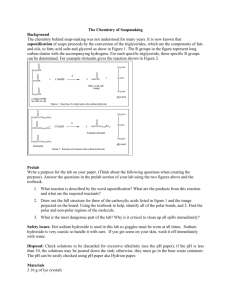

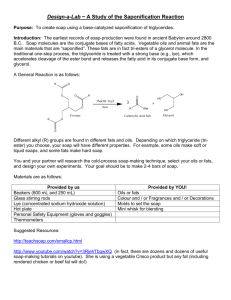

LEARN AND FORMULATE YOUR OWN SOAP By Lunhaw Beautyssentials July 18, 2020 08:00 PM 1|Page What is Soap? It is a cleansing agent created by the chemical reaction of a fatty acid with an alkali metal hydroxide (Oil + Lye). It has been used for centuries and continues to be widely used as a cleansing agent, mild antiseptic and ingestible antidote to some forms of poisoning. Characteristics Hardness Cleansing Conditioning Bubbly Lather Creamy Lather History According to the ancient writings, it was already known to the Phoenicians as early as around 600 B.C. It was used to some extent by the ancient Romans. Soap was made by boiling tallow (animal fat) or vegetable oils with alkali containing wood ashes. This costly method of production coupled with negative social attitudes toward cleanliness made soap a luxury item affordable only to the rich until the late eighteenth century. Methods of soap making improved when two scientific discoveries were made in the late eighteenth and early nineteenth centuries. In 1790, the French chemist Nicholas Leblanc (1742-1806) invented a process for creating caustic soda (sodium hydroxide) from common table salt (sodium chloride). His invention made inexpensive soap manufacture possible by enabling chemists to develop a procedure whereby natural fats and oils can react with caustic soda. In 1823, soap making method was further refined by another French chemist, Michel Eugène Chevreul (1786-1889) when he discovered the nature of fats and oils. Over the years, soap production became less expensive and attitudes toward cleanliness changed. Thus, soap making became an important industry. 2|Page Three Kinds of Soap Making Process Hot Process It is made by combining oils and sodium hydroxide lye (alkali), but requires an external heat source to bring the soap into gel phase. Cold Process It is made by combining oils and sodium hydroxide lye (alkali), which causes saponification, a kind of chemical reaction. Melt and Pour Melt and pour soap has already gone through Cold Process. Made by melting a premade soap base, adding the choice of your additives, and pouring it into your mold. Important Terminologies Trace Point when the oils and lye water are emulsified. At thin trace, there will be no streaks of oil and the soap will be the consistency of thin cake batter. As the soap sits, it will continue to thicken to medium and thick trace. Gel Phase Soap gets as hot as 180°F and develops a gelatinous appearance. Gelled soap has a brighter color and a slightly shiny appearance. It can also be unmolded more quickly. Some soap makers force their soap through gel phase with blankets and heating pads. However, gel phase isn’t required – it’s personal preference. aIt only affects the look of the bars, not the quality. Ungelled Soap It has a more matte appearance. You can prevent gel phase by putting soap in the freezer for 24 hours. Curing 3|Page A cold process soap is safe to use after a few days; however, as per recommendation, let the soap cure for 4-6 weeks in a cool, dry place with good airflow. Excess water will evaporate, which creates harder and milder bars that last longer in the shower. Lye Calculator A tool that makes formulating cold process recipes easy. Just enter the oil weight or percentage and the Lye Calculator will give you the lye and liquid amount you need for your recipe. It also calculates the superfat level. Soda ash It creates an uneven, white, ashy film on soap. It forms when unsaponified lye reacts with naturally-occurring carbon dioxide in the air. It doesn’t affect the quality and the soap is safe to use; however, it can obscure more intricate designs or make the bars feel crumbly. Prevent it by including a 10% water discount and gel phase. Superfatting Adding extra oil to make your soap gentler, deep conditioning, and extra moisturizing. 