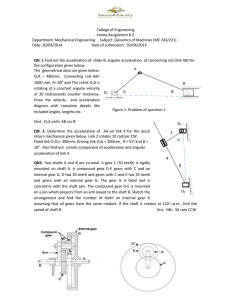

TRANSMISSION SYSTEM: GEAR DRIVE GEARBOX FUNDAMENTAL, OPERATION & MAINTENANCE Presentation by Nirjhar Chakravorti Features… ► Introduction ► Why gears are used? ► Fundamentals of gearing ► Classification of gears ► Gear Making process ► Type of gear boxes ► Material for gear boxes ► Gear lubrication and cooling ► Gear failures ► Trouble shooting ► Market products and specification Introduction The term gear is defined as a machine element used to transmit motion and power between rotating shafts and by means of progressive engagement of projections called teeth. Toothed gearing system evolved gradually from the primitive forms where wooden pins were arranged on the periphery of simple wooden wheels to drive opposite member of the pair. These wheels served the purpose of gears those days. Of course the operation was neither smooth nor quite and obviously speeds were very slow. The motive power to turn these systems was generally provided by the trade mills, which were operated by men, animals and windmills. Archimedes knew primitive forms of gear before the Christian era. Leonardo de Vinci used the concept of gear system in many of his proposed machines. In recent times, however, the technologists and engineers have concentrated their efforts to device curves for gear teeth, which would provide constant relative velocity of the gear tooth faces. With the invention of various geometric curves (such as involutes, cycloids) the gearing system has become very attractive, quite and continuous. For the evolution of modern day gearing technology we must acknowledge the contribution of scientists like Louise, Buckingham, Euler. Why gears are used? ► To transmit torque/ power from one shaft to another shaft. Other commonly used power transmitting elements: Belt drive major limitation: Slippage Rope drive Chain drive major limitation: Discontinuous drive To avoid slippage and discontinuity during power transmission, the best solution is gear drive. ► ► ► To get desired rotational speed To change direction of rotation Where distance between drive shaft and driven shaft is very small Disadvantages of gear drive Disadvantages: • Gear drive is costlier than other drives • Error during cutting teeth causes vibration & noise while operation • Gear drive requires proper lubrication for smooth running So as usual, designers has to be logical and optimal during selection of drive. Fundamental of Gearing How gears transmit power and motion: Concept of friction wheel The motion and power transmitted by gear is kinematically equivalent to that transmitted by friction wheel. Consider two circular wheels A & B mounted on two parallel shafts and the wheels are pressed against each other. Shafts are mounted on anti-friction bearings. When wheel A is rotated by shaft, it will rotate wheel B in Force on the system: opposite direction. • R = Normal reaction between two rubbing wheels N F=µRN RN A T B (Separation force) • T= Tangential force Frictional Force (F= µRN), • F= where µ= co-efficient of friction When T≤ µRN wheel B will rotated by wheel A When T> µRN slippage will take place How to prevent this slippage? ► Simply by increasing the frictional resistance between the two surfaces. To increase this frictional resistance, a number of projections (called teeth) are made on the periphery of both the wheels. ► A friction wheel with teeth cut on it is called gear. Gear Tooth Terminology Important definitions Pitch circle: It is the imaginary circle that rolls without slip with a pitch circle of a mating gear. ► Pitch Point: It is the point of tangency of two pitch circles and is on the line-of-centers. The pitch point of a tooth profile is at its intersection with the pitch circle. ► ► Circular pitch: It is the distance measured on the circumference of the pitch circle from a point on the tooth to the corresponding point on the next tooth. Mathematically, circular pitch, pc=∏D/T, where, D= P.C.D. T= No. of teeth ► Module: It is the ratio of the pitch circle diameter in millimeters to the number of teeth. Mathematically, Module, m=D/T The recommended series of the modules in Indian standard are 1, 1.25, 1.5, 2, 2.5, 3, 4, 5, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50. ► Backlash: It is the distance between the tooth space and the tooth thickness of mating gear as measured on the pitch circle. Purpose of backlash: prevent gears from jamming together making contact on both sides of their teeth simultaneously. Lack of backlash may cause noise, overloading, overheating of the gears and bearings, and even seizing and failure. Excessive backlash is objectionable, particularly if the drive is frequently reversing, or if there is an overrunning load as in cam drives. Excess backlash causes noisy operation. Backlash does not affect involute action. ► Pressure