NSN P-1120 Mariner Skills Training Center - Air-Cooled Chiller (CH-1 & CH-2) Submittal 9-25-20

advertisement

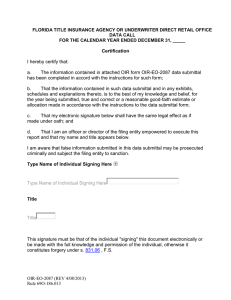

Air-Cooled Chiller Submittal Prepared For: NAVFAC MIDLANT & Jacobs 5701 Cleveland Street Virginia Beach, VA 23462 Date: September 25th, 2020 Mechanical Contractor: Warwick Mechanical Group 11048 Warwick Boulevard Newport News, VA 23601-3229 Job Name: NSN P-1120 Mariner Skills Training Center (MSTC) Contract No.: N400800-17-D-0018 Trane U.S. Inc. is pleased to provide the enclosed submittal for your review and approval. Product Summary Qty Tags 2 CH-1 & CH-2 Product 230 Ton Air-Cooled Screw Chiller Model RTAF230 Specification 23 64 10, Paragraph 2.4 NOTE(s): • In Addition To The Specification Referenced Above, Plans Dated 6-12-20 Were Used • Chiller Performance Schedule Can Be Found On Mechanical Sheet M-601 • When Air-Cooled Chillers Are Located Side by Side 84” of Space Between Them Is Recommended For Proper Air Circulation and To Mitigate Any Performance Degradation. Condenser Air Recirculation Can Occur With Less Than 84” Of Separation. • CH-1 & CH-2 Variable Evaporator Flow: o These Chillers Are Capable Of Handling Variable Flow Through The Evaporator As A Standard Function Of The Unit Controller. Flow Through The Evaporator Must Remain Above The 261 GPM Minimum Allowed Flow Rate At All Times. To Ensure Tight Chilled Water Temperature Control The Rate Of Flow Change Must Be Considered, Please See The Guidelines Below: ▪ Up To A 10% Change In Flow Per Minute and Maintain +/-0.5°F Off The Setpoint ▪ Up To A 30% Change In Flow Per Minute and Maintain +/-2.0°F Off The Setpoint • Submittal Contains Product Data, Specifications, Performance and Shop Drawings. Brandon Rouse Trane U.S. Inc. 1100 Cavalier Blvd. Chesapeake, VA 23323-1506 Phone: (757) 558-3412 Fax: (757) 558-9715 The attached information describes the equipment we propose to furnish for this project, and is submitted for your approval. Product performance and submittal data is valid for a period of 6 months from the date of submittal generation. If six months or more has elapsed between submittal generation and equipment release, the product performance and submittal data will need to be verified. It is the customer’s responsibility to obtain such verification. Table Of Contents Product Summary ...........................................................................................................................1 230 Ton Air-Cooled Screw Chiller (Item A1) Tag Data .................................................................................................................................................. 3 Product Data (SD-03) ............................................................................................................................... 3 Performance Data (SD-03) ...................................................................................................................... 4 Mechanical Specifications (SD-03) .......................................................................................................... 7 Unit Dimensions (SD-02) ....................................................................................................................... 11 Weight, Clearance & Rigging Diagram (SD-02) ..................................................................................... 16 Center of Gravity Diagram (SD-02) ........................................................................................................ 17 Circuit Breaker & Control Panel Detail (SD-02) ...................................................................................... 18 Service Clearance Diagram (SD-02) ...................................................................................................... 19 Point Load & Mounting Location Diagram (SD-02) ................................................................................ 20 Field Wiring (SD-02) ............................................................................................................................... 