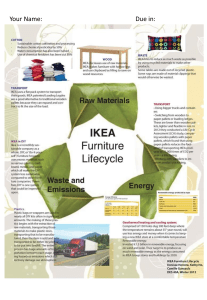

CUSTOMER RELATIONSHIP MANAGEMENT AT IKEA • Flat Pack Assembly Kit Design Most of IKEA's products are delivered as "flat-pack" self-assembly kits. However, IKEA's products had been designed not only to reduce shipping costs, but also to minimize production assembly costs. Clever design has been used to produce goods which can be assembled by the purchaser with minimal skill (use of a screwdriver and spanner only), from parts manufactured by machine with little human effort in the production plant. The design also ensured a robust, stylish piece of furniture despite the limited skills of the assembler. Much of the work involved in manufacturing the piece of furniture had been moved from the factory, to the customer. The reduction in cost had also been passed onto the customer. For at least this customer, there was also a significant feeling of achievement in assembling the table or chair. Ikea's out-of-town, large-scale outlet had the space to attempt something different. The products are displayed in a number of room mock-ups so that pieces could be seen in relation to other products, with 'design stations' to help the customer to build their own design. Ikea staffs are on hand, but not as sales assistants, more to advice on design, check whether stock was available, etc. This approach helps with the interior design aspects of selecting furniture, again for this customer at least, a difficult aspect of buying furniture. • Customer Direct Transactions: If you think about it for a minute, because Ikea won't take orders, it is a key that customers can find out if Ikea has a particular item in stock. Ikea have recognized this and so provide an automated phone service to allow you to check whether the item you want is in stock. That item is number 1 in the automated service menu - first plus mark. There are a large number of stores which customers wish provided a similar service. They then tell you the items on that page at that price and you confirm which one you want. A pretty weird transaction by the IT standards, but customer-friendly. If you're a customer interested in stock levels, you're very likely to have the catalogue open. The page number is meaningful to you, is short and easy to enter on a phone keypad (all digits). The price is also meaningful, again short and easy to enter (all numeric). No company has such simple stockcodes. Someone has designed this transaction with the end-user (the customer) in mind. Ikea have chosen to change from a conventional business model to reduce prices significantly, by placing a lot of burden onto the customer. CRM is not necessarily about better customer service, but about giving the customer a better value proposition, or 'increased value for money'. Their change in business model leads to a need for a new transaction for the customer. That transaction is designed to be simple and fast for the customer to use. In Ken's words (nearly) in this week' newsletter - they've listened to their customers. • Social Interactions The most apparent reasons for people choosing to shop at IKEA is a combination of the store being perceived as offering a major cost-advantage with their products being relatively cheap in comparison to other retailers and that the product assortment is wide and constantly changing. People do not tend to visit IKEA by themselves and women in particular like to have a few people accompanying them when going to IKEA. The access to restaurants and coffee-shops provides the customer with social activities in combination with the shopping experience, it also makes it very convenient for the customer to know that even a basic need like having to eat can be satisfied at the same place they shop at. By visiting a retailer like IKEA, with a large number of customers shopping at the same time the chance of social interaction between customer’s increases. IKEA follows the concept of self-service where the contact between customer and store-clerks is not very extensive and therefore customer’s looks to other customers for help or questions. Due to the wide product assortment being offered at IKEA a visit to a retailer is subject to careful planning since the visit is more time-consuming than most shopping- experiences. But because the customer spends a long time at the store it provides a great chance for customers to discover and get acquaintance with many products. The many various products also make IKEA more personal since it appeals to various tastes and preferences. • Informative Stores Customers do not tend to have any difficulties finding information about IKEA´s products. The catalogue that IKEA sends out to almost every household in Sweden helps to create interest among customers and makes it easy for them to attain information about the products. The catalogue also functions as pre-purchase planning tool, especially for women, where a customer can decide what they need and want to purchase from IKEA, before seeing the actual products. Another way for customer to get information