Planned-Order Releases of 90 E * 2 = 180. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [100 + 0 – 0] + 30 = 130. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [130 + 0 – 0] + 0 = 130. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [130 + 50 – 180] + 0 = 0 D(2) & D(2) LT = 1 Lot size: Multiples of 40 Gross requirements Beg. Inv. 1 2 3 4 100 440 80 20 Net requirements 20 420 Planned-order receipts 40 440 5 6 7 20 20 20 Scheduled receipts Projected on hand 80 80 80 Planned-order releases 40 440 Notes: Gross Requirements (week 3) = Planned-Order Releases of 50 C * 2 = 100. Gross Requirements (week 4) = Planned-Order Releases of 220 B * 2 = 440. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [80 + 40 – 100] + 0 = 20. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [20 + 440 – 440] + 0 = 20. Planned-Order Receipts (week 3) = 1 * 40 = 40 (multiples of 40 must be used). Planned-Order Receipts (week 4) = 11 * 40 = 440 (multiples of 40 must be used). 12-13 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 6. Given: The company that makes a table wants to ship 100 units at the beginning of day 4, 150 units at the beginning of day 5, and 200 units at the beginning of day 7. Receipts of 100 wood sections are scheduled at the beginning of day 2. On hand balances: Braces = 60 and Legs = 120. Lead times (in days) for all items are shown in the table below. The product structure tree is shown below also: Quantity Lead Time 1-200 1 201-550 2 551-999 3 Table Wood Sections(2) Braces(3) Legs(4) Prepare a material requirements plan using lot-for-lot ordering for all items: Master Schedule for: Table Day 1 2 3 Quantity Table Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 100 150 4 5 100 150 0 0 100 100 150 200 150 200 200 6 7 200 Scheduled receipts Projected on hand 0 0 0 Net requirements Planned-order receipts 0 0 0 Planned-order releases 100 150 200 Notes: POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [0 + 100 – 100] + 0 = 0. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [0 + 150 – 150] + 0 = 0. Planned-Order Releases (days 3, 4, & 6) were back-scheduled 1 day from their Planned-Order Receipts because all lead times = 1 day for quantities of 1-200. 12-14 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Wood Sections(2) Lot size: Lot-for-Lot Beg. Inv. 1 2 3 4 200 300 100 0 Net requirements 100 Planned-order receipts 100 300 300 Gross requirements Scheduled receipts Projected on hand 5 6 7 400 100 0 0 100 0 0 0 400 400 Planned-order releases 400 400 Notes: Gross Requirements (day 3) = Planned-Order Releases of 100 Tables * 2 = 200. Gross Requirements (day 4) = Planned-Order Releases of 150 Tables * 2 = 300. Gross Requirements (day 6) = Planned-Order Releases of 200 Tables * 2 = 400. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3 POH3 = [100 + 0 – 0] + 0 = 100. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [100 + 100 – 200] + 0 = 0. Planned-Order Releases (day 2) = 100 from Planned-Order Receipts of 100 in day 3 (lead time = 1 day for quantities of 1-200) + 300 from Planned-Order Receipts of 300 in day 4 (lead time = 2 days for quantities of 201-550) = 400. Planned-Order Releases (day 4) = 400 from Planned-Order Receipts of 400 in day 6 (lead time = 2 days for quantities of 201-550). Braces(3) Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 300 450 60 0 240 240 450 600 450 600 7 600 Scheduled receipts Projected on hand 60 60 60 Net requirements Planned-order receipts 0 0 0 Planned-order releases 240 450 600 Notes: Gross Requirements (day 3) = Planned-Order Releases of 100 Tables * 3 = 300. Gross Requirements (day 4) = Planned-Order Releases of 150 Tables * 3 = 450. Gross Requirements (day 6) = Planned-Order Releases of 200 Tables * 3 = 600. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [60 + 240 – 300] + 0 = 0. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [0 + 450 – 450] + 0 = 0. Planned-Order Releases (day 1) = 240 from Planned-Order Receipts of 240 in day 3 (lead time = 2 days for quantities of 201-550). Planned-Order Releases (day 2) = 450 from Planned-Order Receipts of 450 in day 4 (lead time = 2 days for quantities of 201-550). Planned-Order Releases (day 3) = 600 from Planned-Order Receipts of 600 in day 6 (lead time = 3 days for quantities of 551-999). 12-15 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Legs(4) Lot size: Lot-for-Lot Beg. Inv. 1 2 Gross requirements 3 4 5 6 400 600 120 0 280 280 600 800 600 800 7 800 Scheduled receipts Projected on hand 120 120 120 Net requirements Planned-order receipts 0 0 0 Planned-order releases 880 800 Notes: Gross Requirements (day 3) = Planned-Order Releases of 100 Tables * 4 = 400. Gross Requirements (day 4) = Planned-Order Releases of 150 Tables * 4 = 600. Gross Requirements (day 6) = Planned-Order Releases of 200 Tables * 4 = 800. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3 POH3 = [120 + 0 – 0] + 0 = 120. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [120 + 280 – 400] + 0 = 0. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [0 + 600 – 600] + 0 = 0. Planned-Order Releases (day 1) = 280 from Planned-Order Receipts of 280 in day 3 (lead time = 2 days for quantities of 201-550) + 600 from Planned-Order Receipts of 600 in day 4 (lead time = 3 days for quantities of 551-999) = 880. Planned-Order Releases (day 3) = 800 from Planned-Order Receipts of 800 in day 6 (lead time = 3 days for quantities of 551-999). 12-16 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 7. Given: 80 units of end item X are needed at the beginning of week 6, and another 30 units are needed at the beginning of week 8. D can be ordered only in whole cases (50 units per case). One case of D (50 units) is received automatically every other week, beginning in week 1. On hand balances: B = 30 and D = 20 units. Lead times are a function of quantity as shown in the table below. The product structure tree is shown below also: Quantity Lead Time 1-100 1 wk 101-200 2 wk 201-300 3 wk 301+ 4 wk X B(2) D(2) D(3) F(2) Prepare a material requirements plan for component D using lot-for-lot ordering for all items except D. We will need to prepare material plans for X, B, and D. Master Schedule for: X Week 1 2 3 4 5 Quantity X Lot size: Lot-for-Lot Gross requirements 6 7 80 Beg. Inv. 1 2 3 4 5 6 8 30 7 80 8 30 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 0 0 Net requirements 80 30 Planned-order receipts 80 30 Planned-order releases 80 30 Notes: Planned-Order Releases (week 5 and week 7) have a lead time of 1 week (lead time = 1 week for quantities of 1-100). 12-17 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP B(2) Lot size: Lot-for-Lot Beg. Inv. 1 2 3 4 Gross requirements 5 6 160 7 8 60 Scheduled receipts Projected on hand 30 30 30 30 30 30 0 0 Net requirements 130 60 Planned-order receipts 130 60 0 Planned-order releases 130 60 Notes: Gross Requirements (week 5) = Planned-Order Releases of 80 X * 2 = 160. Gross Requirements (week 7) = Planned-Order Releases of 30 X * 2 = 60. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [30 +130 – 160] + 0 = 0. Planned-Order Releases (week 3) = 130 from Planned-Order Receipts of 130 in week 5 (lead time = 2 weeks for quantities of 101-200). Planned-Order Releases (week 6) = 60 from Planned-Order Receipts of 60 in week 7 (lead time = 1 week for quantities of 1-100). D(2) & D(3) Lot size: Multiples of 50 Gross requirements Beg. Inv. Scheduled receipts Projected on hand 1 2 50 20 70 70 Net requirements 3 5 6 7 260 240 120 90 50 50 120 140 150 Planned-order receipts 4 10 8 50 60 20 50 180 200 100 100 40 10 50 Planned-order releases 150 200 100 50 Notes: Gross Requirements (week 3) = Planned-Order Releases of 130 B * 2 = 260. Gross Requirements (week 5) = Planned-Order Releases of 80 X * 3 = 240. Gross Requirements (week 6) = Planned-Order Releases of 60 B * 2 = 120. Gross Requirements (week 7) = Planned-Order Releases of 30 X * 3 = 90. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3 POH3 = [70 + 0 – 0] + 50 = 120. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [120 + 150 – 260] + 0 = 10. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [60 + 200 – 240] + 0 = 20. POH7 = [POH6 + Planned-Order Receipts6 – Gross Requirements6] + Scheduled Receipts7 POH7 = [20 + 100 – 120] + 50 = 50. POH8 = [POH7 + Planned-Order Receipts7 – Gross Requirements7] + Scheduled Receipts8 POH8 = [50 + 50 – 90] + 0 = 10. 12-18 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 8. Given: Oh No! Inc. sells three models: A, B, and C. Lead times are 1 week for all items except C (2 weeks). On hand balances: B = 10, C = 10, and D = 25 units. Lot-sizing rules are lot-for-lot for all items except D, which must be ordered in multiples of 100. There is a scheduled receipt of 100 units of D in week 1. The master schedule shows that 40 units of A are needed at the beginning of week 4, 60 units of B at the beginning of week 5, and 30 units of C at the beginning of week 6. The product structure tree for each item is shown below: A B D E C D(2) F D(4) G Prepare a material requirements plan for component D and its parents. We will need to prepare material plans for A, B, C, and D. Master Schedule for: A Week 1 2 3 Quantity A LT = 1 Lot size: Lot-for-Lot Gross requirements 4 5 6 5 6 0 0 5 6 40 Beg. Inv. 1 2 3 4 40 Scheduled receipts Projected on hand 0 0 0 0 0 Net requirements 40 Planned-order receipts 40 Planned-order releases Master Schedule for: B 40 Week 1 2 3 4 Quantity B LT = 1 Lot size: Lot-for-Lot Gross requirements 60 Beg. Inv. 1 2 3 4 5 6 60 Scheduled receipts Projected on hand 10 10 10 10 10 10 Net requirements 50 Planned-order receipts 50 Planned-order releases 0 50 12-19 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Master Schedule for: C Week 1 2 3 4 5 Quantity C LT = 2 Lot size: Lot-for-Lot Gross requirements 6 30 Beg. Inv. 1 2 3 4 5 6 30 Scheduled receipts Projected on hand 10 10 10 10 10 10 10 Net requirements 20 Planned-order receipts 20 Planned-order releases D, D(2), & D(4) LT = 1 Lot size: Multiples of 100 Gross requirements 20 Beg. Inv. Scheduled receipts Projected on hand 1 2 3 4 40 180 125 85 5 6 5 5 100 25 125 125 Net requirements 95 Planned-order receipts 100 Planned-order releases 100 Notes: Gross Requirements (week 3) = Planned-Order Releases of 40 A * 1 = 40. Gross Requirements (week 4) = (Planned-Order Releases of 50 B * 2) + (Planned-Order Releases of 20 C * 4) = 100 + 80 = 180. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [125 + 0 – 40] + 0 = 85. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [85 + 100 – 180] + 0 = 5. Planned-Order Receipts (week 5) = 1 * 100 = 100 (must order in multiples of 100). 12-20 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 9. Given: 50 chain saws are needed at the start of week 8. The inventory information (shown in bold) and the product structure tree are listed below in the problem solution: a. Product tree structure: Saw A(2) B E(3) D C(4) D(2) F(3) E(2) D(2) D Assembly time chart: A E F Saw B D D C E 1 2 3 4 5 6 7 8 week Start of week 2 Start of week 8 Master schedule: Master Schedule for: Saw Week 1 2 3 4 5 6 7 Quantity 8 50 b. Material requirements plan for E using lot-for-lot ordering for all items. We will need to prepare material plans for Saw, A, C, and E. Master Schedule for: Saw Week 1 2 3 4 5 6 7 Quantity Saw LT = 2 Lot size: Lot-for-Lot Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases 8 50 Beg. Inv. 1 2 3 4 5 6 7 8 50 15 15 15 15 15 15 15 15 15 35 35 35 12-21 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP A(2) LT = 1 Lot size: Lot-for-Lot Gross requirements Scheduled receipts Projected on hand Net requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 7 8 0 0 6 7 8 0 0 0 70 10 10 10 10 10 Planned-order receipts Planned-order releases 10 10 60 60 60 Notes: Gross Requirements (week 6) = Planned-Order Releases of 35 Saws * 2 = 70. C(4) LT = 2 Beg. 1 2 3 4 5 6 Lot size: Lot-for-Lot Inv. Gross requirements 140 Scheduled receipts Projected on hand 65 65 65 65 65 65 65 Net requirements 75 Planned-order receipts 75 Planned-order releases 75 Notes: Gross Requirements (week 6) = Planned-Order Releases of 35 Saws * 4 = 140. E(3) & E(2) LT = 1 Lot size: Lot-for-Lot Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Beg. Inv. 10 1 10 2 10 3 10 4 5 150 180 10 140 140 0 180 180 Planned-order releases 140 180 Notes: Gross Requirements (week 4) = Planned-Order Releases of 75 C * 2 = 150. Gross Requirements (week 5) = Planned-Order Releases of 60 A * 3 = 180. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [10 + 0 – 0] + 0 = 10. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [10 + 140 – 150] + 0 = 0. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [0 + 180 – 180] + 0 = 0. 12-22 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 10. Given: 40 units of an industrial robot are needed at the beginning of week 7. Subassembly G must be ordered in multiples of 80 and all other components are ordered lot-for-lot. The inventory information (shown in bold) and the product structure tree are listed below in the problem solution. Prepare the material plan for G. We will need to prepare material plans for Robot, C, & G. Robot C(3) B E Master Schedule for: Robot F G Week 1 G(2) 2 3 4 H 5 6 Quantity Robot LT = 2 Lot size: Lot-for-Lot Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts 40 Beg. Inv. 1 2 3 4 5 6 7 40 10 10 10 10 10 Planned-order releases C(3) LT = 1 Lot size: Lot-for-Lot Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases 7 10 10 10 30 30 6 7 0 0 30 Beg. Inv. 1 2 3 4 5 90 20 20 20 20 20 20 70 70 70 Notes: Gross Requirements (week 5) = Planned-Order Releases of 30 Robots * 3 = 90. 12-23 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP G & G(2) LT = 2 Lot size: Multiples of 80 Gross requirements Scheduled receipts Beg. Inv. Projected on hand Net requirements 1 2 15 15 3 15 15 Planned-order receipts 4 5 140 30 15 125 35 6 7 5 5 160 Planned-order releases 160 Notes: Gross Requirements (week 4) = Planned-Order Releases of 70 C * 2 = 140. Gross Requirements (week 5) = Planned-Order Releases of 30 Robots * 1 = 30. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [15 + 0 – 0] + 0 = 15. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [15 + 160 – 140] + 0 = 35. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [35 + 0 – 30] + 0 = 5. 