21 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal Tag Data - 230 Ton Air-Cooled Screw Chiller (Qty: 2) Item Tag(s) Qty Description A1 CH-1, CH-2 2 230 Ton Air-Cooled Screw Chiller September 25th, 2020 Model Number RTAF230 Product Data - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Air-Cooled Screw Chiller (R-134a) 230 Nominal Tons Capacity 460V/60Hz/3Ø Single Point Unit Power Connection Circuit Breaker with Thru The Door Handle Factory Mounted and Wired UL Listed, ASME Pressure Rated Vessel, AHRI Certified, ASHRAE 90.1 (2016) Compliant High Efficiency Variable Speed Screw Compressors 2-Pass Evaporator Fluid Type - Water Factory Installed Thermal Dispersion Flow Switch (45 cm/s), For Proof of Flow Factory Installed 3/4” Armaflex Insulation Applied To All Cold Parts Low Ambient Controls To Allow Operation Down to 0°F Factory Applied CompleteCoat Corrosion Resistant Coating On Microchannel Condenser Coil Variable Speed Condenser Fans Factory Installed Freeze Protection (Cartridge Heaters and Heat Trace) – See Power Requirements Below Integral Oil Cooler 15A – 115V/1Ø Convenience Outlet – See Power Requirements Below BACnet Interface Condenser Coil Louvered Panels Factory Witness 5 Point Test with Report, See Testing Details Within Submittal Test At AHRI Conditions with AHRI Condenser Relief Standard AHRI 550/590 Tolerances Test Points; 100%, 75%, 50%, 25% and 15% Shipped With Tarp Covering Full Unit Startup, Checkout & First Year Parts/Labor Warranty Provided By Damuth Services Notes: 1. All Accessories Must Be Field Installed By The Mechanical Contractor. 2. Not Included: Fused Disconnect Switches, Rigging, Power Wiring, Pump Interlocks, Piping Specialties, Maintenance Service, Copper Tube/Fin Condenser Coil, Owner Training & Water Balancing. 3. A Separate 120 Volt / 60 Hertz / 1 Phase, 25 Amp Fused Disconnect Switch Must Be Provided & Installed By The Mechanical Contractor To Feed Evaporator Barrel Heater Tape. 4. A Separate 120 Volt / 60 Hertz / 1 Phase, 15 Amp Fused Disconnect Switch Must Be Provided & Installed By The Mechanical Contractor To Feed Convenience Outlet. 5. For Proper Freeze Protection, In Addition To Heat Trace Being Powered, Chillers Must Be Interlocked To The Chilled Water Pumps. Interlock Wiring By Others. FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 3 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Performance Data - 230 Ton Air-Cooled Screw Chiller Tags Actual Refrigeration Capacity (tons) Cooling Efficiency (EER) IPLV.IP NPLV.IP Evaporator Flow (gpm) Ambient Air Temp (°F) Entering Evap Fluid Temp (°F) Leaving Evap Fluid Temp (°F) Pressure Drop Evap (ft H2O) Minimum Evap Flow (gpm) Pressure Drop at Min Flow (ft H2O) Evap Fouling Factor (hr-ft2°F/Btu) Evap Fluid Freeze Point (°F) Altitude (ft) CH-1, CH-2 205.46 10.029 17.250 16.987 409.04 96.90 54.00 42.00 7.69 261.00 3.13 0.000100 32.00 0.00 Saturated Evap Temp - Ckt 1 (°F) Saturated Evap Temp - Ckt 2 (°F) Saturated Cond Temp - Ckt 1 (°F) Saturated Cond Temp - Ckt 2 (°F) Refrigerant Charge - Ckt 1 (lb) Refrigerant Charge - Ckt 2 (lb) Oil charge - Ckt 1 (gal) Oil charge - Ckt 2 (gal) 38.58 40.66 130.67 127.11 155.9 155.2 2.35 2.35 AHRI Rated Efficiency (EER) AHRI Rated Capacity (tons) 10.485 215.88 Total Power (kW) Compressor Power (kW) Fan Power (kW) Single Point Power MCA (A) Single Point Power MOP (A) Short Circuit Current Rating (A) Compressor 1A - RLA/AFD Input (A) Compressor 2A - RLA/AFD Input (A) Condenser Fan RLA, each (A) Number of Condenser Fans 245.84 226.40 18.63 453.00 600.00 65000 198.00 164.00 2.80 14 Shipping Weight (lb) Operating Weight (lb) Length (in) Width (in) Height (in) 13,117.5 13,225.5 318.0 87.0 98.0 A-weighted Sound Pressure (dBA) A-weighted 75% Sound Pressure (dBA) A-weighted 50% Sound Pressure (dBA) A-weighted 25% Sound Pressure (dBA) A-weighted Sound Power (dBA) A-weighted 75% Sound Power (dBA) A-weighted 50% Sound Power (dBA) A-weighted 25% Sound Power (dBA) 75 70 68 63 103 98 95 91 FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 4 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) FLD = Furnished by Trane U.S. Inc. / Installed by Others Air-Cooled Chiller Submittal Equipment Submittal September 25th, 2020 Page 5 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) FLD = Furnished by Trane U.S. Inc. / Installed by Others Air-Cooled Chiller Submittal Equipment Submittal September 25th, 2020 Page 6 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Mechanical Specifications - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 General Units are leak and pressure tested at 385 psig high side, 220 psig low side, then evacuated and charged. Unit panels, structural elements and control boxes are constructed of galvanized steel and mounted on a bolted galvanized steel base. Unit panels, control boxes and the structural base are finished with a baked on powder paint. Anytime water only is present in the evaporator, the Trane UC800 controller must have flow control of the chilled water system. Flow control can be done either directly or through an input to