4|Page Soap Making Oil Chart 5|Page Hard and Brittle Oils Soap made with higher percentages of hard and brittle oils will be easier and quicker to un-mold. These soaps set up quickly and harden faster than soaps made with high percentages of soft oils. Recipes high in hard or brittle oils can be hard to swirl or do advanced designs with that take time as the soap can set up too quickly. Recipes high in hard and brittle oils make un-molding soap easier in single cavity molds. Soap made with higher percentages of hard and brittle oils will require higher temps when mixing. If you soap at too low of a temperature you can get what is called false trace. This is when the solid and brittle oils start thickening up/re-solidifying because of the low temperatures. It looks similar to trace so you might end up pouring your soap before you reach trace. Keep the oil temps in the range of 100-110 F. Soft Oils Soap made with high percentages of soft oils tend to be softer and stickier when unmolding. Simply leave them in the mold a day or two longer before un-molding and cutting. If you are using single cavity molds, you can try freezing them to harden and hopefully the soap will pop out easier. Soap made with soft oils, especially olive oil, is slower to trace and setup. This makes them perfect for swirling. You have more time to color and play with the soap batter. 6|Page Dos and Don'ts in Soap Making 1. Use only 100% lye. You can get 100% lye at most hardware stores. You can also buy lye online from soap making suppliers, where it's sold under its chemical name sodium hydroxide. 2. Wear gloves for protection. The lye crystals, lye water, and raw soap batter is caustic and can burn you. Don them before you beginning and don't remove them until cleanup is done. 3. Use gloves that you feel most comfortable in. 4. Always pour lye into water, NEVER the other way around. Sprinkle lye into the water while gently stirring to ensure all crystals fully dissolve. Never pour water into the lye. 5. Don't use aluminum pots or utensils. Aluminum and lye react badly together. Soaping in an aluminum pot can cause pitting of your pot, and can throw of noxious fumes. It may also create a black smoke. 6. Use stainless steel pots, rubber spoons, plastic pitchers and measuring cups, just no aluminum. Check the bottom of the pot for a "stainless steel" stamp if you're unsure. 7. Use heat-safe containers for the lye water mixture. When you add the lye to your water, it will get really hot, nearly boiling. Make sure your lye water container can handle the heat without melting. Plastic pitchers that are stamped with the recycling #5 are durable enough and are inexpensive. They also make it easy to pour lye water without spilling. If you're not sure your container is up for the task, fill it with plain boiling water first and check for melting or warping. Be sure to set the container in the sink first, in the off chance it does melt the scalding water will go down the drain rather than all over your kitchen. 8. Don't use glass containers for your lye water. The rapid temperature shift can cause the glass to shatter. 9. Use cool water. Because lye heats the water so drastically, make sure you start off with cool water (it doesn't need to be icy, cold from the tap is fine). If your water is too warm, you can end up with water well past the boiling point. Boiling lye water equals scary stuff. 10. Set your lye water container in the sink. Before pouring the lye into the water, set the container down into the sink, and leave it here until you're ready to pour it into your soap pot. 11. Protect yourself from unexpected splashes by covering any exposed skin. 12. Wear a face mask, especially if you’re sensitive to lye fumes or if you’re making large batches. You can also wear a dust mask. 7|Page Basic Materials Containers Use heat-safe glass, plastic, or stainless steel bowls. Don’t use aluminum – it can react with the lye and create toxic fumes. Stick/Immersion Blender Using a whisk or stand mixer can take hours. Stick blenders emulsify the soap in just a minute or two, so it’s worth the investment. Silicone Spatulas and Spoons Use these to scrape every last bit of soap out of your container and into the mold. They’re also great for smoothing the top or creating texture. Scale For accuracy, all of our soap recipes are measured by weight instead of volume. Soap Molds Silicone molds are easy to use, unmold, and clean. They’re a great option for beginner and advanced crafters. Wood molds are great for large batches and they make it easy to force gel phase. They need to be lined with freezer paper or a silicone liner. Plastic molds can be used for cold process, but they do require a few extra steps. We recommend a recipe with lots of hard oils to help the bars come out cleanly and quickly. 