11. a. Given: Refer back to Solved Problem 3. On hand balances: N = 100 and E = 0. Scheduled receipts: I = 40 and V = 10 at the beginning of week 3. 120 E are needed at the start of week 5. We have the product structure tree shown below. Determine material requirements plans for E, I, N, and V using lot-for-lot ordering as was used in Solved Problem 3: E M(3) R(2) Master Schedule for: E I(2) P N(4) Period 1 V 2 3 4 Quantity E LT = 1 Lot size: Lot-for-Lot Gross requirements 5 6 7 8 6 7 8 0 0 0 120 Beg. Inv. 1 2 3 4 5 120 Scheduled receipts Projected on hand 0 0 0 0 0 0 Net requirements 120 Planned-order receipts 120 Planned-order releases 120 12-24 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP I(2) LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 4 5 6 7 8 0 0 0 0 240 Scheduled receipts Projected on hand 3 40 0 0 0 40 40 Net requirements 200 Planned-order receipts 200 Planned-order releases 200 Notes: Gross Requirements (week 4) = Planned-Order Releases of 120 E * 2 = 240. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [40 + 0 – 0] + 0 = 40. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [40 + 200 – 240] + 0 = 0. N(4) LT = 2 Lot size: Lot-for-Lot Beg. Inv. 1 2 Gross requirements 3 4 5 6 7 8 0 0 0 0 0 800 Scheduled receipts Projected on hand 100 100 100 100 Net requirements 700 Planned order receipts 700 Planned order releases 700 Notes: Gross Requirements (week 3) = Planned-Order Releases of 200 I * 4 = 800. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [100 + 700 – 800] + 0 = 0. V LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 4 5 6 7 8 0 0 0 0 0 200 Scheduled receipts Projected on hand 3 10 0 0 0 10 Net requirements 190 Planned order receipts 190 Planned order releases 190 Notes: Gross Requirements (week 3) = Planned-Order Releases of 200 I * 1 = 200. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3 POH3 = [0 + 0 – 0] + 10 = 10. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [10 + 190 – 200] + 0 = 0. 12-25 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP b. Given: Assume that on hand balances and scheduled receipts remain the same as in part a. On hand balances: N = 100 and E = 0. Scheduled receipts: I = 40 and V = 10 at the beginning of week 3. New information: 100 E are needed at the start of week 5 and 55 are needed at the start of week 7. Determine the material requirements plans for E, I, N, and V using lot-for-lot ordering for E and I, and multiples of these order sizes: N = 800 and V = 200. E M(3) R(2) Master Schedule for: E I(2) P N(4) Period 1 V 2 3 4 Quantity E LT = 1 Lot size: Lot-for-Lot Gross requirements 5 6 100 Beg. Inv. 1 2 3 4 5 7 8 55 6 100 7 8 55 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 0 Net requirements 100 55 Planned-order receipts 100 55 Planned-order releases I(2) LT = 1 Lot size: Lot-for-Lot Gross requirements 100 Beg. Inv. 1 2 4 55 5 200 Scheduled receipts Projected on hand 3 0 6 7 8 0 0 110 40 0 0 0 40 40 0 0 Net requirements 160 110 Planned-order receipts 160 110 Planned-order releases 160 110 Notes: Gross Requirements (week 4) = Planned-Order Releases of 100 E * 2 = 200. Gross Requirements (week 6) = Planned-Order Releases of 55 E * 2 = 110. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [40 + 0 – 0] + 0 = 40. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [40 + 160 – 200] + 0 = 0. 12-26 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP N(4) LT = 2 Lot size: Multiples of 800 Gross requirements Beg. Inv. 1 2 3 4 640 5 6 7 8 620 620 620 440 Scheduled receipts Projected on hand 100 100 100 Net requirements 100 260 540 800 Planned order receipts 260 180 800 Planned order releases 800 800 Notes: Gross Requirements (week 3) = Planned-Order Releases of 160 I * 4 = 640. Gross Requirements (week 5) = Planned-Order Releases of 110 I * 4 = 440. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [100 + 800 – 640] + 0 = 260. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [260 + 800 – 440] + 0 = 620. V LT = 2 Lot size: Multiples of 200 Gross requirements Beg. Inv. 1 2 4 160 Scheduled receipts Projected on hand 3 5 6 7 8 140 140 140 110 10 0 0 0 Net requirements 10 150 200 Planned order receipts 50 50 60 200 Planned order releases 200 200 Notes: Gross Requirements (week 3) = Planned-Order Releases of 160 I * 1 = 160. Gross Requirements (week 5) = Planned-Order Releases of 110 I * 1 = 110. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3 POH3 = [0 + 0 – 0] + 10 = 10. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [10 + 200 – 160] + 0 = 50. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [50 + 0 – 0] + 0 = 50. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [50 + 200 – 110] + 0 = 140. 12-27 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP c. Case 1 Given: Refer back to part b. 1 week has elapsed. It is now the start of week 2. 100 E are needed at the start of week 9. Assume that all orders were released and received as planned. Notes: a. We will drop 1 week (week 1) from the material plans and add 1 week at the end of each plan. b. Any Planned-Order Releases from week 1 must now show up as Scheduled Receipts: Item N: Change Planned-Order Receipts of 800 in week 3 to Scheduled Receipts in week 3. Item V: Change Planned-Order Receipts of 200 in week 3 to Scheduled Receipts in week 3. The revised amount of Scheduled Receipts (week 3) = original amount of 10 + 200 = 210. c. Determine the on hand balances at the start of week 2: Determine the ending inventory for each item at the end of week 1. These will become the beginning inventory balances in week 2. Remember: Scheduled receipts increase inventory while gross requirements decrease inventory. Ending Inventory = Beginning Inventory + Scheduled Receipts – Gross Requirements Item E Ending Inventory Week 1 0+0–0=0 Item I Ending Inventory Week 1 0+0–0=0 Item N Ending Inventory Week 1 100 + 0 – 0 = 100 Item V Ending Inventory Week 1 0+0–0=0 E M(3) R(2) I(2) P N(4) V 12-28 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP c. continued Master Schedule for: E Period 2 3 4 Quantity E LT = 1 Lot size: Lot-for-Lot Gross requirements 5 6 100 Beg. Inv. 2 3 4 5 7 8 55 6 100 7 9 100 8 55 9 100 Scheduled receipts Projected on hand Net requirements 100 55 0 100 Planned-order receipts 100 55 100 0 0 0 Planned-order releases I(2) LT = 1 Lot size: Lot-for-Lot Gross requirements 0 100 Beg. Inv. 2 3 4 0 0 55 5 200 Scheduled receipts Projected on hand 0 6 0 100 7 110 8 9 200 40 0 0 40 40 0 0 0 0 Net requirements 160 110 200 Planned-order receipts 160 110 200 0 Planned-order releases 160 110 200 Notes: Gross Requirements (week 4) = Planned-Order Releases of 100 E * 2 = 200. Gross Requirements (week 6) = Planned-Order Releases of 55 E * 2 = 110. Gross Requirements (week 8) = Planned-Order Releases of 100 E * 2 = 200. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [40 + 0 – 0] + 0 = 40. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [40 + 160 – 200] + 0 = 0. POH9 = [POH8 + Planned-Order Receipts8 – Gross Requirements8] + Scheduled Receipts9 POH9 = [0 + 200 – 200] + 0 = 0. 