Angle: If a tangent is drawn to the involute profile of a tooth at any point on the curve, and if a radius line is drawn through this point of tangency connecting this point with the centre of the gear, then the acute angle included between this tangent and radial line is defined as pressure angle at that point. In gear design, the pressure angle is measured at the pitch point. Principle of transmission &conjugate action When a pair of gear teeth act together against each other, rotary motion is produced which is transmitted from the driver to the driven gear. If such a pair of tooth profiles which are so designed that a constant angular velocity ratio is produced and maintained during meshing, the two gears are said to have conjugate action and the tooth profiles are said to have conjugate curves. Conjugate action In other words, conjugate action is assumed if, ω1/ ω2=constant, where, ω1= Angular velocity of the driver (generally called pinion) ω2= Angular velocity of the driven (generally called gear) In case of conjugate action, ω1/ ω2= D2/D1 D1= PCD of pinion D2= PCD of gear Gear teeth profile To produce conjugate action, following tooth profiles are used: ► Involute teeth ► Cycloidal teeth ► Epi-cycloidal teeth ► Hypo cycloidal teeth Involute curve The involute curve is most easily understood as the trace of a point at the end of a taut string that unwinds from a cylinder. It is imagined that a point on a string, which is pulled taut in a fixed direction, projects its trace onto a plane that rotates with the base circle. The base cylinder, or base circle as referred to in gear literature, fully defines the form of the involute and in a gear it is an inherent parameter, though invisible. Involute curve ► Involute teeth is most commonly used profile for industrial gears. Cycloidal curve ► Consider a point, “P” on the perphery of a circle. Now if the circle rolls on a fixed line, then the contour made by the point “P”, is known as cycloidal curve. ► If the circle rolls on the outer periphery of another circle (which is fixed), then the contour made by the point “P”, is known as epi-cycloidal curve. ► If the circle rolls on the inner periphery of another circle (which is fixed), then the contour made by the point “P”, is known as hypocycloidal curve. Cycloidal curve P (Trajectory followed by point “P” is called Cycloidal Curve) P (Trajectory followed by point “P” is called Epi-cycloidal Curve) Fixed circle P (Trajectory followed by point “P” is called Hypo-cycloidal Curve) Fixed circle Why involute curve is widely used? The involute curve is almost exclusively used in modern gearing system. The advantage of involute profile over the cycloidal profile is given below: ► The form of the basic rack tooth is straight-sided, and therefore is relatively simple and can be accurately made; as a generating toolift imparts high accuracy to the cut gear tooth. A hob cutter for the cycloidal gear is not as easily made. Continued to next page……. Why involute curve is widely used? ► In cycloidal gears, for a mating pair, there is only one theoretical correct centre distance for which this will transmit motion maintaining a constant angular velocity ratio. in case of involute gearing system, the centre distance can be changed without affecting the angular velocity ratio. This advantage of involute system is of prime importance as most of the modern gears are corrected ones having changed centre. Also, in case of gearing systems having standard centre distance, it is not possible to accurately maintain that distance due to mounting inaccuracies, misalignments and a number of other diverse factors. Continued to next page……. Why involute curve is widely used? ► While the cycloidal tooth profile has double curvature, an involute tooth has single curvature, which facilitates ease of manufacturing. ► In involute profile as the path of contact is straight line and the pressure angle is constant, there is constant force acting on the axes. In cycloidal gear, the pressure angle continuously changes. This results in separating forces of variable magnitude, which in turn gives rise to unquiet operation. Disadvantages of involute curve over cycloidal curve: ► In case of cycloidal gear, minimum number of teeth can be as low as 6 or 7; but in case of involute gears, minimum number of teeth is 17. ► The cycloidal teeth is stronger than the involute teeth. There is more material at the root portion of the cycloidal tooth as compared to an involute tooth. ► Involute teeth has the problem of interference, but the cycloidal gears do not have interference and the problem thereof. Interference & Undercutting ► The maximum length of the line-of-contact is limited to the length of the common tangent. ► Any tooth addendum that extends beyond the tangent points (T and T') is not only useless, but interferes with