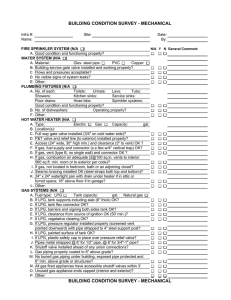

ExxonMobil Safety in LPG Design LHHA(CO) if filled by Pipeline or by Ship Water Draw-off to Location LI LHA PRV min. 15 m from Fence PI LHHA Concrete Wall TI Distance Valve to Fence15 m to ESS min. 0.9 m LPG Tank Slope 1:100 EBV Removable Part Removable Fill First Edition by Exxon Company, International Florham Park, New Jersey ExxonMobil Fairfax, Virginia ExxonMobil Proprietary Information This manual was produced using Doc-To-Help® Version 4, WexTech Systems, Inc. Revision History First Edition - January, 1996 Second Edition –October, 1999 Third Edition ExxonMobil – March, 2001 now including Mobil EPT 15-T-02 and Mobil SCS Volumes 1 and 2 For future additions, suggestions and changes please contact either: Detlef Robertz/CentralEurope/ExxonMobil@xom or Herbert Pui-Shui Ho/HKPRCTWN/ExxonMobil@xom Contents 1 PREFACE 1.1 1.2 2 2-1 2.1 2-1 2-1 2-2 2-2 2-2 2-3 2-4 2-9 2-9 2-15 2.3 2.4 Exposures from and to the Site 2.1.1 Planning Considerations and Criteria 2.1.2 Topography and Prevailing Wind 2.1.3 Road Access and Traffic Situation LPG Plant Layout 2.2.1 Space Requirements 2.2.2 Equipment Spacing to Maximize Separation Electrical Equipment Specifications 2.3.1 Electrical Area Classification Emergency Shutdown System BULK STORAGE 3-1 3.1 3.2 3-1 3-2 3-2 3-3 3-6 3-11 3-12 3-14 3-15 3-15 3-16 3-16 3-17 3-17 3-23 3-23 3-25 3-26 3-27 3-28 3-29 3-30 3.3 3.4 3.5 3.6 4 1-1 1-2 PLANT SITE 2.2 3 1-1 Introduction Objectives for Safety in LPG Storage in Plants and Industry Mounded and Above Ground Storage 3.2.1 Dimensional Sizing of Drums 3.2.2 Materials Selection for Tanks 3.2.3 Design Basis for Mounded Drums 3.2.4 Testing Requirements 3.2.5 Horizontal “Bullets” and Spherical Tanks 3.2.6 Spill Containment 3.2.7 Vacuum Conditions Refrigerated LPG Storage Overpressure Protection for Tanks 3.4.1 Contingencies to be Expected 3.4.2 Refinery and Upstream Pressure Relief 3.4.3 Pressure Relief in Marketing Terminals Emergency Block Valves on Bulk LPG Tanks 3.5.1 Tank EBV's in Liquid Service 3.5.2 Tank Shutoff Valves in Vapor Service Tank Instrumentation 3.6.1 Tank Level Measurement 3.6.2 Pressure and Temperature Indicators 3.6.3 Grounding Connections for Tanks 3.6.4 Product Odorization PUMPS & COMPRESSORS 4-1 4.1 4-1 4-1 4-11 4-12 4-14 4.2 Pumps 4.1.1 Pump Types Commonly Used Compressors 4.2.1 Compressor Types Used 4.2.2 Compressor Sizing Safety in LPG Design Contents i 5 PIPING AND VALVES 5-1 5.1 5-1 5-1 5-4 5-4 5-5 5-5 5-6 5-7 5-8 5-9 5-9 5-9 5-10 5-10 5-11 5-11 5.2 6 PRODUCT TRANSFER 6-1 6.1 6-1 6-3 6-4 6-5 6-6 6-6 6-8 6-10 6-10 6-13 6-15 6-15 6-21 6.2 7 7-1 7.1 7-1 7-2 7-8 7-8 7-10 7-11 7-13 7-14 7-15 7-15 7-16 7-17 7-17 7-22 7-30 7-33 7-33 7-33 7-35 7.3 7.4 7.5 7.6 7.7 Cylinder Purchasing Specifications 7.1.2 Cylinder Specifications Cylinder Valve Purchasing Specifications 7.2.1 Manufacturing Design Standards Regulator Purchasing Specifications 7.3.1 Manufacturing Design Standards Hose Purchasing Specifications 7.4.1 Hose clips Cylinder Filling Plant Cylinder Filling 7.6.1 Cylinder Processing and Filling 7.6.2 Manual Filling System 7.6.3 Automated Filling System 7.6.4 Integrated Automated Filling Plant 7.6.5 Purchasing Guidelines for Filling Plants 7.6.6 Third Party Cylinder Filling Plant Cylinder Distribution 7.7.1 Distribution Center 7.7.2 Dealer and Reseller Cylinder Storage FIRE PROTECTION 8.1 ii Principles of Product Transfer 6.1.1 Loading or Unloading with Pumps 6.1.2 Loading or Unloading with Compressors 6.1.3 Using Pumps Versus Compressors 6.1.4 Static Electricity in Unloading and Loading 6.1.5 Hard Arms 6.1.6 Hoses in Product Transfer Loading and Unloading 6.2.1 Truck Loading and Unloading 6.2.2 Rail Car Loading and Unloading 6.2.3 Marine Loading and Discharge 6.2.4 Marine Pier Installations 6.2.5 Pipeline Dispatch and Receipt LPG CYLINDERS 7.2 8 Piping in Plants 5.1.1 Piping Arrangements 5.1.2 Piping Location 5.1.3 Piping Integrity 5.1.4 Pressure Ratings 5.1.5 Pipe Sizing 5.1.6 Pipe Connections 5.1.7 Small Piping Connections 5.1.8 Installation Valves in Piping 5.2.1 Valve Integrity 5.2.2 Shutoff Valves 5.2.3 Backflow Check Valves 5.2.4 Thermal Relief Valves 5.2.5 Emergency Block Valves for Piping 5.2.6 Valve Packings 8-1 Passive and Active Fire Protection 8.1.1 Fireproofing, a Passive Fire Protection 8.1.2 Fire Resistant Coatings Contents 8-1 8-1 8-2 Safety in LPG Design 8.2 9 Fire Protection System Design Philosophy 8.2.1 Firewater System, an Active Fire Protection 8.2.2 Protection Requirements 8.2.3 Flammable Gas Detectors 8.2.4 Fire Detectors 8-7 8-8 8-16 8-19 8-20 TRANSPORTATION 9-1 9.1 9.2 9-1 9-1 9-1 9-2 9-7 9-11 9-12 9-13 9.3 9.4 9.5 Means of Product Movement Road Bulk Transportation Equipment 9.2.1 Truck Design and Procurement 9.2.2 Basic Design Considerations 9.2.3 LPG Truck Discharge System Road Cylinder Transportation Rail Tank Cars Marine 10 CUSTOMER INSTALLATIONS 10.1 10.2 10-1 Cylinder Bank Installations 10.1.1 Design of Cylinder Banks 10.1.2 Installation of Cylinder Banks 10.1.3 Vaporization Rate in Cylinders 10.1.4 Icing or Sweating on Cylinders. Containers at Customer Sites 10.2.1 Spacing and Location of Containers 10.2.2 Designing Customer Storage Systems 10.2.3 Sizing Of Containers and Vaporization Rates 10.2.4 Sizing Containers for Vaporizing Liquid 10.2.5 Enforced Vaporization by Means of Vaporizers 10.2.6 Installation of containers 10.2.7 Container Fittings and Piping 10.2.8 Container Valves and Accessories 11 AUTOMOTIVE LPG 11.1 11-1 Automotive LPG Stations 11.1.1 Design of Automotive LPG Equipment 11-1 11-1 12 LPG PROPERTIES 12.1 12.2 12-1 Product Properties LPG Hazards 12-1 12-5 13 GLOSSARY OF TERMS Safety in LPG Design 10-1 10-1 10-2 10-2 10-5 10-5 10-5 10-7 10-8 10-9 10-12 10-14 10-17 10-18 13-1 Contents iii 1 PREFACE 1.1 Introduction The manual is primarily intended for assisting managers and engineers responsible for design, construction, or modification of LPG facilities. It should also be useful as a ready reference for members of management who have a need to understand LPG equipment and design practices. The LPG guidelines included in this manual are intended for application to new construction or alterations to existing facilities. The manual covers guidelines for the safe receipt, storage, loading, transport, and unloading of LPG for refining, upstream, and marketing bulk storage, as well as marketing cylinder filling plants and depots. The manual is not intended to cover refinery onsites, upstream gas plant facilities, or offshore platforms. Design practices among the functions are quite similar, although in a few cases some differences appear due to the scale of operations in refineries or upstream plants compared with marketing plants. These are noted. When deviations from the guidelines become necessary they should receive safety review and approval by the country/cluster. If local regulatory requirements or current country/cluster practices are more restrictive, however, they will of course supersede the guidelines described herein. Local regulations have to be followed as a minimum. The manual references EMRE Global Practices (GPs), EMRE Design Practices (DPs) and ExxonMobil Engineering (EMRE) reports. GPs are typically referenced to provide detail on the implementation of design concepts. Within GPs, individual paragraphs are identified as to their purpose, i.e. safety, operability, reliability, maintainability, etc. Deviation from “safety” paragraphs should receive formal safety review and approval. The lead design engineer would control deviation from “other” paragraphs. DPs are referenced to provide considerations for design. Their application requires engineering judgment and the lead designer should determine when deviations require formal safety review. EMRE reports are referenced to provide additional design considerations on special topics. The lead design engineer should determine their applicability by reviewing or contacting EMRE. Industry standards used in this manual include NFPA (National Fire Protection Association), LPGA (Liquefied Petroleum Gas Association), API (American Petroleum Institute), NPGA (National Propane Gas Association), and IP (Institute of Petroleum, UK). The material contained in this manual is considered “Proprietary” and its distribution limited according to company procedures for safeguarding proprietary company information. If there is a strong business reason to give portions of the material to customers or contractors, only the minimum portion containing pertinent information shall be released. Safety in LPG Design PREFACE 1-1 Quality Assurance Whenever possible, equipment for LPG Marketing applications should be purchased from manufacturers who have submitted their product to a recognized governmental or independent laboratory for analysis, evaluation, and performance testing in LPG service, and have been granted approval as indicated by listing and/or labeling. Organizations performing or sponsoring the type of testing recommended include US Underwriters Laboratories, the UK Board of Trade, Lloyds Underwriters, the German BAM (Bundesanstalt für Materialprüfung) or similar institutions, which are widely recognized. It is desirable to have selected equipment covered by a testing program that provides periodic quality assurance of the manufacturer that design, materials, and procedures are unchanged from the initial approval. The Underwriters Laboratories listing program incorporates this feature. Approved LPG equipment will often be available for standard Marketing equipment, e.g. cylinders, cylinder valves, filling equipment, small pumps and seals, and regulators. Equipment for larger scale LPG operations in refining and upstream is often not submitted for formal LPG approval, because it is manufactured in accordance with industry standards for hydrocarbon service, which includes LPG. When equipment has not been approved for LPG, its mechanical design and materials of construction reviewed by the project engineer, with input from specialists when necessary, to determine suitability for LPG use, and to ensure that the device will function satisfactorily for the intended service life. The conversion of valves and accessories originally designed and fabricated for another service is not recommended. All valves and accessories shall be supplied by the manufacturer as assembled and tested at the factory, without subsequent modifications 1.2 Objectives for Safety in LPG Following are objectives to maintain high standards of equipment design and operations. 1. Minimize or eliminate LPG incidents 2. Develop and coordinate inter-functional LPG safety training programs. 3. Monitor regulatory trends. 4. Update manuals at regular intervals. 5. Publish information on lessons learned from incidents that occurred in the company or industry. Procedures for LPG Inter-functional training programs for LPG safety have been developed and coordinated through the LPG Safety Network. The LPG design guidelines contained in this manual are based on current ExxonMobil and industry design philosophy and practices, and on the results of company LPG risk assessment programs. Where differences exist between country/cluster design practices and those presented in this manual, it is suggested that country/cluster management consider adopting the practices described herein. ExxonMobil issues this manual to its country/clusters for suggested use in design of Liquefied Petroleum Gas (LPG) facilities used in Upstream, Refining and Marketing operations. Relevant aspects of safety for LPG design are documented in this third edition (2001) of the “Safety in LPG Design” manual. LPG safety design and operations manuals will be updated on a 3-yearly basis. More urgent updates will be communicated through the LPG Safety Network and through the BestNet. Recommended changes to guidelines and practices will be developed as appropriate. 1-2 PREFACE Safety in LPG Design New directives and standards are coming from legislative bodies and industrial associations, which every nation is directed to follow. Regulatory developments will be controlled by following the OIMS systems. Distribution of industry and company incidents and lessons learned will be done on a timely basis through the LPG Safety Network. Responsibilities ExxonMobil LPG Technical Advisors provide guidance and assistance to help plants to implement procedures and practices described in the LPG manuals and solve their problems. The ExxonMobil LPG Advisors are primary contacts for Marketing country/cluster LPG issues such as incidents and lessons learned, training needs, suggested revisions to LPG safety manuals. They attend industry LPG meetings, monitor technical and regulatory trends, evaluate changes in industry procedures and practices for applicability. They communicate to the country/clusters as appropriate. Representatives from Upstream, Refining, Marketing, and Marine will have an influence on company LPG standards reflected in the “Safety in LPG Design” and “LPG Safe Operations Guidelines.” Ultimate decisions on technical issues will be made by the ExxonMobil LPG Technical Advisors and ExxonMobil Research and Engineering. Verification and Feedback Yearly verification of SHE performance of LPG operations by the SHE organization. Summary of incidents, lessons learned. Identify areas for system improvement and implement. Safety in LPG Design PREFACE 1-3 2 PLANT SITE 2.1 Exposures from and to the Site Before choosing a plant site it is important to study all relevant facts that may be of influence on the choice. Such items of influence are exposure to and from the neighborhood, topography, prevailing wind direction and the road traffic situation. It is considered appropriate to locate an LPG plant in an industrial zone. The plants in the neighborhood may preferably be refineries or storage plants or similar industries where ignition sources are rare or under control. Therefore, neighborhood to any type of facility which incorporates obvious ignition, sources, or which employ hazardous processing methods (e.g. storing powerful oxidizing agents), shall be avoided. If known exposures are more severe, increased clearances may be necessary. Warning signs “NO SMOKING,” “FLAMMABLE GAS” shall be posted at all LPG handling areas and outside the gate. The locations of the signs shall be determined by local conditions, but the lettering shall be large enough to be visible and legible from each point of transfer. 2.1.1 Planning Considerations and Criteria The input data required to start the design of an LPG system shall be available from the ExxonMobil marketing unit responsible for the proposed facility. This data shall include the following: 1. Products to be handled and peak volumes in bulk and in cylinders. 2. Total storage capacity required for each product. 3. Requirements of local government agencies with jurisdiction. 4. Allowances for future expansion. 5. Product sampling requirements. 6. Toxic materials in plant. 7. Site data including limitations or restrictions. 8. Possibility of storage and handling of other petroleum products within the facility. 9. Evaluation of any surrounding external hazards at the site. 10. Capacity and frequency of each type of LPG delivery to the site from tank trucks, railroad cars, marine vessels and pipelines. 11. Number of tank truck or railroad tank car unloading positions required. 12. Maximum and minimum flow rates for each type of equipment. Safety in LPG Design PLANT SITE 2-1 13. Method used to verify quantity of shipment: weight, volumetric measurement or meters. 14. Types of unloading pumps or compressors carried by transporting equipment. 15. Number, size and type of connections on transporting equipment. 16. For cylinder filling, the type, number and layout of scales, and the size, number and type of cylinders to be filled. 17. Cylinder painting, stenciling, washing and testing facility requirements. If possible, this task should be contracted to third party companies. 18. Method of receipt, storage and handling of cylinders: Manual handling or palletization, forklift, hand truck or other. 2.1.2 Topography and Prevailing Wind Considering the basic characteristics of LPG vapor, it is desirable to locate a plant in an area which is free of depressions and contours radiating from the plant which might convey vapors to a point of exposure. In the event of an accidental discharge of product within the plant, LPG tends to vaporize rapidly. Dissipation of vapors below the lower flammable limit develops more rapidly if the plant site is elevated slightly above the general terrain, or is slightly inclined. Dissipation of vapors in a flat location will mainly depend on wind or time. In low-lying areas vapors may stay trapped despite wind. This potential shall be considered in connection with gas leaks. Any site considered for a marketing plant shall be analyzed with respect to the prevailing wind direction. Prevailing winds may have an influence on potential exposures. Based on prevailing wind, sites shall, whenever possible be located down wind (meteorological data) of population centers or known ignition sources. Tanks shall always be located downgrade and downwind from possible ignition sources. 2.1.3 Road Access and Traffic Situation Any streets adjacent to the plant site shall be analyzed to determine that a safe traffic flow in and out of the plant is possible. The access road shall be of such width that vehicles could enter and leave the plant without creating a hazardous condition. Consideration shall be given to the traffic conditions on the access road during peak traffic flow in and out of the plant. Visibility, which is influenced by road curves etc., may play an important role in these considerations. 2.2 LPG Plant Layout Following are some concepts that govern the layout/plot plan of the bulk LPG storage facilities. Bulk LPG Tanks shall be located together to minimize piping and general site size. Before the final location for bulk storage is selected, a site survey shall be conducted and if deemed necessary, soils investigation shall be done. It should be defined whether the storage is above or below ground and whether cylindrical or spherical tanks shall be used. These investigations shall provide sufficient data on the bearing capacity, drainage characteristics, estimates of settlement, and remedial measures, if necessary. Future expansion plans shall also be considered. Bulk transports that discharge or receive product within the plant shall be provided with a clear access through the plant, which can be negotiated without, at any time, reversing the unit. Sufficient space shall be provided at a loading or unloading location to allow for positioning the transport with minimal chance of collision with other vehicles or fixed objects. Loading or unloading 2-2 PLANT SITE Safety in LPG Design facilities shall be protected with guardrails or stanchions to prevent damage from vehicles. Vehicles shall be facing an exit while loading or unloading. Pipeline or marine loading and discharge operations will utilize the least amount of land since pipelines need only metering and control equipment and ships need only shore-based compressors for the unloading operation. However, a considerable amount of waterfront space shall be allocated for marine berth(s). With product delivered by rail tank car, sufficient space shall be allotted to the rail line and the racks and compressors for the unloading operation. Pumps and compressors shall be grouped together and arranged such that the piping is as simple and direct as possible. Electrical control panels and other support equipment shall be located in accordance with the electrical area classifications. Figure 2.1 a: - Example for plant layout in sloped terrain The Cylinder Filling Plant, with storage area, loading dock and access area, shall be laid out to ensure: 2.2.1 1. Optimum traffic pattern/parking for cylinder transport trucks. 2. Minimum interference between truck and fork lift traffic. 3. Clear separation of filled/empty cylinders. 4. A minimum of necessary cylinder handling. Cylinders should “flow” from the empty to filled area. 5. Optimize natural ventilation by positioning the cylinder filling plant such that natural air currents will be utilized in the most effective manner. 6. A separate area is designated for cylinders requiring repair or refurbishment. Space Requirements Space requirements will normally incorporate the following functions: Safety in LPG Design 1. Gate house and security fence. 2. Administration and Control Building. 3. Bulk product receiving and dispatching areas, including weighbridge. 4. Tank truck loading and unloading area with access roadway. 5. Railroad siding, including loading and unloading area. 6. Tanker or barge loading or unloading facilities. 7. Stenching facilities for odorization of the LPG. PLANT SITE 2-3 8. Bulk product storage. 9. Cylinder handling and storage (new, empty, filled, scrapped, truck parking). 10. Cylinder filling and inspection processes. 11. Other fuels storage or manufacturing facilities. 12. Pumps and compressors for loading and unloading trucks, rail cars, tankers and barges. 13. Pumps normally used for filling cylinders. 14. Cylinder repair and re-qualification processes (if located in filling plant). 15. Maintenance shop and warehouse. 16. Storage area for reserve supply of cylinders and customer containers. 17. Staff, customer and plant vehicle parking areas. 18. Fire water systems. 19. Firefighting access. All of the above should be interrelated to the spacing requirements which are discussed below. A qualified company outside the filling plant may preferably carry out the cylinder repair and re-qualification process. Figure 2.1-.b: Filling plant with unloading rack, tanks, pump/compressor house and filling area 2.2.2 Equipment Spacing to Maximize Separation The most important objective of spacing is to separate risks by zoning. The higher a risk, the larger the spacing. Spacing requirements between tanks will help to limit the spread of fire, should it occur. In case of accidental leakage, spacing between equipment and the fence will help to disperse flammable mixtures below lower flammability limits (LFL) such that ignition by uncontrollable external ignition sources (e.g. passing cars) may be prevented. Another aspect that influences spacing is the requirement for safe access of the operator to perform an emergency shutdown/activities but also for normal operations and maintenance. Also traffic patterns for truck and rail loading shall be considered. The safe location of the control room and firefighting pumps may be of importance during an emergency. The equipment spacing requirements detailed below are minimum figures, which in general will satisfy the above objectives. Whenever a special consideration or particular factors (e.g. plot space available) require deviation from the spacing rules a safety specialist shall perform a risk assessment. Additional safety and firefighting equipment requirements may compensate for a lack of spacing. So, if for instance, LPG is stored in vicinity to housing, passive fire protection may be the answer to reducing the risk. This may be achieved by mounded storage of the tanks. 2-4 PLANT SITE Safety in LPG Design Where sufficient space is available, the ground can be contoured and sloped such that the liquid from a potential leak will flow away from the storage tank to a remote location. In case of a subsequent fire, this would be desirable since the liquid from the leak would burn at a place away from the tank. Admittedly for Propane and hot climates this is not a major mitigation factor since the bulk of the leaking gas will flash right at the leak. But for Butane and colder climates it may mitigate the situation considerably. 2.2.2.1 Spacing at Refining and Upstream Gas Plants Spacing of storage and loading and unloading facilities at Refining and Upstream Gas Plants shall be in line with spacing requirements documented in the Design Practices DP XV-G, “Equipment Spacing” and GP 9-1-1, “Spacing and Dikes for Storage Vessels and Tanks.” 2.2.2.2 Spacing Requirements for Marine Berths Planning for Marine berths requires considering a number of issues affecting spacing. Generic marine issues such as berth layout, approaches to the berth, dredging etc. may affect the location of the berth and spacing requirements regarding other shore-based facilities. Information on such issues is available in the Marketing Engineering Standard EE.3M.86 “Marine Facilities, Design, Specification and Evaluation.” If multiple LPG berths are planned, additional spacing considerations between berths shall be taken into account. The minimum spacing criteria for fire and safety considerations is 30 m. However, in most cases, other plant design considerations shall require berth spacing greater than 30 m. More detailed descriptions of such considerations and additional commentary is provided in the ERE report EE.131E.79 “Suggested Design Considerations for Refrigerated Liquefied Gas Facilities.” Additional clarifications are provided in “Clarifications of Recommendations Arising from the ‘Betelgeuse’ Incident” (83 EEEL 514 or 83 CMS3 R9). EMRE's Marine Section should be consulted from the early stages of the project to ensure that the appropriate issues have been considered regarding berth layout and spacing. 2.2.2.3 Spacing at Marketing Plants Spacing to the property line for Marketing Plants is consistent with API 2510, as indicated in the table below. Marketing plants may store considerably smaller volumes of LPG than Refineries or Upstream sites. Individual Tank Capacity, m3 Spacing to Property Lines, m 8 - 110 < 260 < 340 < 450 < 760 15 20 30 40 60 < 3800 > 3800 90 120 Table 2.2.2.3-a: Spacing to property lines At some locations, where risk exposure is considerably lower than usual the design engineer may deviate from the spacing requirements. A typical example would be a marketing plant on a riverbank surrounded by industrial plants (no housing). When additional storage is required at existing sites, and the spacing guidelines cannot be met, risk assessment techniques may be used to evaluate reduced spacing. As explained earlier, compensation for reduced spacing may be achieved by adding active/passive fire protection. The ExxonMobil LPG Technical Advisor or an EMRE Safety Engineer should be consulted when planning to deviate from spacing requirements. The rationale for deviating shall be documented in the design memorandum. In addition to property line spacing, Marketing sites have other spacing guidelines not covered by DP XV-G. Additional guidelines, as well as spacing from DP XV-G commonly applied at Marketing plants, are covered by the following table. Safety in LPG Design PLANT SITE 2-5 Property Lines Office Building Cylinder Filling Loading, Unloading Sphere Horizontal Bullet Mounded Tank Pump or Compressor Sphere Note 1 30 30 30 Note 2 Note 3 Note 6 Note 9 Horizontal Bullet Note 1 30 15 15 Note 3 Note 4 Note 7 Note 10 Mounded Tank Valving 15 15 15 15 Note 3 Note 5 Note 8 5 Mounded Tk. Covered Part 3 3 3 3 Note 6 Note 7 Note 8 3 Truck Loading/Unloading 30 30 30 15 30 15 3 3 Rail Unloading/Loading 15 30 30 15 30 15 3 3 Cylinder Filling 30 30 Note 11 30 30 15 Note 12 5 Note 11 Note 11 30 30 30 30 Note 12 30 Spacing Distances, in Meters Firewater Tank or Pump Table 2.2.2.3-b: Spacing within Marketing LPG bulk storage plant 1. Note 1: Above ground tank spacing from property lines according to the above Table 2.2.2.3-a: Spacing to property lines. 