12-29 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP N(4) LT = 2 Lot size: Multiples of 800 Gross requirements Beg. Inv. 2 4 640 Scheduled receipts Projected on hand 3 5 6 440 7 8 9 620 620 800 800 100 100 900 260 Net requirements 260 620 180 800 Planned order receipts 620 180 800 Planned order releases 800 800 Notes: Gross Requirements (week 3) = Planned-Order Releases of 160 I * 4 = 640. Gross Requirements (week 5) = Planned-Order Releases of 110 I * 4 = 440. Gross Requirements (week 7) = Planned-Order Releases of 200 I * 4 = 800. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3 POH3 = [100 + 0 – 0] + 800 = 900. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [900 + 0 – 640] + 0 = 260. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [260 + 800 – 440] + 0 = 620. POH8 = [POH7 + Planned-Order Receipts7 – Gross Requirements7] + Scheduled Receipts8 POH8 = [620 + 800 – 800] + 0 = 620. V LT = 2 Lot size: Multiples of 200 Gross requirements Beg. Inv. 2 4 160 Scheduled receipts Projected on hand 3 5 6 110 7 8 9 140 140 200 210 0 0 210 Net requirements 50 50 60 200 Planned order receipts 140 140 60 200 Planned order releases 200 200 Notes: Gross Requirements (week 3) = Planned-Order Releases of 160 I * 1 = 160. Gross Requirements (week 5) = Planned-Order Releases of 110 I * 1 = 110. Gross Requirements (week 7) = Planned-Order Releases of 200 I * 1 = 200. POH3 = [POH2 + Planned-Order Receipts2 – Gross Requirements2] + Scheduled Receipts3 POH3 = [0 + 0 – 0] + 210 = 210. POH4 = [POH3 + Planned-Order Receipts3 – Gross Requirements3] + Scheduled Receipts4 POH4 = [210 + 0 – 160] + 0 = 50. POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [50 + 0 – 0] + 0 = 50. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [50 + 200 – 110] + 0 = 140. POH8 = [POH7 + Planned-Order Receipts7 – Gross Requirements7] + Scheduled Receipts8 POH8 = [140 + 200 – 200] + 0 = 140. 12-30 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Case 2 Given: Refer back to the previous update. It is now the start of week 4. Assume that all orders were released and received as planned in weeks 2 and 3. Notes: a. We will drop 2 weeks (weeks 2 & 3) from the material plans and add 2 weeks at the end of each plan. b. Any Planned-Order Releases from weeks 2 & 3 must now show up as Scheduled Receipts: Item I: Change Planned-Order Receipts of 160 in week 4 to Scheduled Receipts in week 4. Item N: Change Planned-Order Receipts of 800 in week 5 to Scheduled Receipts in week 5. Item V: Change Planned-Order Receipts of 200 in week 5 to Scheduled Receipts in week 5. c. Determine the on hand balances at the start of week 4: Determine the ending inventory for each item at the end of week 3. These will become the beginning inventory balances in week 4. Remember: Scheduled receipts increase inventory while gross requirements decrease inventory. Ending Inventory = Beginning Inventory + Scheduled Receipts – Gross Requirements Item E Ending Inventory Week 2 0+0–0=0 Item I Ending Inventory Item N Ending Inventory Item V Ending Inventory Week 3 0+0–0=0 Week 2 0+0–0=0 Week 3 0 + 40 – 0 = 40 Week 2 100 + 0 – 0 = 100 Week 3 100 + 800 – 640 = 260 Week 2 0+0–0=0 Week 3 0 + 210 – 160 = 50 E M(3) R(2) I(2) P N(4) V 12-31 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Master Schedule for: E Period 4 Quantity E LT = 1 Lot size: Lot-for-Lot Gross requirements 5 6 100 Beg. Inv. 4 5 7 8 55 6 100 7 9 10 11 10 11 0 0 9 10 11 0 0 0 100 8 55 9 100 Scheduled receipts Projected on hand Net requirements 100 55 0 100 Planned-order receipts 100 55 100 0 Planned-order releases I(2) LT = 1 Lot size: Lot-for-Lot Gross requirements 0 100 Beg. Inv. 4 0 0 55 5 200 Scheduled receipts Projected on hand 0 6 0 100 7 110 8 200 160 40 200 0 0 0 0 Net requirements 110 200 Planned-order receipts 110 200 Planned-order releases 110 200 Notes: POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [200 + 0 – 200] + 0 = 0. 12-32 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP N(4) LT = 2 Lot size: Multiples of 800 Beg. Inv. 4 5 Gross requirements 440 Scheduled receipts 800 Projected on hand 260 260 1060 6 7 8 9 10 11 620 620 620 620 800 620 620 Net requirements 180 Planned order receipts 800 Planned order releases 800 Notes: POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [1060 + 0 – 440] + 0 = 620. V LT = 2 Lot size: Multiples of 200 Gross requirements Beg. Inv. 4 6 110 Scheduled receipts Projected on hand 5 7 8 9 10 11 140 140 140 140 200 200 50 50 250 140 140 Net requirements 60 Planned order receipts 200 Planned order releases 200 Notes: POH5 = [POH4 + Planned-Order Receipts4 – Gross Requirements4] + Scheduled Receipts5 POH5 = [50 + 0 – 0] + 200 = 250. POH6 = [POH5 + Planned-Order Receipts5 – Gross Requirements5] + Scheduled Receipts6 POH6 = [250 + 0 – 110] + 0 = 140. 12-33 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 12. Given: 200 carts must be ready at the beginning of week 8. The product structure tree, assembly time chart, and inventory information are shown in the solutions below: a. Product structure tree: Golf Cart Top Supports(4) Base Cover Motor Body Frame Controls Seats(2) Wheels(4) Assembly Time Chart Supports Top b. Cover Cart Motor Frame Body Controls Base Wheels Seats 2 3 4 5 6 7 week Start of week 2 Start of week 8 12-34 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP c. Develop a material requirements plan that will provide 200 golf carts by week 8 assuming lot-for-lot ordering. Master Schedule for: Golf Cart Week 1 2 3 4 5 6 7 Quantity Golf Cart LT = 1 Lot size: Lot-for-Lot Gross requirements 8 200 Beg. Inv. 1 2 3 4 5 6 7 8 200 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 0 0 Net requirements 200 Planned-order receipts 200 Planned-order releases Top LT = 1 Lot size: Lot-for-Lot Gross requirements 200 Beg. Inv. 1 2 3 4 5 6 7 8 200 Scheduled receipts Projected on hand 40 40 40 40 40 40 40 40 Net requirements 160 Planned-order receipts 160 0 Planned-order releases 160 Notes: Gross Requirements (week 7) = Planned-Order Releases of 200 Golf Carts * 1 = 200. Supports(4) LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 640 Scheduled receipts Projected on hand 200 200 200 200 200 200 200 Net requirements 440 Planned-order receipts 440 Planned-order releases 440 Notes: Gross Requirements (week 6) = Planned-Order Releases of 160 Tops * 4 = 640. 12-35 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 12. c. (continued) Cover LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 7 8 160 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 Net requirements 160 Planned-order receipts 160 Planned-order releases 160 Notes: Gross Requirements (week 6) = Planned-Order Releases of 160 Tops * 1 = 160. Base LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 200 Scheduled receipts Projected on hand 20 20 20 20 20 20 20 20 Net requirements 180 Planned-order receipts 180 0 Planned-order releases 180 Notes: Gross Requirements (week 7) = Planned-Order Releases of 200 Golf Carts * 1 = 200. Motor LT = 2 Lot size: Lot-for-Lot Beg. Inv. 1 2 3 4 5 Gross requirements 6 7 8 120 120 180 Scheduled receipts Projected on hand 300 300 300 300 300 300 300 Net requirements Planned-order receipts Planned-order releases Notes: Gross Requirements (week 6) = Planned-Order Releases of 180 Bases * 1 = 180. 