a building automation system to conduct an action resulting in minimum flow through the chiller evaporator barrel to avoid potentially catastrophic damage to the evaporator due to freezing. If the system has sufficient glycol to protect down to the lowest expected ambient, flow control is optional. A control power transformer shall be factory-installed and factory-wired to provide unit control power. Chiller is built and certified to UL2014 US and Canadian safety standard. Power Requirements Unit is provided with single-point electrical unit power connection. Standard power connection includes main three phase power to the compressors, condenser fans and control power transformer. Note: A separate field supplied low voltage power source is required to power the evaporator freeze protection. Note: An additional separate field supplied low voltage power source is required to power the Convenience Outlet. Factory Refrigerant Charge (R-134a) Packaged units ship with a full operating charge of oil and HFC-134a refrigerant. Evaporator The evaporator is a tube-in-shell heat exchanger design with internally and externally finned copper tubes roller expanded into the tube sheets. All tubes can be individually replaced. The evaporator is designed, tested and stamped in accordance with ASME Pressure Vessel Code Section VIII for a refrigerant side working pressure of 200 psig. The evaporator is designed for a water side working pressure of 150 psig. Each shell includes a vent, a drain, and fittings for temperature control sensors. Evaporator water connections are grooved pipe. Evaporator will be configured with a 2 pass arrangement. Heaters, with thermostat, are provided to help protect the evaporator from freezing at ambient temperatures down to -4°F, depending on application. Note: A separate field supplied low voltage power source is required to power the evaporator freeze protection. Evaporator is insulated with UV resistant 0.75 inch Armaflex II or equal insulation (K=0.28). Insulation also covers the liquid and suction line and evaporator heads. Operating Temperatures & Low Ambient Operation Unit is designed for operation in standard leaving evaporator temperature (equal to or greater than 40.0 °F). Chiller shall be able to start and operate in ambient conditions down to -4⁰F and up to 115⁰F. Low ambient operation is accomplished with factory installed and tested protection. Chiller shall be capable of starting up with 90⁰F entering fluid temperature to the evaporator. Maximum water temperature that can be circulated with the chiller not operating is 104⁰F, Pressure Vessel Code Chiller complies with ASME Pressure Vessel Code Section VIII. ASME nameplates are attached to applicable pressure vessels, including oil separators. Condenser and Fans Air-cooled microchannel condenser coils use all aluminum brazed fin construction. The condenser coil will have an integral subcooling circuit. The maximum allowable working pressure of the condenser is 350 psig. Condensers are factory proof and leak tested at 525 psig. Coils can be cleaned with high pressure water. Direct-drive, vertical-discharge condenser fans are dynamically balanced. The condenser fan motors are permanent magnet motors with integrated drive to provide variable speed fan control for all fans. Units are equipped with EC condenser fan motors with permanently lubricated ball bearings and external overload and overcurrent protection. The fan impeller is a 5 bladed-shrouded fan. Fans are insulation IP54 compliant. Completely assembled coils are dipped and baked in an electro-mechanically bonded flexible epoxy coating. Provides uniform epoxy coating of all surfaces on microchannel coil. No associated surfaces remain bare. Allows for corrosion resistance without performance degradation. Coils with coating passed 6000-hour salt spray test. FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 7 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Standard Noise Sound Package Unit will be built with low noise condenser fans. Compressor and Lube Oil System The rotary screw compressor is semi-hermetic, direct drive with capacity control via an adaptive frequency drive, rolling element bearings, differential refrigerant pressure oil pump and oil heater. The motor is a suction gas cooled, hermetically sealed two pole squirrel cage induction motor. Oil separation is provided to separate oil and refrigerant prior to entrance into condenser to preserve the integrity of heat transfer in the condenser. Oil filtration is provided internal to the compressor. Check valves