2. Note 2: ¾ Diameter of larger sphere. 3. Note 3: ¾ Diameter of sphere. 4. Note 4: 1 Diameter of larger bullet (or 1.5 m min.). 5. Note 5: 1 Diameter of bullet. 6. Note 6: At sphere bund wall. 7. Note 7: Next to bullet toe wall. 8. Note 8: Spacing between mounded drums does normally not involve any fire hazard considerations, therefore, the following is recommended: a. Tanks up to 135 m3 water capacity shall have a minimum spacing of 1.5 m between the tanks. b. Tanks over 135 m3 water capacity: The site conditions and the needs for safe installation, testing, maintenance, and removal shall determine the spacing between adjacent tanks. Note 9: Pumps, compressors, and other equipment (including piping not related to LPG tanks) shall be outside bund walls. 9. 10. 11. 12. Note 10: Pump drawing from individual bullet may be outside toe wall and minimum 3 m from bullet. Other pumps or compressors 5 m. Note 11: No minimum. Provide spacing appropriate for access. Note 12: From drains, vents, and valving or flanges 15 m; from covered part of mounded drum 3 m. For spacing to atmospheric storage of other fuels or refrigerated storage see GP 9-1-1. Spacing of groups or “stacks” of cylinders to the property line is discussed in Chapter 7. Dikes spacing to spheres shall be according to GP 9-1-1 “Spacing and Dikes for Storage Vessels and Tanks.” Toe wall spacing to shell of bullet shall be 3 m. Also refer to section 3.2.6 “Spill Containment.” 2-6 PLANT SITE Safety in LPG Design Minimum Distances Flammable Liquid Storage Tank Bullet up to 135 m3 Bullet over 135 m3 Flash Point lower than 37 oC 6 m to bund wall 15 m to bund wall Flash Point from 37 to 65 oC. Tank size up to 3,000 liters Safety distances for LPG tank or 3 m to the tank / bund wall, whichever is the less 6 m to tank, bund wall or diversion wall Tank size over 3,000 liters 3 m to bund wall or diversion wall and 6 m to tank 15 m to tank, bund wall or diversion wall Table 2.2.2.3-c: Minimum separation distances for LPG horizontal tanks (bullets) from other flammable liquid storage Non pressurized hazardous and Flammable Storage Tank Type and Product Minimum separation distances Refrigerated LPG Tank ¾ diameter of the larger tank or sphere Storage Tank with product flashpoint 37 oC or less 1 diameter of the larger tank or sphere Storage Tank with product flashpoint more than 37 oC ½ diameter of the larger tank or sphere Table 2.2.2.3-d: Minimum separation distances for LPG sphere tanks from other flammable liquid storage. LPG tanks shall not be installed within the bunded area for flammable or combustible liquid storage tanks. The minimum distances of separation between a LPG horizontal tank and a storage tank containing a flammable liquid shall be according to Table 2.2.2.3-c. For LPG spherical tank and a tank containing flammable liquid, Table 2.2.2.3-d shall be used. Open drains, gullies or ducts located within the tank safety distances in Tables 2.2.2.3-a and b, carrying water runoff from the ground underneath aboveground LPG tanks shall be provided with an LPG trap or be sealed to prevent LPG liquid and vapor from passing through. No permanent source of heat shall be located within 1.5 m of a LPG tank. LPG tanks shall not be located directly beneath electrical power cables. LPG tanks shall be located such that a break in overhead electrical lines shall not cause exposed ends to fall onto any tank or equipment. No horizontal separation shall be required between an aboveground LPG tank and underground tanks containing flammable or combustible liquids installed in accordance with NFPA 30. If, in industrial installations, LPG and oxidizing gases or hydrogen are stored on the same premises, the following minimum distances shall be observed: Chlorine LPG Oxygen* (> 0.75 t) LPG (> 1.9 m3) Gaseous Hydrogen* (> 7 kg) LPG (> 1.9 m3) *see NFPA 58 for smaller capacities Safety in LPG Design PLANT SITE 300 m 15 m 15 m 2-7 Depending on Tank Size Electrical Insulation Remote Impoundment min. 15 m min. 15 m min. 3 m RAIL CARS SPHERE Distance depends on drum size MOUNDED TANK Dike BULLET MOUNDED TANK BULLET 3/4 Sphere Diameter one bullet diameter 15 m Depending on Tank Size 15 m RAILWAY Toe Wall Earth Mound Depending on Tank Size min. 30 m from Sphere or Bullet min. 15 m from LPG bulk storage 30 m Propane Loading Butane Loading FIRE WATER TANK FILLED CYLINDERS FIRE PUMPS 30 m CYLINDER FILLING EMPTY CYLINDERS OFFICE BUILDING 30 m min. 15 m from manhole of Mounded Drum min. 30 m from Sphere/Bullet or Cylinder filling Pumps or compressors must be outside spill containment and may be 3 m away from tanks they take suction from, but 5 m from other tanks (like next bullet or next sphere dike) One Way GATE Figure 2.2.2: Spacing in marketing LPG bulk plant with cylinder filling 2.2.2.4 Siting of Aboveground Tanks and Equipment Pressurized LPG tanks shall not be located within buildings, within the spill containment area of flammable or combustible liquid storage tanks as defined in NFPA 30, or within the spill containment area for refrigerated LPG tanks. Rotating equipment and pumps taking suction from the LPG tanks shall not be located within the spill containment area of any storage facility. Horizontal tanks used to store LPG may be oriented so that their longitudinal axes do not point toward other tanks, process equipment, control rooms, loading or unloading facilities, or flammable or combustible liquid storage facilities located in the vicinity of the horizontal tank. Horizontal LPG tanks shall not be stacked one above the other. Horizontal tanks used to store LPG shall be grouped with no more than six tanks in one group. Where 2-8 PLANT SITE Safety in LPG Design multiple groups of horizontal LPG tanks are to be provided, a minimum horizontal shellto-shell distance of 15 m shall separate each group from adjacent groups. 2.3 Electrical Equipment Specifications Electrical equipment and wiring shall comply with the specifications of, and be installed in accordance with the requirements of the local electrical codes. For reference on reliability in electrical design, see the related electrical GPs. 2.3.1 Electrical Area Classification Normal electrical equipment can be considered an ignition source. Therefore, where flammable liquids, gases or vapors are handled, or stored, special electrical equipment shall be installed, which normally will not serve as an ignition source. The industry has produced standards to differentiate the ignition potential of electrical equipment. Following are the levels of protection: 1. Equipment that will never produce a spark, even if it fails. 2. Equipment that, when operating normally, will not produce a spark, but may do so if it fails. 3. Equipment that will produce a spark during normal operation. The likelihood of encountering flammable vapors in plants governs the level of equipment needed. Plants shall be divided into separate areas according to the likelihood of flammable LPG vapors being present. FILLING HOSE FLAMMABLE VAPORS FLAMMABLE Figure 2.3.1-a: Example for Zone 1 area Based on experience, minimum distance requirements between points of potential gas release and electrical installations have been developed. These minimum distance requirements are defined in both NFPA 497A and API 500. Classifications used in LPG and other Hydrocarbon service are called Zone 0, Zone 1 and Zone 2 distances. Zone 0 is an area where an explosive gas atmosphere is continuously present, or present for a long period. Definition of Zone 1 and 2 follow below. Different Zones require different quality electrical installation. Areas that require no special electrical equipment are called “Unclassified.” Following are definitions for the electrical classification areas. Zone 1 areas are defined as locations where ignitable concentrations of flammable gases or vapors are likely to occur in normal operation. Below grade spaces such as trenches, Safety in LPG Design PLANT SITE 2-9 pits and sumps are typical Zone 1 areas. This may be by frequent releases or by infrequent releases or small releases combined with inadequate ventilation. The Example in Figure 2.3.1-a shows a solvent drum filling area, for LPG it would be around the filling nozzles. FLAMMABLE VAPORS PUMP SEAL LEAK VAPORIZING LIQUID Figure 2.3.1-b: Example for Zone 2 area Zone 2 areas are defined as locations where an ignitable concentration of flammable gases or vapors is not likely to occur in normal operations. If it does occur it will be infrequent and will exist for a short period. Examples for Zone 2 are areas adjacent to Zone 1 (and not separated by a vapor barrier), areas normally prevented from explosive mixtures by positive ventilation, and areas where abnormal operation or equipment breakdown might create an explosive mixture. Figure 2.3.1-c: Example for Unclassified area Unclassified is defined as locations where there are little or no hazards from flammable gases or vapors under normal or abnormal operating conditions. Plant roads, adequately ventilated LPG cylinder storage areas, and maintained, adequately ventilated piping systems, which may include valves, fittings, meters and flanged or threaded connections (per GP 16-1-1) are examples of unclassified areas. 2-10 PLANT SITE Safety in LPG Design Following selected example drawings from NPFA 497A showing how the electrical classifications apply. It is important to notice that they also include the space above the potential leak source. The hatched areas indicate that in these spaces only certified (Zone 1 or 2) electrical equipment can be installed. SOURCE OF POTENTIAL LEAK 7.5 m UNCLASSIFIED 7.5 m UNCLASSIFIED 7.5 m 0.6 m 15 m BELOW GRADE LOCATION SUCH AS A SUMP OR TRENCH 30 m ADDITIONAL ZONE 2 AREA ZONE 2 ZONE 1 UNCLASSIFIED Figure 2.3.1-d: Electrical classification area around pump seal. The contour of the envelope roughly approximates the flow that gases may follow in case of leak. It is important to notice that the complete area below a potential leak is considered classified. However, if a vent exits through a roof the hemisphere of a 7.5 m radius may be considered Zone 2 area. Pits and trenches, unless ventilated by force, shall be considered as Zone 1 areas. The outer 0.6 m Zone 2 region in the figure above is additional area to reflect crawling of heavier-than-air vapors along the ground. This area would normally be included for LPG applications, as explained in NFPA 497A. 7.5 m SOURCE OF POTENTIAL LEAK 7.5 m UNCLASSIFIED UNCLASSIFIED 7.5 m 0.6 m BELOW GRADE LOCATION SUCH AS A SUMP OR TRENCH 15 m 30 m ZONE 1 ZONE 2 ADDITIONAL ZONE 2 AREA UNCLASSIFIED Figure 2.3.1-e: Electrical classification area around an elevated source of potential release Notice that a sump on a pier is a Zone 1 area due to potential collection of vapors. At a Pier the Zone two area extends to the water level. Electrical installations are rarely found below the pier level but this may be important for small vessel traffic. Safety in LPG Design PLANT SITE 2-11 The area around the valves of rail cars and trucks is Zone 1 because of frequent making and breaking of loading and unloading connections. Depending on conditions, a 7.5 m diameter zone may be required around the pressure relief valve as indicated in the truck drawing. 15 m 15 m 7.5 m 7.5 m 7.5 m UNCLASSIFIED 15 m 7.5 m 0.6 m PIER SUMP WATER LEVEL ZONE 1 ZONE 2 UNCLASSIFIED Figure 2.3.1-f: Electrical classification area around marine unloading facility 2.3.1.1 Electrical Codes The US National Fire Protection Association Codes #70 (National Electrical Code) and #58 (LP-Gas Code), or UK Institute of Petroleum “Model Code of Safe Practices in the Petroleum Industry,” Parts 1, (Electrical) and 9, (Liquefied Petroleum Gas), supplemented by Health and Safety Executive publications HSG 34, “The Storage of LPG at Fixed Installations” and HSG 22, and British Standard 5345 are commonly used as the design basis for electrical systems. 1.5 m ZONE 1 ZONE 2 7.5 m UNCLASSIFIED Figure 2.3.1-g: Electrical classification area around LPG rail car 2-12 PLANT SITE Safety in LPG Design Truck PRV 7.5 Truck ESS m Truck ESS 7.5 m 1.5 m Electrostatic Bonding Cable EBV EBV ZONE 2 ZONE 1 UNCLASSIFIED . Figure 2.3.1-h: Electrical classification area around LPG truck Standard Continuous Hazard Intermittent Hazard Hazard under abnormal conditions IEC/CENELEC/ EUROPEAN Zone 0 Zone 1 Zone 2 NORTH AMERICA Division 1 Division 2 Table 2.3.1.1-a: Comparison of Area Classification IEC / CENELEC / EUROPEAN NORTH AMERICA (CLASS 1) Acetylene II C A Hydrogen II C B Ethylene II B C Propane/Butane II A D GAS Table 2.3.1.1-b: Gas Grouping for Area Classification Protection Techniques 2.3.1.2 Electrical Installations Both European and American practices are acceptable. The requirements for electrical installations shall be in accordance with NFPA 70 or equivalent. Current-carrying Safety in LPG Design PLANT SITE 2-13 conductors shall be made of copper. Electrical wiring shall be installed such that the system is free from short circuits and from grounds. All protection devices shall be properly sized, selected and installed. An overall electrical study for the entire electrical system shall be undertaken by qualified electrician or electrical engineer. Internal parts of electrical equipment shall not be damaged or contaminated by foreign materials. There shall be no damaged parts that may adversely affect safe operation or mechanical strength of the equipment. Conductors of dissimilar metals shall not be inter-mixed in a terminal or splicing connector where physical contact can occur between the dissimilar conductors. Live parts of electric equipment shall be designed to guard against accidental contact using any of the following means: 1. Approved enclosures. 2. Locations in a room or similar enclosure accessible only to qualified persons. 3. Suitable partitions arranged so that only qualified persons will have access to space within the reach of live parts. 4. Location on platform so elevated and arranged as to exclude unqualified persons. 5. Elevation of 2.5 m or more above the working surface. Parts of electric equipment which in ordinary operation produces arcs or sparks shall be enclosed or separated and isolated from all combustible material. Circuit breakers for electrical equipment shall be legibly marked to indicate its purpose. 2.3.1.3 Emergency Shutdown Systems The emergency shutdown system in a liquid transfer operation shall close all emergency shutoff valves and stop all pumps when activated. The location of Emergency Shutdown Pushbuttons is described below under “Emergency Shutdown Systems.” The shutdown buttons shall be RED in color of the Push-to-Activate, Pull-To-Reset type. They shall be clearly marked for the purpose for which it is intended and protected against accidental activation. All emergency shutoff valves shall be provided with both open and closed position indicators. All wiring and logic diagrams shall include a written description of the proposed operation. Each sequence trip and alarm shall be described in detail. 2.3.1.4 Instrumentation Instrumentation shall meet the requirements of the applicable national codes. All instruments, pneumatic or electronic, shall fail to the safest position or lock in place upon air or power failure. Enclosures and cabling for all instrumentation shall conform to the requirements of the electrical area classification of the area of installation. Instrument installations shall meet all area classifications and code requirements. All electronic instrumentation shall be grounded at a single, common point separate from the plant ground grid. Cable and conduit shall be routed in underground trenches where practical. Armored cable may be installed by direct burial methods. Where underground routing is not practicable, overhead cabling shall be routed in cable racks. All terminal strips used shall be of modular construction. Electric terminals shall be of the pressure-plate type, with all “live” parts recessed into the insulated block. 2.3.1.5 Lightning Protection Aboveground LPG tanks do not require lightning protection for tank integrity. However, it is common practice in refineries and production plants to ground all towers and drums. This is done to protect electronic instrumentation and control systems. Therefore, grounding is recommended when electronic instruments are on the tank, but 2-14 PLANT SITE Safety in LPG Design is optional if the tank has no electrical instruments or control systems. Grounding rods shall be provided for tanks supported on non-conductive foundations. 2.3.1.6 Plant Lighting Adequate lighting is needed for security as well as operations. It shall be provided to illuminate operating facilities such as walkways and essential control valves and devices. Any loading or unloading facility to be used after daylight hours shall be provided with adequate lighting, as well as gates within the plant fence area. The quality of the lighting installations as well as all other electrical installations shall comply with the Electrical Area Classifications. Adequate lighting shall be provided for the following: 1. All storage and operating areas for normal operation. 2. To illuminate storage tanks, tanks being loaded, control valves and other equipment. Facility gates. 3. In addition, sufficient emergency lighting shall be provided to allow safe operations during an emergency. Lighting shall be designed to provide the average maintained illumination in Table 2.3.1.6. Location Lux Footcandles Cylinder inspection and filling 540 50 Cylinder processing plant (general) 320 30 Tank car, tank truck, loading point 320 30 Piers, loading point 110 10 Entrance gate 55 5 Table 2.3.1.6: Average maintained illumination 2.4 Emergency Shutdown System There shall be an Emergency Shutdown System (ESS) by which the facility can be shut down in case of emergency. At the following strategic locations throughout the plant, emergency push-buttons shall be installed which relay a signal to the central emergency shutdown system. 1. One in a central area which is at least 15 m from LPG tanks. 2. One at each loading or unloading position. 3. One, located 15 m from each loading or unloading position. The actuating system shall be designed to close valves upon failure of any system component. More information on Electrical requirements are described under “Electrical Classification” above. When one of these push-buttons is activated the following shall happen: 1. Safety in LPG Design Shutdown power to all product pumps, compressors, and cylinder filling. Rundown streams from processes are not included in this requirement. They shall be handled individually based on “fail safe” considerations. PLANT SITE 2-15 2. Closing of all Emergency Block Valves (EBV) at unloading, loading, tankage and cylinder filling. EBV’s in rundown streams from refinery or gas plant process units are not included in this requirement. They shall be closed or kept open individually based on “fail safe” considerations. 3. An audible alarmshall be activated. 4. The power to the firewater system shall be maintained throughout the emergency/alarm. 5. Emergency push buttons at the pier may shut down the pier lines only or they may be tied into total plant shutdown. This may depend on distance to the pier and on other factors. The necessity shall be determined in a Hazard and Operability Analysis (HAZOP). In any case, the closure of the pier valves shall result in an alarm at the plant. 6. When the loading/unloading area is part of a refining or upstream site, activation of the ESS shall not necessarily require a shutdown in the process area. This shall be confirmed during the design. MARINE PIER RAIL CAR EBV EMERGENCY PUSH BUTTON EBV EMERGENCY PUSH BUTTON SHORE EBV EMERGENCY PUSH BUTTON BULLETS EBV SPHERE MOUNDED DRUMS EBV EBV EBV EBV EMERGENCY PUSH BUTTON FIRE WATER EBV EMERGENCY PUSH BUTTON TRUCKS EQUIPMENT SHUT DOWN POWER TO FIRE PUMP NOT ESS INTERRUPTED EMERGENCY SHUTDOWN SYSTEM EBV CYLINDER FILLING ALARM OFFICE EMERGENCY PUSH BUTTON EMERGENCY PUSH BUTTON Figure: 2.4: Plant Emergency Shutdown System (ESS). Only control system shown. 2-16 PLANT SITE Safety in LPG Design 3 BULK STORAGE 3.1 Storage in Plants and Industry This chapter is intended to provide general technical guidance to engineers who are responsible for the design and installation of bulk tanks for Liquefied Petroleum Gas (LPG). The guidelines are intended to assist engineers in the development of technical specifications, which meet company and industry standards for design, fabrication, installation, and testing of such facilities. These specifications aim to maximize the integrity and safety of these facilities. Achieving this objective is dependent upon using design concepts, which are proven to be safe and conform to good operating and maintenance practices throughout the operating life of such facilities. In developing these specifications, designers shall also follow Global Practices (GP's), Design Practices (DP's) specified in this section, and local regulations. This guide tries to use consistent wording for LPG storage. “Tanks,” “mounded drums,” “spheres” and “bullets,” are used for bulk storage at company plants or industry. “Vessels” means ships and barges only. Note that the GP's, DP's and other codes do use “vessel” for refining drums and towers. “Containers” are used in small bulk and domestic use. “Cylinders” (also often called “bottles”) are used for small portable LPG containment. If LPG tanks for commercial, utility, or industrial customers are as large as plant bulk LPG tanks they shall be designed to the same principles. Typically commercial consumers or domestic users require containers. Such containers may be designed according to requirements in the chapter “Customer Storage” of this Guide. For all new designs or design modifications in LPG storage service, a review of all applicable local regulations, codes, standards, practices and operating permits is needed. Major pressure tank manufacturers have developed standard designs for different tank capacities, permitting the purchaser to specify only the code required at the proposed plant site, and the tank openings and fittings required. Standardization can provide substantial savings over development of an individual design. However, the standard shall meet all the requirements of the GPs specified in this section. For new designs the use of “mounded drums” for pressure storage is required for some countries (Europe). These are horizontal tanks placed on above ground foundations or on sand beds but thereafter completely covered by an earth mound. This type of storage is inherently safer since its passive fire protection makes it not vulnerable to external fires. The most frequent tank types used in the past and still in use in many countries today are the horizontal cylindrical (“bullet”) tank and the sphere. These are above ground tanks on concrete foundations. The horizontal “bullet” tank was the most common design in the past for tanks sized between 28 and 282 m3. For larger capacities, often Safety in LPG Design BULK STORAGE 3-1 the most economic solution was the spherical tank. Depending on location and exposure in some cases it may still be appropriate to use this approach for new designs, however, more and more regulations ask now for retroactive passive fire protection by fireproofing. Vertical “bullet” type tanks have also been installed by industry. They may have their merits when spacing is tight, however, from a safety and firefighting standpoint this is an undesirable configuration and shall be avoided. The following International Codes may be applicable to the design of pressurized LPG tanks: 3.2 1. The United States American Society of Mechanical Engineers, “ASME Boiler and Pressure Vessel Code, Section VIII” Section VIII is subdivided into Division 1 “Unfired Pressure Vessels” and Division 2 “Rules for Construction of Pressure Vessels.” To be more economical, LPG horizontal tanks shall be designed and fabricated according to ASME VIII Division 1 while LPG sphere tanks shall be designed and fabricated according to ASME VIII Division 2. 2. API STD 2510 and NFPA 58. 3. BS 5500 Specification for Unfired Vessels. 4. BS 1501 Steels for Fired and Unfired Pressure vessels - Plates, or Equivalent. 5. BS 1502 Specifications for Steels for Fired and Unfired Pressure vessels Sections and Bars. 6. BS 1503 Specifications for Steel Forgings (including semi-finished forged products) for Pressure Purposes. 7. Finnish Standards (SFS) 3205, 3339, 3340, 3341, and 3342. Finnish Government Statues 98/73, 636/77, 257/84, 258/84, 312/79, and 1106/81. 8. Japan High Pressure Gas Law (HPGL). Japan Industrial Standards (JIS). 9. Australian Pressure Vessel Code AS 1210. Mounded and Above Ground Storage The guidelines and technical considerations discussed below refer to facilities, which utilize large horizontal mounded drums for storing LPG. Storage in aboveground tanks presents the risk of a BLEVE. Storage of LPG in mounded drums avoids the risk of external fire exposure. Mounded drums are long horizontal cylindrical tanks, with dished heads, which are installed above grade level and covered completely with sand bed fill and general fill material. The mounding of drums permits reduced spacing when compared to the space needed for spheres/bullets, which is mandated by regulatory requirements. As of 1993 there are several mounded drum installations in company Refining and Marketing facilities in Europe and the Asia Pacific region. These tanks have been used to store LPG since 1982-83. Operating experience with the installations during the years has been good. 3.2.1 Dimensional Sizing of Drums The specific dimensions for the drums are based on LPG storage requirements, available space on site, safety considerations, spacing from buildings, facilities, and other equipment, orientation, and the costs associated with fabrication, transport and installation. The capacities of the drums should be based on planned sales. However, shipment parcel size, transport delays, seasonal effects, future business outlook or other factors may have an influence on the capacity. 3-2 BULK STORAGE Safety in LPG Design LPG Vapor Return Mounded drum sizes vary substantially in diameter and tangent length. The drum sizes that are currently in use have diameters in the 4 to 6.5 meter range and tangent lengths of 34 to 88 meters. The diameter and length chosen are dependent upon transportation and site spacing. In addition, considerations such as field assembly and fabrication of drum sections should be used to optimize LPG storage and inventory needs at specific installations. LPG Filling Distance PRV to Fence15 m Water Draw-off to Location min. 15 m from Fence PRV LHHA(CO) if filled by Pipeline or by Ship LI LHA LHHA Concrete Wall TI PI to ESS min. 0.9 m LPG Tank Slope 1:100 EBV Removable Part with Sleeve Removable Fill Figure 3.2.1-a: Typical LPG mounded drum LHHA(CO) if filled by Pipeline or by Ship LHHA Distance PRV to Fence 15 m Water Draw-off to Location min. 15 m from Fence LI LHA PRV Distance to Fence 3 m min. 0.9 m to ESS PI Submerged Pump TI Tank Slope 1:100 Figure 3.2.1-b: Mounded drum, spacing alternative with submerged pump In general, it is preferable to have the drums fabricated in the manufacturer shop and transported to site. However, due to the large sizes involved, transportation, site access and off-loading at the plant usually dictate the feasibility of shop manufacture or the need for site assembly of major drum sections. Recent LPG mounded drum installations have used both shop fabrication and field construction practices. 