12-36 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 12. c. (Continued) Body LT = 3 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 7 8 0 0 180 Scheduled receipts Projected on hand 50 50 50 50 50 50 50 Net requirements 130 Planned-order receipts 130 Planned-order releases 130 Notes: Gross Requirements (week 6) = Planned-Order Releases of 180 Bases * 1 = 180. Seats(2) LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 360 Scheduled receipts Projected on hand 120 120 120 120 120 120 120 Net requirements 240 Planned-order receipts 240 Planned-order releases 240 Notes: Gross Requirements (week 6) = Planned-Order Releases of 180 Bases * 2 = 360. Frame LT = 1 Lot size: Lot-for-Lot Beg. Inv. 1 2 Gross requirements 3 4 5 6 7 8 0 0 0 0 0 130 Scheduled receipts Projected on hand 35 35 35 35 Net requirements 95 Planned-order receipts 95 Planned-order releases 95 Notes: Gross Requirements (week 3) = Planned-Order Releases of 130 Body * 1 = 130. 12-37 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 12. c. (Continued) Controls LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 0 0 130 Scheduled receipts Projected on hand 0 0 0 0 Net requirements 130 Planned-order receipts 130 Planned-order releases 130 Notes: Gross Requirements (week 3) = Planned-Order Releases of 130 Body * 1 = 130. Wheel Assemblies(4) LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 0 0 520 Scheduled receipts Projected on hand 240 240 240 240 Net requirements 280 Planned-order receipts 280 Planned-order releases 280 Notes: Gross Requirements (week 3) = Planned-Order Releases of 130 Body * 4 = 520. 12-38 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 13. Given: Refer back to Problem 12. The revised plan calls for 100 golf carts to be available at the start of week 6, 100 at the start of week 8, and 100 at the start of week 9. a. Develop a master schedule for this revised plan. Master Schedule for: Golf Carts Week 1 2 3 4 5 Quantity 6 7 100 8 9 100 100 8 9 100 100 0 0 b. Determine the timing and quantities for orders for tops and bases. Golf Cart LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 100 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 0 Net requirements 100 100 100 Planned-order receipts 100 100 100 Planned-order releases Top LT = 1 Lot size: Lot-for-Lot Gross requirements 100 Beg. Inv. Inv. 1 40 40 2 3 4 5 6 100 100 100 7 8 100 100 0 0 9 Scheduled receipts Projected on hand 40 40 40 40 0 Net requirements 60 100 100 Planned-order receipts 60 100 100 Planned-order releases Base LT = 1 Lot size: Lot-for-Lot 60 Beg. Inv. 1 2 3 4 Gross requirements 5 100 100 6 7 8 100 100 0 0 100 0 9 Scheduled receipts Projected on hand 20 20 20 20 20 20 0 Net requirements 80 100 100 Planned-order receipts 80 100 100 Planned-order releases 80 100 0 100 12-39 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP c. The firm’s capacity limits the assembly of bases to 50 units per week. Revise the plan, but still meet delivery dates. Note: We should try to minimize inventory also. The key will be to move Planned-Order Receipts and Planned-Order Releases earlier in the plan. Consider the plan for Bases in b above: Planned Order-Receipts (week 8) = 100 Planned Order-Receipts (week 7) = 100 Planned Order-Receipts (week 5) = 80 Given the capacity limit of 50 per week, we could divide the Planned-Order Receipts as follows: Week 8 (100): Week 7 (50) & Week 8 (50) Week 7 (100): Week 5 (50) & Week 6 (50) Week 5 (80): Week 3 (30) & Week 4 (50) Note: Because some of these Planned-Order Receipts need to be planned earlier than they should be, the planner will have to lock in the timing and quantity of these Planned-Order Receipts by designating them as Firm Planned Orders so that the MRP system does not reschedule them automatically. Master Schedule for: Golf Carts Week 1 2 3 4 5 Quantity Golf Cart LT = 1 Lot size: Lot-for-Lot Gross requirements 6 7 100 Beg. Inv. 1 2 3 4 5 6 7 100 8 9 100 100 8 9 100 100 0 0 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 0 Net requirements 100 100 100 Planned-order receipts 100 100 100 Planned-order releases Base LT = 1 Lot size: Lot-for-Lot 100 Beg. Inv. 1 2 3 4 Gross requirements 5 6 100 100 100 7 8 100 100 9 Scheduled receipts Projected on hand 20 20 20 20 50 100 50 100 50 30 50 50 50 50 50 50 50 50 50 50 0 Net requirements Planned-order receipts Planned-order releases 30 12-40 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 14. Given: a. Draw a product structure tree (tree diagram) for the scissors. Lead times are 1 day for each component and final scissor assembly, but 2 days for the plastic grips. 600 scissors are needed on Day 6. On hand inventory: Straight blades = 200, bent blades = 350, and top blade assembly = 40. Scissors Bottom Blade Assembly Straight Blade Screw Top Blade Assembly Straight Plastic Grip Bent Blade Bent Plastic Grip b. Material plans: Master Schedule for: Scissors Week Beg. Inv. 1 2 3 4 5 Quantity Scissors LT = 1 Lot size: Lot-for-Lot Gross requirements 6 7 8 7 8 0 0 6 7 8 0 0 0 600 Beg. Inv. 1 2 3 4 5 6 600 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 Net requirements 600 Planned-order receipts 600 Planned-order releases Bottom Blade Assembly LT = 1 Lot size: Lot-for-Lot Gross requirements 600 Beg. Inv. 1 2 3 4 5 600 Scheduled receipts Projected on hand 0 0 0 0 0 0 Net requirements 600 Planned-order receipts 600 Planned-order releases 600 Notes: Gross Requirements (week 5) = Planned-Order Releases of 600 Scissors * 1 = 600. 12-41 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Top Blade Assembly LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 600 Scheduled receipts Projected on hand 40 40 40 40 40 40 Net requirements 560 Planned-order receipts 560 Planned-order releases 560 Notes: Gross Requirements (week 5) = Planned-Order Releases of 600 Scissors * 1 = 600. Screw LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 600 Scheduled receipts Projected on hand 0 0 0 0 0 0 Net requirements 600 Planned-order receipts 600 Planned-order releases 600 Notes: Gross Requirements (week 5) = Planned-Order Releases of 600 Scissors * 1 = 600. Straight Blade LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 0 600 Scheduled receipts Projected on hand 200 200 200 200 200 Net requirements 400 Planned-order receipts 400 Planned-order releases 400 Notes: Gross Requirements (week 4) = Planned-Order Releases of 600 Bottom Blade Assembly * 1 = 600. 12-42 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Straight Plastic Grip LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 0 600 Scheduled receipts Projected on hand 0 0 0 0 0 Net requirements 600 Planned-order receipts 600 Planned-order releases 600 Notes: Gross Requirements (week 4) = Planned-Order Releases of 600 Bottom Blade Assembly * 1 = 600. Bent Blade LT = 1 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 0 560 Scheduled receipts Projected on hand 350 350 350 350 350 Net requirements 210 Planned-order receipts 210 Planned-order releases 210 Notes: Gross Requirements (week 4) = Planned-Order Releases of 560 Top Blade Assembly * 1 = 560. Bent Plastic Grip LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 2 3 4 5 6 7 8 0 0 0 0 560 Scheduled receipts Projected on hand 0 0 0 0 0 Net requirements 560 Planned-order receipts 560 Planned-order releases 560 Notes: Gross Requirements (week 4) = Planned-Order Releases of 560 Top Blade Assembly * 1 = 560. 