about products being offered at IKEA is by visiting the company’s official website. Furthermore the IKEA store itself is a great source of information since tags, describing the product and how to use it, are attached to all products. Because IKEA have extensive opening hours with their stores being open both on weekdays as well as weekends it is easy for all types of customers to be able to be to find time to visit them. MERCHANDISE MANAGEMENT AT IKEA (INVENTORY) • Combining Retail And Warehouse Processes Every IKEA store has a warehouse on the premises. On the main showroom floor, customers can browse for items. They then obtain the products themselves from the floor pallet location with racking as high as the typical person could reach, where furniture can be purchased and taken home. Additional products are stored in reserve racks above these locations. Inventory is let down to the lower slots at night (forklifts and pallet jacks are not used during store hours for safety reasons). About one third of the lower level is comprised of a warehouse off limits to customers. This space contains items too bulky for customers to load without help from the staff. Since IKEA wants as much self-service as possible, it works to minimize the number of items in this bulk storage area. • Cost-Per-Touch Inventory Tactic Having customers select the furniture and retrieve the packages themselves is an inventory management tactic called ‘cost-per-touch’. As a rule of thumb, companies find that the more hands touch the product, the more costs are associated with it. For example, imagine when someone selects a piece of furniture to buy. The item is then ordered, shipped from the manufacturer, moved from the delivery truck into storage in the warehouse, moved from the warehouse to the customer’s vehicle or delivered by the furniture retailer to the customer’s home. Every time the product is shipped, moved, and loaded, it costs money. The fewer times someone moves or touches the item, the fewer costs are associated with it. IKEA saves costs with this guiding principle to minimize touches because it doesn’t have to pay the customer to retrieve the furniture and take it home. • In-Store Logistics IKEA also relies on something rare and unique concerning its logistical management of reordering products – it employs in-store logistics personnel to handle inventory management at its stores. There is an in-store logistics manager responsible for the ordering process and a store goods manager responsible for material handling logistics at all IKEA stores. The duties of the logistics personnel are to monitor and record deliveries, carefully check delivery notices, sort and separate the goods, and get them off to the correct sales area or designated overstock locations. Overall, they ensure an efficient flow of goods within IKEA stores, which is essential to maintaining high sales and enhancing customer loyalty. • Maximum/Minimum Settings As Proprietary System The in-store coordination supervisors utilize a stock renewal the board cycle created by IKEA called 'least/most extreme settings' to react to store-level stock reorder focuses and reorder items. Least settings: The base measure of items accessible prior to reordering. Most extreme settings: The greatest measure of a specific item to arrange at one time. Because of the way that all IKEA stock is just supplied around evening time in the wake of opening times, the rationale of its min/max settings depends on the quantity of items that will be sold from the save heap of canister in a solitary day or two-day duration. The cycle satisfies client need while limiting requesting too not many or an excessive number of items. This system likewise guarantees that IKEA has prepared stock to satisfy clients' needs, bringing down the expense of lost deals. Utilizing IKEA's restrictive stock framework, coordination administrators realize what is sold through retail location (POS) information and how much stock comes into the store through direct delivery and from dissemination focuses through distribution center administration framework information. From these information, they can gauge deals for the following couple of days and request in the reasonable measure of items to fulfill that need. In the event that the business information doesn't coordinate the extended number of things that ought to have been sold that day, the coordination administrator goes straightforwardly to the bed and receptacle to physically check the item stock. IKEA accepts its cycle and situation takes into consideration the correct merchandise to be in the store with more noteworthy sureness, and at a lower cost, than the customary retail determining and renewal measure. • Usage Of High-Flow and Low-Flow Warehouse Facilities IKEA's store activities are upheld by high-stream offices (zeroed in on the 20% of SKUs that represent 80% of the volume) and low-stream distribution centers that are more manual. In its high-stream distribution centers, IKEA utilizes programmed capacity and recovery