8|Page Manual Calculation of the Lye, Lye Solution, and Water Remember: SAP Values are the traditional numeric values that allow you to calculate the precise amount of sodium hydroxide required to fully saponify a given weight of oil/s. For your manual calculation of the lye, lye-water solution, and water to be used, you only need to remember three important formula: 1. Manual Calculation of the Lye (Amount of Fat) × (Saponification Value of the Fat) = (Amount of Lye) 2. Manual Calculation of the Lye-Water Solution (Amount of Lye) ÷ 0.3 = (Total Weight of Lye-Water Solution) 3. Manual Calculation of the Water (Total Weight of Lye-Water Solution) − (Amount of Lye) = (Amount of Water) A. Calculation of Lye The SAP values are the traditional numeric values that allow you to calculate the precise amount of sodium hydroxide required to fully saponify a given weight of oil/s. For example: Step 1. 24 oz of olive oil (SAP olive oil = 0.135) 16 oz of coconut oil (SAP = 0. 183) 16 oz of palm oil (SAP = 0.142) 4 oz of shea butter (SAP = 0.128) 2 oz of castor oil (SAP = 0.128) __________________ 62 oz of oils 9|Page Step 2. (24 oz x 0.135) + (16 oz x 0.183) + (16 oz x 0.142) + (4 oz x 0.128) + (2 oz x 0.128) = 3.24 + 2.928 + 2.272 + 0.512 + 0.256 = 9.208 oz Lye is needed to fully saponify of 62 oz of oils. Note: Round the numbers up to the last two or three decimal points. Super Fatting So, the 9.208 oz will be saponified oils to become a perfect soap, but it will not make your soap moisturizing. To make a moisturizing soap, you must reduce 5% to 10% from the total lye, or discount the lye from your the final calculation. Also called as super fatting. It also ensures that your soap does not have too much lye. So, the 9.208 x .95 = 8.7476 oz Lye (discount 5%) for 62 oz oils. B. Calculation of Lye-Water Solution Always remember that the numerical value 0.3 is CONSTANT. Step 1. 9.208 oz Lye ÷ 0.3 = 30.693 oz is the total weight of the lye and water combined as lye-water solution, which is needed to fully saponify of 62 oz of oils. C. Calculation of the Water What’s left for you to do is to find the value of the needed water for the solution. Step 1. 30.693 oz total weight of the lye-water solution – 9.208 oz Lye = 21.485 oz of water needed for the lye-water solution. 10 | P a g e SAP Values 11 | P a g e Solve your SOAP Formula here: You can access your Practical Application Assignment on this Link: https://forms.gle/6RtRjupfEEFJm2Mg8 12 | P a g e How to Make Cold Process Soap STEP 1 Weigh all the ingredients. Prepare the equipment’s and materials that you will be using. Make sure that there is proper flow of air within your work area. STEP 2 Start with the LYE. Carefully pour the lye into water, stirring gently with a heatproof utensil until the lye has fully dissolved. Set aside, and let it cool. STEP 3 While the lye solution is cooling, weigh oils or solid butters. If you will be using solid butters, melt with a double-boiler until up to 100 degrees. Combine all the oils and melted butters. STEP 4 Pour the lye solution into the container of oils. Stir until trace is reached. (Trace refers to the point when the oils and lye solution have emulsified. At this stage, there should be no streaks of oil and the soap will have the consistency of batter.) STEP 5 Add any extra ingredients-such as natural exfoliants, essential oils, or colorants-stirring to combine. STEP 6 Carefully, pour it into the mold. The soap is still caustic at this stage, so keep your safety gear on when handling. Set aside for up to 2 days or until completely cool and solid. When ready, remove homemade soap from the mold and slice into bars, or pop it out of the designed silicon mold. Let the bar soaps cure in the open air for four to six weeks before using. 13 | P a g e COMPUTING THE COSTS 135g PAPAYA SOAP 1. Formulate your own soap. The total must be equivalent to 100%. Ex. Water = 24% Lye = 11% Coconut Oil = 63.5% Active Ingredient = 1.3% Fragrance = 0.10% Color = 0.10% TOTAL Percentage: 100% 2. Based from your Formula’s Percentage, calculate the quantity. Ex. Water = 32.4g Lye = 14.85g Coconut Oil = 85.7g Active Ingredient = 1.75g Fragrance = 0.135g Color = 0.135g TOTAL Weight: 135g 3. Identify the price for every ingredient that you will use. Ex. Water = 2 Lye = 90 Coconut Oil = 90 Active Ingredient = 2,000 Fragrance = 3,000 Color = 3,500 4. Compute the price. Price per kg. x Quantity 1,000 Ex. Water = 0.0648 Lye = 1.3365 Coconut Oil = 7.713 Active Ingredient = 3.5 Fragrance = 0.405 Color = 0.4725 PRICE for every 135g of soap = 13.4918 14 | P a g e Overall Review Materials Lecturer What to Improve 15 | P a g e