in the compressor discharge and lube oil system are also provided. Refrigeration Circuits Each unit has two refrigerant circuits, with one rotary screw compressor per circuit. Each refrigerant circuit includes a compressor suction and discharge service valve, liquid line shutoff valve, removable core filter, liquid line sight glass with moisture indicator, charging port and an electronic expansion valve. Fully modulating compressors and electronic expansion valves provide variable capacity modulation over the entire operating range. Adaptive Frequency Drive Compressor Starter Trane's Adaptive Frequency Drive (AFD) technology is specifically designed for Trane air-cooled chillers. The AFD incorporates the Trane communication protocol enabling seamless integration with the unit controller. The AFD data such as drive status, temperature modes, and diagnostic information are accessible to the unit controller. AFD will protect itself and the compressor motor from over current, low or high line voltage, phase loss, incoming phase imbalance, and over temperature due to loss of panel ventilation. The AFD incorporates improved serviceability and troubleshooting tools. All AFD control circuits are powered with class 2 low voltage. The drive is air-cooled with a ventilation fan in the panel. Unit Controls All unit controls are housed in an outdoor rated weather tight enclosure per UL2014 with removable plates to allow for customer connection of power wiring and remote interlocks. All controls, including sensors, are factory mounted and tested prior to shipment. Microcomputer controls provide all control functions including startup and shut down, leaving chilled water temperature control, evaporator flow proving, compressor staging and speed control, electronic expansion valve modulation, condenser fan sequencing and speed control, anti-recycle logic, automatic lead/lag compressor starting, load limiting and chilled water pump control. The UC-800 unit control module with Rapid Restart, utilizing Adaptive Control microprocessor, automatically takes action to avoid unit shutdown due to abnormal operating conditions associated with low refrigerant pressure, high condensing pressure and motor current overload. Should the abnormal operating condition continue until a protective limit is violated, the unit will be shut down. Unit protective functions of the UC-800 include: low evaporator refrigerant pressure, high condenser refrigerant pressure, low oil flow, critical sensor or detection circuit faults, current overload, high compressor discharge temperature, communications lost between modules, electrical distribution faults, phase loss, phase imbalance, phase reversal, external and emergency stop, momentary power loss, under/over voltage, and loss of evaporator water flow. Unit Mounted Color Touchscreen Display/Interface A full color TD-7 AdaptiView touch screen display indicates all important unit and circuit parameters, in logical groupings on various screens. The parameters including chilled water set point, leaving chilled water temperature, demand limit set point, evaporator and condenser refrigerant temperatures and pressures, compressor and fan speeds, and all pertinent electrical information. The display also provides on screen trending graphs of predefined parameters as well as customizable trend graphs based on user defined parameters from a list of all available parameters. The display also provides indication of the chiller and circuits top level operating modes with detailed sub-mode reports available with a single key press, as well as diagnostics annunciation and date and time stamped diagnostic history. The standard color display is fully outdoor rated, and can be viewed in full daylight without opening any control panel doors. The display is outdoor capable including an UV resistant touchscreen with an operating range between -40.0ºF to 158.2ºF operating temperature. Chilled Water Reset This provides the control logic and factory installed sensors to reset leaving chilled water temperature. The set point can be reset based on ambient temperature or return evaporator water temperature. FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 8 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Factory Mounted Thermal Dispersion Flow Proving Switch The factory installed evaporator water flow switch is provided with the control logic and relays to turn the chilled water flow on and off as the chiller requires for operation and protection. The flow switch installed on this chiller is designed for use with