3.2.2 Materials Selection for Tanks All materials of construction shall meet the requirements of Section II of ASME “Boiler and Pressure Vessel Code”, or equivalent national code. Low melting point materials of construction such as aluminum and brass shall not be used for LPG storage drums. It is recommended that the drum materials consist of fully killed, grain refined and normalized carbon steel plates and forgings, with adequate mechanical strength and toughness properties for the storage of LPG. The presence of H2S in has led to wet H2S cracking problems associated with hard welds (> 225 Brinell Hardness). The tendency for in service cracking increases as the H2S concentration and strength of the material increases. H2S is more of a problem in refining and less in marketing where H2S Safety in LPG Design BULK STORAGE 3-3 contents by specification is in the order of magnitude of 1 ppm. Minimum specified tensile strength of the tank steel historically has been below 483 MPa. However, with more recent technology development higher strength steel is used to keep the thickness of spheres below 38 mm, so PWHT can be waived per ASME Code. Experience shows that if a proper procedure is taken (e.g. pre-heating 90-150 ºC), high strength steel can provide satisfactory service. The amount of H2S in the product to be stored is a very important factor to determine metallurgic characteristics of the material of construction. Steel specifications shall include chemistry control per GP 9-2-1, and requirements for impact properties at the Critical Exposure Temperature (CET), and heat treatment per GP 5-1-1. Impact Requirement for Materials shall follow GP 18-10-1 "Additional Requirements for Materials." Additional information which may be useful to the designer is available from GP 18-7-1 “Welding Procedures,” GP 5-3-1 “Hydrostatic Testing of Vessel,” and GP 5-2-1 “Internals for Towers & Drums.” Material of construction for the pressure parts shall comply with ASME Sec II D Appendix 5. Alternative materials equivalent to the ASME Code material specification may be used. However, alternative materials shall be provided with the following to EMRE for approval: 1. Nomenclature and complete chemical and physical properties of the proposed material stated along with ASME equivalent. Any additional requirement necessary for equivalence shall be stated. 2. Where necessary to demonstrate the equivalence of alternative material, test specimens shall be provided for Charpy V-Notch testing according to applicable ASME material specification. 3. Quenched and tempered steel is limited to a maximum tensile strength of 690 Mpa and an actual yield-to-tensile ratio of < 0.85. The following shall NOT be used as material of construction for pressure parts: 3.2.2.1 1. SA36, SA283 and other structural grade steel. 2. Steel casting. 3. Low melting point materials such as aluminum and brass. Minimum and Maximum Design Temperature The principal purpose for specifying impact requirements is to ensure that a catastrophic brittle fracture of the drum will not occur during hydrotesting, start-up, shutdown, and normal operations throughout its service life. Impact requirements are based on the Critical Exposure Temperature (CET, also “Minimum Design Temperature”), metal thickness of the drum component, and the material specification selected. The CET for a LPG pressurized storage drum or sphere shall be based on the lower of the following: 1. 2. Lowest one-day mean temperature. This would account for filling the drum or sphere up to the safety valve pressure limit on the coldest day. The temperature equivalent to 25% of the design pressure on the vapor pressure curve for the material to be stored. The minimum design temperature shall be the minimum metal temperature expected in service, taking into consideration ambient temperature and auto-refrigeration of the stored product when it flashes to atmospheric pressure. For storing Propane, this temperature will be –42 °C. In no case shall the minimum design temperature be higher than –18 oC. In many situations, the owner prefers to set the minimum design temperature at the lowest possible temperature due to depressurizing the LPG to atmospheric pressure (–42 °C). This is almost always more conservative than the criteria provided above. It adds an extra safety margin for protection against brittle fracture and is recommended. Using modern carbon steels, this should not significantly add to the cost for the drum, bullet or sphere. 3-4 BULK STORAGE Safety in LPG Design 3.2.2.2 Post-Weld Heat Treatment For aboveground bullets with a plate thickness below 38 mm Post Weld Heat Treatment (PWHT) is not required. However, Post-Weld Heat Treatment is recommended for mounded drums due to service considerations. These requirements are independent of PWHT that may be required from Code considerations of plate thickness, and material specification. The preferred method of PWHT for shop fabricated drums is to heat treat the entire drum or major sections of the drum in a heat treating furnace. This minimizes the thermal stresses, which can be introduced by local PWHT, which typically involves banding the weld seams with electric resistance heating jackets. If this capability is not available in the shop or if PWHT in the field becomes necessary, then local Post-Weld Heat Treatment of the individual seams may be done, subject to careful control of temperature and temperature gradients. 3.2.2.3 Materials Specifications The recommended materials specifications for bullets and mounded drums are identical to ASTM Specifications as follows: SA 516 Grade 70 normalized SA 333 Grade 1 or 6 SA 350 Grade LF2 SA 352 Grade LCB SA 334 Grade 1 or 6 for the shell and heads for nozzles for flanges & fittings for fittings for tubing Substitute Materials specifications may be made provided they meet with the requirements in GP 18-1-1. Materials not covered in GP 18-1-1 should be evaluated on a case by case basis. 3.2.2.4 External Corrosion Protection The earth mounds used on mounded LPG Drums increase the potential for soils induced corrosion and holing through. In addition, the design does not permit on stream thickness measurements and/or visual inspection of the drum surface. Shop fabrication is preferred when drum size permits. Any damage during transport to the coatings on shop fabricated drum shall be repaired. It is extremely important, therefore, to consider the following: 1. Develop an earthwork specification for the mound. Specify sand bed fills, general fills, and acceptance tests, in accordance with ASTM Standards and Global Practice GP 4-9-1. 2. Provide an adequate corrosion resistant coating on the external surface of the drum per GP 19-1-1. Shop-applied coatings are preferred, but field applications are also acceptable. Irrespective of type and application method of coatings, a holiday test on the coating shall be carried out immediately prior to back-filling on site. The following specification is the normal requirement: 3. 4. Safety in LPG Design Surface Preparation: Abrasive Blast Clean to SSPC SP-10 Near White 1st Field Coat: Coal Tar Epoxy @ 6-8 mils DFT 2nd Field Coat: Coal Tar Epoxy @ 6-8 mils DFT Install a cathodic protection system utilizing sacrificial anodes. Permanent reference electrodes shall be buried along with the drum at each end of the drum and above and beneath the drum at its midpoint. Requirements for a cathodic protection system are a twenty-year life and a maximum exposed steel surface of 10%. Insulating flanges shall separate permanent lines connected to plant piping from this cathodic protection BULK STORAGE 3-5 system. The cathodic system may be used to protect short runs of buried pipe provided the pipe coating is equal or better than the tank coating. 5. Any special plant refinery/production applications where the LPG is expected to contain wet H2S, shall have the drums lined internally. The exterior surface of aboveground tanks, including the steel supports, shall be grit blasted to SSPC SP-10 standard or chemically treated and adequately painted. After grit blasting horizontal LPG storage bullets and LPG sphere tanks, shall be painted with a primer coat of alkyd zinc phosphate (75 microns dry film thickness), build-coat of alkyd micaceous iron oxide (50 microns dry film thickness) and topcoat of white alkyd enamel (30 microns dry film thickness). 1. Sphere legs shall be fireproofed and left unpainted 2. Bases and saddles of bullets that are concreted shall not be painted. 3. If bases and saddles on bullets have exposed metal, they shall be painted with same primer coat, build-coat and finished with topcoat. The exterior of aboveground LPG tanks shall be inspected every 2 years. Repainting shall be carried where necessary. 3.2.3 Design Basis for Mounded Drums The mechanical design of large mounded drums is complex, due to its mounded configuration, internal pressure, nozzle geometry and piping loads, type of support, foundation pad design and soils settlement characteristics. In addition, if these facilities are located in earthquake zones, the seismic loads substantially increase the complexity of mechanical design considerations. Most national codes entrust the responsibility to users for defining and specifying the loading mentioned above. Therefore, it is recommended that users develop Mechanical Specifications (MSpec) for these drums and ensure that all pertinent design criteria and loads are specified. The following guidelines are intended to assist users when developing MSpecs for mounded drums. 3.2.3.1 Design Conditions for LPG Drums Design conditions for LPG drums should preferably be based on Propane storage. This will allow the flexibility to switch to Propane and will provide protection against inadvertent loading of Propane to a lower design pressure drum. Based on local regulations in several countries, the minimum design pressure is specified as 17.2 bar gauge with a corresponding design temperature of 55 °C. Under design conditions, 1.6 mm corrosion allowance shall be added to the design thickness of a drum. In addition, external pressure of 1 bar gauge is used to allow for the soil pressure from the earth mound. In the absence of local regulations, the maximum design temperature shall be taken as the highest ambient temperature that has been recorded over the last 10 years at the nearest meteorological station. In no case shall this temperature be lower than 38 °C. 3.2.3.2 Design Codes Applied Most nationally recognized Codes can be used for the design of mounded drums. However, design, fabrication, inspection, and testing requirements shall be based, as a minimum, on the requirements of Global Practice 5-1-1. Design and fabrication inspection of LPG tanks shall be carried out by an internationally recognized and EMRE Engineering approved third party inspection agency. 3-6 BULK STORAGE Safety in LPG Design 3.2.3.3 Permanent Identification is Needed For continuous reference, a non corrosive identification plate shall be fixed to the drum in a suitable and clearly visible location. It shall be stamped with the following information as a minimum: Drum Serial Number: Owner’s Name: Designer’s Name: Design Code: Manufacturer’s Name: 3.2.3.4 Design Pressure, min./max.: Design Temperature, min/max: Product Stored: Water Capacity in volume units: Date of test and test pressure: Earth Mound Design The following supplementary requirements shall apply to mounded drums: 3.2.3.5 1. Partial mounding is not recommended. Partial mounding continues to have the design considerations of storage in aboveground bullets so that little or nothing is gained. 2. The depth of the mound over all surfaces of the drum shell shall be a minimum of 0.9 m. The mound cover shall include the heads of the drums, which shall not be exposed. 3. The backfill used for mounding shall consist of washed sand totally free of rocks or abrasive materials likely to damage the drum coating. The mounds shall have good stabilization to prevent erosion by firewater or heavy rain. Furthermore, it shall be capable of withstanding prolonged heat radiation or jet flame impingement. This is important since the pressure relief valves on such drums are not designed to provide protection against heat input by external fire. Therefore, if the drum is being uncovered later, e.g. for external inspection, LPG shall be taken out of the drum before it is uncovered. If a drum has to be removed and the adjacent drum is still filled with LPG the side of the filled drum shall still be covered by a mound of 0.9 m thickness. Nozzles on LPG Drums As a matter of principle the number of nozzles on mounded drums shall be kept to the necessary minimum. This pertains in particular to the lower part of the drum. Following nozzles are considered necessary: 1. Pressure relief valve (PRV) connection to the vapor space. 2. Water draw-off connection via the top (similar to GP 9-2-1, para. 9.5). 3. Connection for the level indicator with high level alarm. 4. Connection for the independent high level alarm. 5. Connection for the fixed level gauge. 6. Filling connection at the top of the drum. 7. Withdrawal connection at the top or bottom of the drum. 8. Vapor return connection at the top of the drum. 9. Vent connection to atmosphere. 10. Connection for the temperature indicator. 11. Pressure indicator connection to the vapor space. Careful engineering may permit the combination of some of the above fittings to reduce the number of nozzles on the drum. The preferred location for nozzles is at the manhole (see below). All nozzles on new drums are preferred to be flanged and not smaller than 50 mm. This type of connection presents adequate integrity against Safety in LPG Design BULK STORAGE 3-7 mechanical damage or leak during fire. Fittings on underground or mounded tanks shall preferably be accessible from above ground level. As a matter of principle nozzles on above ground drums are preferably located in the vapor phase section, however, those necessary for liquid withdrawal shall be at the bottom. All tank nozzles’ connections and nozzles’ flange joints shall be welded. Flanged joints on tanks (and pipelines) shall be designed based on the relationship of pressure limits against temperature of carbon steel. The material class shall not be inferior to that based on the pressure limit at the design temperature. Gaskets for flanged joints shall be resistant to liquid LPG and shall be made of metal or other suitable material confined in metal having melting point over 816 °C. Gaskets of natural rubber or bonded with natural rubber shall not be used. Figure 3.2.3.5-a: Submerged pump The following shall be considered when designing nozzles on LPG drums. The requirements below are intended to address the mechanical and structural design considerations of nozzles on LPG mounded drums. They are not intended to cover the instrumentation, controls and alarms that are recommended from a safety and operability standpoint. 3-8 1. All nozzles, with the exception of the pump suction, shall be installed at the top of the drum. If the drum is located in an earthquake zone, the bottom suction design shall be a last resort and requires additional assessments for possible structural failure, corrosion and leakage. An access chamber shall permit inspection of the bottom suction nozzle for the pump. The access chamber may be filled with sand and closed by a cover, which can be removed to permit inspection, with the drum in service. 2. Installations where the suction line for an external pump enters through the top shall be avoided. Even though a compressor may permit continuous vapor return, often NPSH problems are encountered. Solar radiation may cause vapor lock in the line and it may be impossible to empty the drum below a certain level. BULK STORAGE Safety in LPG Design 3. Since pumps have become highly reliable, the submerged pump is an elegant solution for locating the pump suction nozzle on the top of the drum. A bottom shutoff valve permits removal of the pump while the drum is filled. 4. Shell penetrations between bullet supports shall be avoided. They are more difficult to access in mounded drums. When the tank is above ground, they are difficult to reach with cooling water in the event of a fire. 5. It is recommended that drum larger than 56 m3 or exceeding 2 m diameter be provided with a manhole of not less than 610 mm. Manholes on mounded drums must be located at the top of the drum in form of an extended nozzle and shall be protected from direct involvement in a fire by covering the opening with a removable insulated lid. A manhole may be positioned below the mound rim however, in such cases it shall be adequately protected from corrosion by providing a steel skirt with cover. The skirt shall be attached at a level below the flange ensuring that the nuts and bolts are not buried inside the mound. In drum 56 m3 or smaller volumetric capacity, provision of a manhole is optional unless a need for cleaning is anticipated, or required by local regulations. The manhole shall be located to facilitate cross ventilation with the tank nozzles. It is suggested to locate nozzles and connections for instrumentation, PRV and other on the manhole in order to reduce the penetrations to the tank shell and to facilitate later changes should they be necessary. However, it should be checked whether the code is not restrictive on nozzles on manholes. Figure 3.2.3.5-b: Two-plane gusset 6. The nozzle shall be of fully integrally reinforced and shall not permit the use of reinforcement pads. All nozzles shall be flanged and valved. The flanged joint shall not be buried inside the mound. 7. Nozzles shall be adequately spaced to ensure that localized stresses would satisfy the criteria of ASME Section VIII and GP 5-1-1 and GP 9-2-1. 8. If the drums are frequently filled and emptied, cyclic loading effects shall be considered in the nozzle attachment design (See GP 5-1-1). 9. The nozzle to shell design shall be adequate to accommodate external piping loads, as appropriate. 10. The following minimum nozzle wall thickness shall be used: Nominal Nozzle Size < 50 mm 75-150 mm > 200 mm Pipe Schedule or Thickness Schedule 80 or 160 Schedule 80 12,5 mm 11. All nozzles 50 mm or smaller shall be gusseted in two planes in accordance with GP 3-18-1. 12. Sampling connections may be provided on piping to tanks. Adequate gussetting of small connections and piping in sampling lines shall be provided Safety in LPG Design BULK STORAGE 3-9 to minimize vulnerability to mechanical damage. The inlet piping to sampling connections shall be double valved. For above ground drums, sample locations shall not be under the drum. Connections shall be oriented so that the purge vapors do not engulf the operator or approach an ignition source. Ideally the purge shall be discharged into a closed system (blowdown in refining). Consider the addition of a restriction orifice (< 2 mm) external to the sampling valve. 13. Appropriate startup and shutdown connections shall be provided for commissioning storage drums and taking them out of service. Pressure drums may be purged by water filling, with a 50 mm vent connection to remove air displaced as the water rises. A 50 mm vapor connection to an adjacent drum in the same service, where available, allows vapor to be drawn in when the water is drained. The same connection can be used for taking the drum out of service. When water is injected, the residual liquid and vapor is displaced over the top into another drum. 3.2.3.6 3.2.3.7 Drum Shell Design 1. The non-uniform external loads transmitted to the drum shell, by the earth mounds, should be analyzed using Finite Element Analysis (FEA) methods. The FEA stresses should comply with ASME Section VIII Div 2. In addition, a theoretical safety factor of 3.0, for buckling design, should be used as acceptance criteria for minimum shell plate thickness. Review with the fixed equipment specialists in EMRE or EMPRCo may determine when FEA may not be required. 2. When calculating shell thickness due to internal pressure no credit shall be taken for the restraint provided by the earth mound on the drum shell. Corrosion allowance as per section “Design Conditions for LPG Drums” above. 3. Stiffeners, used on the drum shell shall be attached to the internal surface. Design calculations and details as well as fabrication and NDE (Non Destructive Examination) requirements shall ensure that shear and lamellar tearing does not occur (see also ASME Section V “Non-destructive Examination”). Drum Support and Foundation Design The recommended type of supports for mounded drums is as follows: 1. For locations, which are subjected to earthquake forces, mounded drums shall be located on sand beds. Saddle supports are not recommended due to the increased risk of failure from liquid sloshing and dynamic forces during a seismic event. 2. For other locations, saddle supports on rigid slabs supported on piled foundations are permissible. However, the mounded drum shall be investigated for buckling, local circumferential bending and shear stresses per GP 5-1-1. 3. In addition, reinforced concrete retaining walls have been used to confine the earth mound. Reinforced concrete walls shall have adequate drainage and the concrete shall not touch the drum or it can cause accelerated corrosion. See also GP 4-9-1 “Site Preparation/Earthwork.” It is recommended that soils investigation and assessments be completed prior to determining the most suitable type of foundation. The primary objective of these investigations should be to reduce to an absolute minimum the potential for differential settlement. The foundation design shall be based on the weight of the drum full of water (needed for pressure test). If these settlements are not kept to a practical minimum, they may introduce unacceptably high stresses at the drum support locations and increase the risk of in- 3-10 BULK STORAGE Safety in LPG Design service failures. The sensitivity to such settlements is due to the large length to diameter ratios and the relatively thin shells in these drums. Also the piping connecting to the drum must be kept free floating and not embedded into concrete or other fixations. It is important that connecting piping is not subjected to any stress from earth movement etc. In view of the above considerations, a maximum differential settlement of 25 mm on a 16.5 m long drum has been used at one facility. Where groundwater or possible flooding makes it advisable, anchorage shall be provided to prevent flotation. Underground pipes and services, such as steam, water, electricity and sewer, shall be at least 1.5 m horizontally from the mounded tank. Above ground horizontal LPG tanks of more than 7.6 m3 water capacity shall be provided with structural steel saddles designed to be mounted on flat-topped concrete foundations by means of anchor bolts or other adequate devices. Lifting lugs for LPG horizontal tank, where provided, shall be designed for taking 1.5 times of the total weight of an empty tank. LPG horizontal tanks’ supports shall be of reinforced concrete, masonry or fireproofed structural steelworks. Design of the supports and foundations shall take into consideration: 3.2.4 1. Ground conditions, including allowable bearing pressure and differential settlement. 2. Possibility of flotation. 3. Expansion and contraction of the tank shell. 4. The greatest combination of static loading due to weight of the tank, its contents, weight of water used for testing, wind loading, vibration, thermal effects and seismic conditions. Testing Requirements NDE and testing of LPG horizontal tanks shall be per ASME Code Section VIII, Division 1. For a tank which has a wall thickness of: More than 38 mm, the minimum Non-Destructive Examination (NDE) shall be per the following sequence: 1. 100% X-ray on all seams. 2. Post Weld Heat Treatment (PWHT). Hardness test after PWHT shall not be more than 225 HB unless waived by EMRE Engineering. 3. 100% ultrasonic test on all seams. 4. 100% Magnetic Particle Test (MT) on all seams. 5. Hydrostatic test at 1.3 times of the design pressure. (The 1999 ASME Section VIII, Div.1 specify 1.3 times of MAWP as Hydrostatic testing pressure, since ASME has lowered the safety factor for materials from 4 to 3.5. For any alteration of a tank built prior to 1999, EMRE Engineering shall be consulted.) Also refer to GP 5-3-1 "Pressure Testing of Unfired Pressure Vessels", which has a clearer description for hydrostatic testing. It states: In the hydrostatic test condition, the maximum membrane stress in the tank in the un-corroded or corroded condition shall not exceed 90% of the specified minimum yield strength for ferritic steels, nor 100% of the specified minimum yield strength for austenitic steels or non-ferrous materials. 6. 100% MT on all seams. Between 32 mm to 38 mm, the minimum NDE shall be per the following sequence: Safety in LPG Design BULK STORAGE 3-11 1. If a service condition permits (e.g. H2S concentration under 50 ppm), PWHT can be waived provided that the Metal is preheated prior to welding. Otherwise, follow the procedures as above. 2. 100% X-ray on all seams. 3. Hydrostatic test at 1.3 times of the design pressure. 4. 100% MT on all seams. Less than 32 mm, the minimum NDE shall be per the following sequence: 1. If a service condition permits (e.g. H2S concentration under 50 ppm), PWHT can be waived. Otherwise, follow the procedures as above. 2. 100% X-ray on all seams. 3. Hydrostatic test at 1.3 times of the design pressure. 4. 100% MT on all seams. NDE and testing of LPG sphere tanks shall be per ASME Code Section VIII, Division 2. For a tank which has a wall thickness of: More than 38 mm, the minimum Non-Destructive Examination (NDE) shall be per the following sequence: 1. 100% X-ray on all seams 2. 3. Post Weld Heat Treatment (PWHT). Hardness test after PWHT shall not be more than 225 HB unless waived by EMRE Engineering. 100% ultrasonic test on all seams. 4. 100% Magnetic Particle Test (MT) on all seams. 5. Hydrostatic test at 1.25 times of the design pressure. 6. 100% MT on all seams. Between 32 mm to 38 mm, the minimum NDE shall be per the following sequence: 1. If a service condition permits (e.g. H2S concentration under 50 ppm), PWHT can be waived provided that the Material is preheated prior to welding. Otherwise, follow the procedures as above. 2. 100% X-ray on all seams. 3. Hydrostatic test at 1.25 times of the design pressure. 4. 100% MT on all seams. Less than 32 mm, the minimum NDE shall be per the following sequence: 1. If a service condition permits (e.g. H2S concentration under 50 ppm), PWHT can be waived. Otherwise, follow the procedures as above. 2. 100% X-ray on all seams. 3. Hydrostatic test at 1.25 times of the design pressure. 4. 100% MT on all seams. Documentation from fabricator shall include MDR (manufacturer's data report) and all test recordings according to ASME VIII requirement. 