the root fillet area of the mating tooth. This results in the typical undercut tooth. The undercut not only weakens the tooth with a wasp-like waist, but also removes some of the useful involute adjacent to the base circle. ► From the geometry of the limiting length-ofcontact (T-T') it is evident that interference is first encountered by the addenda of the gear teeth digging into the mating-pinion tooth flanks. Continued to next page……. Interference & Undercutting Continued to next page……. Interference & Undercutting Geometry of proper teeth meshing Tooth correction: One of the method of avoiding undercut, is tooth correction or tooth enlargement. This is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a standard cutter, are shifted radially ourward to form a full involute tooth free of undercut The tooth is enlarged both radially and circumferentially. Interference & Undercutting ► Interference condition becomes more severe as the number of teeth on the gear increases. The limit is reached when the gear becomes a rack. This is a realistic case since the hob is a rack-type cutter. The result is that standard gears with tooth numbers below a critical value are automatically undercut in the generating process. The limiting number of teeth in a gear ► meshing with a rack is given by the expression: ► Nc = 2/sin²α ► This indicates the minimum number of teeth free of undercutting decreases with increasing Pressure angle. ► For 14½º the value of Nc is 32, and for 20° it is 17. System of gear teeth Following four system of gear teeth is commonly used: ► 14 ½ ° composite ► 14 ½ ° full depth involute ► 20 ° full depth involute ► 20 ° full stub involute Classification of gears According to the position of shafts: ► Parallel shaft: (i) Spur gear: gear teeth are straight along the length and are parallel to the axes. (ii) Helical gear: (a) Single helical gear: the teeth are helices and these helices may be left handed or right handed. (b) Double helical gear (herringbone gear): these gears are actually two helical gears of hands, placed side by side and cut on the same blank to obtain composite unit. ► ► Intersecting shaft: (i) Bevel gear: (a) Straight bevel gear: the gear blank is cone on which teeth are generated. The teeth are straight. (b) Spiral bevel gear: the elements are curved in the shape of spiral, so that contact between intermeshing teeth become gradual and continuous. Non-intersecting and non-parallel shaft: (i) Hypoid gear: these are similar to spiral bevel gears, but have non-intersecting axes, ie. the axis of the pinion is offset relative to the gear axis. (ii) Crossed helical gear: these are cylindrical helical gears, but their axes are at am angle when in mesh and do not intersect. (iii) Worm gear: the axes are normally at right angles to each other. The tooth elements of both the components are helices. Classification of gears Spur Gear Straight Bevel Gear Single Helical Gear Spiral Bevel Gear Double Helical Gear Worm Gear Gear Making process Modern methods of producing gear teeth cover a wide variety: ► Machining ► Grinding ► Casting ► Molding ► Forming (drawing, extruding, rolling) ► Stamping Each method offers special characteristics relating to quality, production quantity, cost, material and application. Machining Machining constitutes the most important method of generating gear teeth. It is suitable for high precision gears in both small and large quantities. Various methods of machining is described below: ► Teeth formation process ► Tooth finishing process Teeth formation process Gear Milling: Basic Principle: After each tooth is milled, gear blank is rotated to the next cutting. ► Disadvantage: (1)Time consuming (2) Involves heavy stock removal operation which require high accuracy of indexing mechanism Hob generation: This is the most widely used method of cutting gear teeth. ► Basic Principle: In this process the work piece rotates in constant relationship with the cutting tool ie. The gear hob. The rack is in the form of a worm. ► The central section of the hob is identical to that of the worm and gear. The differences are that the thread of the hob is axially gashed or fluted in several places so as to form cutting edges, while the sides and top of these teeth are relieved behind the gash surface to permit proper cutting action. This arrangement, in eftect, gives an infinitely long rack so that cutting is both steady and continuous. To generate the full Width of the gear, the hob slowly traverses the face of the gear as it rotates. Thus, the hob has a basic rotary motion and a unidirectional traverse at right angles. ► Hob generation continued to next page……. Hob generation: ► Both movements are relatively simple to effect, resulting in a very accurate process. ► A further advantage of hobbing is that the hob can be swiveled relative to the blank