water in the evaporator with a set point of 45 cm/s. High Fault Circuit Breaker A molded case high interrupting capacity circuit breaker (UL approved) is available. The circuit breaker can also be used to disconnect the chiller from main power with a through the door handle and comes wired from the factory with terminal block power connections. The external operator handle is lockable. Short Circuit Current Rating (SCCR) A short circuit current rating offers a measure of safety for what the starter panel enclosure is able to withstand in the event of an explosion caused by a short circuit. BACnet (BCI-C) Communication Interface BACnet interface allows the user to easily interface with using BACnet MS/TP via a single twisted-pair wiring to a factory-installed and tested communication board. Control Inputs Building Automation System Communication Interface permits remote leaving evaporator temperature set point and remote current limit set point by accepting a 4-20 mA or 2-10 Vdc analog signal. Convenience Outlet Provides a 15 amp, 115 volt (60 Hz) convenience outlet on the unit. Note: An additional field supplied power connection must be provided to power the convenience outlet. Shipping Tarp The unit will be covered at the factory with a PVC coated polyester tarp that is tied to the chiller base to help protect the chiller from debris during shipment, especially in the winter months and on shipping vessels. Foundation Provide rigid, non-warping mounting pads or a concrete foundation of sufficient strength and mass to support the applicable operating weight (i.e. including completed piping, and full operating charges of refrigerant, oil and water). Once in place, the unit must be level within 1/2" across the length and width of the unit. The Trane Company is not responsible for equipment problems resulting from an improperly designed or constructed foundation. Center of Gravity Different unit configurations and options may cause a variation in the center of gravity from what is listed in the submittal. Refer to the Installation, Operating and Maintenance manual for specific lifting instructions. FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 9 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Factory Quality Tests Compressor Test All compressors undergo a high pressure test, helium leak check and a mechanical functionality test after compressor assembly. In addition, a high potential test is performed to check for electrical functionality. Evaporator Shell Test Outside the water tank, one circuit is pressurized to 20 psi; the opposite circuit is checked for pressure. Then the shell is loaded into the water tank. Both circuits are pressurized to 1.1 maximum allowed working pressure (MAWP); 200 psi x 1.1 = 220 psi and held for 1 minute. Then, the pressure is dropped to equal MAWP, the vessel is removed from the water tank, soap/water visually inspected for leaks (bubbles) at all the weld and tube roll joints (outside tube sheets). Evaporator Vacuum Test Refrigerant shell side on one circuit of evaporator is vacuumed to at least 250 microns and pressure is added to the opposite circuit. The vacuum is held in the evaporator for five minutes. Vacuum in evaporator shall not rise more than 25 microns per minute. Any rise above 25 microns indicates a leak. Evaporator Water Box Test After evaporator water box installation, water lines are attached. The evaporator is then filled with water and pressurized to 1.5 times the maximum allowable working pressure or 225 psig. The joints between the water box and evaporator shell are then visually inspected to verify no leaks are present. General Assembly Proof After completing assembly, the high and low side of the unit is pressure tested to 385 and 220 psig respectively. A visual inspection and soap bubble test is performed followed by a helium leak check at 110 psig before the unit is evacuated and charged. General Assembly Vac-Rise Test Each circuit within the unit is evacuated to 250 microns. This value shall not increase more than 125 microns in ten minutes. Any rise above 125 microns indicates a leak or contamination. End-of-Line Functionality Test After fully assembled and charged with refrigerant, the unit is checked for electrical component functionality. A high potential test is performed in which a voltage equal to 1.2 X (2*Rated Voltage + 1000) is run through each component of both the power and controls circuits for 1 second to test for shorted lines and leakage current. A fully functional electrical test including condenser fans is performed. Factory