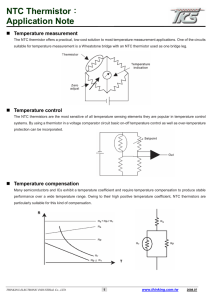

Temperature Measuring Devices Part Liquid Filled Glass Thermometers Details Sealed Glass Thermometers - Immersion Depth 76 mm 1 x Spirit Filled, Range: -10°C to 110°C 1 x Low toxicity liquid, Range: -10°C to 260°C Bi-metal Thermometer Stainless steel shaft with mechanical gauge Bi-metal system Range: 0 to 100°C Indicator Accuracy: 1.5% of scale Gas (Vapour Pressure) Thermometer Stainless steel shaft with mechanical gauge Inert gas system Range: 0 to 100°C Indicator Accuracy: 1% of scale NTC Thermistor Negative Temperature Coefficient 100 Ohm at 25°C Tolerance: +/- 5% Reference Sensor and Resistance Temperature Detector (RTD) Platinum Resistance Thermometers (PRTs), type PT100 (platinum - 100 at 0°C) Normal Temperature range: -50°C to 250°C Class A - High Accuracy 100 +/- 0.06 at 0°C. Thermocouples 2 x K type - Nickel-Chrome, Nickel Aluminium IEC Colour codes: Green wire - Positive (+) White wire - Negative (-) Normal Temperature range: 0°C to 1100°C Approximate Maximum Temperature range: -200°C to 1350°C Accuracy +/- 1°C 1 x J type - Iron, Copper-Nickel IEC Colour codes: Black wire - Positive (+) White wire - Negative (-) Normal Temperature range: 0°C to 700°C Approximate Maximum Temperature range: -40°C to 750°C Accuracy +/- 1°C Infrared Thermometer Hand-held, battery powered. Approximately 0.25 kg NTC Thermistor - Standards NOTE Nominal resistance accuracy for the NTC Thermistor is +/- 5%. °C °C 0 261.0 55 37.82 5 212.6 60 32.64 10 174.4 65 28.33 15 144.2 70 24.70 20 119.9 75 21.57 25 100.0 80 18.91 30 84.18 85 16.65 35 71.08 90 14.71 40 60.32 95 13.02 45 51.42 100 11.56 50 44.04 Table 2 NTC Thermistor - Resistance For Temperatures K Type Thermocouple Standards °C V °C V °C V °C V °C V 0 0 1 39 21 838 41 1653 61 2478 81 3308 2 79 22 879 42 1694 62 2519 82 3350 3 119 23 919 43 1735 63 2561 83 3391 4 158 24 960 44 1776 64 2602 84 3433 5 198 25 1000 45 1817 65 2644 85 3474 6 238 26 1041 46 1858 66 2685 86 3516 7 277 27 1081 47 1899 67 2727 87 3557 8 317 28 1122 48 1941 68 2768 88 3599 9 357 29 1163 49 1982 69 2810 89 3640 10 397 30 1203 50 2023 70 2851 90 3682 11 437 31 1244 51 2064 71 2893 91 3723 12 477 32 1285 52 2106 72 2934 92 3765 13 517 33 1326 53 2147 73 2976 93 3806 14 557 34 1366 54 2188 74 3017 94 3848 15 597 35 1407 55 2230 75 3059 95 3889 16 637 36 1448 56 2271 76 3100 96 3931 17 677 37 1489 57 2312 77 3142 97 3972 18 718 38 1530 58 2354 78 3184 98 4013 19 758 39 1571 59 2395 79 3225 99 4055 20 798 40 1612 60 2436 80 3267 100 4096 Experiment 1- Calibration of the Liquid in glass, Gas (vapour) pressure and Bi-metal Devices Aim To show the linearity and accuracy of the liquid in glass, gas (vapour) pressure and Bi-metal devices, by calibration against the reference sensor. Procedure 1. Create a blank results table, similar to Table 13. Calibrating Devices Reference Temperature (°C) Indicated Temperature (°C) Deviation (difference) (°C) Error () Table 13 Blank Results Table 2. Choose one of the liquid in glass thermometers. Put the reference sensor and the thermometer into the icebox (through the holes in its lid). Wait a few minutes for the readings to stabilize and record them (the reference temperature should be between 0°C and 1°C). 3. Now put both devices into the heater tank (through the holes in its lid). Switch on the heater and note the reference temperature. 4. At intervals of 10°C (shown by the reference temperature), record the readings of the thermometer. 5. Stop the experiment and switch off the heater when the reference temperature reaches 100°C. 6. Repeat the experiment for the other liquid in glass thermometer, the gas (vapour) pressure thermometer and the bi-metal thermometer. Allow the heater water to cool down (and change it if necessary for cooler water) between tests. Results Analysis For each device, find the deviation and calculate the percentage error to complete your results tables. Create charts of the indicated temperature (vertical axis) against reference temperature (horizontal axis). Add to your charts, the reference temperature (against its own readings) to create a linear standard to compare against the indicated readings. On your results table, find the difference between the standard and your results (the deviation) and calculate the percentage error. Percentage error = (deviation/standard) x 100 Compare the devices against the standard to see which is the most accurate over the range. Can you identify any possible causes of error. Experiment 2 - NTC Thermistor Linearity Aims • To show how the NTC Thermistor works. • To show the non-linearity of the NTC Thermistor. Procedure INPUT 1 INPUT 2 INPUT 3 INPUT 4 MILLIVOLTMETER NTC THERMISTOR 100R 100R R4 R3 1mA WHEATSTONE BRIDGE 100R 100R NTC Thermistor R2 Vx REFERENCE SENSOR CONSTANT CURRENT SOURCE R1 PRT SIMULATOR CONSTANT VOLTAGE SOURCE Figure 40 Connections for Experiment 3 1. Create a blank results table, similar to Table 14. 