frameworks to drive down its expenses per-contact. Items supplied in a low-stream office are not sought after, and activities depend on manual cycles since laborers won't be moving a lot stock around something over the top. These procedures have made IKEA the world's best furniture retailer with low working expenses and high item interest. This permits the organization to remain serious in the business as it persistently looks for further developed techniques to smooth out store network the executives. IKEA has a reasonable vision upheld by integral cross-useful rationale. This separates IKEA from its companions, yet additionally furnishes it with an upper hand that is hard to copy at different associations. While it could be difficult for different associations to duplicate IKEA's fruitful recipe with stock administration and request satisfaction, IKEA's inventory network methodologies pushes against limits. This will ideally move you to build up your organization's stock systems appropriate for your organization's specific activities. IKEA'S RETAIL PRICING AND PRICING POLICIES • .99 Pricing IKEA costs their item with value finishing in 99 just in Sweden. Following this effective value technique usage in Sweden, it has extended to each nation that IKEA has store. It turned into a symbol of IKEA's low-value philosophy. In this manner, all items are valued closure in 99, for example, $3.99 or $9.99 in IKEA Australia and India too. • Product Design The item configuration measure at IKEA assumes a focal job in controlling the costs of its items. IKEA doesn't make items that it should cost higher. Rather than making items first and valuing them later, it works in reverse. The organization first sets the costs and afterward checks in the event that it can construct the item at this cost. The whole offer of the organization lays on its valuing procedure since the organization needs to improve regular daily existence for everybody. It is the reason it sets the costs first and afterward starts the plan cycle. The plan cycle at IKEA is called vote based plan and incorporates structure, work, quality, plan, and manageability at moderate costs. IKEA sets the costs that it needs to sell its items for and afterward architect and providers together beginning working around the plan and organization of the item. The inquiry that the planners pose to themselves prior to beginning the plan cycle is if there is a superior method to make a similar item to sell at lower costs. • Bulk Production IKEA doesn't make only a couple bits of each plan since that won't resist support its plan of action. All things considered, the organization produces in mass which implies all that IKEA plans is created in hundreds or thousands so the organization can utilize economies of scale and monitor costs. Mass creation permits the organization to get limits on creation and hence the organization figures out how to keep costs lower. Along these lines, the items that fill in prominence and whose request rises, experience a value decrease. It is on the grounds that the organization begins delivering a greater amount of them and can keep its overall revenue on every unit low while additionally accomplishing mass deals and higher income. • Reference Pricing IKEA regularly considers a value change; however how they cause shoppers to accept that new cost is a decent arrangement. At that point, when IKEA sets the new costs, they put the past costs also. At the point when buyers gauge a cost of item to choose whether they consider the cost is a decent arrangement, they need to check the cost with certain references. In the event that the new cost is with certain references, individuals may think the current cost is a decent arrangement dependent on reference they are given. Hence, IKEA dispatches new cost of items with reference and have incredible appeal to clients. • Saving on Sales and Transportation Costs IKEA has dealt with these parts of its business likewise very well to limit expenses and keep costs low for clients. Above all else, it doesn't keep the same number of staff as different retailers inside its stores. Nonetheless, every kind of data that you may require identified with the item is accessible with it including costs and different details. On the off chance that you need uphold inside the stores, IKEA staff is accessible to deal with your questions. The organization saves money on transportation with the assistance of level bundling. IKEA packs everything level which implies more furniture can be stuffed into trucks and shipped from the stockrooms to the stores. Different territories where expenses are limited or wiped out incorporate conveyance and get together of furniture. Self-get together permits IKEA to eliminate the expenses related with amassing furniture. Clients get the furniture from stores and accordingly they don't pay the concealed expenses related with free conveyance. In any case, on the off chance that somebody needs assistance with amassing furniture then one can employ from Task-Rabbit.