Witness Performance Test A 5 point witness test will be conducted in the presence of the customer's designated witness at customer specified ambient and water temperature conditions to certify chiller performance before shipment. A test report showing actual performance at specified parameters is provided. Testing will be performed in accordance with AHRI Standard 550/590. Upon test completion, the customer and factory witness will sign the report and a copy will be provided to the customer. FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 10 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 DIMENSION TOLERANCE FOR ISOLATOR LOCATIONS +/- 1" 6572 in3 EVAPORATOR WATER VOLUME 6"(150mm)/6"(150mm) WATER CONNECTION DIAMETER (INLET/OUTLET) TOPSS VERSION 238 NOMINAL TONS 230 Unit Dimensions - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 11 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) September 25th, 2020 Air-Cooled Chiller Submittal FLD = Furnished by Trane U.S. Inc. / Installed by Others RIGHT SIDE RIGHT SIDE 315 7/16" 317 15/16" 5 3/4" 31 1/4" 9 3/4" DISCONNECT SWITCH 22 3/4" INCOMING CUSTOMER POWER LOCATION 82 11/16" LIFTING LOCATION 4 PLACES 182 5/16" 99 1/4" 310 1/8" 82 11/16" MOUNTING LOCATION 8 PLACES Unit Dimensions - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Equipment Submittal Page 12 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) September 25th, 2020 Air-Cooled Chiller Submittal FLD = Furnished by Trane U.S. Inc. / Installed by Others NOTE: COIL BOX SUPPORTS ARE 6 3/8" WIDE. LEFT SIDE LEFT SIDE NOTE: COIL BOX SUPPORTS ARE 6-3/8” WIDE 7 7/8" 36 13/16" 22 3/16" 44 5/16" 44 5/16" 44 5/16" 44 5/16" 44 5/16" 44 5/16" Unit Dimensions - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Equipment Submittal Page 13 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) September 25th, 2020 Air-Cooled Chiller Submittal 6” OUTLET WATER CONNECTION CONDENSER REMOVED FOR CLARITY RELIEF VALVE 5/8" RELIEF VALVE 3/8" RELIEF VALVE 5/8" RELIEF VALVE 3/8" 270 5/8" TOP VIEW 172 5/16" 168 1/2" 6” INLET WATER CONNECTION Unit Dimensions - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 14 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) September 25th, 2020 Air-Cooled Chiller Submittal END VIEW NON-CONTROL PANEL END 89 1/16" 3 1/16" 1 15/16" 98 7/16" 1 9/16" 86" 49 1/16" 37" 19 7/8" INLET WATER CONNECTION OUTLET WATER CONNECTION 20 1/2" Unit Dimensions - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 15 of 22 Other lifting arrangements could result in death, serious injury or equipment damage. WARNING LIFTING AND MOVING INSTRUCTIONS Use the spreader bar as shown in the diagram. Refer to installation instructions located inside control panel for further rigging information. NOTES: 1. LIFTING CHAINS/CABLES WILL NOT BE THE SAME LENGTH. ADJUST TO KEEP UNIT LEVELWHILE LIFITNG. 2. DO NOT FORK LIFT UNIT. 3. LIFTING DIAGRAM IS A GENERIC REPRESENTATION FOR ALL UNITS, IT MAY NOT REPRESENT SIZE OF UNIT SELECTED. 4. DO NOT ALLOW LIFTING STRAPS TO CONTACT UNIT THE UNIT DURING LIFTING. FLD = Furnished by Trane U.S. Inc. / Installed by Others LIFITNG LOCATION 1 (LIFTING LOCATION 2 OTHER SIDE OF UNIT) 96" SPREADER BAR LIFTING LOCATION 3 (LIFTING LOCATION 4 OTHER SIDE OF UNIT) TOTAL SHIPPING WEIGHT 13117.5 lb NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal Equipment Submittal September 25th, 2020 Weight, Clearance & Rigging Diagram - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Page 16 of 22 FLD = Furnished by Trane U.S. Inc. / Installed by Others RIGHT SIDE Equipment Submittal 43 1/4" CONTROL PANEL END VIEW CG 34 5/8" Air-Cooled Chiller Submittal NOTE: UNIT PICTURED IS A REPRESENTATION OF THE ENTIRE PRODUCT AND MAY NOT SHOW ACTUAL UNIT SIZEOR OPTIONS SELECTED. HOWEVER, CENTER OF GRAVITY DIMENSIONS DO REPRESENT UNIT AND OPTIONS SELECTED. 118 1/4" CG Different unit configurations and options may cause a variation in the center of gravity from what is listed. Refer to the Installation, Operating and Maintenance manual for specific lifting instructions. CENTER OF GRAVITY NSN P-1120 Mariner Skills Training Center (MSTC) September 25th, 2020 Center of Gravity Diagram - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Page 17 of 22 3 3/16" FLD = Furnished by Trane U.S. Inc. / Installed by Others 13 11/16" 2 3/16" 2 15/16" TRACER TD7 LOW VOLT KNOCKOUTS ARE 2" UP FROM PREVIOUS KNOCKOUT. INCOMING CUSTOMER LOW VOLT WIRING LOCATIONS Equipment Submittal 75 5/8" 1 3/8" 25 7/16" 47 11/16" Page 18 of 22 5 7/16" 25 7/8" 14 13/16" INCOMING CUSTOMER POWER LOCATION Air-Cooled Chiller Submittal 30 3/16" 13 1/2" 11 15/16" Short Circuit Rating 65000.00 A (2) 500 kcmil - 2/0 Lug Wire Size Range (Per Phase) CIR 1 & CIR 2 Single Point Power Power Wire Connection to High Fault Circuit Breaker CUSTOMER WIRE SELECTION TABLE NSN P-1120 Mariner Skills Training Center (MSTC) September 25th, 2020 Control Panel & Wiring Detail - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 FLD = Furnished by Trane U.S. Inc. / Installed by Others NO OBSTRUCTIONS ABOVE UNIT Equipment Submittal REFER TO THE CLOSE SPACING BULLETIN. 