2. Connect the reference sensor to its socket and connect the NTC Thermistor to the millivoltmeter and the constant current source as shown in Figure 40. 3. Put the reference sensor and the NTC Thermistor into the icebox (through the holes in its lid). Wait a few minutes for the readings to stabilize and record them (the reference temperature should be between 0°C and 1°C). 4. Now put both devices into the heater tank (through the holes in its lid). Switch on the heater and note the reference temperature. NTC Thermistor Calibration Reference Temperature (°C) Measured Voltage (mV) Calculated Resistance () Standard Resistance () Deviation () Error (%) Table 14 Blank Results Table 5. At intervals of 10°C (shown by the reference temperature), record the input 1 readings of the millivoltmeter. 6. Stop the experiment and switch off the heater when the reference temperature reaches 100°C. Results Analysis Given that the constant current is 1 mA, use Ohm’s law (see Theory section) to calculate the resistance of the Thermistor for each row in your table. You should see that is directly proportional to the measured voltage. Plot a chart of resistance (vertical axis) against temperature (horizontal axis). Draw a best fit curve through your results to see how the NTC Thermistor gives a non-linear resistance change over the range 0 to 100°C. Note how your results prove that resistance goes down as temperature increases. Add to your results table and chart, the standard resistances for the NTC Thermistor from Table 2 on page 16 and compare the curves. On your results table, find the difference between the standard and your results (the deviation) and calculate the percentage error. Percentage error = (deviation/standard) x 100 Experiment 3: K Type Thermocouple Linearity Aims • To show how thermocouples work • To show and compare the linearity and output signal levels of J and K type thermocouples Procedure INPUT 3 INPUT 4 INPUT 1 INPUT 2 MILLIVOLTMETER WHEATSTONE BRIDGE REFERENCE SENSOR CONSTANT CURRENT SOURCE PRT SIMULATOR SOURCE J - Type = Black K - Type = Green J - Type = White K - Type = White JUNCTIONS Thermocouple Figure 41 Connections for Experiment 6 - J and K Type Thermocouple Linearity 1. Create a blank results table, similar to Table 15. 2. Connect the reference sensor to its socket and connect the J or K type thermocouple to the amplifier and the millivoltmeter as shown in Figure 40. The amplifier amplifies the small voltage from the thermocouple by 20. This makes it suitable for the millivoltmeter. The actual voltage from the thermocouple will therefore be 1/20 of the reading from the millivoltmeter. 3. Setup the heater and icebox as shown in Initial Setup (for Experiment 3 onwards) on page 35. 4. Put the reference sensor and the thermocouple into the icebox (through the holes in its lid). Wait a few minutes for the readings to stabilize and record them (the reference temperature should be approximately 0°C). 5. Now put both devices into the heater tank (through the holes in its lid). Switch on the heater and note the reference temperature. J and K Type Thermocouple Calibration Reference Temperature (°C) Measured Voltage (mV) Measured Voltage/20 (V) Standard Voltage (V) Deviation (mV or V) Error (%) Table 15 Blank Results Table 6. At intervals of 10°C (shown by the reference temperature), record the input 1 readings of the millivoltmeter. 7. Stop the experiment and switch off the heater when the reference temperature reaches 100°C. 8. Repeat the procedure for the other thermocouple. Results Analysis Divide your millivoltmeter readings by 20 to find the actual measured voltage generated by the thermocouples for each row in your table. For each thermocouple, plot a chart of actual measured voltage (vertical axis) against temperature (horizontal axis). NOTE If you have VDAS®, the software already has a divide by 20 data field. Draw a best fit curve through each of your results to see how linear the voltage change is for each thermocouple over the range 0 to 100°C. Note how your results prove that voltage goes up as temperature increases. Compare your results with the standard specifications for the thermocouples given in Table 3 on page 17 and Table 4 on page 18. On your results table, find the difference between the standard and your results (the deviation) and calculate the percentage error. Percentage error = (deviation/standard) x 100 Your results should be reasonably linear, but the deviation may be large and consistent (an offset). Can you identify the causes of any errors? Hint - think about the thermocouples and the connections to the amplifier. Can you understand why thermocouple connections are important, and why you cannot simply connect a thermocouple directly to an ordinary measuring device and expect it to work correctly?