axis. This permits cutting helical gears of all angles with the same tooling. ► With regard to accuracy, hobbing is superior to the other cutting processes. Gears can be directly hobbed to ultra-precision ► tolerances without resorting to any secondary refining processes. Gear shaping: ► It’s a continuous generating process. ► Cutter is a gear with cutting edges. Profile is generated with number of enveloping cuts produced by the cutter teeth. ► It is time consuming as time is lost during return stroke of cutter and half of the total machining time is spent in metal removal. Gear grinding: Although grinding is often associated with quantity fabrication of high quality gears as a secondary refining operation, it is also a basic process for producing hardened gears. In addition, many high-precision finepitch gears have their teeth entirely ground from the blank state. ► There are a number of distinct advantages to ground gears. These are listed as follows: 1. Achievement of high precision is possible because the process can remove very little material in the final pass. 2. Grinding results in a much finer surface finish than any machining process. 3. Hardened steel alloys can be ground. 4. Residual surface stresses are minimal. ► Grinding continued to next page……. Gear grinding: Ground gears’ superior load carrying capacity is not only due to the hardened alloys higher mechanical properties, but also because of the finer surface finish. A fine finish enables maintenance of a good continuous oil film versus boundary lubrication and breakthrough. The result is higher load capactry along with reduced wear and longer useful life. ► Although there are distinct advantages for ground gears, there are some limitations and disadvantages. These are: 1. Grinding is limited to ferrous materials. 2. Hard metals grind better than soft ones. 3. Grinding of helicals and worms has limitations that possibly involve profile deviations and removal. 4. Pro-grind hobbing requires special protruberance hobs to provide grind wheel clearance at the root. 5. Gear grinding machinery is scarcer than hobbing machines. 6. Grinding is a secondary operation which increases total gear cost ► Despite involving higher cost and other limitations, ground gears are always superior in precision and strength. ► Tooth finishing process Lapping: ► Gear finishing process, used after heat treatment. ► It improves surface finish, correct distortions and improved wear life. ► Lapping also contribute to have proper backlash, between meshing teeth. Other tooth finishing operations are shaving, honning, etc. Type of gearbox Generally following gearboxes are used in industries: ► Helical gearbox ► Bevel-helical gearbox ► Worm gearbox ► Heli-worm gearbox ► Geared motor Material Gear steels may be divided into two general classes: ► the plain carbon ► the alloy steels. Alloy steels are used in the industrial field, but heat-treated plain carbon steels are also common. The advantages obtained from using heat-treated alloy steels in place of heat-treated plain carbon steels are as follows: 1) Increased surface hardness and depth of hardness penetration for the same carbon content and quench. 2) Ability to obtain the same surface hardness with a less drastic quench and, in the case of some of the alloys, a lower quenching temperature, thus giving less distortion. 3) Increased toughness, as indicated by the higher values of yield point, elongation, and reduction of area. 4) Finer grain size, with the resulting higher impact toughness and increased wear resistance. 5) In the case of some of the alloys, better machining qualities or the possibility of machining at higher hardness. There are generally two types of heat treated alloy steels: ► Volume hardened steel (or through hardened steel) ► Case hardened steel Volume hardened steel (or through hardened steel) Thru-hardening steels are used when great strength, high endurance limit, toughness, and resistance to shock are required. These qualities are governed by the kind of steel and treatment used. Fairly high surface hardnesses are obtainable in this group, though not so high as those of the casehardening steels. For that reason, the resistance to wear is not so great as might be obtained, but when wear resistance combined with great strength and toughness is required, this type of steel is superior to the others. Thru hardening steels become distorted to some extent when hardened, the amount depending upon the steel and quenching medium used. ► When the grinding of gear teeth is not practicable and a high degree of accuracy is required, hardened steels may be drawn or tempered to a hardness that will permit the cutting of the teeth. This treatment gives a highly refined structure, great toughness, and, in spite of the low hardness, excellent wearing qualities. ► Case hardened steel