3.2.5 Horizontal “Bullets” and Spherical Tanks Design procedures for horizontal “bullet” tanks and spheres are similar to those described above for mounded drums except those items that are specific to mounded drums. All connections shall be flanged. Existing screw type connections in older Marketing tanks need not be retrofitted to flange connections. Older Marketing bullets also may have 3 meters from the edge of the bullet to the water drain discharge point 3-12 BULK STORAGE Safety in LPG Design compared with the latest 4.5 meter recommendation in DP XXII-C. Existing drain points do not need to be retrofitted. For aboveground bullets the bottom nozzles should be positioned at the two ends and not between foundations. This is to facilitate access of valves and better firewater coverage if needed. If possible the bottom nozzles may be reduced in favor of top nozzles. This may avoid the potential for liquid leaks. Top spray filling is desired for bullets and spheres since it lowers the pressure during filling. Typical sphere and bullet designs are shown in Figure “Typical horizontal bullet tank” and Figure “Typical spherical tank.” Tanks used in loading and unloading service would normally have a vapor balancing line, which is not shown in these figures. REFERENCES SAFETY VALVE 7 DRAIN WITH ELL RELIABLE GAUGE MAINTAINABLE WITH BULLET IN OPERATION CSO BLEED (GUSSETED) LI PI PI 1 PLATFORM ACCESS VIA LADDERS 7 3 1 GP9-2-1 2 GP9-1-1 3 GP15-1-3 4 GP3-2-3 5 GP3-5-1 6 GP14-3-1 7 GP3-2-4 GENERAL LHA LHA 1 (INDEPENDENT) 3 LHA AND LHHA FOR ALL BULLETS LHCO IF FILLED BY RUNDOWN, PIPELINE OR SHIP. GP9-2-1 DPM XV-J INSTRUMENTS NO GAGE GLASSES 3 PI PdI NON-FREEZE DRAIN (IF COLD CLIMATE) 30 m MIN. WATER FLOOD (IF LARGE BULLET) FILL & DISCHARGE 1 THROTTLING EBV(D) (FIREPROOFED OR FIRE SAFE ACTUATOR) 4 FILL HYDRANTS (PREFERABLY WITH MONITORS) 1 FIRE-SAFE 5 QUICK CLOSING SUPPORTS FIREPROOFED 4m MIN. SAMPLE CONNECTION 5 OUTSIDE TOE WALL SLO H WATER DRAW-OFF PE 5 TOE WALL 2 SLOPE SLOPE 4 6 5 CATCH BASIN 5 2 GROUNDED 1 TO SEWER OR DRAINAGE SYSTEM NC NOTES: 2 IF POSSIBLE ALL CONNECTIONS SHOULD BE AT ONE END OF VESSEL AND THE CATCH BASIN SHOULD BE LOCATED NEARBY. DR, 3/2001 Figure 3.2.5-a: Typical horizontal bullet tank (from DP XXII-C) REFERENCES SAFETY VALVE 8 RELIABLE GAGE MAINTAINABLE WITH SPHERE IN OPERATION TYPICAL AREA LAYOUT GP9-1-1 GP15-1-3 DRAIN WITH ELL CSO 1 DELUGE SYSTEM 3 4 GP3-2-3 5 GP3-5-1 6 GP14-3-1 7 GP4-2-1 8 GP3-2-4 4 INSTRUMENTS LHA STAIRWAY & PLATFORM 1 (INDEPANDENT) 3 LHA IF FILLED BY RUNDOWN, PIPELINE, OR SHIP GENERAL DPM XV-J NO GAGE GLASSES 3 SUCTION CONNECTION 1 1 SUPPORTS FIREPROOFED TI THROTTLING 5 FIREWATER SPRAY SYSTEM BELOW SPHERE 4 WATER FLOOD 1 6 NON-FREEZE DRAIN (IF IN COLD CLIMATE) FIRE-SAFE QUICK CLOSING 3 EBV(D) (FIREPROOFED OR FIRE-SAFE ACTUATOR) MIN 30 m WATER DRAW-OFF 1 1 5 5 WATER DELUGE INSTRUCTION SIGN 4 SAMPLE CONNECTION 2 OR MORE FIRE HYDRANTS (PREFERARLY WITH MONITORS) 4 5 SLO PE FILL 5 SLOPE 2 FILL & DISCHARGE COATED OR SLEEVED GP9-2-1 7 PdI LI OUTSIDE DIKED AREA GP9-2-1 2 BLEED (GUSSETED) PI 1 1 3 5 DIKE 4 m MIN H 4 2 2 CATCH BASIN 1 2 NC TO SEWER OR DRAINAGE SYSTEM GROUNDED 5 2 1 DR 1999 GREATER OF 30 m OR ONE DIAMETER Figure 3.2.5-b: Typical spherical tanks (from DP XXII-C) Note: GP 15-1-3 referenced in the both figures further refers to GP 9-7-1 for details on installing level devices. GP 9-7-1 shows welding to an atmospheric tank. Welding shall not be done to pressure tanks and an alternate means of level device support is necessary. Safety in LPG Design BULK STORAGE 3-13 Aboveground pressurized LPG tanks need certain considerations as to siting and location. These are explained under section 2.2.2.4 “Siting of Aboveground Tanks and Equipment.” Horizontal bullets and spheres are more vulnerable to fire exposure than mounded drums. Therefore, codes recommend installation of some kind of fixed fire protection. Depending on risk, fire resistant coatings may be needed for bullets and spheres that are normally equipped with fixed water spray or water deluge systems. These requirements are discussed in depth in Chapter 8 under “Firewater Sprays,” “Firewater Deluge for Spheres,” and “Fire Resistant Coatings.” Storage at refineries and Upstream Gas Plants shall be provided with water flooding facilities to inject water and displace LPG in the lower parts of tanks, in the event of a tank leak. Spheres shall be built in accordance with GP 9-2-1. They are normally equipped with top and bottom manholes. The filling and withdrawal connections for spheres are normally at the bottom. LPG Sphere tanks shall be provided with steel support columns and wind (earthquake) girders. Columns shall be mounted on concrete foundation with anchor bolts. The columns shall be fireproofed from ground level to intersection of the support with the tank shell (see also drawing in Chapter 8). 3.2.6 Spill Containment Spill containment shall be considered for all locations and shall be provided in locations in which either of the following would result in a significant hazard to important nearby facilities, nearby properties, or public areas, per API 2510: 1. The physical properties of the stored LPG make it likely that liquid material will collect on the ground. The more hydrocarbons like Butane (or Pentane) is contained in the LPG the more it will spill as a liquid. 2. Climatic conditions during portions of the year make it likely that liquid LPG will collect on the ground. The ground beneath aboveground LPG tanks shall be of impervious construction and graded to be sloping away from the tanks at minimum 1 percent gradient, to drain any liquid spills to a safe area away from the tanks and piping. Diversion kerbs with a height not exceeding 380 mm to avoid formation of gas traps may be permitted if necessary for directing possible spillage away from bullet tanks. If spill containment is to be provided, it shall be either remote impoundment or diking of the area surrounding the spherical tank. If diking around the tank is to be used for spill containment, the diked area shall be designed according to GP 9-1-1. Remote impoundment collects any spill at a location away from the tank. This may be of significant importance shall the vaporizing LPG ignite during the spill. However, installation of remote impoundment may need more land. In any case, all materials for components of spill containment shall be capable of withstanding the effects of a thermal shock associated with spilling LPG. Furthermore, spill containment shall allow for adequate venting of the vapor generated during an LPG spill. If remote impoundment is to be used for spill containment, the remote impoundment facility shall be designed as follows: 3-14 1. Grading of the area under and surrounding the tanks shall direct any leaks or spills to the remote impoundment area. Grading shall be at a minimum of 1 percent slope. 2. Walls, dikes, trenches, or channels may be used to assist in draining the area. 3. The remote impoundment area shall be located at least 15 m from the tanks draining to it and from any piping or other equipment. 4. The holdup of the remote impoundment area shall be not less than 25 percent of the volume of the largest tank draining to it. If the material stored in the BULK STORAGE Safety in LPG Design 5. tank has a vapor pressure less than 690 kPa at 38 °C, the holdup for the remote impoundment facility shall be not less than 50 percent of the volume of the largest tank draining to it. Larger holdups shall be provided in the remote impoundment facility at locations where the expected vaporization is less than that specified above because of climatic conditions or the physical properties of the material. The electrical classification is to be the same as a diked area. Whether spill containment is provided or not, the ground under and surrounding a tank used to store LPG shall be graded to drain any spills to a safer area away from the tank. The drainage system shall be designed to prevent liquid spilled from one tank from flowing under any other tank. The spill drainage area shall not contain equipment like pumps or LPG piping not associated with the tank. 3.2.7 Vacuum Conditions An additional design consideration shall be addressed where commercial Butanes are stored in cold climates in horizontal “bullet” tanks and spheres. If the temperature of the stored liquid can fall below boiling point of Butane (approximately –7 °C, for the typical commercial Butane/Butene mixture and 0 °C for pure normal Butane), the pressure in the tank can drop below atmospheric pressure. There are several options to handle this low pressure situation. 1. The tank can be designed to withstand the maximum degree of partial vacuum possible by increasing wall thickness or adding stiffening rings. If an adequate margin of safety is provided, this is a satisfactory solution, because it requires no operational control. 2. Pressure can be maintained by bleeding vapor from nearby Propane tanks or 50 kg cylinders. 3. Provision can be made to heat the liquid by means of hot gas return from an external vaporizer, thereby maintaining positive pressure. 4. The supplying refiner can be asked to raise the vapor pressure of the Butane during periods when cold weather can be anticipated by increasing the Propane/Propylene content. 5. Vacuum breakers may be installed. However, this is discouraged and should be considered only if no other solution can be implemented since they involve uncontrolled introduction of air into the system, and may create potential operating and safety problems. It is always best to design the system such that it can withstand full vacuum. All other design options should be evaluated using risk assessment techniques. In an emergency case, inert gas (Nitrogen) may be injected to maintain pressure. Partial pressure effects and associated lifting of the pressure relief valves may be encountered. Therefore, extreme care shall be required when embarking on such activities. The proposals are ranked by preference. Options 2), 3), 4), and 5) require control and alarm instrumentation, and are subject to operator error and maintenance deficiencies. 3.3 Refrigerated LPG Storage Using refrigerated storage (–50 °C for Propane) normally accommodates large capacity requirements. This type of storage involves a thermally insulated tank operated at approximately atmospheric pressure. Additionally, a cooling system involving pumps, compressors and exchangers as well as an emergency blowdown system (flare) are Safety in LPG Design BULK STORAGE 3-15 needed. Details on refrigerated storage are not outlined in this Guide. For design, reference shall be made to EMRE Design Practices, GP 9-6-1 and NFPA 58 Section 9. 3.4 Overpressure Protection for Tanks This chapter discusses overpressure protection for LPG tanks, the different types of Pressure Relief Valves (PRV) used, the procedure on how to size them, the principles of installation and the testing frequency. Prevention of loss of containment is by far the most important concept during the design of a pressure system. Overpressuring a system has the potential for loss of containment. Therefore, it is important to incorporate adequate facilities to prevent overpressuring LPG systems. 3.4.1 Contingencies to be Expected A “contingency” is a normal or abnormal event during plant operation that could lead to overpressuring. The magnitude of the contingency will have a direct impact on sizing the pressure relief system. Following is a description of common contingencies that may affect LPG storage: 1. Tank exposure to external heat in the form of impinging fire or heat radiation from an adjacent fire will lead to boiling and subsequent pressure increase. 2. Overfilling to liquid full can cause overpressure. 3. Thermal expansion of the liquid can cause overpressure. If a tank is filled with cold product and filling has exceeded 85% and the tank is exposed to external heat (sun) its contents will expand and may exceed 100% of tank volume. 4. Introduction of Propane into a Butane tank, which has been designed only for Butane, could cause overpressure. 5. Improper commissioning (air freeing) of a tank may lead to high pressure because of presence of non-condensables (inert gas, Nitrogen). Bullets and spheres exposed to external heat normally will produce the largest relief requirements. Therefore, this will dominate sizing of the valve. This is not true for mounded drums. Avoiding loss of containment by overpressure can be accomplished in two ways. First, a pressure relief device protects the system. A Pressure Relief Valve (PRV) is the most cost effective solution to protect the system. Typical PRVs in LPG service are spring loaded valves that are designed to open automatically if the set pressure (tank design pressure) is reached. Second, the system could be designed for a pressure considerably above the operating pressure. The cost for this in most cases would be considerably higher than that of a normal tank, yet, in some countries such designs are required for tanks in transportation services. The draw-back here is that in case of truck overfilling there is no protection against thermal expansion pressure increase. The latter design method shall only be used where local codes prohibit Pressure Relief Valves. It should be noted that during fire impingement on a tank, the containment could ultimately be lost due to excessive metal temperatures causing a Boiling Liquid Expanding Vapor Explosion (BLEVE). Overpressure protection cannot prevent a BLEVE since red-hot tank walls will fail at pressures far below the design pressure of the tank. The best way to prevent this kind of failure is by providing passive fire protection by mounding the tank. Fireproofing combined with firewater protection most likely may prevent a BLEVE, however, if the firewater fails during a prolonged 3-16 BULK STORAGE Safety in LPG Design fire the tank may fail since fireproofing is only good for a limited duration of fire exposure. 3.4.2 Refinery and Upstream Pressure Relief Pressure relief requirements for LPG storage and loading/unloading facilities at Refineries and Upstream Gas Plants are described in Design Practices Section XV-C. To prevent liquid discharge and undersizing of PRVs the ERE report EE.28E.90 “Sizing Pressure Relief Valves in Flashing and Two Phase Service, An Alternative Procedure” shall be followed. Furthermore, API RP 520 “Design and Installation of Pressure Relieving Systems,” as well as API RP 521 “Guide for Pressure Relieving and Depressuring Systems” apply. Refineries and Upstream facilities typically use conventional pressure relief valves. The typical pressure relief valve in Marketing is the axial flow valve described below. Figure 3.4.2: Conventional pressure relief valve 3.4.3 Pressure Relief in Marketing Terminals Sizing of pressure relief valves is governed by codes. If local codes are more stringent than those discussed below, they shall apply. Tanks for bulk storage have typically been Safety in LPG Design BULK STORAGE 3-17 designed according to the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII. This code also covers requirements for overpressure protection and relief devices. In addition, the Compressed Gas Association (CGA) has applicable provisions in their three pamphlets on Pressure Relief Device Standards S-1.1, S-1.2, and S-1.3. National Fire Protection Association (NFPA) has included the CGA provisions in NFPA 58, Appendix E and in NFPA 59, Chapter 9. Capacity requirements for pressure relief valves on above ground, nonrefrigerated ASME tanks (bullets, spheres) shall be in accordance with the applicable provisions in these standards. Following are the details on the sizing of PRVs for bullets, spheres and for mounded drums. Figure 3.4.3-a: Large pressure relief valves on marketing sphere The set pressure of a pressure relief valve shall be equal to or less than the design pressure of the tank. Historically this was not always the case. Tanks built before 1950 3-18 BULK STORAGE Safety in LPG Design had different settings, which can be taken from NFPA 58. The CGA pamphlets also mention the “start to discharge pressure” which is the pressure at which the PRV shows the first signs of leakage. This is typically at about 90% of the set pressure but is only relevant for judging the quality of PRV maintenance. The flow rating pressure (at which the capacity of the pressure relief valve is determined) is 121% of the set pressure when the valve is sized for the fire contingency only. The reseating pressure (at which the PRV closes again) shall be 7% below set pressure. Figure 3.4.3-b: Multi-port pressure relief valve Flow rating requirements are determined as follows. As already stated earlier for bullets and spheres the largest relief requirement originates from external heat exposure caused by fire. For these tanks the heat input will be related to the size of the tank and its total surface area. 1. For tanks below 186 m2 total surface area the adequate rate of discharge in cubic meters per minute of air at 121% of the set pressure is presented in Table 3.4.3 “Flow Requirements for Pressure Relief Valves for Tanks.” 2. If the tank surface area is larger than 186 m2 the adequate rate of discharge in cubic meters per minute of air at 121% of the set pressure is determined by the formula: PRV Flow Rate (m3/min., Air) = 10.66 x A 0.82 Where A = Total outside surface area of the tank in m2. Safety in LPG Design BULK STORAGE 3-19 A simplified method for calculating the surface of tanks is outlined below. The surface area is the total outside surface area of the tank in square meters. The tank surface area can be calculated by using one of the following simplified calculating formulas: 1. Cylindrical tank with hemispherical heads: Area = Over-all length x outside diameter x π. 2. Cylindrical tank with other than hemispherical heads: Area = (Over-all length + 0.3 outside diameter) x outside diameter x π. Note that this formula is not exact, but results will be within the limits of practical accuracy for the sole purpose of sizing relief valves. 3. Spherical tank: Area = Outside diameter squared x π. Figure 3.4.3-c: Internal and external pressure relief valves used in marketing facilities It should be borne in mind that it is important to choose the valve(s) to match the flow rating as close as possible. The appropriate choice of valve orifice size (or the sum of orifices if more than one valve is used) will result in slight oversizing. Undersizing could lead to overpressure; however, grossly oversizing could lead to valve “chattering” (a rapid succession of opening and closing the valve) and self destruction of the PRV. If a multi-port manifold is used, one valve shall be spare, the other(s) good for a total 100% of the required relieving rate. 3.4.3.1 Pressure Relief on Mounded Drums Mounded drums shall be protected against overpressure as follows. The larger of the two figures shall be used to determine the flow rate for PRVs on mounded drums. 1. 3-20 Determine the required PRV flow capacity by considering the maximum flow caused by overfilling, high vapor pressure (if Butane is stored), improper commissioning (air freeing), or inert accumulation (Nitrogen). Since in all BULK STORAGE Safety in LPG Design of the above cases the filling process will cause overpressure, the pumping capacity shall be checked when determining the PRV size. 2. The codes propose the following simplified orifice sizing approach to estimate fire loads. Calculate the surface area of the mounded drum. If the mounded drum surface is less than 186 m2 establish 30% of the corresponding flow rate in Table 3.4.3 “Flow Requirements for Pressure Relief Valves for Tanks.” If the tank surface exceeds 186 m2, calculate 30% of PRV Flow Rate (m3/min, Air) = 10.66 x A 0.82. Check whether this figure is larger than the pumping capacity mentioned above. Since mounded drums are completely covered by an earth mound they will not be subject to direct radiation from external fire and PRVs are not sized for this contingency. If the tank has to be uncovered for maintenance (See LPG Safe Operations Guide) or other reason, LPG shall first be completely removed from the tank. Otherwise, should a fire occur during maintenance the tank would not be protected against this contingency. Likewise, during first commissioning the tank shall be mounded before filling. Surface Area Air Flow Rate 3 Surface Area Air Flow Rate Surface Area 3 Air Flow Rate 3 Surface Area Air Flow Rate 3 m2 m /min m2 m /min m2 m /min m2 m /min >1.86 17.57 12.07 82.12 26.01 154.30 83.61 401.80 2.32 21.27 12.54 84.67 26.94 158.90 88.26 419.90 2.79 24.69 13.00 87.22 27.87 163.10 92.90 438.00 3.25 28.03 13.47 89.77 28.80 167.60 97.55 455.90 3.72 31.15 13.94 92.32 29.73 172.10 102.19 473.50 4.18 34.55 14.40 94.87 30.66 176.40 106.84 491.30 4.65 37.66 14.86 97.42 31.59 180.90 111.48 508.60 5.11 40.49 15.33 99.96 32.52 185.20 116.13 525.80 5.57 43.61 15.79 102.50 33.45 189.40 120.77 543.10 6.04 46.44 16.26 104.80 34.37 193.70 125.42 560.10 6.50 49.56 16.72 107.30 35.30 198.20 130.06 577.10 6.97 52.39 17.19 109.90 36.23 202.50 134.71 594.10 7.43 55.22 17.65 112.10 37.16 206.70 139.35 610.80 7.90 58.05 18.12 114.70 41.80 227.70 144.00 627.50 8.36 60.88 18.58 116.90 46.45 248.00 148.65 643.90 8.83 63.43 19.51 121.80 51.09 268.20 153.29 660.30 9.29 66.26 20.44 126.60 55.74 287.90 157.93 676.80 9.76 69.09 21.37 131.10 60.39 307.50 162.58 692.90 10.22 71.64 22.30 135.90 65.03 327.00 167.23 709.30 10.68 74.48 23.22 140.50 69.68 346.00 171.87 725.50 11.15 77.02 24.15 145.30 74.32 364.70 181.16 757.50 11.61 79.57 25.08 149.80 78.97 383.40 185.81 773.30 Table 3.4.3: Flow requirements for pressure relief valves for tanks (below 186 m2) NOTE: The required flow capacity is in cubic meters per minute of air at standard conditions, 15.6 °C and atmospheric pressure. For intermediate values of surface area, the rate of discharge may be interpolated. 3.4.3.2 Installation of Pressure Relief Valves All pressure relief valves shall bear a substantial non-corrosive metal identification plate giving, at a minimum, the manufacturer's name, code under which fabricated, set pressure and orifice size. Safety in LPG Design BULK STORAGE 3-21 The total required relief valve capacity can be covered by multiple pressure relief valves. These may be installed with a manifold that includes provision for selectively closing off any particular relief valve to permit removal for inspection while the remaining relief valves provide the discharge capacity required for the tank. Pressure relief valves shall be located on top of the tank in direct flow connection to the vapor space such that the frictional pressure drop between tank and PRV nozzle under full flow conditions (at rated capacity of the PRV) does not exceed 3% of the PRV set pressure. Long or narrow piping connections between the tank and the PRV are not allowed because this could result in excessive pressure drop and the associated difficulties (inadequate relief and “chattering”). Regulations concerning valving between tank and PRVs allow for the following options: 1. Install pressure relief valves without block valves. 2. Provide excess relief capacity with multi-port arrangement valves, interlocked valves, or sealed (CSO = Car Sealed Open) block valves. Isolating one valve shall not result in reducing the capacity below required relieving capacity. 3. Install pressure relief valve with CSO block valve and warehoused spare. PRV can be removed and replaced under carefully managed procedure which minimize time without PRV and control operations and pressure during that time. In the first case, the tank has to be emptied for testing and maintaining the PRV. The latter cases permit removal with the tank in operation. CSO valves may not be permitted by some local codes. If CSO gate valves are installed upstream or downstream in piping associated with a PRV their stems shall be oriented horizontally or upside down. This is to prevent the gate from dropping by gravity, should it detach from the stem. Pressure relief valve discharges on tanks having volumetric capacity of 10 m3 or larger shall be discharged via a vertical vent stack extending above the heads of personnel who could be on the PRV platform (minimum of 2.1 m typical in Marketing and 3 m in Refining and not less than 3.0 m above ground level.) into open air or closed flare systems if so required by authorities. The discharge vent or header shall be sized such that at full flow the pressure drop does not exceed 10% of the PRV set pressure. Discharges shall not be allowed to enter enclosed spaces. The vent shall be piped to prevent impingement of escaping gas on the tank, nearby tanks, operating pipelines and equipment. Vents shall be protected against mechanical impact and be designed to handle any thrust during PRV discharge. Vent systems where several vents discharge into a header are not permitted since the discharge velocity at the end of the vent system may be so low that proper dispersion of the vapors is not guaranteed. Drilling a 20 mm weep hole in the vent line low point shall prevent accumulation of liquid or condensate. If vapor exiting the weep hole would impinge on the tank or other equipment, an elbow or deflector plate may be used to redirect flow. Small diameter discharge lines (typically Marketing) could have their mechanical integrity compromised by a 20 mm hole. For these small lines a loose fitting plastic rain cap at the top of the vent may be combined with a smaller weep hole. 3.4.3.3 Pressure Relief Valve Testing Requirements Pressure relief valves in LPG service normally operate in a clean, non-corrosive environment. Pressure relief valves in LPG service have shown a good reliability over the years. However, since no mechanical device can be expected to remain in operative condition indefinitely it is recommended to test or replace PRVs on LPG bulk storage within a 5 year interval. Local regulations, if more stringent, may overrule this 3-22 BULK STORAGE Safety in LPG Design interval. Testing of PRVs requires special procedures and equipment, manufacturer’s advice shall be obtained if testing is to be carried out at plant. 3.5 Emergency Block Valves on Bulk LPG Tanks Emergency Block Valves (EBV) are provided to stop LPG liquid flow from the tank to potential downstream emergencies. EBVs permit quick control of hazardous situations by stopping leaks at pump seals, at hose ruptures, or at fires. EBVs are recommended to be metal gate or plug valves or high performance ball or butterfly valves with metal seats (not soft seats). They shall meet the requirements of GP 3-12-1 and Design Practices Section XV-F. Soft-seated valves NPS 4 and smaller meeting GP 3-12-1 may be used. Soft-seated valves over NPS 4 shall not be used as EBVs. They may be used in non-EBV service provided they meet the fire-safe requirements of API 607 and GP 314-1. EBV shall be of approved make and shall incorporate all the following means of closing: 1. Local manual shutoff. 