Machining Operations & Machine Tools: Turning, Milling, Drilling

advertisement

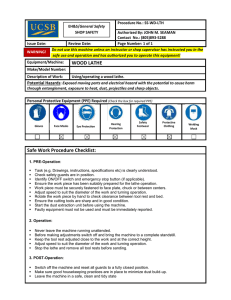

Manufacturing Processes 1 (MDP 114) First Year, Mechanical Engineering Dept., Faculty of Engineering, Fayoum University Dr. Ahmed Salah Abou Taleb 1 Machining Operations & Machine Tools Turning Planner Milling Gears Drilling Machine Screw Thread Shaper Saw Broacher 2 Classifications of Machined Parts 1. Rotational - cylindrical shape 2. Non-rotational (also called prismatic) – block or plate Machined parts are classified as: (a) rotational, or (b) non-rotational, 3 Part Geometry Each machining operation produces a characteristic part geometry due to two factors: 1. Relative motions between the tool and the workpart. • Generating – part geometry is determined by the feed trajectory of the cutting tool. 2. Shape of the cutting tool. • Forming – part geometry is created by the shape of the cutting tool. 4 Part Geometry Generating shape: (a) straight turning, (b) taper turning, (c) contour turning, (d) plain milling, (e) profile milling 5 Part Geometry Forming to create shape: (a) form turning, (b) drilling, and (c) broaching 6 Part Geometry Combination of forming and generating to create shape: (a) thread cutting on a lathe, and (b) slot milling 7 Turning/Lathe Machine 8 Definition Turning/Lathe is a single point cutting tool machine, which removes the metal from a rotating piece of work to generate the required cylindrical shape &size. 9 Types of Turning/Lathe Engine Turning/Lathe: The most common form of lathe, motor driven and comes in large variety of sizes and shapes. Bench Turning/Lathe: A bench top model usually of low power used to make precision machine small work pieces. Tracer Turning/Lathe: a lathe that has the ability to follow a template to copy a shape or contour. 10 Types of Turning/Lathe Automatic Turning/Lathe: A lathe in which the work piece is automatically fed and removed without use of an operator. Cutting operations are automatically controlled by a sequencer of some form Turret Turning/Lathe: lathe which have multiple tools mounted on turret either attached to the tailstock or the cross-slide, which allows for quick changes in tooling and cutting operations. Computer Controlled Turning/Lathe: A highly automated lathe, where both cutting, loading, tool changing, and part unloading are automatically controlled 11 by computer coding. Turning/Lathe Machine 12 Turning/Lathe Machine 13 Turning/Lathe Machine Head Stock Tail Stock Bed Feed/Lead Screw Carriage 14 Size of Turning/Lathe Machine Workpiece Length Swing 15 Size of Turning/Lathe Machine Example: 300 - 1500 Lathe • Maximum Diameter of Workpiece that can be machined = SWING (= 300 mm) • Maximum Length of Workpiece that can be held between Centers (=1500 mm) 16 Lathe Operations Turning: produce straight, conical, curved, or grooved workpieces Facing: to produce a flat surface at the end of the part or for making face grooves. Drilling: to produce a hole by fixing a drill in the tailstock 17 Lathe Operations Boring: to enlarge a hole or cylindrical cavity made by a previous process or to produce circular internal grooves. Threading: to produce external or internal threads Knurling: to produce a regularly shaped roughness on cylindrical surfaces 18 Lathe Operations Contouring: tool follows a contour that is other than straight, thus creating a contoured form. Chamfering: Cutting edge cuts an angle on the corner of the cylinder, forming a "chamfer". Cut-off: Tool is fed radially into rotating work at some location to cut off end of part. 19 Lathe Operations Threading: Pointed form tool is fed linearly across surface of rotating workpart parallel to axis of rotation at a large feed rate, thus creating threads. Face Grooving: Taper Turning: Cutting with a form Tool: 20 Methods of Holding the Work • • • • • Holding the work between centers. Chuck. Mandrel. Collet. Face plate. 21 Work holding Devices Centers Headstock center (Live Centre) Tailstock center (Dead Centre) Workpiece 22 Workholding Devices .. Chucks Three jaw Four Jaw 23 Work holding Devices. Chucks Three jaw chuck This is dependant chuck has three jaws for holding cylindrical shapes, which are adjusted collectively. Four-Jaw Chuck This is independent chuck generally has four jaws for holding square and rectangle shapes, which are adjusted individually on the chuck face by means of adjusting screws 24 Work holding Devices . Mandrels Workpiece (job) with a hole Workpiece Mandrel 25 Work holding Devices . Collet 26 Work holding Devices . Face Plate 27 Operating/Cutting Conditions 1. 2. 