3. CLEARANCE OF 78" ON THE SIDE OF THE UNIT IS REQUIRED FOR COIL REPLACEMENT. IF SUFFICIENT SIDE CLEARANCE IS NOT POSSIBLE, COIL MUST BE REPLACED 78" SEE NOTE 3 24" Air-Cooled Chiller Submittal NOTES: 1.) Area above unit required for operation, maintenance, panel access and airflow. No Obstructions Above Unit NOTES: 2.) For installations with obstructions or multiple units, see Close Spacing and Restricted Airflow Bulletin RLCPRB037. 1. AREA ABOVE UNIT REQUIRED FOR OPERATION, of 78” on the side of the unit is required for coil replacement. If sufficient clearance is not available on this side of 3.) Clearance MAINTENANCE, ACCESS PANEL AND AIRFLOW. the unit, coil replacement should be performed through top of unit. 4.) A full 36” clearance is required in front of the control panels. Must be measured from front of panel, not end of unit base. NO OBSTRUCTIONS ABOVE UNIT. shown are sufficient for tube pull. 5.) Clearances 2. FOR OBSTRUCTIONS OR MULTIPLE UNITS, 36" 36" CONTROL PANEL UNIT CLEARANCE NSN P-1120 Mariner Skills Training Center (MSTC) September 25th, 2020 Service Clearance Diagram - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Page 19 of 22 FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal LOAD RDP-4 LIME 3000.0 lb 2397.0 lb POINT 1 RDP-4 LIME 3000.0 lb 2390.0 lb POINT 2 MOUNTING HOLE DIAMETER 9/16" 1 2 DIAGRAM IS A GENERIC REPRESENTATION FOR ALL UNITS, IT MAY NOT REPRESENT SIZE OF UNIT SELECTED. 3 4 RDP-4 LIME 3000.0 lb 1858.0 lb POINT 3 RDP-4 LIME 3000.0 lb 1853.0 lb POINT 4 RDP-4 LIME 3000.0 lb RDP-4 LIME 3000.0 lb 5 6 1444.0 lb POINT 6 1448.0 lb POINT 5 RDP-4 BROWN 1500.0 lb 730.0 lb POINT 7 MOUNTING LOCATIONS AND POINT LOAD WEIGHTS TOTAL OPERATING WEIGHT 13225.5 lb INDIVIDUAL WEIGHTS DO NOT ADD UP TO TOTAL WEIGHT. TISOLATOR SELECTION MAX LOAD CONTROL PANEL RDP-4 BROWN 1500.0 lb 728.0 lb POINT 8 7 8 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Point Load and Mounting Location Diagram - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Page 20 of 22 CLASS 1 WIRING CLASS 2 WIRING 18 18 LIMIT SETPOINT 10 9 TO NEXT UNIT BACNET INTERFACE TO MOD BUS OR 115/60/1 OR 230/50/1 8 14 EXTERNAL DEMAND EXTERNAL CHILLED WATER SETPOINT 15 5K23 13 5K22 5K24 5K26 5K25 5K27 Equipment Submittal 5K28 FLD = Furnished by Trane U.S. Inc. / Installed by Others 5K29 5S1 5K1 5K2 5Q10 PAIR LEADS SHIELDED TWISTED 2-10 VDC CAPACITY OFF ON AUTO W1 W2 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 5 6 7 8 1 2 3 4 1 2 3 4 1 2 3 4 5 6 1 2 3 4 5 6 J2 J2 J2 J2 J2 J2 J2 1K23 1K16 1K1 1K26 1K25 1K24 1K24 QUAD RELAY OUTPUT PROGRAMMABLE REPLAY UNIT STATUS DUAL RELAY OUTPUT WATER PUMP RELAYS 21 17 UC800 LOCKOUT EXTERNAL STOP & EMERGENCY STOP DUAL LOW VOLTAGE BINARY INPUT 19 DUAL VOLTAGE BINARY INPUT SETPOINT SETPOINT ENABLE (OPTIONAL) CHILLED WATER DUAL VOLTAGE BINARY INPUT & CHILLED WATER SETPOINT (OPTIONAL) PERCENT CAPACITY DUAL ANALOG I/0 & CHILLED WATER SETPOINT (OPTIONAL) PERCENT CAPACITY CONTROLS SECTION 1Q1 CIRCUIT BREAKER OR TERMINAL BLOCK 4 11 L3 L2 L1 1X6 1 2 EVAP HEATERS POWER SECTION 3 4 CONVENIENCE OUTLET (OPTIONAL) 5 ! WARNING POWER HOOD 4 11 H N N H 22 115V/60/1 6 115V/60/1 iVOLTAJE PELIGROSO! DESCONECTE TODA LA ENERG??A EL??CTRICA, INCLUSO LAS DESCONEXIONES REMOTAS Y SIGA LOS PROCEDIMIENTOS DE CIERRE Y ETIQUETADO ANTES DE PROCEDER AL SERVICIO. ASEG??RESE DE QUE TODOS LOS CAPACITORES DEL MOTOR HAYAN DESCARGADO EL VOLTAJE ALMACENADO. PARA LAS UNIDADES CON TRANSMISI??N DE VELOCIDAD VARIABLE, CONSULTE LAS INSTRUCCIONES PARA LA DESCARGA DEL CONDENSADOR. NO REALIZAR LO ANTEDICHO PUEDE PROVOCAR LA MUERTE O LESIONES GRAVES. ! ADVERTENCIA TENSION DANGEREUSE! COUPER TOUTES LES TENSIONS ET OUVRIR LES SECTIONNEURS ?? DISTANCE, PUIS SUIVRE LES PROC??DURES DE VERROUILLAGE ET DES ??TIQUETTES AVANT TOUTE INTERVENTION. V??RIFIER QUE TOUS LES CONDENSATEURS DES MOTEURS SONT D??CHARG??S. DANS LE CAS D'UNIT??S COMPORTANT DES ENTRA??NEMENTS ?? VITESSE VARIABLE, SE REPORTER AUX INSTRUCTIONS DE L'ENTRA??NEMENT POUR D??CHARGER LES CONDENSATEURS. UN MANQUEMENT ?? LA PROC??DURE CI-DESSUS