2. Remote-operated manual shutoff. Remote activation device or pushbutton shall be accessible during an emergency Valves which are sandwiched between 2 flanges by long, exposed bolts shall not be used. EBV's may be either automatic/remote operation or manual operation as defined below. In Upstream and Refining typically EBV's may be fitted externally between tank flange and piping. For Marketing EBV's are often installed internally upstream of the outlet flange. More details on Emergency Block Valves can be found in ERE reports EE.27E.84, “Guidelines for Selection and Installation of Emergency Block Valves” and EE.44E.94, “Possible Risk Reduction Design Items for Above Ground Pressurized LPG Storage.” 3.5.1 Tank EBV's in Liquid Service All liquid phase inlet and outlet connections on the tank larger than 25 mm diameter shall have an EBV and an additional manual shutoff valve located as close as practicable to the tank. The EBV may be installed inside tank (manual or automatic remote hydraulic operation). Externally installed EBVs to the liquid phase shall either close by remote operation or automatically. Remote operated valves may be either fail safe or their actuators and energizing lines fireproofed. Connections to the liquid phase below 25 mm may only have two manual block valves. Automatic fail safe valves close upon failure of motive energy or control signal. Their motive energy supply shall be designed to fail (melt) in the event of a fire. Remote operation non fail safe valves (gate or quarter turn) usually rely on an electrical or hydraulic actuator. In order to function, these valves need to be energized during a potential fire. Therefore, signal and electric cables (or hydraulic ducts) as well as actuators shall be fireproofed in order to function during the first 15 minutes of an emergency. The 15 minutes are based on API 2510 and on the assumption that within 15 minutes of a fire developing appropriate action has been taken. Normally refineries have fireproofed valves and new Marketing installations have fail safe valves. The control system shall be arranged so that these valves can be closed individually and can also all be closed simultaneously by an emergency shutdown system that shuts down all LPG pumps and compressors at the facility as well. See also Chapter 2, “Emergency Shutdown system.” Means of remote actuation of EBV may be pneumatic, hydraulic, electrical or mechanical. The actuation point shall be in a safe location outside the immediate risk area, at least 15 m away from an aboveground tank or the valve assembly on an underground or mounded tank. Signage shall be installed at the actuation point to indicate its location and mode of operation. Safety in LPG Design BULK STORAGE 3-23 Manual shutoff valves installed close to the tank shall be capable of an adequate seal under fire conditions as specified in the 30 minutes fire test in API 607 or equivalent. 3.5.1.1 External Shutoff Valve Remote operated external shutoff valves installed immediately at the first flange of the tank are the preferred option to provide emergency blocking capability. Spring actuated quarter turn ball valves (NPS 4 or less) with electric, hydraulic or pneumatic spring release is an adequate choice to perform fail safe operation. The signal lines to operate the valve shall be either of plastic or low melting point metal. Should a fire develop in the vicinity of the tank, these lines should fail and the valve would close automatically. Tying the valve into the plant Emergency Shutdown System (ESS) provides remote shutdown capability. Figure 3.5.1.2-a: Internal excess flow shutoff valve 3.5.1.2 Internal Excess Flow Shutoff Valve Another option for the remote operated tank emergency block valve is an “internal excess flow shutoff valve.” It is located inside at the bottom of the tank and kept open by a hydraulic system. The signal lines to operate the valve shall be either of plastic or low melting point metal. In case of fire close to the tank these lines fail and the valves close automatically. Tying a depressuring valve into the plant Emergency Shutdown System (ESS) provides remote shutdown capability. However, such valves are only available for sizes up to 100 mm. Larger internal valves without excess flow shutoff have been installed in the past and may continue to be used. Selecting the closing flow rate of an excess flow valve involves an analysis of the flow characteristics of the complete piping system. If the closing flow rate happens to be considerably above the flow that could be obtained by rupture of downstream piping/hose the valve will not close automatically. The valve shall be mounted in the correct direction. Furthermore, installation shall be such that adequate clearance is provided around the inlet ports of the valve, otherwise the pressure conditions during normal flow may be equal to excess flow conditions and the valve would close under normal operating conditions. Excess flow valves shall have a rated closing flow about 50% greater than the expected design flow rate. All liquid and vapor withdrawal 3-24 BULK STORAGE Safety in LPG Design connections on the tank (except for the pressure relief valve connection or where the effective opening into the tank is smaller than 1.4 mm diameter) shall have a positive shutoff valve located as close as practicable to the tank, in combination with an excess flow valve installed on the tanks’ withdrawal nozzles. Figure 3.5.1.2-b: Internal excess flow shutoff valve operation The effectiveness in the event of a line/hose break of an excess flow valve is limited by certain conditions. It can only be maintained when the tank is taken out of service. The valve may not close automatically if: 1. Piping system restrictions (due to pipe length, branches, reduction in pipe size or number of valves) decrease the flow rate to less than the valve's closing flow. 2. The break or damage to the downstream line is not large enough to create enough differential pressure across the valve to close it. 3. A shutoff valve in the line is only partially open and will not allow enough flow to close the excess flow valve. 4. LPG pressure upstream of the excess flow valve, particularly due to low temperature, is not high enough to produce a closing flow rate. 5. Foreign matter (such as welding slag, scale or sludge) is lodged in the valve and prevents closing. Figure 3.5.1.3: Quarter turn ball valves 3.5.1.3 Manual Back-up Valve All automatic or remote operated EBVs shall be provided with a second, manually operated isolation block valve. This double block is provided as a backup for malfunction of the automatic or remote operated valve and to ensure additional shutoff in case of leak. The best choice is a quick closing quarter turn ball valve, which shall meet the requirements of GP 3-14-1. 3.5.2 Tank Shutoff Valves in Vapor Service Vapor return lines and other tank connections to the vapor phase shall have two manual isolation valves. Any ball valve shall meet the requirements of GP 3-14-1. Safety in LPG Design BULK STORAGE 3-25 3.6 Tank Instrumentation The following LPG tank instrumentation is needed to satisfy the basic needs for safe operation of LPG bulk storage: 1. Tank level measurement shall be based on risk of overfill considerations. Tanks receiving rundown streams from processes or pipelines or ship unloading shall be equipped with two independent level gauges and a high level alarm. Tanks receiving smaller parcels like road bulk trucks or single rail cars may need only one level gauge. 2. Independent level high-high alarm (LHHA) for continuous rundown and large parcel receipt. If tank is filled by ship or pipeline the LHHA may also act as a Cut Off (LHHA(CO)) on the tank inlet valve. 3. Pressure indicator. 4. Temperature indicator. Figure 3.6: Typical connections for LPG sphere tank Legend: 1. 2. 3. 4. 5. 6. 3-26 Inlet Nozzle Outlet Nozzle Pressure Relief Valve Nozzle Atmospheric Vent Drain Nozzle Top Manhole BULK STORAGE 7. Bottom Manhole 8. Top Pressure Gauge Connection 9. Top Level Indicator Connection 10. Bottom Level Indicator Connection (DP Cell) 11. Top and Bottom Temp. Indicator Connect. 12. Level Gauge Connection Safety in LPG Design The level high alarm and the independent level high-high alarm need an audible alarm at the control room and, if the control room is not permanently manned, also a local audible alarm. There shall be a local read-out for the tank level gauge, the pressure gauge, and the temperature indicator, however, the design engineer may decide to have additional remote read-outs at the control room. The alarm instrumentation shall be designed and installed so that the alarms can be tested without taking the tank out of service. In addition, an appraisal of the measurement needs of the particular location may reveal the need for more instrumentation depending on automatic stock control, custody transfer etc. Instrumentation shall be replaceable without taking the tank out of service. Level and flow indicators with glass components shall not be used, because the glass is subject to breakage from fire, mechanical damage, or improper assembly. Figure 3.6.1: Radar gauge (Saab) 3.6.1 Tank Level Measurement New or renovated installations may be equipped with radar type tank level measurement. This technology developed recently and has proven to be reliable. It is suitable for complete custody transfer automation with control from remote locations. It has no moving parts and is easy to be repaired with the tank in operation. The previous type of tank level measurement was the servo gauge. Servo-gauge technology also offers high measurement precision but has moving parts and therefore needs more maintenance Servo gauges employ a small displacer, rather than a float, attached to a tape that passes over a measuring drum. A shaft to a servo motor (or “stepping motor” that continuously balances the downward force of the barely immersed displacer and its tape against a stress transducer connects the measuring drum. This Safety in LPG Design BULK STORAGE 3-27 balanced system completely eliminates measurement error due to tape weight variations or tape system friction. The Magnetic Gauge may often be a solution to low cost installations in bullet tanks. It consists of a gauge constructed with a float inside the tank resting on the liquid surface which transmits its position through suitable leverage to a pointer and dial outside the tank indicating the liquid level. The motion is transmitted magnetically through a nonmagnetic plate and, since no venting of LPG is required, the magnetic gauge is a recommended type. However, it cannot be used for Custody Transfer of product. Early installations have used dip-tubes, fixed level gauges or rotary gauges for level indication. The fixed maximum liquid level gauge shall have the liquid level determined on the maximum permitted filling limit when the liquid is at 4 °C for aboveground tanks or at 10 °C for underground or mounded tanks. Though outdated, they may still serve their purpose especially as a back-up indication for the radar or servo gauges. If such a vent type gauge is the only level control, a more modern level measurement system may be warranted. Float and tape gauges have been frequently installed in LPG sphere tanks. However, reliability has not been satisfactory. Their precision is limited by two factors inherent in their design: friction in the tape guides and pulleys, and varying weight of the tape itself as product level changes in the tank. Therefore, installation is no longer recommended. 3.6.1.1 Level High Alarms Up to two level high alarms may be provided for LPG bulk tanks. The first alarm (Level High Alarm, LHA) can be integrated into the level gauge system. If there is a computerized level measurement system the first alarm may be an integrated software alarm. The second alarm (Level High-High Alarm, LHHA) shall be entirely independent. It shall be installed for continuous rundown or large parcel receipt. It shall be hard wired, fail safe (i.e. self checking with failure indication) and shall continue working when the level gauge and/or the first alarm fails. If the alarms are not fail safe the system shall be tested frequently. The first alarm shall be set just above the 85% level, the second shall be set as close as possible above the first. If the plant is supplied by pipeline or tanker large volumes come into the tanks at high velocity. Therefore, the level high-high alarm shall also act as a cut off (LHHA(CO)) on the supply line. Alarm systems shall be tested quarterly with the option to change if there is a documented good history, but not less than annual. Therefore, installation of a high level alarm system shall provide for complete testing of all mechanical and electronic system components without depressuring the LPG tank. The system shall be configured to actuate the alarm when the electrical power circuit is de-energized, thus assuring protection in the event of an undetected power supply failure. This latter feature shall necessitate battery back-up for the alarm system. For horizontal pressure tanks a packless ball float in an external chamber, actuating a micro switch outside the chamber, is the preferred option. This typical design, explained in Section XII-C of Design Practices, permits maintenance and testing without depressuring the LPG tank, but requires two 38 mm valved connections on 609 mm centers for installation. A similar, but more complex installation, also described in Section XII-C, could be made using a refinery type displacer level measuring device. 3.6.2 Pressure and Temperature Indicators A pressure indicator shall be installed on a 13 mm valved fitting to the 50 mm connection at the top of the tank. The indicator shall be a high quality instrument designed to permit test bench re-calibration, and shall be capable of accurately reading 3-28 BULK STORAGE Safety in LPG Design pressures up to 120 percent of the pressure relief valve setting. There shall be a 50 mm block valve on the tank nozzle and a 13 mm quarter turn valve as a second block valve. The tank shall be equipped with a stainless steel thermowell, and a precision liquid filled dial thermometer capable of accurately reading all expected tank operating temperatures. This requirement is not eliminated by provision of resistance temperature detectors or thermocouples. The independent thermowell and thermometer are still required as a quick verification check on accuracy of the electrical/electronic devices. The liquid filled dial thermometer is recommended as it can easily be removed for check-calibration or for storage in a secure place when not in use. Flanges shall attach thermowells since this arrangement cannot result in erroneous unscrewing of the whole attachment. Figure 3.6.2-a: Pressure and temperature indicators Pressure Indicator Temperature Indicator Double Block Valves Tank Shell Thermowell Figure 3.6.2-b: Pressure indicator (PI) and temperature indicator (TI) 3.6.3 Grounding Connections for Tanks Each tank having electric instrumentation shall be grounded to earth from at least two points. It shall be designed to dissipate lightning strokes, which may affect the instrumentation. Copper tape, 25 mm by 3 mm shall be used for this connection and each grounding point shall be taken to a separate electrode. The ground electrode (ground rod) may be a 16 mm diameter extensible type copper rod with a minimum Safety in LPG Design BULK STORAGE 3-29 length of 2.4 m. These electrical connections shall be checked and tested on an annual basis. Therefore, the connections shall be accessible. Some local regulations require grounding on all tanks above a minimum size. Equipment using cathodic protection shall not be grounded. Cathodic protection shall comply with GP 19-5-1. 3.6.4 Product Odorization LPG product, which is provided for sale for combustion use, shall be odorized. Odorization systems are offered as package units by companies like Williams, (Valencia, Ca. USA) and Lewa (Leonberg, Germany). They are fully integrated, electro-pneumatically operated and may have one or two injection pumps. They may be controlled from either the digital or analog output signal from measuring equipment in the gas line. A standby solid state repeat cycle timer may permit manual operation and stroke rate adjustment in the event the flow signal is temporarily lost or disconnected for maintenance. The odorant may be delivered in ordinary 200 liter drums and pumped over into a storage tank, or a dedicated stainless steel drum may be filled at the manufacturer site and transported to the plant. Figure 3.6.4: Odorization systems by Williams and Lewa 3-30 BULK STORAGE Safety in LPG Design 4 PUMPS & COMPRESSORS 4.1 Pumps 4.1.1 Pump Types Commonly Used There are two fundamental types of pumps used for any service including LPG. These are the positive displacement pump or “PD” pump and the centrifugal pump. Positive displacement pumps have internal gears, vanes or other geometry's which enclose discrete volumes of liquid at the suction and transport them to the discharge. Positive displacement pumps do not in themselves generate pressure but simply move the fluid to the discharge where it assumes the back pressure in the piping. In a centrifugal pump, the liquid enters an impeller and is accelerated to a high velocity. Upon exiting the impeller the fluid is slowed down in the pump diffuser and the energy imparted in the form of velocity is changed to pressure. Pump Head Centrifugal Pump Curve Positive Displacement Pump Curve Pump Flow Figure 4.1.1: Pump characteristic curves Safety in LPG Design PUMPS & COMPRESSORS 4-1 Positive displacement pumps are virtually insensitive to the type of fluid being pumped, the fluid viscosity and fluid density. They deliver essentially the same flow rate regardless of the fluid or pressure in the discharge. Centrifugal pumps on the other hand are very sensitive to the type of fluid (density) and the pressure developed is a function of both the density and flow rate. The figure above shows the characteristic flow curves for both types of pumps. 4.1.1.1 Rotary Shaft Positive Displacement Pumps The type of positive displacement pump normally used in LPG service is a rotary shaft positive displacement pump (see the Design Practices, Section X-F, “Positive Displacement Pumps” for a complete description of all positive displacement pump types). Figure 4.1.1.1-a: Multiple gear pump Figure 4.1.1.1-b: Internal gear "Crescent" pump The design and installation of positive displacement pumps for most operating plants are governed by American Petroleum Institute API 676, “Positive Displacement Pumps, Rotary Shaft;” GP 10-2-2; and Design Practices Section X, “Pumps.” The reader may wish to review these documents to determine applicable features dependent on the particular installation. See also GP 10-1-1 4-2 PUMPS & COMPRESSORS Safety in LPG Design “Centrifugal Pumps.” The following API codes may apply: API 610 “Centrifugal Pumps for Petroleum, Heavy Duty Chemical and Gas Industry Series.” ASME B73.1M “Horizontal End Suction Centrifugal Pumps,” ANSI B73.2M “Vertical In-Line Centrifugal Pumps.” The figures here show two different types of internal gear pumps, one with several gears and one with only two gears, also called a Crescent pump. In these pumps fluid is trapped between the teeth of the gear and casing and transported to the discharge. The figure below shows a sliding vane pump. Fluid is trapped between the vanes and the casing and transported to the discharge. The benefit of the sliding vane pump is that as wear occurs, the vanes simply move out automatically compensating. In both of these pump types, a single shaft penetrates the pressure casing and shall be sealed to keep the LPG in the pump. See the section on “Shaft Sealing” below, for additional details. Figure 4.1.1.1-c: Vane pump The advantages of positive displacement or “PD” pumps include: 1. PD pumps are capable of handling some vaporization in the suction. 2. PD pumps can tolerate more change in the net positive suction head available (NPSHa) and are self priming. 3. PD pumps are generally smaller and operate at lower speed than centrifugal pumps making them ideal for mounting on road transport and taking power from an engine power take off (PTO). 4. PD pumps have higher efficiency than centrifugal pumps (dependent on the viscosity of the fluid). 5. The pumping direction is reversible by reversing the direction of rotation. The disadvantages of PD pumps include: 1. Safety in LPG Design Higher maintenance costs due to actual rubbing of the internal parts causing wear. PUMPS & COMPRESSORS 4-3 2. Potentially higher cost due to the need for special low speed motor or gear. 3. Not suitable for continuous operation over many weeks of duration. 4. Requires a pressure relief valve on the discharge. Pressure relief valves are always required in the discharge of PD pumps because the pump simply pushes the fluid into the discharge line. If the discharge is blocked, the pump will continue to push the fluid until either there is insufficient power to turn the pump or the pump casing or piping breaks. Pressure relief valves shall be sized for the maximum pump capacity and there shall not be any valves in the line between the pump discharge and relief valve. See Design Practices Section XV-C, Safety in Plant Design, “Pressure Relief” for a complete description of relief valve sizing and installation. Figure 4.1.1.2-a: Centrifugal pump operation Figure 4.1.1.2-b: Multi-stage centrifugal pump 4.1.1.2 Centrifugal Pumps The figure below shows a cross section of a centrifugal pump. Inside the stationary casing (C), turns the shaft (A) to which the rotating impeller (B) is attached. The blades of the impeller accelerate the liquid inside the impeller and push it to the impeller outside diameter at high speed. This action creates a lower pressure at the impeller eye or inlet (D) thus drawing more fluid into the impeller. The high velocity fluid at the impeller exit is slowed within the casing that converts the velocity energy to head or pressure before the fluid exits the casing at (E). More information about the many styles of centrifugal pumps can be found in the Design Practices, Section X: “Pumps.” 4-4 PUMPS & COMPRESSORS Safety in LPG Design As previously stated, the head or pressure developed by a centrifugal pump varies with flow. To match the required flow and pressure, centrifugal pumps can be designed with different width and diameter impellers, different speeds, and by providing multiple impellers on one shaft as shown on the figure below. Figure 4.1.1.2-c: Tank mounted submersible pump The design and installation of centrifugal pumps for typical operating plants are governed by API 610, “Centrifugal Pumps for Petroleum, Heavy Duty Chemical and Gas Industry Service,” GP 10-1-1, “Centrifugal Pumps” and for less severe duties, ANSI B.73. Unlike PD pumps, centrifugal pumps develop their own pressure and the maximum pressure they can develop is at zero flow. Therefore, the pump casing and downstream equipment are usually designed accounting for the maximum pressure and a relief valve is not normally provided in the discharge. The advantages of centrifugal pumps include: 1. Can provide very high flow rates economically. 2. Lower maintenance cost (no rubbing parts). 3. Lower installation cost on a cost per unit capacity basis. 4. Wide discharge pressure and flow range. The disadvantages of centrifugal pumps include: Safety in LPG Design 1. Lower efficiency, especially at lower flow rates. 2. Need to be primed. 3. Not tolerant of vapor in the suction. 4. More sensitive to inlet system problems and NPSH. PUMPS & COMPRESSORS 4-5 4.1.1.3 Minimizing Pump Cavitation and Vaporization Pumping systems and the choice and location of pumps shall be based on an assessment of the Net Positive Suction Head (NPSH) required at the pump with the aim of minimizing the likelihood of pump cavitation and vaporization occurring in the pump's suction system. NPSH or Net Positive Suction Head, is the amount of energy available at the inlet of a pump above the total energy at which the fluid will vaporize. All pumps have a Net Positive Suction Head requirement or NPSHr expressed in feet or meters of water. The suction system that the pump is connected to has an available NPSH or NPSHa. The available NPSH must always exceed the required NPSH or vapor bubbles will form at the inlet to the pump. These bubbles form at the impeller eye and then implode within the impeller in a process called cavitation. Cavitation is damaging to the pump and will eventually cause failure. In addition to adequate NPSH, the inlet line to the centrifugal pump shall be free of vapor bubbles and shall be completely filled with liquid: There shall not be any high point in the suction line where vapor can collect and restrict the flow. A vapor return line to the supplying LPG tank will help to reduce vaporization in the suction line. Heat reflective paint, shading from the sun or similar arrangements to reduce the temperature of the product in the suction system may be helpful to prevent vaporization. Vaporization of liquid LPG can also be reduced by providing sufficient static head on each restrictive piping device to cancel out the pressure drop of each device. A 1370 mm column of LPG creates about 6.9 kPa (0.069 bar g) of static pressure. Suction line and NPSH problems usually occur in centrifugal pumps for the following reasons: 1. 2. Suction line is too long or too small or both. Suction lines are typically at least one size larger than the flange of the pump to which they are connected. Too many bends, valves or fittings in the suction line. 3. Too high a flow rate causing increased pipe friction and inability to vaporize fluid in the suction tank to accommodate the drop in liquid level. A guideline to help control liquid LPG boiling is that no more than 2 - 3 percent of the total tank volume shall be removed per minute. For underground tanks, it is even less: 1 - 2 percent.. 4. Pump installed on a level that is higher than the tank minimum operating level. 5. Suction line has high points between the pump and tank. Typically the suction line shall slope upwards continuously from the pump back to the tank. 6. LPG temperature higher than normal. 7. Debris or obstructions (such as valves not fully open) in suction line. This may include strainers or filters. Taking these factors into account leads to the design criteria that the pressure drop in the suction line shall not exceed 0.07 to 0.14 bar. Complete information on pump NPSHa calculation can be found in the Design Practices Section X-D, “NPSH” and other Design Practice Sections on sizing lines for pressure drop, Section XIV, “Fluid Flow.” One method to resolve NPSH and suction line concerns is to use a tank mounted submersible pump as shown in the figure above. Here, the pump is installed in a 4-6 PUMPS & COMPRESSORS Safety in LPG Design pipe or barrel inside the tank with a ball valve on the barrel bottom. maintenance, the ball valve is closed and the barrel is de-pressurized. 