3. Cutting Speed v Feed f Depth of Cut d Tool post Workpiece N (rev/min) Chip Tool D S peripheral speed (m/min) 28 Operating/Cutting Conditions Tool post Workpiece N (rev/min) Chip Tool D Relative tool travel in 1 rotation = πD Peripheral speed S = πDN S peripheral speed (m/min) 29 Operating/Cutting Conditions D – Diameter (mm) N – Revolutions per Minute (rpm) ν = πDN/1000 m/min The Peripheral Speed of Workpiece past the Cutting Tool =Cutting Speed 30 Operating/Cutting Conditions Fed (f) – the distance the tool advances for every rotation of workpiece (mm/rev) Fed rate (fr) – linear travel rate (mm/min) fr = f N D1 D2 f Feed 31 Operating/Cutting Conditions Depth of cut (d) perpendicular distance between machined surface and uncut surface of the Workpiece d = (D1 – D2)/2 (mm) D1 D2 d Depth of Cut 32 Operating/Cutting Conditions Cutting speed Workpiece Depth of cut (d) Machined surface N Chuck Feed (f ) Tool Chip Depth of cut 33 Operating/Cutting Conditions Material Removal Rate (MRR): Volume of material removed in one revolution MRR = D d f mm3 • Job makes N revolutions/min MRR = D d f N (mm3/min) • In terms of v MRR is given by MRR = 1000 v d f (mm3/min) MRR = D d f N (mm)(mm)(mm/rev)(rev/min) = mm3/min 34 Operating/Cutting Conditions Machining Time (Tm): required time to machine one pass. • Job length (L) mm, Feed (f ) mm/rev, speed (N) rpm, outer diameter (D0) mm, cutting speed (v) mm/min, feed rate (fr) mm/min L L L D0 Tm min f N fr fv 35 Operating/Cutting Conditions Manufacturing Time: the overall time to produce the product. Manufacturing time= Machining Time + Setup Time + Moving Time + Waiting Time 36 Operating/Cutting Conditions • • • • • • Workpiece Material Tool Material Tool signature Surface Finish Accuracy Capability of Machine Tool 37 Operations on Lathe .. Operations on Lathe • • • • • Turning Facing knurling Grooving Parting • • • • Chamfering Taper turning Drilling Threading 38 Operations on Lathe .. Turning Cylindrical job 39 Operations on Lathe .. Turning .. Cylindrical job Cutting speed Workpiece Depth of cut (d) Machined surface N Chuck Feed Tool Chip Depth of cut 40 Operations on Lathe .. Turning .. Excess Material is removed reduce Diameter • Cutting Tool: Turning Tool • to a depth of cut of 1 mm will reduce diameter by 2 mm 41 Operations on Lathe .. Facing Flat Surface/Reduce length Chuck Workpiece d Machined Face Cutting speed Depth of cut Tool Feed 42 Operations on Lathe .. Facing .. • machine end of job Flat surface or to Reduce Length of Job • Turning Tool • Feed: in direction perpendicular to workpiece axis –Length of Tool Travel = radius of workpiece • Depth of Cut: in direction parallel to workpiece axis 43 Operations on Lathe .. Facing .. 44 Operations on Lathe .. Eccentric Turning 4-jaw chuck Axis of job Ax Cutting speed Eccentric peg (to be turned) 45 Operations on Lathe .. Knurling • Produce rough textured surface – For Decorative and/or Functional Purpose • Knurling Tool A Forming Process MRR~0 46 Operations on Lathe .. Knurling Knurled surface Cutting speed Feed Knurling tool Tool post Movement for depth 47 Operations on Lathe .. Knurling .. 48 Operations on Lathe .. Grooving • Produces a Groove on workpiece • Shape of tool shape of groove • Carried out using Grooving Tool A form tool • Also called Form Turning 49 Operations on Lathe .. Grooving .. Shape produced by form tool Form tool Feed or depth of cut Groove Grooving tool 50 Operations on Lathe .. Cut Off • • • • • Cutting workpiece into Two Similar to grooving Parting Tool Hogging – tool rides over – at slow feed Coolant use 51 Operations on Lathe .. Cut Off Parting tool Feed 52 Operations on Lathe .. Chamfering Chamfer Feed Chamfering tool 53 Operations on Lathe .. Chamfering Beveling sharp machined edges Similar to form turning Chamfering tool – 45° To • • • Avoid Sharp Edges Make Assembly Easier Improve Aesthetics 54 Operations on Lathe .. Taper Turning • Taper: tan α = D1 – D2 / 2L 90° D1 B A L D2 C 55 Operations on Lathe .. Taper Turning.. Conicity K = D1 – D2 / L Methods • • • • Form Tool Swiveling Compound Rest Taper Turning Attachment Simultaneous Longitudinal and Cross Feeds 56 Operations on Lathe .. Taper Turning .. By Form Tool Workpiece Taper Form Straight tool cutting edge Direction of feed 57 Operations on Lathe .. Taper Turning ,, By Compound Rest Dog Mandrel Tail stock quill Tail stock Face plate Tool post & Tool holder Cross slide Direction of feed Compound rest Slide Compound rest Hand crank 58 Operations on Lathe .. Drilling Drill – cutting tool – held in TS – feed from TS Quill clamp Drill moving quill Tail stock Feed Tail stock clamp 59 Operations on Lathe .. Process Sequence • How to make job from raw material 45 long x 30 dia.? 15 Steps: •Operations •Sequence 20 dia •Tools •Process 40 60 Operations on Lathe .. Process Sequence .. Possible Sequences • • • • • • TURNING - FACING - KNURLING TURNING - KNURLING - FACING FACING - TURNING - KNURLING FACING - KNURLING - TURNING KNURLING - FACING - TURNING KNURLING - TURNING – FACING X X X X What is an Optimal Sequence? 61 Simple Problems Problem -1 A mild steel rod having 50 mm diameter and 500 mm length is to be turned on a lathe. Determine the machining time to reduce the rod to 45 mm in one pass when cutting speed is 30 m/min and a feed of 0.7 mm/rev is used. Solution Given data: D = 50 mm, Lj = 500 mm v = 30 m/min, f = 0.7 mm/rev Substituting the values of v and D in V = ΠDN/1000 M/min Required spindle speed as: N = 191 rpm 62 Simple Problems Problem -2 Determine the angle at which the compound rest would be swiveled for cutting a taper on a work piece having a length of 150 mm and outside diameter 80 mm. The smallest diameter on the tapered end of the rod should be 50 mm and the required length of the tapered portion is 80 mm. Solution Given data: D1 = 80 mm, D2 = 50 mm, Lj = 80 mm (with usual notations) tan = (80-50) / 280 or = 10.620 The compound rest should be swiveled at 10.62o 63