12-43 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 15. Given: A company has the following demand for its products, labor and machine standards, and available capacities: Week number Material (tons) 1 40 2 80 Production standard (hours per ton) Weekly production capacity (hours) 3 60 4 70 Labor 4 Machine 3 300 200 a. Determine capacity utilization for labor and machine for each of the four weeks: Capacity Requirements (Load) = Units * Standard Labor and/or Machine Requirements per Unit Week number Material (tons) Labor standard Labor requirements (load) Machine standard Machine requirements (load) Week number Labor requirements Labor capacity Labor utilization Machine requirements Machine capacity Machine utilization Labor and Machine Capacity Requirements (Load) 1 2 3 40 80 60 4 4 4 4 70 4 40 * 4 = 160 80 * 4 = 320 60 * 4 = 240 70 * 4 = 280 3 3 3 3 40 * 3 = 120 80 * 3 = 240 60 * 3 = 180 70 * 3 = 210 Capacity Utilization (round % to two decimals) 1 2 3 160 320 240 4 280 300 160/300 * 100 = 53.33% 120 300 320/300 * 100 = 106.67% 240 300 240/300 * 100 = 80.00% 180 300 280/300 * 100 = 93.33% 210 200 120/200 * 100 = 60.00% 200 240/200 * 100 = 120.00% 200 180/200 * 100 = 90.00% 200 210/200 * 100 = 105.00% b. Capacity utilization exceeds 100% for both labor and machine in week 2, and for machine in week 4. Production could be shifted to earlier or later weeks in which capacity is underutilized. Shifting to an earlier week would result in added carrying costs; shifting to later weeks would mean backorder costs. Another option could be to work overtime. Labor cost would increase due to overtime premium, a probable decrease in productivity, and a possible increase in accidents. 12-44 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 16. Given: A company produces 2 products that go through a 3-day sequence of fabrication, assembly, and packaging. Each step requires 1 day for a lot to be processed and moved to the next department. Processing requirements for the departments (hours per unit) are: Product A B FABRICATION Labor Machine 2 1 1 1 ASSEMBLY Labor Machine 1.5 1 1 1 PACKAGING Labor Machine 1 .5 1.5 .5 Department capacities are all 700 hours of labor and 500 hours of machine time, except Friday, when capacities are 200 hours for both labor and machine time. The following production schedule is for next week: Product A B Mon 200 300 Tue 400 200 Wed 100 200 Thu 300 200 Fri 100 200 a. Determine the labor and machine capacity requirements for each product and the total load at each department for each day. For example, the 200 units of Product A & 300 units of Product B will be processed at Fabrication on Monday, Assembly on Tuesday, and Packaging on Wednesday. Monday Fabrication Labor Load = (200 A * 2 = 400) + (300 B * 1 = 300) = 700. Monday Fabrication Machine Load = (200 A * 1 = 200) + (300 B * 1 = 300) = 500. Tuesday Assembly Labor Load = (200 A * 1.5 = 300) + (300 B * 1 = 300) = 600. Tuesday Assembly Machine Load = (200 A * 1 = 200) + (300 B * 1 = 300) = 500. Wednesday Packaging Labor Load = (200 A * 1 = 200) + (300 B * 1.5 = 450) = 650. Wednesday Packaging Machine Load = (200 A * .5 = 100) + (300 B * .5 = 150) = 250. 12-45 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Day Product Fabrication Labor Machine Assembly Labor Machine Packaging Labor Machine Mon A B Load Capacity 400 300 700 700 200 300 500 500 Tue A B Load Capacity 800 200 1000 700 400 200 600 500 300 300 600 700 200 300 500 500 Wed A B Load Capacity 200 200 400 700 100 200 300 500 600 200 800 700 400 200 600 500 200 450 650 700 100 150 250 500 Thu A B Load Capacity 600 200 800 700 300 200 500 500 150 200 350 700 100 200 300 500 400 300 700 700 200 100 300 500 Fri A B Load Capacity 200 200 400 200 100 200 300 200 450 200 650 200 300 200 500 200 100 300 400 200 50 100 150 200 b. Evaluate the loading for the first 3 days of the week: Monday: Fabrication: Load = capacity for both labor and machine. Tuesday: Fabrication: Labor load is over capacity by 300 hours. Machine load is over capacity by 100 hours. Assembly: Labor load is under capacity by 100 hours. Machine load = capacity. Wednesday: Fabrication: Labor load is under capacity by 300 hours. Machine load is under capacity by 200 hours. Assembly: Labor load is over capacity by 100 hours. Machine load is over capacity by 100 hours. Packaging: Labor load is under capacity by 50 hours. Machine load is under capacity by 250 hours. The schedule does not appear to be feasible. Fabrication is overloaded for labor and machine on Tuesday and underloaded for labor and machine on Wednesday. In addition, Assembly is overloaded for labor and machine on Wednesday. One solution could be to shift some of the 400 A & 200 B scheduled in Fabrication on Tuesday to Wednesday. For example, we could shift 150 A in Fabrication from Tuesday to 12-46 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Wednesday. We now would schedule 250 A on Tuesday (400-150) and 250 A on Wednesday (100+150). The new load values are highlighted in bold in the table below: Day Product Fabrication Labor Machine Assembly Labor Machine Packaging Labor Machine Mon A B Load Capacity 400 300 700 700 200 300 500 500 Tue A B Load Capacity 500 200 700 700 250 200 450 500 300 300 600 700 200 300 500 500 Wed A B Load Capacity 500 200 700 700 250 200 450 500 375 200 575 700 250 200 450 500 200 450 650 700 100 150 250 500 Thu A B Load Capacity 600 200 800 700 300 200 500 500 375 200 575 700 250 200 450 500 250 300 550 700 125 100 225 500 Fri A B Load Capacity 200 200 400 200 100 200 300 200 450 200 650 200 300 200 500 200 250 300 550 200 125 100 225 200 12-47 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 17. Given: The MRP department’s computer died just as it spit out the following information: Planned-Order Releases for Item J27 = 640 units in week 2. We have the following product structure tree and inventory information shown below: 565 X43 Y36(2) J27(4) N78 X43 Part Number 565 X43 On Hand 0 60 N78 Y36 J27 0 200 0 Lot Size Lot-for-lot Multiples of 120 Lot-for-lot Lot-for-lot Lot-for-lot Lead Time 1 week 1 week 2 weeks 1 week 2 weeks Step 1: Look at which items are linked together by the Planned-Order Releases for J27: J27, Y36, and 565. Step 2: Work from the bottom to the top of the product structure tree. Start with J27 to determine its Planned-Order Receipts, Net Requirements, and Gross Requirements. a. We know that J27 has a Planned-Order Release = 640 in week 2. The lead time for J27 = 2 weeks. This means that the Planned-Order Receipts = 640 in week 4 (2 weeks later). The lot size for J27 = lot-for-lot. This means that the Net Requirements = Planned-Order Receipts in week 4 = 640. The on hand balance for J27 = 0. This means that the Gross Requirements in week 4 = Net Requirements + On Hand = 640 + 0 = 640. b. If the Gross Requirements for J27 = 640 in week 4, then the Planned-Order Releases for Y36 = 160 (640 / 4) in week 4. The lead time for Y36 = 1 week. This means that the Planned-Order Receipts = 160 in week 5 (1 week later). The lot size for Y36 is lot-for-lot. This means that the Net Requirements = Planned-Order Receipts in week 5 = 160. The on hand balance for Y36 = 200. This means that the Gross Requirements in week 5 = Net Requirements + On Hand = 160 + 200 = 360. 