4.1.1.4 For Selecting Pump Type and Pump Features Selection of the correct pump type is the key to a reliable, low cost installation. The following guides shall be used when selecting the pump type. For most LPG transfer applications which are not in continuous service and where highly variable suction conditions exist, where maximum evacuation of the tank is desired, where pumps are motor transport mounted and power take-off driven, a positive displacement pump shall be used. The sliding vane pump is preferred over a gear pump since it operates at higher speed (more compatible with available drivers) and is self compensating for wear when the correct vane and casing materials are chosen. The sliding vane type pumps are mostly used in cylinder filling and loading/unloading applications with capacities up to 80 m3/h and pressure differential of 1.4 – 5.5 bar. The regenerative turbine type pump is very reliable in cylinder filling applications where filling rates are up to 8 m3/h and pressure differentials up to 10 bar. The low NPSH vertical turbine canned type centrifugal pumps are used in loading/unloading marine tanks or in applications where the flow rates are higher than 80 m3/h. Figure 4.1.1.4: Regenerative turbine pump For LPG services, which are continuous, 24 hour a day, seven days a week, involve large flow rates (typically over 12 m3/h), have relatively constant inlet conditions or are outside the range of commercially offered vane pumps, a centrifugal pump shall be selected. For additional information on selecting pumps for any general service, see Design Practices Section X, “Pumps.” Safety in LPG Design PUMPS & COMPRESSORS 4-7 Pumps used in LPG service shall have the following minimum features: 1. Pumps shall be designed for LPG service. The characteristics of LPG require that all shaft and stem seals, set disks and other resilient parts be of materials that are impervious to the action of both LPG vapor and liquid. 2. Steel is the best choice of material for pressure containing parts of LPG pumps. However, some manufacturers produce pumps in ductile iron due to limited market demand on steel. Ductile iron would be the second choice. Cast iron is not allowed. 3. All pumps shall have proven experience in LPG service at or near the conditions of the service they will be used in. See GP 10-1-1 for the experience clause required. 4. Positive displacement pumps shall have a relief valve in the discharge piping. Integral relief valves in the pump are not considered a replacement for PRVs. 5. Centrifugal pumps shall be self venting or incorporate a vent connection. 6. All pumps shall have a mechanical seal (proven LPG service), not packing. More information DP X- G. 7. O-rings shall be of a fluorelastomer material such as viton. 8. Consideration shall be given to the non-lubricating characteristic of LPG product when selecting pump for LPG service. 9. Pumps shall be selected and installed with sufficient net positive suction head (NPSH) to avoid cavitation under both normal operating conditions. 10. Suction and discharge piping systems shall be sized to accommodate the maximum design flow rate of the pump and the related pressure losses. 11. Check valve shall be installed on the discharge side of all centrifugal pumps. 12. Where positive displacement pumps are used, a suitably sized pressure bypass system shall be installed. The product shall be re-circulated to the pump suction line at least 5 m ahead of the pump suction. 13. Pumps capable of producing pressure high enough to damage any component on the discharge side shall be equipped with a suitable relief device that discharges to a safe location. This device shall be located upstream of the of the first block valve. 14. Electric motors shall be Class I, Division 2, Group D or equivalent. Motor enclosure shall be flameproof. Other electrical equipment shall be approved for operation in the hazardous area in which they are located. All equipment located in the open shall be weatherproof. 4.1.1.5 Pump Sizing Pumps shall be sized to suit the maximum operational flow rates and pressures required. Pumps, compressors and piping systems shall have a loading rate sized according to the size of the tank being filled. Adequate controls shall be provided to prevent tanks from being filled beyond their maximum liquid level. A loading rate of 11.5.- 23 m3/h shall prove satisfactory for tank truck units up to a capacity of 9500 liters. A loading rate of 23 - 46 m3/h shall be required for 38,000 liter units. In larger terminals, consideration shall be given to loading rates of 68 - 114 m3/h to reduce the number of loading positions required. See Table 4.1.1.4 for typical pump flow rates and pressure differentials. 4-8 PUMPS & COMPRESSORS Safety in LPG Design Flow Rate Pressure Differential m3/h kPa With vapor return 23–34 340–520 Without vapor return 7–11 520–860 Pump Sizing Rail car or truck unloading Loading delivery tank truck With vapor return 23–34 340–520 Without vapor return 7–11 520–860 Cylinder filling 3–11 410–860 Table 4.1.1.4: Typical Pump Flow Rates and Pressure Differentials 4.1.1.6 Shaft Sealing Whether the pump is a rotary shaft PD pump or centrifugal, the shaft must incorporate some kind of device to keep the LPG in the pump. The characteristics of LPG require that all shaft and stem seals, set disks and other resilient parts be of materials that are impervious to the action of both LPG vapor and liquid. Most pumps of current design will use a face contact mechanical seal consisting of a carbon ring and a silicon carbide or tungsten carbide ring. Either of the rings may rotate or is stationary depending on the pump vendor's design. The primary concern in sealing LPG is to ensure that there is a back-up device, which will limit the release of product in the event of primary seal failure. Current practice for onsite units and operating plants is to utilize a single mechanical seal with a contacting, dry running back up seal, which takes over in the event of primary seal failure. There is also a pressure switch connected to the area between the primary and back up seal to alarm a rise in pressure. Note: Due to a large population of high pressure pump applications, Upstream requires at least tandem seals in all hydrocarbon applications, including LPG. Complete details for selection of seals, seal types and seal arrangements can be found in the “ERE Pump Sealing Technology Manual,” No. TMEE-23 and in the Design Practices section X - G. 4.1.1.7 Pump Pressure Control Valve Where positive displacement pumps are used or pumps run at intermittent service for long intervals at shutoff conditions (e.g., topping off transports, filling cylinders), a suitably sized pressure bypass system shall be installed. In such conditions a pressure control valve shall return the product to the tank. This is important since just returning the product to the suction side or relying on the internal pressure relief valve will result in rapid heat up, loss of suction and potentially in damage to the pump. Spring loaded valves can be used to control the pressure, however they are not as good as the “Camflex” valves, which have smooth flow characteristics. The Pressure Relief Valve shall not serve as a pressure control valve since this will result in chattering, vibration and destruction of the pressure relief valve. Safety in LPG Design PUMPS & COMPRESSORS 4-9 4.1.1.8 Strainers Temporary strainers are used to protect a pump or compressor during the startup of new equipment. The piping layout shall permit insertion and removal of the strainer without disturbing equipment alignment. Fittings such as tees, Ys, or spool pieces may be used for this purpose. The manufacturer of the equipment being protected should be consulted concerning the size and type of strainer or filter required. A permanent strainer or filter may be needed to protect a meter or other sensitive equipment. Its design and location shall permit cleaning without removing the strainer body or draining long sections of line. Block valves and bypasses shall be provided for this purpose. Connections larger than 50 mm diameter shall be flanged. 4.1.1.9 Pump Installation Requirements Regardless of the pump type selected, the pump installation shall incorporate the following items to help ensure safety and reliability: 1. The pump shall be located outside the LPG tank drainage and impound area in a freely ventilated space. Pumps shall not be positioned underneath LPG tanks or containers. Drainage shall be provided to prevent liquid accumulation around a pump and to drain a spill to a safer area to minimize exposure to other pumps and piping. 2. The pump suction line shall be as short and large as possible with a minimum of bends, fittings and other obstructions. The suction line shall slope up continuously from the pump to the tank with no high points or vertical U-bends than can trap vapor. Typical installation details for piping at a pump can be found in GP 3-3-2, “Suction and Discharge Piping for Centrifugal Pumps.” 3. Suction and discharge piping shall have flexibility and shall be properly aligned to the pump in order not to exert excess forces on the pump. Incorporation of one or two horizontal ninety degree bends in the suction and discharge near the pump will impart flexibility to minimize thermal stresses as ambient temperature changes. However, the best method is to have a piping flexibility analysis done and compare the results to the allowable flange stresses from the pump vendor. Additional requirements and information on piping installation can be found in GP 3-7-1, “Piping Flexibility and Support;” GP 3-18-1, “Piping Fabrication;” and GP 3-19-1, “Piping Erection and Testing.” 4. When a stationary pump is installed it shall be bolted and grouted to a substantial concrete foundation and steel base plate. The pump shall also be level and the driver aligned to the pump within the manufacturer's tolerances. Pump installation information can be found in the pump and driver's manual from the vendor and in the API 686 “Recommended Practices for Machinery Installation and Installation Design.” Standard valving around the pump shall be as follows: 5. 4-10 + Remote and automatic shutdown valve at the tank outlet. + Manual block valve at the pump suction. + Manual block valve at the pump discharge. + Check valve in the pump discharge just inside the block valve. + A valved connection on the discharge within the check valve for a pressure gauge. The connection shall be seal welded and two plane gusseted. PUMPS & COMPRESSORS Safety in LPG Design 6. If the pump will be operated for any period of time below the minimum allowable flow from the vendor or at shutoff (such as in topping off transports, filling cylinders, etc.) then a pressure controlled recycle system shall be installed (see Pump Pressure Control Valve). This would be in addition to the relief valve on a positive displacement pump. 7. Suction and discharge piping systems shall be sized to accommodate the maximum design flow rate of the pump and the related pressure losses. If high transfer rates (above approximately 2.5% of tank volume per minute) must be achieved, provision shall be made to supply additional vapor to the tank. The vapor pressure within the tank being emptied may become sufficiently depressed during high flow rates to cause loss of suction to the pump. A vapor return line from the tank or vehicle being filled automatically eliminates this problem. Withdrawing liquid from two or more tanks at the same time may also eliminate this situation. A tank with fireproofing, which retards heat transfer from the surroundings, may also need supplemental vapor at medium rates. 8. A pressure relief valve shall be installed on the discharge of all positive displacement pumps. The valve shall be located in the piping before the check valve and discharge block valve. The relief valve shall be sized for the maximum pump flow rate. Since such relief valves release LPG in the liquid phase, the discharge piping of the valve shall be directed back to the LPG tank. 9. If the LPG is stored below the freezing point of water, special provisions for the pump, seal, piping and installation are required. These include such items at special pump materials to withstand the Critical Exposure Temperature, special seal designs to avoid hang up from icing, and special connections to allow chill down of the pump prior to starting. For such services contact EMRE for special requirements. 10. Pump discharge piping shall be securely anchored as close as practical to prevent system vibrations from acting directly on the pump. 11. The pumps shall be provided with the following operational and safety feature: A local start-stop pushbutton shall be installed in the vicinity of the pump. A remote Emergency Shutdown System (ESS) pushbutton shall be provided in a safe location in case the local start-stop pushbutton is not accessible because of fire or vapor cloud. Pump shall be interlocked to stop when any Emergency Shutdown (ESS) pushbutton is activated if such a system is provided. 12. LPG pump shall be provided with block valves to isolate the pump from LPG source. The block valves shall be installed on both suction and discharge piping lines. They shall be located within 3 m from the pump flanges. 4.2 Compressors In transfer operations, compressors are used to create a pressure differential between two drums causing a flow of liquid from the drum at higher pressure. Compressors are also employed to transfer residual vapor from supplying drums and other facilities in transport and maintenance operations. When designing a compressor system, consideration shall be given to the principal safety requirements of selecting a compressor that is fit for the purpose of handling LPG vapor in the specified conditions of service and that the system prevents liquid entering the compressor. Safety in LPG Design PUMPS & COMPRESSORS 4-11 Transfer of product by compressor is usually less economic compared to pumping. However, sometimes it is the best or only available method. Compressors are used for the following two purposes: 1. To transfer liquid product by aspirating LPG (taking compressor suction) from the tank to be filled and discharging into the tank to be emptied. The pressure differential thus created will cause liquid to flow into the tank to be filled. This transfer method is used to unload rail cars, trucks and marine vessels since it will completely empty the tank without harming the equipment making the transfer. 2. To evacuate tanks. This may be done for economic reasons when receiving product by rail or for maintenance when a tank (or container) or cylinder has to be taken out of service. . Figure 4.2.1-a: Reciprocating compressor (Corken) 4.2.1 Compressor Types Used Reciprocating, single stage, air cooled piston type compressors are most frequently used in LPG plants. These operate at low compression ratio. They are used to create pressure differentials between tanks to transfer liquids. Generally they are small skid-mounted units. The exception may be larger reciprocating compressors used to off-load large ships. Various cylinder configurations (vertical, horizontal, 2 stage etc.) are used, depending on the flow rate and differential pressure required. There are also several different methods for power transmission but belt drive is the most common. All belts drives shall comply with GP 10-11-1 para. 5.9 (static conductive belts). A typical reciprocating compressor is shown below. In Marketing operations centrifugal compressors are 4-12 PUMPS & COMPRESSORS Safety in LPG Design not normally justified unless very large amounts of gas and liquid must be transferred and they are not covered in the requirements below. 4.2.1.1 Design Requirements for Compressors Compressor shall be designed for LPG service. The characteristics of LPG require that all parts be made of materials that are impervious to the action of both LPG vapor and liquid. Compressors shall be equipped with a device to prevent excessive pressure in the delivery system. The design of the compressor shall limit or exclude lubricating oil contamination of LPG vapor. Compressor shall be sized within the maximum flow rating of the excess flow valves, if available, on the incoming supply tanks. Size, configuration and speed of compressors shall be selected on the basis of the maximum operational flow rate and pressure required. Electric motors shall be Class I, Division 2, Group D or equivalent. Motor enclosure shall be flameproof. Other electrical equipment shall be approved for operation in the hazardous area in which they are located. In addition to the electrical area classification, all equipment located in the open shall be weatherproof Figure 4.2.1-b: Typical reciprocating compressor package (Corken) For reference, larger reciprocating compressors intended for services in refineries and chemical plants are governed by API 618, “Reciprocating Compressors for General Refinery Services” GP 10-4-1, “Reciprocating Process Compressors; and for less severe installations,” API 11P, “Specification for Packaged Reciprocating Compressors for Oil and Gas Production Services.” Small compressors intended for LPG transfer service shall have the features listed below as a minimum: Safety in LPG Design 1. Compressors shall have proven experience in LPG at or near the conditions for which they will be installed. See GP 10-4-1 for experience requirements. 2. Reciprocating compressors may be of the lubricated (where some oil is injected into the cylinder to lubricate and seal the piston rings) or nonlubricated type. When the compressor is lubricated, some means shall be provided in the discharge to remove the excess oil from the vapor stream. Filters and/or centrifugal traps may do this. Non-lubricated compressors and compressors specially designed for LPG applications do not require oil removal facilities. PUMPS & COMPRESSORS 4-13 4.2.2 3. Some means (control) shall be provided to limit the suction pressure to the maximum for which the compressor is designed, otherwise, the driver will be overloaded. In addition, compressors shall have at least one high pressure cut-off switch on the discharge side or similar device to prevent excessive pressure in the delivery system. 4. The compressor shall have a high temperature alarm to signal that the pressure differential becomes too high. As an alternate, temperature indication on the discharge or differential pressure alarm may be used. As the compression ratio of a compressor increases, the discharge temperature also increases which can then damage the compressor. 5. Traditionally, most reciprocating compressors (for LPG and other hydrocarbons) have been manufactured with cast iron cylinders. In fact, current standards by API allow cast iron up to 69 bar gauge. However, if steel or ductile iron equipment can be obtained, it is the preferable material choice. Compressor Sizing Size, configuration and speed of compressors shall be selected on the basis of the maximum operational flow rates and pressures required. Compressors shall be sized within the maximum flow rating of the excess-flow valves installed on the incoming supply tanks when used for unloading shipments and on the plant's LPG tanks when used for loading shipments. When a compressor is used for transferring liquid LPG in this manner, the liquid transfer rate is less than the vapor displacement of the compressor. The compressor manufacturer shall be consulted to obtain the expected transfer rate under the plant operating conditions. Typical compressor volume flows and pressure differentials for operations in an LPG marketing terminal are as follows: Volume Differential Pressure 25–340 std m3/h 70–140 kPa 3 Table 4.2.2: Compressor Volume Flows and Pressure Differentials Flow Rate: std m /h at 15.6 °C and 101.325 kPa 4.2.2.1 Compressor Installation Requirements Compressors shall be installed in a freely ventilated location. The compressor shall be securely mounted on a suitable foundation or base plate in accordance with the compressor manufacturer’s recommendations. The compressor casing shall not be subjected to excessive strains transmitted to it by the suction and discharge piping. Compressor piping shall be suitably braced to minimize vibration Properly sized knock out pots, fabricated to appropriate pressure vessel code, shall be installed on the inlet of the compressor to prevent liquid from entering the compressor. On each knock out drum, a high level shutdown system is required so that if too much liquid accumulates in the drum, the compressor will automatically shutdown before liquid carry over to the compressor occurs. Check valve shall be installed on the discharge side of all centrifugal compressors. Strainers shall be installed on the suction piping. The strainer element shall be designed and installed so that it can be serviced. The compressor shall be provided with the following operational and safety features: 4-14 PUMPS & COMPRESSORS Safety in LPG Design 1. A local start-stop pushbutton shall be installed in the vicinity of the compressor. 2. A remote Emergency Shutdown (ESS) pushbutton shall be provided in a safe location in case the local start-stop pushbutton is not accessible because of fire or vapor cloud. Compressor shall be interlock to stop when any Emergency Shutdown System (ESS) pushbutton is activated if such a system is provided. Figure 4.2.2: Knock-out drums (liquid traps) Positive displacement compressors shall be equipped with suction and discharge shutoff valves. A blowdown valve which relieves the trapped pressure when the compressor is shut down shall be provided. Automatic blowdown valve is acceptable. Each positive displacement compressor shall be equipped with a pressure-relieving device on the discharge side discharging to a safe location. Following are installation requirements for compressors in LPG bulk plant service: Safety in LPG Design 1. Compressors shall not be positioned underneath LPG tanks. They shall be located outside LPG drainage and impound areas and in accordance with the spacing requirements defined in the section of this guide entitled “Equipment Spacing to Maximize Separation” in Chapter 2. 2. The compressor shall be bolted and grouted to a substantial concrete foundation in accordance with compressor manufacturer's recommendations. Often the compressor and auxiliary equipment are supplied on a steel frame, which is then bolted and grouted to the foundation. The proper procedures to mount, level, install and shim the compressor can be found in the API 686 “Recommended Practices for Machinery Installation and Installation Design.” Pipework to the compressor shall be fitted and supported in accordance with the manufacturer's recommendations so as not to subject compressor components to excessive stress. 3. On the suction side of the compressor appropriate means shall be provided to prevent liquid phase of LPG from entering the compressor. PUMPS & COMPRESSORS 4-15 This is typically done by installing a suction knock out drum (liquid trap) with a high level shut down to stop the compressor driver. Traps shall be fabricated to an approved pressure vessel code and in addition, equipped with an independent liquid level alarm switch and a liquid drain connection. For small compressors a knock out drum with a float to close the inlet line to the compressor may be provided. When the inlet valve is closed the compressor should trip, e.g. on high current or low suction pressure, prior to pulling vacuum. 4. 5. 6. 7. 4-16 Reciprocating compressors, since they are positive displacement machines, require a pressure relief valve on the discharge line. There shall be no valves in the line between the compressor outlet and relief valve. The pressure relief valve shall be sized for the maximum flow of the compressor. The valve may be routed to an appropriate, safe location. Standard valving on the inlet and outlet of a compressor is as follows: + Remote and automatic shutdown valve at the tank inlet and outlet. + Manual block valve at the compressor suction. + Manual block valve at the compressor discharge. + A valved connection on the discharge for a pressure gauge. This connection shall be two plane gusseted and seal welded in accordance with GP 3-18-1. + An optional four way valve to automatically reverse the suction and discharge when the compressor is to be used for both loading and unloading. Suction and discharge piping shall be fabricated so that they exert minimum stress on the compressor. Guidelines for piping fit up can be found in GP 3-19-1. Incorporation of one or two horizontal ninety degree bends near the compressor may provide adequate flexibility but a piping stress analysis will reveal any significant problems. Suction piping shall also be designed without low points and pockets to trap liquids. For reference, GP 3-3-4 provides requirements for reciprocating compressor suction and discharge piping. Pipework for the transfer of liquid LPG shall be sized so the overall pressure drop in the system does not result in excessive condensation. Experience in typical LPG installations indicates that this pressure drop is generally not in excess of 200 kPa. Install suction and discharge lines so that any condensate that may form in the piping system does not drain into the compressor. Isolating valves shall be installed on either side of the compressor to permit its removal or maintenance while minimizing the volume of LPG vented to atmosphere. In cold climates compressor suction lines in Butane service shall be specially reviewed to ensure condensed vapor cannot collect in the suction line. Sloping the line continuously back to the tank and avoiding low points may do this. PUMPS & COMPRESSORS Safety in LPG Design 5 PIPING AND VALVES 5.1 Piping in Plants This chapter discusses piping in plants. It highlights that piping shall run above ground whenever possible, clarifies choice of piping materials and briefly explains pressure and temperature ratings for piping. All metallic LPG piping shall be designed according to ASME B31.3 “Chemical Plant and Refinery Piping” and shall meet the requirements of the appropriate Global Practices (GPs) noted in this chapter. All Pipelines shall be labeled to indicate contents and function. Country language must be used. Piping arrangements for customer installations and automotive LPG can be found in the respective Chapters 10 and 11. 5.1.1 Piping Arrangements 5.1.1.1 Small LPG Plant Figure 5.1.1.1 shows a small LPG plant with a truck unloading facility and cylinder filling. This figure shows the pump installation in the plant for unloading trucks. A compressor is preferred for unloading a tank car when a flooded suction is not available or when vapor recovery from the tank car is required. The pump supplying the cylinder filling operation requires a liquid bypass line with a back-pressure regulator because of the intermittent duty of the filling operations. Internal excess-flow valves and internal back-flow check valves are preferred on horizontal LPG tanks to prevent a major release on accidental breakage of external piping or fittings. When external valves are used, they shall be installed so that any undue strain beyond their limits will not cause breakage between the tank and the valves. The liquid volume between the block valve at the unloading vehicle and the block valve of the plant must be minimized. Figure 5.1.1.1: Small LPG Plant–Truck Unloading and Cylinder Filling Using a Pump Safety in LPG Design PIPING AND VALVES 5-1 Description (A) Use self-sealing couplings and rigid steel pipe/swing joint connections to truck or tank car. (B) Equip vent line valves at unloading connections with spring-loaded actuators that must be manually held open. (C) The emergency fail-safe shutdown system that closes valves must also stop the pumps. Valves are not required at unloading point when receipt lines hold less than 0.05 m3 (50 l) of product. (D) If pump bypass is not required, valve after pump may be eliminated for short discharge lines. (E) Piping at unloading point must be securely anchored to prevent piping damage from vehicles that pull away while connected. Notes: 5.1.1.2 1. ASME tanks of 8 m3 or less capacity shall have no more than two plugged openings (typical in all installations). 