PEUT ENTRA??NER DES BLESSURES GRAVES, VOIRE LA MORT. ! AVERTISSEMENT HAZARDOUS VOLTAGE! DISCONNECT ALL ELECTRIC POWER INCLUDING REMOTE DISCONNECTS AND FOLLOW LOCK OUT AND TAG PROCEDURES BEFORE SERVICING. INSURE THAT ALL MOTOR CAPACITORS HAVE DISCHARGED STORED VOLTAGE. UNITS WITH VARIABLE SPEED DRIVE, REFER TO DRIVE INSTRUCTIONS FOR CAPACITOR DISCHARGE. FAILURE TO DO THE ABOVE COULD RESULT IN DEATH OR SERIOUS INJURY. NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Field Wiring - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 Page 21 of 22 NSN P-1120 Mariner Skills Training Center (MSTC) Air-Cooled Chiller Submittal September 25th, 2020 Field Wiring - 230 Ton Air-Cooled Screw Chiller Item: A1 Qty: 2 Tag(s): CH-1, CH-2 GENERAL NOTES 1. CAUTION-DO NOT ENERGIZE THE UNIT UNTIL CHECK OUT AND STARTUP PROCEDURES HAVE BEEN COMPLETED. 2. ALL MOTORS ARE PROTECTED FROM PRIMARY SINGLE PHASE FAILURES. 3. CAUTION-TRANE PUMP CONTROL MUST BE USED TO PROVIDE PUMP CONTROL. EVAPORATOR CHILLED WATER PUMP MUST BE CONTROLLED BY THE CHILLER OUTPUT. FAILURE TO COMPLY WITH THIS REQUIREMENT MAY RESULT IN DAMAGE TO THE UNIT. 4 SINGLE SOURCE POWER IS PROVIDED AS STANDARD ON THESE PRODUCTS, FIELD CONNECTIONS ARE MADE TO 1Q1. WIRING REQUIREMENTS 5. RECOMMENDED FIELD WIRING CONNECTIONS ARE SHOWN BY DASHED LINES 6 POWER FOR THE EVAPORATOR HEATER AND/OR OPTIONAL CONVENIENCE OUTLET IS SUPPLIED BY A CUSTOMER PROVIDED POWER. MAX FUSE FOR 115 TO 180T UNITS IS 20A WHEN HEATER POWER DRAW IS 1640VA. MAX FUSE SIZE FOR 200 TO 250T UNITS IS 25A WHEN HEATER POWER DRAW MAX FUSE SIZE FOR OPTIONAL CONVENIENCE OUTLET IS 15 AMPS. 7. DO NOT RUN LOW VOLTAGE CONTROL WIRING (30 VOLTS OR LESS) IN CONDUIT WITH 110 VOLT OR HIGHER WIRING. DO NOT EXCEED THE FOLLOWING MAXIMUN RUN LENGTHS FOR A GIVEN SIZE: 14 AWG, 5000 FT; 16 AWG, 2000 FT; 18 AWG, 1000FT. 8 SHIELDED TWISTED PAIR LEADS ARE REQUIRED FOR CONNECTIONS TO THE COMMUNICATIONS INTERFACE MODULE (1K1 AND 1K2). THE SHIELD SHOULD BE GROUNDED AT THE RTAF CONTROL PANEL END. CUSTOMER SUPPLIED POWER 115/60/1PH OR 230/50/1PH TO POWER RELAYS. MAX. FUSE SIZE IS 20 AMPS. GROUND ALL CUSTOMER 9 SUPPLIED POWER SUPPLIES AS REQUIRED BY APPLICABLE CODES. GREEN GROUND SCREWS ARE PROVIDED IN UNIT CONTROL PANEL. WIRED TO NEXT UNIT. 22 AWG SHIELDED COMMUNICATION WIRE EQUIVALENT TO HELIX LF22P0014216 RECOMMENDED. THE SUM TOTAL OF ALL 10 INTERCONNECTED CABLE SEGMENTS NOT TO EXCEED 4500 FEET. CONNECTION TOPOLOGY SHOULD BE DAISY CHAIN. REFER TO BUILDING AUTOMATION SYSTEM (BAS) COMMUNICATION INSTALLATION LITERATURE FOR END OF LINE TERMINATION RESISTOR REQUIREMENTS. 11 ALL UNIT POWER WIRING MUST BE 600 VOLT COPPER CONDUCTORS ONLY AND HAVE A MINIMUM TEMPERATURE INSULATION RATING OF 90 DEGREES C. REFER TO UNIT NAMEPLATE FOR MINIMUM CIRCUIT AMPACITY AND MAXIMUM OVERCURRENT PROTECTION DEVICE. PROVIDE AN EQUIPMENT GROUND IN ACCORDANCE WITH APPLICABLE ELECTRIC CODES. REFER TO WIRERANGE TABLE FOR LUG SIZES. 12. ALL FIELD WIRING MUST BE IN ACCORDANCE WITH NATIONAL ELECTRIC CODE AND LOCAL REQUIREMENTS. CONTACT RATINGS AND REQUIREMENTS 13 WIRED TO CUSTOMER CHILLED WATER SET POINT 2-10 VDC FROM FACTORY. SEE OPERATING INSTRUCTIONS TO CONFIGURE FOR 4-20mA. 14 WIRED TO CUSTOMER CURRENT LIMIT SET POINT 2-10 VDC FROM FACTORY. SEE OPERATING INSTRUCTIONS TO CONFIGURE FOR 4-20mA. 15 WIRED TO CUSTOMER COMPRESSOR %%% RLA OUTPUT 2-10 VDC. 16. ALL CUSTOMER CONTROL CIRCUIT WIRING MUST BE COPPER CONDUCTORS ONLY AND HAVE A MINIMUM INSULATION RATING OF 300 VOLTS, EXCEPT AS NOTED, ALL CUSTOMER WIRING CONNECTIONS ARE MADE TO CIRCUIT BOARD MOUNTED BOX LUGS WITH A WIRE RANGE OF 14 TO 18 AWG OR DIN RAIL MOUNTED SPRING FORCE TERMINALS. UNIT PROVIDED DRY CONTACTS FOR THE CONDENSER/CHILLED WATER PUMP. RELAY CONTACT RATINGS FOR 120VAC, 7.2 AMPS RESISTIVE, 2.88 AMPS PILOT 17 DUTY, OR 1/3 HP. CONTACTS ARE RATED FOR 5 AMPS GENERAL PURPOSE DUTY 240 VOLTS. CUSTOMER SUPPLIED CONTACTS FOR ALL LOW VOLTAGE CONNECTIONS MUST BE COMPATABLE WITH DRY CIRCUIT 24 VOLTS DC FOR A 12mA RESITIVE 18 LOAD. SILVER OR GOLD PLATED CONTACTS RECOMMENDED. 19 THE CONTACTS FOR AUTO STOP AND EMERGENCY STOP SWITCHES ARE JUMPERED AT THE FACTORY BY JUMPERS 1W1 & 1W2 TO ENABLE UNIT OPERATION. IF REMOTE CONTROL IS DESIRED, REMOVED THE JUMPERS AND CONNECT TO THE DESIRED CONTROL CIRCUIT. 20. SOLID OVALS REPRESENT MAX NUMBER OF CONDUITS AND/OR CABLE GLANDS USED. 21 FIELD WIRING REQUIRED ONLY WITH FIELD INSTALLED PUMP OPTION. 22 400V, 50Hz UNITS WILL BE FACTORY WIRED TO UTILIZE 230V ACROSS THE EVAP HEATERS. FLD = Furnished by Trane U.S. Inc. / Installed by Others Equipment Submittal Page 22 of 22