12-48 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP c. If the Gross Requirements for Y36 = 360 in week 5, the Planned-Order Releases for 565 = 180 (360 / 2) in week 5. The lead time for 565 = 1 week. This means that the Planned-Order Receipts = 180 in week 6 (1 week later). The lot size for 565 is lot-for-lot. This means that the Net Requirements = Planned-Order Receipts in week 6 = 180. The on hand balance for 565 = 0. This means that the Gross Requirements in week 6 = Net Requirements + On Hand = 180 + 0 = 180. Conclusion: There should be a quantity of 180 listed in week 6 of the master schedule for Item 565. Below are the MRP tables verifying the proof discussed above: Master Schedule for: 565 Week 1 2 3 4 5 7 8 7 8 0 0 6 7 8 0 0 0 5 6 7 8 0 0 0 0 Quantity 565 LT = 1 Lot size: Lot-for-Lot 6 180 Beg. Inv. 1 2 3 4 5 Gross requirements 6 180 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 Net requirements 180 Planned-order receipts 180 Planned-order releases Y36(2) LT = 1 Lot size: Lot-for-Lot 180 Beg. Inv. 1 2 3 4 Gross requirements 5 360 Scheduled receipts Projected on hand 200 200 200 200 200 200 Net requirements 160 Planned-order receipts 160 Planned-order releases J27(4) LT = 2 Lot size: Lot-for-Lot Gross requirements 160 Beg. Inv. 1 2 3 4 640 Scheduled receipts Projected on hand 0 0 0 0 0 Net requirements 640 Planned-order receipts 640 Planned-order releases 640 12-49 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP 18. Given: Develop a material requirements plan for component H. Use lot-for-lot ordering for all items. Lead times for the end item and each component (except B) = 1 week. The lead time for B = 3 weeks. On hand balances: B = 15 & E = 130. Scheduled Receipts for H = 50 in week 2. 60 units of A are needed at the start of week 8. We have the following product structure tree: A C B(2) D(2) E(2) D(2) H(3) E(4) K H(3) K We will need material plans for A, B, C, E, & H. Master Week Schedule for: A Quantity A LT = 1 Lot size: Lot-for-Lot 1 2 3 4 5 6 7 8 60 Beg. Inv. 1 2 3 4 5 6 7 Gross requirements 8 60 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 0 0 Net requirements 60 Planned-order receipts 60 Planned-order releases 60 12-50 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP B(2) LT = 3 Lot size: Lot-for-Lot Beg. Inv. 1 2 3 4 5 6 Gross requirements 7 8 120 Scheduled receipts Projected on hand 15 15 15 15 15 15 15 15 Net requirements 105 Planned-order receipts 105 Planned-order releases C LT = 1 Lot size: Lot-for-Lot 0 105 Beg. Inv. 1 2 3 4 5 6 Gross requirements 7 8 60 Scheduled receipts Projected on hand 0 0 0 0 0 0 0 0 Net requirements 60 Planned-order receipts 60 Planned-order releases E(2) & E(4) LT = 1 Lot size: Lot-for-Lot 0 60 Beg. Inv. 1 2 3 Gross requirements 4 5 210 6 7 8 0 0 240 Scheduled receipts Projected on hand 130 130 130 130 130 0 0 Net requirements 80 240 Planned-order receipts 80 240 Planned-order releases 80 240 Notes: Gross Requirements (week 4) = Planned-Order Releases of 105 B * 2 = 210. Gross Requirements (week 6) = Planned-Order Releases of 60 C * 4 = 240. 12-51 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP H(3) LT = 1 Lot size: Lot-for-Lot Beg. Inv. 1 2 Gross requirements 4 240 Scheduled receipts Projected on hand 3 5 6 7 8 0 0 0 720 50 0 0 50 50 0 0 Net requirements 190 720 Planned-order receipts 190 720 Planned-order releases 190 720 Notes: Gross Requirements (week 3) = Planned-Order Releases of 80 E * 3 = 240. Gross Requirements (week 5) = Planned-Order Releases of 240 E * 3 = 720. Case: Promotional Novelties Given: Promotional Novelties has received an order for 20,000 toy Tractor-Trailers to be ready at the beginning of week 8. The company can complete final assembly of the Tractor-Trailers at a rate of 10,000 a week. Tractors and Trailers are purchased and have a lead time = 3 weeks. The company has sufficient supply of Brackets on hand. Assembly time = 1 week for Tractors, Trailers, and Wheel Assembly. However, the Wheel Department can assemble a maximum of 100,000 Wheels a week. The manager plans to use the Wheel Department to full capacity, starting in week 2 of the schedule, and order additional Wheels from a supplier as needed. Wheels are ordered in sets (multiples) of 6,400, and the lead time from the supplier = 2 to 3 weeks. All items use lot-for-lot ordering except for the purchased Wheels (lot size = multiples of 6,400). Comments on the product structure tree shown in the text: The Wheel Assembly of the Tractor differs from the Wheel Assembly of the Trailer. The Body of the Tractor differs from the Body of the Trailer. The Tractor and the Trailer use the same Wheel. We will develop material plans for Tractor-Trailer, Tractor, Trailer, Tractor Wheel Assembly, Trailer Wheel Assembly, & Wheels. If the order of 20,000 tractor-trailers is due at the start of week 8 and final assembly is limited to 10,000 per week, then we must list 10,000 in week 7 and 10,000 in week 8 of the master schedule. 12-52 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Master Week Schedule Quantity 1 2 3 4 5 6 7 8 10,000 10,000 7 8 10,000 10,000 0 0 Net requirements 10,000 10,000 Planned-order receipts 10,000 10,000 Tractor-Trailer LT = 1 Lot size: Lot-for-Lot Beg. Inv. 1 2 3 4 5 6 Gross requirements Scheduled receipts Projected on hand 0 0 0 0 0 0 Planned-order releases 0 10,000 10,000 6 7 10,000 10,000 0 0 Net requirements 10,000 10,000 Planned-order receipts 10,000 10,000 Tractor LT = 1 Lot size: Lot-for-Lot Beg. Inv. 1 2 3 4 5 Gross requirements 8 Scheduled receipts Projected on hand 0 0 0 0 0 Planned-order releases 0 10,000 10,000 5 6 7 10,000 10,000 0 0 Net requirements 10,000 10,000 Planned-order receipts 10,000 10,000 Trailer LT = 1 Lot size: Lot-for-Lot Beg. Inv. 1 2 3 4 Gross requirements 0 8 Scheduled receipts Projected on hand 0 0 0 0 Planned-order releases 0 0 10,000 0 10,000 12-53 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Tractor Wheel Assembly LT = 1 Beg. Inv. 5 6 10,000 10,000 0 0 Net requirements 10,000 10,000 Planned-order receipts 10,000 10,000 Lot size: Lot-for-Lot 1 2 3 4 Gross requirements 7 8 0 0 7 8 0 0 Scheduled receipts Projected on hand 0 0 0 0 Planned-order releases 0 10,000 10,000 4 5 6 10,000 10,000 0 0 Net requirements 10,000 10,000 Planned-order receipts 10,000 10,000 Trailer Wheel Assembly LT = 1 Lot size: Lot-for-Lot Beg. Inv. 1 2 3 Gross requirements Scheduled receipts Projected on hand 0 0 0 0 Planned-order releases 0 10,000 10,000 12-54 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Wheels (6) & (12) LT = 1 Lot size: Lot-for-Lot Beg. Inv. 1 2 3 Gross requirements 4 5 180,000 180,000 100,000 20,000 80,000 160,000 6 7 8 4,000 4,000 4,000 Scheduled receipts Projected on hand 0 0 0 0 Net requirements Planned-order receipts Planned-order releases 100,000 64,000* 100,000 100,000 100,000 100,000 100,000 64,000* Notes: Gross Requirements (week 4) = Planned-Order Releases of (10,000 Tractor Wheel Assembly * 6) + (10,000 Trailer Wheel Assembly * 12) = 60,000 + 120,000 = 180,000. Gross Requirements (week 5) = Planned-Order Releases of (10,000 Tractor Wheel Assembly * 6) + (10,000 Trailer Wheel Assembly * 12) = 60,000 + 120,000 = 180,000. The Planned-Order Receipts in weeks 3, 4, & 5 would be entered as Firm Planned Orders locked in by the MRP planner so that the MRP system does not re-schedule these amounts automatically. Planned-Order Releases (week 2) = [Planned-Order Receipts (week 3) of 100,000] + [Planned-Order Receipts (week 5) of 64,000] = 100,000 + 64,000 = 164,000. 