2. Only liquid lines shall have thermal relief valves between all shutoff valves. Small Plant with Rail Supply A small LPG plant with truck or rail car supply and cylinder and truck filling facilities is shown in Figure: 5.1.1.2. This figure illustrates the piping arrangement required when a compressor is used for unloading tank trucks or tank cars. Although a compressor can be used for truck loading, a pump is more common because it permits loading without the use of vapor return from the truck. . The liquid volume between the block valve at the unloading vehicle and the block valve of the plant must be minimized. Figure 5.1.1.2: Small LPG Plant–Truck or Rail Supply, Compressor Unloading, Cylinder and Truck Filling 5-2 PIPING AND VALVES Safety in LPG Design Description (A) Use self-sealing couplings and rigid steel pipe/swing joint connections to truck or tank car. (B) Equip vent line valves at unloading connections with spring-loaded actuators that must be manually held open. (C) The emergency fail-safe shutdown system that closes valves must also stop the pumps and compressor. Valves are not required at loading point when receipt lines hold less than 0.05 m3 (50 l) of product. (D) Flow reversal four-way valve. Piping at loading/unloading points must be securely anchored to prevent damage from vehicles that pull away while connected. NOTE: Only liquid lines shall have thermal relief valves between all shutoff valves. 5.1.1.3 Multi-tank Installation Figure 5.1.1.3 a shows a multi-bullet installation for cylinder and truck filling. When several LPG tanks are installed to meet the storage requirements, they shall be manifolded in groups to provide operating flexibility. The maximum number of tanks allowed in any one group shall comply with the limitations as stated in NFPA 58. . The liquid volume between the block valve at the unloading vehicle and the block valve of the plant must be minimized. Figure 5.1.1.3: Multi-tank Installation Safety in LPG Design PIPING AND VALVES 5-3 Description (A) Use self-sealing couplings and rigid steel pipe/swing joint connections to truck or tank car. (B) Equip vent line valves at unloading connections with spring-loaded actuators that must be manually held open. (C) The emergency fail-safe shutdown system that closes valves must also stop the pumps. Valves are not required at loading point when receipt lines hold less than 0.05 m3 (50 l) of product. (D) Piping at loading/unloading points must be securely anchored to prevent damage from vehicles that pull away while connected. NOTE: Only liquid lines shall have thermal relief valves between all shutoff valves. 5.1.2 Piping Location Piping shall be located above ground and adequately supported and secured. Installations shall incorporate sufficient flexibility to withstand thermal expansion or contraction, movement or settling of tanks, pumps, compressors, etc. Suction lines from tanks or unloading racks to pumps shall slope continuously down from the tank outlet or rack to the pump suction. For reference also see GP 3-7-1, “Piping Layout, Flexibility and Supports.” Where piping is installed under a driveway, underground installation shall be within a conduit of sufficient size to accommodate the pipeline and the pipe shall have a protective coating. The protective coating shall be suitable to withstand corrosion and shall extend at least 150 mm beyond the ends of the conduit. Both ends of the conduit shall be open to atmosphere. 5.1.3 Piping Integrity LPG poses a higher risk than many liquid hydrocarbons because at atmospheric pressure it vaporizes readily and may develop large vapor clouds. All components of the piping system shall be able to withstand internal temperatures and pressures, plus external corrosion and mechanical stresses. They also need a high degree of fire resistance. For reference, also see GP 3-18-1 “Piping Fabrication” and GP 3-19-1 “Piping Erection and Testing.” Piping shall conform to the provisions of ASME B31.3 or other appropriate national standard. Piping shall also meet the provisions of GP 3-10-1 “Piping Selection and Design Criteria”. Although ASME B31.3 allows construction of pipelines to meet only B31.4, within the plant site any pipeline shall meet the more stringent requirements of B31.3. All welding at metallic piping shall be in accordance with the ASME Boiler and Pressure Vessel Code Section IX. Piping LPG service shall be selected from the following options: Seamless pipe meeting the requirements of ASTM A106, API 5L or approved equal. The use of non seamless pipes shall be approved by the LPG Technical Advisor. Electric fusion welded pipe (submerged arc or gas metal arc) meeting the requirements of API 5L or approved equal. Electric resistance welded pipe meeting the requirements of API 5L and the following supplementary limitations and/or requirements: 5-4 PIPING AND VALVES Safety in LPG Design 1. Grade A25 shall not be used. 2. Minimum pipe size shall be 19 mm. 3. If the percent carbon exceeds 0.23, the Carbon Equivalent (per API 5L) shall not exceed 0.43%. 4. Pipe shall be normalized and tempered. 5. The pipe mill shall be audited or shall provide quality control data that is acceptable to the owner’s engineer. Note: Upstream allows only seamless pipe in all applications, including LPG. Pressure, psig Carbon steel and Stainless steel are satisfactory for LPG piping components; but cast iron, wrought iron, brass and copper shall not be used. Aluminum has limited application for refrigerated LPG in low pressure services. 800 700 600 500 400 300 200 100 0 class 300 # class 150 # -50 0 50 100 150 200 250 300 350 400 Temperature, C Figure 5.1.4: Graph of Pressure Limits Vs Temperature for A106 Carbon Steel 5.1.4 Pressure Ratings It is suggested that all piping be designed for Propane, with a minimum working pressure of 17 bar gauge, even where only Butane or a Propane/Butane mixture is expected to be handled. This provides for flexibility if Propane operation is required at a later date. This requires a minimum flange rating of ASME Class 150. For piping within a plant, minimum wall thickness is as follows: 50 mm and smaller: above 50 mm: Schd. 80 (Extra strong) Schd. 40 (Standard) Higher flange and pipe ratings may be required for piping connected to high pressure sources, such as reciprocating pumps or cross-country pipelines. In such cases, unless a pressure relief valve sufficient in size to relieve the maximum flow from the supply source provides protection, the rating shall be at least equal to that of the supply piping. Where fluid surges may occur due to rapid valve closing, pump starting etc., a surge analysis shall be performed. 5.1.5 Pipe Sizing Piping system shall be designed to meet the highest operating pressure at the expected operating temperature. Pipe sizing for lines shorter than 30 m can usually be determined by the sizes of connections on transfer pumps and compressors. There is little economic incentive for minimizing diameter at these sizes. Safety in LPG Design PIPING AND VALVES 5-5 Pressure drop (Friction Loss) calculations are needed for longer lines, where pump or compressor suction conditions are suspected to be marginal, and where flow from several sources joins in a manifold. The designer shall refer to Design Practices Section XIV for liquid and vapor flow, and Section XV-C for pressure relief valve inlet and discharge lines. Some valve and fitting manufacturers also publish guides for fluid flow calculations. Examples of situations where pressure drop shall be calculated include: 1. Pump suction lines (including internal isolation valve, when present). Where a line size larger than the pump connection is found to be necessary, an eccentric reducer shall be installed, flat side up to prevent collection of vapor in the suction line. 2. Lines containing excess flow valves, to assure that cumulative pressure drop would not limit flow in the event of a break to a rate, which prevents the excess flow device from functioning. 3. Liquid or vapor manifolds or headers. 4. Long lines, such as to or from marine piers. 5. Pressure relief valve inlet and discharge lines. 10 25 32 38 51 64 76 102 mm pipe diameter 1 152 0.1 100 1000 10000 Flow, l/min Figure 5.1.5: Pipe friction loss for Propane (for Butane multiply by 1.15) 5.1.6 Pipe Connections Threaded fittings shall be forged steel while butt-welding fittings shall be seamless steel or equivalent material. Cast iron fittings (elbows, tees, couplings, unions, flanges, and plugs) shall not be used. Pipe joints in steel shall be screwed or welded. Following are requirements for joints and connections used for piping in bulk storage: 1. 5-6 Threaded and socket welded joints are limited to pipe sizes 50 mm and smaller per GP 3-10-1. (Note: Upstream allows threaded and socket welded joints only up to 37 mm). Larger piping can be butt welded or flanged; welded joints shall be used whenever possible, and flanged or threaded PIPING AND VALVES Safety in LPG Design joints shall be minimized. shall not be used. Packed-sleeve and resilient-sealed couplings 2. Flanges shall be weld neck, raised face, per ASME B16.5 or equivalent. Gaskets shall be the self-centering or confined type. Stud bolts shall be used, threaded full length with continuous threads. Flanges, gaskets, bolting and fittings shall meet the requirements of GP 3-16-1, except that slip-on flanges shall not be used for LPG. 3. Pipe bends may be used instead of welding elbows. The centerline bend radius shall be at least 3 times nominal pipe diameter. Bends shall meet the requirements of GP 3-18-1. 4. Flexible bellows type connectors are more vulnerable to mechanical damage than steel pipe and are very difficult to inspect. Therefore, all efforts shall be made to avoid installation of flexible bellows connections. In most situations, multiple welded bends can provide required flexibility without loss of structural integrity. Where flexible connectors (bellows) are used, they shall be stainless steel Type 321 or 316L, with the flexible inner hose covered by a braided wire jacket. Working pressure shall be at least 17.25 bar gauge and burst pressure no less than 69 bar gauge. The connector shall be fabricated as a unit with end fittings for attachment to the piping system. If the connections are flanged, one end shall have a floating flange to avoid twisting. Overall length of a flexible connector shall not exceed 1 m; this is sufficient for an offset up to 50 mm. This type of flexible connector shall not be used in locations where it can come in contact with water, which contains Chlorides. 5. Gaskets shall be suitable to protect against leakage during fire. See GP 3-16-1, “Flanges, Gaskets, Bolting, and Fittings” for specific details. Pipe unions shall not be used except on cylinder filling carrousels, pump seal connections or similar connections that need dismantling for maintenance and which can be reliably blocked off. Unions shall be of forged steel with a working pressure of at least 207 bar gauge, and shall have ground metal-to-metal seats. Gasket unions shall not be used. The designer may consider upgrading to stainless bolts on carbon steel flanges at locations with severely corrosive atmospheres. This will limit the spread of corrosion into the flange itself. 5.1.7 Small Piping Connections Piping 50 mm and smaller has less mechanical strength than larger sizes, and less wall thickness to withstand external corrosion, so additional reinforcement of connections is needed. Safety in LPG Design 1. Branch connection 50 mm and smaller shall meet the requirements of GP 3-18-1. 2. Threaded connections shall be seal welded in accordance with GP 3-18-1. 3. In addition, small connections in vibrating service and where vulnerable to mechanical damage shall be gussetted as required by GP 3-18-1. 4. An emergency block valve (manual) shall be installed in each small piping take-off connection (instrument lines etc.), located as close to the tank or line as possible, with no elbows between the connection and valve. Connections to piping shall be 13 mm or larger. Connections to the bottom of tanks shall be minimized. Tubing downstream of the emergency block valve shall be stainless steel, and in accordance with GP 3-6-1. 5. Liquid drawoff piping (sampling piping) leading to the atmosphere, or to an open tank, shall be double valved if the tank contains stocks which can autorefrigerate. The valve next to the shell shall be a quick action type, such as a PIPING AND VALVES 5-7 metal-seated plug valve. The second valve, for flow control, shall be of a type suitable for partially open operation. 6. 5.1.8 Water drawoff piping shall discharge at a point not less than 4.5 m from the peripheral boundary of the LPG tank. The discharge shall be so located that any flammable spillage will drain away from the tank. Installation All metallic LPG piping shall be installed in accordance with ASME B31.3. All welding of metallic piping shall be in accordance with ASME Boiler & Pressure Vessel Code, Section IX. Aboveground piping shall be supported and protected against physical damage. To prevent corrosion under supported un-insulated pipes, pipe supports and pipe sleepers shall be designed with steel standoffs (19 mm diameter minimum), such as steel rods welded to the top of support to raise the pipes above possible water/liquid pool that may encourage corrosion (Figure 5.1.8). Underground piping shall be avoided, however, when there is no other alternative and piping is beneath driveways, roads, or streets, possible damage by vehicles shall be taken into account. Underground metallic piping shall be protected against corrosion as warranted by soil conditions. Depending on conditions and risk involved some country/clusters have chosen to install double wall stainless steel flexible piping with leak detection. LPG piping shall not be used as a grounding electrode. LPG piping that crosses an open drain where it may contain flammable product (spill in a fuels terminal) shall be protected or fireproofed against any flash fire. Interconnecting piping between tanks and tanks accessories shall be installed to permit flexibility (possible vertical and horizontal movement) due to tanks foundation settlement and tanks expansion. Flexible connectors between tanks and piping system are prohibited, however, they are permitted where local codes require them for earthquake protection. Figure 5.1.8: Typical pipe sleeper with steel rod standoff Metallic pipe joints shall be threaded, flanged or welded using pipe and fittings. When joints are threaded or threaded and back welded the following applies: 5-8 1. For LPG at pressures in excess of 865 kPa or for LPG liquid the pipe and nipples shall be schedule 80. 2. For LPG vapor at pressures of 865 kPa or less, the pipe and nipples shall be schedule 40 or heavier. PIPING AND VALVES Safety in LPG Design The fittings or flanges shall be suitable for the service for which they are to be used. Gaskets used to retain LPG in flanged connections in piping shall be made of metal or other suitable material confined in metal having melting point over 816 °C. The outlet of a differential pressure valve in a pumping system shall be piped back to the pump suction line at a point at least 5 m ahead of pump suction. All drain sets or isolation leading directly to atmosphere shall be double block using one ball and one globe valve. The globe valve shall be located at the end closer to the atmosphere. The minimum distance between the valves shall be 600 mm. All drains and vents shall be closed and capped or plugged when not in use. After assembly, piping systems (including hoses) shall be tested and proven free of leaks at not less than 1.3 times the design pressure or maximum operating pressure whichever is higher. The results of the tests shall be documented. LPG leak tests shall never be made with an open flame. 5.2 Valves in Piping 5.2.1 Valve Integrity All pressure containing metal parts of valves in plants or terminals shall be manufactured in forged or cast carbon steel or stainless steel. All materials use, including valve seat discs, packing, seals, and diaphragms, shall be resistant to the action of LPG under service conditions. Soft-seated valves shall meet API-607 conditions as “fire-safe.” Cast iron or brass valves shall not be used, with the exception that that valves and instruments on LPG cylinders and containers (small tanks) may be made of brass. For reference also see GP 3-12-1 “Valve Selection Criteria.” The following valve types shall be provided in accordance with API STD 2510. Valve used at pressure higher than LPG tank pressure shall be suitable for working pressure of at least 4,830 kPa. Valves to be used with liquid LPG, or with vapor LPG at pressures in excess of 865 kPa, shall be suitable for a working pressure of at least 1,725 kPa. Shut-off valves in LPG service shall provide positive bubble-tight shutoff. To accomplish this, it is usually necessary to employ resilient seating materials. However, resilient materials are inherently susceptible to damage during a fire. All resilient seated valves, other than modified API STD 600 and API STD 602 gate valves shall meet the 30 minutes fire test specified in API STD 607 or equivalent standard. Ball valves with double-sealing feature shall be used. Valve bodies shall be forged or cast carbon steel. Gate and globe valves shall be made to API valve standards or equivalent. 5.2.2 Shutoff Valves The shutoff valve considered most dependable in LPG service is the valve manufactured by the Orbit Valve Company. If a quick-operating valve is needed, the Maxon-Okadee and Everlasting metal-to-metal seated disk valves are acceptable. Other suitable shutoff valves are Stockham Wedgeplug (with a resilient insert in the plug), General Twin Seal, fire-safe ball valves by Neles-Jamesbury and McCanna, firesafe butterfly valves by Neles-Jamesbury, McCanna, Posi-Seal and Flowseal. Ball valves with a double-sealing feature are recommended for LPG service. This feature provides a leakproof shutoff when pressure is applied in either direction. The type of ball valves that effect positive shutoff in only one direction are not suitable. Safety in LPG Design PIPING AND VALVES 5-9 Gate and globe valves shall be made to API valve standards. Most NPS 3 (NPS = Nominal Pipe Size, inches) and larger gate and globe valves shall be purchased to include resilient seating materials in the disk or gate, thereby providing tight shutoff. 5.2.3 Backflow Check Valves Backflow check valves perform an extremely important safety function in tank openings and in pipelines intended for flow in one direction only. All filling or liquid-return tank connections designed for flow into the tank only shall be fitted with backflow check valves. Some of these valves are for tank installation only; others can be used either in tanks or in pipelines. The type most commonly used in larger transfer piping is the swing check, which has relatively little pressure drop. Poppet, lift, and ball type check valves in smaller sizes are used for truck, customer tank, and cylinder filling applications. They are smaller and less expensive, but have more pressure drop. Valves shall meet the requirements of GP 3-14-2. Backflow check valves are required in discharge lines of pumps and compressors. The check valves shall be installed with a positive shut off valve immediately adjacent to the anchor point and on the plant side of the anchor point. They are also recommended in dedicated loading or unloading lines for vapor and liquid, especially in piping from marine berths to shore tankage, where piping is designed for flow only in one direction. In marine applications, check valves shall be positioned in such that they will not present problems when the Cargo Transfer Equipment is being de-pressurized under normal operating conditions. Soft-seated check valves have the advantage of a relatively tight shutoff, and would minimize release of product in case of a hose or connection failure. Figure 5.2.3: Double back check valve and swing check valve Backflow check valves restrict flow but may not provide positive shutoff. Emergency Block Valves are required if it is necessary to stop flow reliably. For maintenance purposes blinds shall be provided for leak tight shutoff. 5.2.4 Thermal Relief Valves Thermal relief valves (hydrostatic relief valves) are designed for installation in any portion of a piping system, or in any equipment in which liquid may become entrapped by shutoff valves at both ends, become heated, expand and develop overpressure. The liquid expansion factor of LPG is twelve times higher than that of water and twice that of gasoline. To protect piping, the set pressure shall be no higher than the lower of 120% of the piping design pressure or system test pressure. This takes advantage of ASME exclusion for thermal relief valves, which protect only blocked in piping. Thermal relief valves are attached directly to piping and manifolds and may be exposed to mechanical damage. Their location shall therefore be carefully selected and adequate 5-10 PIPING AND VALVES Safety in LPG Design protection shall be provided where necessary. The thermal relief valves shall be installed as close as possible to the piping being protected. The piping connection shall be 19 mm along with a quarter turn 19 mm Car Sealed Open (CSO) valve. This will permit maintenance of the PRV without taking the piping system out of service. Where permitted, the discharge of the thermal relief valves may be directed to atmosphere but shall be covered by a plastic cap to prevent ingress of rain. Discharge shall be directed so that it does not impinge on adjacent pipework or equipment. When the discharge of a thermal relief valve goes to atmosphere and might cause a hazardous condition, the vent outlet may be fitted with pipe, extended to a safe area and sized so that the free vent area of the valve is not reduced. The vent outlet shall be at least 15 m away from all fired equipment. A daily walk-by tightness check by the operator is recommended. At marketing terminals, odorized LPG is likely to aid in leak detection during this inspection. Internal valves specified for LPG tanks will relieve pressure from thermal expansion in the attached line into the tank. If the auxiliary manual shutoff valve downstream of the internal tank valve is Car Sealed Open (CSO) in normal operation, lines connecting directly with an internal valve do not require a thermal expansion relief valve. It is recommended to test or replace PRVs in thermal relief service within a 5 year interval. 5.2.5 Emergency Block Valves for Piping For automatic shutoff design of the Emergency Block Valves (EBV), the actuating system shall close valves upon failure of any system component (i.e. also known as failclose FC) Emergency Block Valves, described in Chapter 3, are provided at strategic locations to stop LPG flow to potential downstream emergencies. EBV's in Marketing plants are required for the following services: 1. Tank connections. 2. Transfer Points. 3. Rotating Equipment. 4. Cylinder Filling Shed. The preferred choice for automated Emergency Block Valves in Marketing plants are spring actuated quarter turn ball valves with electric, hydraulic or pneumatic spring release as described under “Emergency Block Valves on Bulk LPG Tanks” in Chapter 3. 5.2.6 Valve Packings The valve stem packings used in LPG service shall be capable of meeting the following requirements: 5.2.6.1 1. Minimize LPG emissions to the atmosphere during normal operations for environmental and safety (fire) reasons, and 2. Be fire-safe, especially when used in block valves, to hinder LPG escaping from the valve stem during a fire. Block Valve Packings Global Practice GP 3-12-8 specifies the packing systems that shall be used in block valves to meet the above requirements. For LPG service all-graphite ring packings (Type 1) shall be used. The individual packing rings, that will perform the sealing function, shall consist of flexible graphite with 1120 kg/m3 nominal density ( Style B2). Safety in LPG Design PIPING AND VALVES 5-11 The end wiper rings shall consist of interlaced braided graphite filament or solid 1600 kg/m3 minimum density compound carbon rings (Style A). Graphite die-formed rings, braided rings, and bushings shall have a minimum carbon content of 95%. Bushings shall be used only to take up excess packing chamber depth. The packing rings shall have an active zinc, or a passive barium molybdate, or a passive phosphorus based corrosion inhibitor. Separate zinc washers between packing rings shall not be used. Five-ring packing sets shall be used on API 600 and ASME B16.34 gate valves and other rising stem valves. Four-ring packings shall be used with API 602 valves and on all quarter turn valves (ball, plug and butterfly types) except that for quarter turn valves NPS 1 and smaller, the wiper rings may be eliminated. Live-loaded glands (using disk or coil springs installed on the gland stud bolts, on the gland itself, or in the stuffing box) are not recommended. Stuffing box clearances, procedures for environmental emissions testing of the valves, and other block valve packing information may be found in GP 3-12-8. Additional pertinent information may be found in the ERE report EE.34E.93 “Low Emission Block Valve Packing Guidelines Updated” and report EE.58E.94 “Valve Packing Fire Tests Reinforce Recommendations Not to Use All-Braided Packings.” 5.2.6.2 Control Valve Packings Graphite packing may also be used for control valves but is not necessary, since control valves do not have to be fire-safe in most cases. Graphite may result in higher stem friction, which in turn may create problems for the control valve actuator motor. This generally happens when graphite is used in a control valve that originally had an elastomer/plastic packing. In such cases, the valve stem actuator shall be tested with the graphite packing installed before the valve is placed in service. For new valves, the actuators are sized for the appropriate friction loads, so there shall not be any problems using graphite packing. Most major control valve manufacturers are providing their own proprietary packings, which have already been tested, for emissions and friction. See ERE report EE.84E.93 “New ‘Low-Emission’ Control Valve Packings Successfully Demonstrated In Plant Performance” for additional details on control valve packings. 