Casehardening steels with their extremely hard, finegrained (when properly treated) case and comparatively soft and ductile core are generally used when resistance to wear is desired. Casehardening alloy steels have a fairly tough core, but not as tough as that of the full-hardening steels. ► But wear resistance combined with toughness, these steels are more effective, and a same size of properly case-hardened gear combination can transmit more torque, compared to a gear pair made of volume hardened steel. ► Material of gear/ gearbox generally used in Indian industries ► ► ► ► Helical gears: (a) Volume hardened steel (or through hardened steel) Pinion: EN 19 (Hardened & Tempered), Hardness: 280-320 BHN Gear: EN 24 (Hardened & Tempered), Hardness: 230-280 BHN (b) Case hardened steel Pinion & Gear: SAE 8620 or 17CrNiMo6 or EN 356, Case Hardness: 55 Rc, Core Hardness: 180-210 BHN Bevel Gears: Same as helical gears Worm Gears: Worm shaft: C45 Worm wheel: Phosphor Bronze Housing: CI FG 400 IS 210 or Fabricated (IS 2062) Modern gear technologists are trying to develop new alloying materials for gears, to increase gear strength, with compact and reduced size. ► Apart from steels, other materials also used for gears (depending upon requirement), ie: Die Cast Alloys, Sintered Powder Metal, Plastics, etc. ► Gear box lubrication ► ► ► ► ► ► Gearbox lubrication: All gears are delivered from manufacturer without oil. Before start up, the gear should be filled with oil recommended. Oil should be filled to oil level indicator. The oil level should be checked regularly. The checking must be made while the drive is stationary. Some times, bearings are normally oil lubricated on primary side and grease lubricated on secondary side. Lubrication continued to next page……. ► First oil change should take place after running-in period. Drain oil immediately after stop while oil is still worm. Second oil change should take place after 200 working hours. Afterwards, oil change is recommended after period of 2000-4000 working hours depending on working conditions. Lubrication continued to next page……. ► The oil in the sump carries out lubrication of the gears and bearings automatically. Units are fitted with filler, oil level indicator and breather for easy routine inspection and maintenance. For low speed application, grease or forced feed lubrication may be necessary. Maximum heat dissipation is achieved by means of a radial fan for directing high velocity air over the cooling ribs of gear case. For higher capacities, the units are provided with cooling coils in the lower part of the housing for allowing cool water passing through a suitable port entry. With pressure lubrication, oil cooler can be mounted in the oil circuit to achieve more efficient and effective cooling. Gear failure ► ► ► ► ► ► Causes for gear failure: Surface fatigue: (a) Case exfoliation (b) Initial pitting (c) Progressive pitting Scuffing: (a) Light scuffing (b) Heavy scuffing Abrasive wear: (a) Foreign matter in the lubricant (scoring) Tooth breakage: (a) Brittle fracture resulting from high shock load (b) Excessive loading causing fatigue fracture Plastic deformation Smooth chemical wear Case exfoliation ► It happens in case of case hardened gears. Causes: ► Improper case hardening process, causes uneven case depth. When the gear is subjected to running conditions, the layer of hardened case comes out from the soft core, causing case exfoliation. Remedies: ► Proper case hardening procedure ► Use of proper lubrication Tooth Pitting ► Pits are formed when material is flaked off the tooth surface near or below the pitch line due to heavy contact pressure. ► This is the removal of small bits of metal from the surface, due to fatigue, thereby leaving small holes or pits. This is caused by high tooth loads leading to excessive surface stress, a high local temperature due to high rubbing speeds, or inadequate lubrication. Minute cracking of the surface develops, spreads and ultimately results in small bits breaking out of the tooth surface. Tooth Pitting Remedies: • Avoid high load concentration • Increase surface strength • Use a higher viscosity oil Tooth Scuffing ► These are due to constantly repeated breakage of the oil film. It happens due to localised welding between two meshing teeth. Remedies: • Use recommended viscosity oil • Provide better cooling by effective spray lubrication • Provide good surface finish Tooth Scoring ► This is a heavy scratch pattern extending from tooth root to tip. It appears as if a heavily-loaded tooth pair has dragged foreign matter between sliding teeth. It can be caused by lubricant failure, incompatible materials and overload. Remedies: • Avoid high load concentration • Increase surface strength • Use proper lubricant Tooth breakage Tooth breakage occurs due to: ► Repeated overloading ► Impact