1. The company will need a total of 360,000 Wheels. It will be able to produce only 300,000 during weeks 2, 3, & 4. The company will need to order at least 60,000 Wheels as indicated with the * in week 2. The company actually would have to purchase 10 sets of 6,400 Wheels per set = 64,000. 2. The company will need the Wheels in week 5. If lead time will be 2-3 weeks, then assume that it will be 3 weeks, and order the Wheels from the supplier in week 2. 12-55 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Case: DMD Enterprises Given: Marty wants to assemble 15 Arrows and 10 Darts each week to have them ready at the start of weeks 4 through 8. The product structure trees are given in the text along with inventory information on lead times, on hand amounts, and lot sizing rules. Scheduled Receipts: Arrows = 20 in week 1 & W = 18 in week 1. Darts = 20 in week 2 & F = 15 in week 2. Develop the material plans for all items. Master Schedule for: Arrows Week Master Schedule for: Darts Week 1 2 3 4 5 6 7 8 15 15 15 15 15 4 5 6 7 8 10 10 10 10 10 4 5 6 7 8 15 15 15 15 15 25 10 0 0 0 Net requirements 5 15 15 15 Planned-order receipts 5 15 15 15 Quantity 1 2 3 Quantity Arrows LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. Scheduled receipts Projected on hand 1 2 3 20 5 25 25 25 5 15 15 15 3 4 5 6 7 8 10 10 10 10 10 22 12 2 0 0 Net requirements 8 10 10 Planned-order receipts 8 10 10 7 8 5 5 Planned-order releases Darts LT = 2 Lot size: Lot-for-Lot Gross requirements Beg. Inv. 1 Scheduled receipts Projected on hand 2 20 2 2 22 22 8 10 10 3 4 5 6 5 15 15 15 5 0 10 20 Net requirements 15 5 Planned-order receipts 25 25 Planned-order releases X LT = 1 Lot size: Multiples of 25 Gross requirements Beg. Inv. 1 2 Scheduled receipts Projected on hand 5 5 5 25 Planned-order releases 25 12-56 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Case: DMD Enterprises (continued) M LT = 1 Lot size: Lot-for-lot Gross requirements Beg. Inv. 3 4 5 6 5 15 15 15 0 0 0 0 Net requirements 5 15 15 15 Planned-order receipts 5 15 15 15 5 15 15 15 2 3 4 5 6 16 20 20 3 0 0 Net requirements 13 20 20 Planned-order receipts 13 20 20 Scheduled receipts Projected on hand 0 1 0 Planned-order releases K(2) LT = 1 Lot size: Lot-for-lot Beg. Inv. 1 2 0 Gross requirements Scheduled receipts Projected on hand 3 3 3 3 7 8 0 0 7 8 0 0 7 8 7 7 Planned-order releases 13 20 20 Gross Requirements (week 4) = Planned-Order Releases of 8 Darts * 2 = 16. Gross Requirements (week 5) = Planned-Order Releases of 10 Darts * 2 = 20. Gross Requirements (week 6) = Planned-Order Releases of 10 Darts * 2 = 20. F&F LT = 1 Lot size: Multiples of 30 Gross requirements Beg. Inv. 3 4 5 6 25 33 10 10 25 0 27 17 Net requirements 33 0 0 Planned-order receipts 60 Scheduled receipts Projected on hand 1 2 15 10 10 25 Planned-order releases 60 Notes: Gross Requirements (week 3) = Planned-Order Releases of 25 X * 1 = 25. Gross Requirements (week 4) = Planned-Order Releases of (8 Darts * 1) + (25 X * 1) = 8 + 25 = 33. Gross Requirements (week 5) = Planned-Order Releases of 10 Darts * 1 = 10. Gross Requirements (week 6) = Planned-Order Releases of 10 Darts * 1 = 10. 12-57 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP W & W(2) LT* = 2 or 3 Lot size: Multiples of 12 Gross requirements Scheduled receipts Projected on hand Beg. Inv. 1 2 3 4 5 6 31 55 55 15 7 8 8 8 18 20 1 6 11 Net requirements 11 49 4 Planned-order receipts 12 54 60 60 12 2 Planned-order releases 20 72 20 60 12 Notes: Gross Requirements (week 3) = Planned-Order Releases of (5 Arrows *1) + (13 K * 2) = 5 + 26 = 31. Gross Requirements (week 4) = Planned-Order Releases of (15 Arrows * 1) + (20 K * 2) = 15 + 40 = 55. Gross Requirements (week 5) = Planned-Order Releases of (15 Arrows * 1) + (20 K * 2) = 15 + 40 = 55. Gross Requirements (week 6) = Planned-Order Releases of 15 Arrows * 1 = 15. *Lead time = 2 weeks for orders < 36 & 3 weeks for orders ≥ 36. Planned-Order Releases (week 1) = [Planned-Order Receipts (week 3) = 12] + [Planned-Order Receipts (week 4) = 60] = 72. Q LT = 1 Lot size: Multiples of 30 Gross requirements Beg. Inv. 3 4 5 13 20 20 15 2 12 Net requirements 18 8 Planned-order receipts 30 30 Scheduled receipts Projected on hand 15 1 15 2 15 6 7 8 22 22 22 Planned-order releases 30 30 Gross Requirements (week 3) = Planned-Order Releases of 13 K * 1 = 13. Gross Requirements (week 4) = Planned-Order Releases of 20 K * 1 = 20. Gross Requirements (week 5) = Planned-Order Releases of 20 K * 1 = 20. 12-58 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Chapter 12 - MRP and ERP Operations Tour: Stickley Furniture 1. Batch processing is used with typical lot sizes of 25 to 60 pieces of different types of furniture, such as tables, chairs, desks, dressers, etc. Repetitive processing is used at sawing, drilling, finishing, etc. Job shop processing is used for expensive one-of-a-kind special orders that may be received. 2. Each job is accompanied by a set of bar codes that identifies the job and the operation. As each operation is completed, the operator removes a bar code sticker and delivers it to the scheduling office, where it is scanned into a computer, thereby enabling production control to keep track of progress on a job, and to know its location in the shop. 3. The information needed to plan, schedule, and process the order for 40 mission oak dining room sets includes: a. Number of finished units presently in inventory b. Type of wood c. Type of furniture d. Style of furniture e. Number of finished products needed f. List of component parts for each finished product g. Operations required for each component part h. Inventory for each component part i. Sequence of operations for each component j. Sequence of operations for each finished product k. Orders already in progress or scheduled to precede this order l. Unutilized equipment and labor m. Processing times for each component and total processing time for the finished product 4. One benefit would be the stability and improved morale brought about by maintaining a constant size workforce. A problem could be the buildup of inventories during certain quarters of the year. 5. Because there is a dependent demand situation for all of the components that go into the finished products, the installation of an MRP system might be of great help to this company in meeting its delivery dates and in keeping inventory costs down. 12-59 Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education.