load during meshing ► Uneven distribution of load due to misalignment of axes Remedies: ► Increase tooth bending strength ► Proper design of the gear teeth ► Use large chamfer at the end of the tooth ► Proper assembly of the drive system to avoid misalignment. Plastic deformation ► Sometimes, due to over loading, uneven stress distribution and misalignment, gear teeth does not break, but it got distorted, and permanent plastic deformation takes place. Remedies: ► Proper hardness of the gear teeth ► Proper design of the gear teeth ► Proper assembly of the drive system to avoid misalignment. Smooth chemical wear Cause: ► Presence of mineral impurities in the lubricant Remedies: ► Case harden the teeth ► Use proper and pure lubricant ► Good surface finish Trouble shooting Common defects in gearbox: ► Gear heating up ► Gearbox leakage ► Gearbox noise ► Gearbox vibration ► Oil seal whistle Gearbox heating up ► ► ► ► ► ► High surrounding temperature may cause heating up Over loading: If gear box is heating considerably right from the beginning of its installation, immediate attention should be paid in the fact whether gearbox was properly selected, taking into account all the factors under which it is required to operate. Use of wrong lubricant: Depending upon the conditions of working, proper lubricant must be used. Excessive churning: High viscosity of oil or over filling of the gearbox will produce excessive churning losses consequently heating up the gearbox. Bearing clearance not proper: Improper bearing clearance may allow the axial floating of shaft and bearing damage. Misalignment: Misalignment between the shaft of gearbox and the prime mover and or the driven load causes non uniform load on bearing and shafts. Whenever possible, use common base plate for motor and gearbox or else proper alignment should be done. Gearbox leakage ► Due to over filling, the oil level may rise above the mark and upto the level of oil seal, and there fore leakage could start. ► Leakage may very rarely take place through joint faces between top and bottom half or end caps in which case tightening of bolts and screws will stop leakage, if not then a fresh layer of good jointing compound will have to be applied to the joint faces. ► Any slight damage to the lips of the oil seals due to wear or misuse could start leakage, in which case they need to be replaced. Gearbox noise Causes of noisy gearbox operation: ► Bearing worn out ► Worn out gears ► Foreign particle in the gearbox, may be mixed with lubricant ► Excessive backlash ► Tooth contact not proper ► Eccentric running of shaft ► Proper action to be taken so that, these errors can be eliminated. Gearbox vibration ► Vibration is another area for concern. Solid foundation and perfect alignment is required for the gearbox. Couplings should be well balanced to avoid vibration. Oil seal whistle ►A dry condition of oil seal lips, which allowed to continue, will char and ruin oil seal lips. Smear the oil seal lips with lubricant and do not let it remain dry even when stored for a long time. Market products and specification Specification: ► Type of gearbox ► Transmitted power ► Ratio=Input RPM/Output RPM ► Duty condition ► Type of loading- application ► Type of prime mover Name of some gearbox manufacturing company used in Indian Industries: ► New Allenberry Works ► Greaves ► Elecon ► Shanthi ► Flender ► SEW ► Bonfiglioli Designation of gearbox Example: ► Helical/ Bevel-helical Gearbox: ► Make: New Allenberry Works ► Unit brand name: Helimax C S Type of gearbox CS-Helical CK-Bevel C Number of stage A-Single stage B-Double stage C-Triple stage D-Quadruple stage H Special case 110 Centre distance H-Foot mounted (last stage) hollow output shaft A-Shaft mounted hollow output shaft V-Vertical output shaft Example: ► Geared motor: ► Make: New Allenberry Works ► Unit brand name: Optimax Gear unit Motor unit R. 93. 52 V DC 90S 4 Type Size Size (only 2 gear casing) No. of stage No. of stage Type Size No. of poles ► ► ► ► ► ► Type of gear unit (for geared motor, New Allenberry make): R- foot mounted with co-axial or offset output shaft & with one or two gear casing RF- flanged type with co-axial or offset output shaft & with one or two gear casing R..F-foot cum flanged type with co-axial or offset output shaft with one or two gear casing RUF-flanged type with extended hub and shaft and with co-axial or offset output shaft with one or two gear casing. Type of motor: DC-three phase with squirrel cage face mounting motor DF-three phase with squirrel cage flange mounting motor Example: ► Worm Gearbox: ► Make: New Allenberry Works ► Unit brand name: Allroyd S U Type of gearbox SU-Underdriven SO-Overdriven SV-Vertical output shaft M Metric unit 3 Centre distance (in inches) For different manufacturer, specification changes; so example given here is only indicative.