5-12 PIPING AND VALVES Safety in LPG Design 6 PRODUCT TRANSFER 6.1 Principles of Product Transfer This section describes design requirements for equipment used to receive bulk product into an LPG plant and ship it to customers. Components of product transfer within the plant is described in Chapters: PUMPS AND COMPRESSORS as well as PIPING AND VALVES. This Chapter discusses: principles of product transfer, static electricity in loading and unloading operations, hoses in product transfer, loading and unloading for trucks, rail cars and marine vessels. Also pipeline dispatch and receipt facilities are discussed. New piping transfer systems shall be designed for Propane vapor pressure. The difference in cost, compared with Butane conditions, is not significant. However, if at a later date a Butane system would be changed to Propane service this could only be done at high cost. Unloading systems can use compressors, pumps or a combination of the two. Pump design ratings shall depend on type of product, desired pumping volume, resistance in liquid line and availability of vapor return line. When a pump alone is used, vapors cannot be recovered from shipment tanks. Vapor Pump Flow Indicator Liquid Figure 6.1-a: Pumping liquid from one tank to another In most design cases, two options are available to provide equipment for the tank filling operations, plant receiving and transport loading. 1. Safety in LPG Design Product can be pumped into the bottom of the receiving tank with vapor returned to the source tank via a vapor balance line, or PRODUCT TRANSFER 6-1 2. Product can be sprayed into the receiving tank vapor space (usually through a longitudinal perforated pipe) and depend on cooling and absorption of the vapor to accommodate the liquid volume transferred. Both methods have advantages and disadvantages: 1. Vapor balanced bottom loading can be accomplished with lower pump head pressure, and consequently, consumes less energy. It provides positive assurance that the receiving tank will not be overpressured as long as its volumetric liquid capacity is not exceeded. However, it requires a vapor balance line with valving and connection fittings and exposes the operator to making and breaking twice as many temporary connections to the transportation tank as is needed for spray filling. Another disadvantage of vapor balanced bottom loading is for custody transfer using meter. On average a quantity (2 - 3%) of vapor is returned to the delivering tank which creates stock accountability problems. 2. Spray filling makes use of the condensation of the LPG vapors and requires only a single discharge piping system, however, it usually requires a higher head transfer pump (consuming more energy) to compress the receiving tank vapor space. Due to higher pressures, loading rates are reduced compared with using a vapor return line. Depending on ambient temperature, product vapor pressure, and receiving tank pressure rating, it may be necessary to reduce the transfer rate to avoid lifting pressure relief valves on the receiving tank. It is difficult to predict precisely the results in limiting pressure. In general, the pressure increase using spray filling is approximately 25 percent of the increase caused by filling into the liquid space without vapor return. For example, if a product has a vapor pressure of approximately 1000 kPa and is filling into the liquid space without vapor return, the terminal pressure may increase by approximately 700 kPa. However, if the spray filling method is used, the terminal pressure increase would be about 175 kPa. Flow Indicator Liquid Compressor Vapor Figure 6.1-b: Transfer by displacement through compressed vapors In order to select the most desirable mode of tank filling, the designer shall consider all of the factors listed above and weigh their relative importance in each individual case. The only normal exceptions shall be: 6-2 1. Receiving from a product pipeline, where there is no place to return vapor, and spray filling into the vapor space is the only option available, and 2. Receiving into a refrigerated tank, which has an integral vapor handling system. The tank shall still be equipped with a jet mixing nozzle to avoid potentially hazardous product “rollover” when the receipt temperature is significantly above inventory temperature. PRODUCT TRANSFER Safety in LPG Design 6.1.1 Loading or Unloading with Pumps Pumping systems designed for the discharge of LPG from plant storage into another tank are closed systems with no venting to the atmosphere. 1. If the two tanks contain liquid product before pumping is started, the pressure shall be approximately the same in both tanks. 2. If there is no vapor line connection between the two tanks, the pressure in the receiving tank increases during the product transfer. 3. With an increase in pressure, some vapors in the tank change to liquid by condensation. Figure 6.1-c: Pumping with vapor balance line Figure 6.1-d: Pumping without vapor balance line Safety in LPG Design PRODUCT TRANSFER 6-3 The rate at which vapor changes to liquid is determined by the following: 1. The differential between the pump discharge pressure and the normal vapor pressure of the product. 2. The temperature of the liquid in the tank. 3. The surface area of the liquid. When the liquid enters from the top of the tank and is sprayed into the vapor space, the total surface area of the liquid is increased and less differential pressure is needed. The most important factor in the design and installation of LPG pumping transfer systems is to keep LPG from vaporizing in the suction system. 1. LPG is usually stored at the product vapor pressure and this makes product transferring more difficult. 2. When internal pressure is reduced due to product volume removal by the pump, LPG vaporizes to maintain its temperature-pressure balance. The vapor bubbles are formed at the tank wall because it is warmer and therefore bubbles at the bottom of the tank that are in close vicinity of the pump suction travel easily to the pump. In addition, vapor bubbles may be formed in the suction line due to higher velocity and lower pressure. 3. Excessive entrained vapor at the suction of the pump could eventually damage it. Design features for avoiding low pressure and vapor bubbles in pump suction systems are discussed in section “Minimizing Pump Cavitation and Vaporization” in Chapter 4. A vapor-equalizing line installed between the two tanks will greatly reduce the differential pressure requirements for the pump and, therefore, shall be used wherever possible. With such a line, the differential pressure will be the total flow resistance through the pipes and fittings of the liquid line, plus the resistance in the vapor lines. This shall not exceed 275 kPa. When the equalizing line is used, a quantity of vapor is transferred from the receiving tank during the pumping operation. 6.1.2 Loading or Unloading with Compressors Vapor compressors are often used to transfer liquid LPG by withdrawing vapor from a container being filled, increasing the pressure through the compressor and discharging the vapor into the supply tank. 1. 2. The increased pressure in the supply tank and the decreased pressure in the receiving container provide the differential pressure needed to force liquid through a pipeline from one tank to the other. The differential pressure is normally 70–140 kPa. Vapor compressors offer an advantage in that the remaining vapor can be removed after the liquid transfer has been completed. If the product is Propane, the savings can be substantial, since 900 kg of product is contained in vapor in a 38 m3 tank at a pressure of 1000 kPa. Approximately 75 percent of it is economically recoverable. 6.1.2.1 Removing Vapor To remove the vapor, the liquid line is closed and the pipe connections at the compressor are reversed, so the vapor is drawn from the supply tank and discharged into the receiving tank. This is usually accomplished automatically through a four-way valve supplied by the compressor manufacturer. As previously described, vapors will be more easily converted to liquid if the liquid surface area can be increased. This is accomplished by discharging vapors into the bottom of the receiving tank so they will 6-4 PRODUCT TRANSFER Safety in LPG Design bubble up through the liquid and get cooled to minimize pressure increase. See Figure 6.1.2.1 for an illustration of a compressor transfer with a four way valve arrangement. Figure 6.1.2.1: Transferring with a Compressor-Liquid Transfer (Top) and Vapor Recovery (Bottom) 6.1.3 Using Pumps Versus Compressors The major criteria for choosing between pumps and compressors for loading/unloading operations are as follows: Use compressors when: 1. Liquid cannot be gravity fed to an unloading pump (negative suction head). 2. Vapor recovery is required. 3. A plant has only one transfer device. Use pumps when: Safety in LPG Design 1. Flooded gravity fed suction is available. 2. Vapor recovery is not required. 3. Differential pressures above 2 bar gauge (200 kPa) are required. PRODUCT TRANSFER 6-5 4. Liquid is to be metered. 5. A lower initial the cost is desired. There are cases where a pump/compressor combination is required. This case is very common where distances between shore LPG tanks and marine LPG tankers are very long. This combination helps to reduce the total head of a tanker pumping system by eliminating the pressure drop of the return vapor line from the LPG tank to the ship. The pressure drop is eliminated from the ship's pumps by installing a compressor to do only the vapor transfer from one tank to another. This way the pumps only need enough head to overcome the pressure drop through the liquid line. 6.1.4 Static Electricity in Unloading and Loading Static electricity can be a hazard during loading/unloading procedures since, when breaking connections, a spark could lead to LPG vapor ignition and fire. Loading/unloading rack structures shall be grounded to earth from at least two points. In addition, there shall be bonds between piping and the rack supports. The objective is to keep all metal parts at the same electrical potential. Copper tape, 25 mm by 3 mm shall be used for this connection and each grounding point shall be taken to a separate electrode. One ground electrode (ground rod) example is a 16 mm diameter extensible type copper rod with a minimum length of 2.4 m. The resistance of these ground circuits shall be tested on an annual basis. All flanged connections on piping, valves, etc. can be considered to be conductive connections. In some countries an additional copper tape link across the flange is required. However, this does not increase conductivity above the flange/bolt/flange connection, in fact it creates the risk of element corrosion since copper and iron have different electrolytic potentials. In addition, copper bonding straps can also cause uneven bolt tensioning. Therefore, such copper tape connections are not recommended. For road delivery vehicles normally the grounding wire is permanently attached to the truck and for loading/unloading a spring-loaded “alligator” clamp at the end of the grounding wire shall be connected to a dedicated bare steel grounding lug at the loading rack or the customer tank respectively. It is preferred that the loading rack grounding system is permissive i.e. the loading pump will only start if the grounding connection is made and properly working. Grounding and bonding to discharge static electricity and stray currents shall be provided at the loading rack. Grounding systems composed of a Scully Biclops with Ground HOG is acceptable. Lightning protection or grounding rods shall be provided at the loading rack structure to protect personnel, piping and equipment on non-conductive foundations. All electrical installations and equipment shall conform to the provisions of NFPA 70. The area classification for the loading rack shall be Class 1 Division 2 0.9 m from point of connection of filling in all direction and up to 0.45 m above ground within 3.3 m radius from point of connection. The electrical fittings shall be explosion proof. In addition to the electrical area classification, all equipment located in the open shall be weatherproof. The electrical and instrumentation of the weighing bridge shall comply with area classification of the installed area. If installed at loading and unloading rack, the area classification shall be of Class 1 Division 2. 6.1.5 Hard Arms A hard arm (also flexible arm, rigid steel pipe with swivel joints) is required to connect a rail car or tank truck to the plant storage system. Hard arms are preferred to hoses for this service. When a dry break connector is used, the bleeder vent is unnecessary for daily operations but shall be installed for maintenance purposes. For sizes 50 mm and larger, rigid steel pipe with swivel joints and counterbalances are recommended. When 6-6 PRODUCT TRANSFER Safety in LPG Design self-sealing couplings or valves are mounted on the end of loading arms, the loading arm manufacturer shall provide for this added weight in the counterbalance design in compliance with the requirements of NFPA 77. Hard arm connections shall withstand a test pressure of 1.5 times the design pressure of the system. Hard arms shall be designed and fabricated from materials compatible with LPG, both liquid and vapor form. They shall also have adequate strength and durability to withstand the pressures, stress, and exposures to which they may be subjected and shall be designed to maintain sound mechanical and structural integrity. They shall be supported in such a manner as to prevent personnel injury and prevent damages or excessive wear. When hard arms are attached to the piping, the end of the piping shall be secured to a concrete anchor or equivalent device capable of withstanding any forces that may be applied by the movement of a vehicle while the arm is attached. The anchor for the above application shall be capable of withstanding at least twice the maximum load that could be applied by the arms singly or in combination. A designated weak joint (breakaway) shall be built into the piping system to ensure that break-off is at a planned location if a vehicle pulls away while connected. Self-sealing dry break couplings shall be provided to prevent uncontrolled discharge of LPG to the surrounding. The piping upstream of the anchor shall have sufficient flexibility to permit adequate thermal movement. Thermal relief valves shall be installed to protect against liquid expansion pressure buildup in the hard arms. Figure 6.1.5: LPG truck loading through hard arm Provision shall be provided to depressurize the loading arm to a safe location after loading or unloading is completed. In some installations the contents of the liquid line can be shifted into the vapor system or blowdown system. However, if this is not possible, the amount of liquid to be vented to atmosphere must be kept to an absolute minimum. This can be achieved by either using dry break couplings (see below) or by installing block valves at the transfer point as close as possible to each other. The liquid and vapor contained between the block valves shall be vented into a vertical pipe into the atmosphere. This pipe may be installed at the truck or at the plant. Vent pipes (5 mm) at trucks are typically installed at the truck nozzle and end at a point above the Safety in LPG Design PRODUCT TRANSFER 6-7 tank. Vent pipes at plants may be larger and usually end at higher elevation in an open area. The vent exit point shall not be in the vicinity of air intakes or fired equipment. 6.1.6 Hoses in Product Transfer Hoses shall be used where no other method of product transfer is practical, such as on hose reels on small bulk delivery trucks. Hoses shall comply with applicable standards (BS 4089 Hose Standards NFPA77), be designed and certified specifically for LPG (in liquid and vapor phase) and the materials used in fabrication shall also be certified resistant to the action of LPG and shall be corrosion resistant. Hoses shall be marked “LPG” at intervals no more than 3 m. Hoses designed to BS 4089 shall have a maximum working pressure of 25 bar gauge and a minimum burst pressure of 100 bar gauge. (Hoses certified to comply with IMO code will have a maximum working pressure of 20 bar gauge and a minimum burst pressure of 100 bar gauge.) Hoses shall be hydro-tested to 1.5 times maximum working pressure. Hose connections and stainless steel hose reinforcement shall be electrically continuous. Wire braid used for reinforcement shall be made from corrosion resistant material such as stainless steel. Reinforcing wire within LPG loading hoses shall be in electrical contact with the end couplings on the hoses to minimize the risk of an electrostatic charge collecting on an electrically isolated wire within the hoses or on the exterior of the hoses. Intermediate joints or couplings in a nonconductive hose shall not be permitted because they can accumulate a charge sufficiently great to spark to an adjacent conductive object. A shutoff valve at the discharge end of the hose shall be provided to minimize vapor escape when the hose is disconnected after product transfer. When not in use, hoses shall be placed on reels or in trays designed to prevent any kinking, torsion etc. to prevent any physical damage. Particular attention shall be given to potentially damaging ice formation on the corrugations of metallic hose. When hoses are used for unloading, bleeder vent valves (connected to a vent stack) are required to depressurize the hoses when they are not in use. Hoses can be equipped with Acme screw thread (or equivalent) fittings and capped with a relieving device that will release any pressure in the hose before threads are disengaged. This relieving device is typically vented to atmosphere away from the person loading the tank. Plants using hoses shall keep a Hose Tracking Program in place. Following are the requirements that should be part of a Hose Tracking Program. 1. There shall be a list showing all hoses used in the plant. The information on each hose shall contain: unique hose number, purchase date, quality certificate, testing conditions, testing schedule, last test date, re-test date, expected hose retirement date. 2. A unique hose number, the last pressure test date and re-test date, shall identify each individual hose in the field. This is to facilitate control. 3. Operators shall receive training that informs them how to prevent and to detect hose damage. More information on hoses used for marine services can be found under “Marine Cargo Dock Hose.” later in this chapter. The design criteria for hoses and connections used for transferring LPG liquid or vapor service at pressures in excess of 35 kPa shall be the following. Truck Loading/Unloading Hoses shall be designed as follows: Working pressure of 2,032 kPa and a Bursting pressure of 10,160 kPa. Hose assemblies shall be designed to withstand a pressure not less than twice the working pressure, 4,830 kPa. Unloading facilities should be designed such that the liquid in a hose can be drained into the vapor system. Liquid contents of hoses shall not be vented to atmosphere. If hoses cannot be drained, they may be kept under liquid, blocked off at both sides with a 6-8 PRODUCT TRANSFER Safety in LPG Design Thermal Relief Valve at one end to protect the hose against excess pressure. The set pressure of the TRV shall be in accordance with the hose manufacturer’s specifications. Venting of the liquid at the transfer point (between truck and hose block valve) shall be performed as described in the previous section “Hard Arms.” The hose length shall be kept as short as possible. Hoses shall be supported in such a manner as to prevent personnel injury and prevent damages or excessive wear. When hoses are attached to the piping, the end of the piping shall be secured to a concrete anchor or equivalent device capable of withstanding any forces that may be applied by the movement of a vehicle while the hose is attached. The anchor for the above application shall be capable of withstanding at least twice the maximum load that could be applied by the arms or hoses singly or in combination. A designated weak point (break-away) shall be built into the piping system to ensure that break-off is at a planned location if a vehicle pulls away while connected. A self-sealing dry break connector shall be provided to prevent uncontrolled discharge of LPG. The piping upstream of the anchor shall have sufficient flexibility to permit adequate thermal movement. Figure 6.1.6: In case of rupture “Smart Hose” is automatically closed at both ends. A recent development in hose technology is the “Smart Hose.” by Smart Hose Technologies. This hose has considerable safety features included in its design. SmartHose will automatically close at both ends if the hose ruptures or if the truck drives away without uncoupling the hose. Valve plungers, wedges or flappers installed at both ends of the hose, accomplish closure. During normal operation they are kept open by a coated cable incorporated Safety in LPG Design PRODUCT TRANSFER 6-9 within the hose bore. This cable acts as a compression spring providing thrust in the direction of both ends of the hose, holding the valves open. Should this thrust be eliminated due to coupling ejection, hose stretching or hose separation, the valves are released and instantly seat, stopping flow in both directions. 6.2 Loading and Unloading 6.2.1 Truck Loading and Unloading This section of minimum standards covers the truck loading and unloading facilities within ExxonMobil’s fence at a terminal. The quantity of shipments may be determined by the weight of the shipping vehicle or by liquid level readings on both shipping and terminal LPG tanks before and after product transfer. Meters are not normally installed in loading or unloading systems. Truck Internal EBVs Truck ESS Truck ESS Break Away Couplings EBV's Operated by Plant Emergency Shutdown System (ESS) Electrostatic Bonding Cable EBV LOCAL EMERGENCY PUSH BUTTON EBV Figure 6.2.1-a: Mini-bulk truck loading The loading rack shall be designed such that when the truck is parked for unloading or loading, it shall be able to move away from loading rack to a safe location in an emergency without backing up. The loading rack should not be located in an area directly along the longitudinal axis of the horizontal LPG bullets. The loading rack shall have a concreted paved mat. The concrete mat shall be designed so that the entire truck will be within the mat during loading and unloading. The concrete mat shall be pitched so that spills will run to LPG trap. The loading/unloading equipment and support structures in the loading rack shall be protected with guard rails or stanchions to prevent damage from vehicles. Emergency shutdown pushbuttons to activate the Emergency Shutdown System shall be installed at an easily accessible area at the loading rack and at a safe remote location at least 15 m from any hazard. This maybe the pushbutton at the filling plant or other. The emergency shutdown pushbutton shall activate an audible alarm of at least 100 Db installed at the loading rack and to shut the flow of LPG. The structure shall be designed to provide structural support for loading equipment and lighting. The structure shall also provide weather protection for the driver, product and 6-10 PRODUCT TRANSFER Safety in LPG Design equipment. The structure shall not have any sides or any restrictions that will inhibit ventilation through the structure. All structural materials installed shall be of noncombustible material. The structure shall have lighting suitable for daytime and nighttime operation. Lighting shall be an minimum of 100 lux measured at the loading connection. Lighting enclosure shall be flameproof type. Figure 6.2.1-b: Principle of the breakaway coupling (Alpha Process Control) Figure 6.2.1-c: Drybreak coupling (Alpha Process Control) The unloading systems can use compressors or pumps or a combination of both. Compressors and pumps shall comply with the requirements in Chapter 4. The fixed piping shall be constructed of steel. No other material is acceptable. Vapor return lines shall have check-valves installed to prevent backflow. When flexible arms or hoses are attached to the piping, the end of the piping shall be secured to a concrete anchor or equivalent device capable of withstanding any forces that may be applied by movement of a vehicle while the arm or hose is attached. The anchor shall be capable of withstanding at least twice the maximum load that could be applied by the arms or hoses singly or in combination. A designated weak point shall be built into the piping system to ensure that break-off is at a planned location if a vehicle Safety in LPG Design PRODUCT TRANSFER 6-11 pulls away while connected. The piping upstream of the anchor shall have sufficient flexibility to permit adequate thermal movement. New or revamped truck loading and unloading points shall be equipped with swivel hard arms and break-away connections for liquid and vapor return lines. It is highly important to install these couplings exactly as prescribed by the manufacturer. If, after installation, the pull-away force cannot be applied as intended, the coupling may not work. In special cases where a variety of customer trucks are loaded, the additional use of hoses may be necessary to accommodate the diversity of connection points. Hard arm material shall be Schedule 80 Seamless Steel - ASTM Specification A-106, Grade B. Figure 6.2.1.1-a: Rotary gauge dial The liquid lines shall be equipped with dry break couplings. Vapor and liquid lines shall be equipped with automatic, fail safe (thermal/fire actuation) emergency block valves (EBV), and a local as well as a remote (accessible during emergency) actuation system to activate the emergency shutdown. The EBV shall be installed in the transfer pipe within 6 meters of the hose connection or loading arm, per NFPA 58. Furthermore, there shall be an interlock system, which can prevent the truck from being moved while hard arms (or hoses in older plants) are still connected. The piping system shall be designed to accommodate maximum forces originating from a truck drive-away rupturing the break-away connections. If this cannot be achieved, a bulkhead with an adequate foundation shall be installed which shall be designed to withstand 65 kN. If the EBV is located at the rack it shall fail safe under fire conditions. Actuation of the valves may be automatic by fusible element, which melts at 120 °C and is 1.5 m at maximum away from the loading connection. In addition to the EBV a manual quarter turn valve shall be provided at the connection between the piping and the hard arm. The loading rack area shall be protected against accidental crash by trucks. An electrostatic grounding (earthing) point shall be provided at each loading and unloading location. A permissive grounding (earthing) system is preferred for road vehicles at each loading rack. This shall ensure that the loading pump shall only work as long as the grounding contact is intact. 6-12 PRODUCT TRANSFER Safety in LPG Design Locations that use hoses instead of hard arms for product transfer will also need the items discussed above. If no dry break couplings are provided, a purging system and good natural ventilation shall be present. Normally unloading of trucks is achieved by using their own pumps. A pump in the plant could also unload trucks if the requirements for Net Positive Suction Head (see NPSH in Chapter 4) for the particular pump can be satisfied. This may be the case if the truck can be placed close to and elevated above the pump in question. Figure 6.2.1.1-b: Rotary gauge tube Hose connections for bulk transfer shall be designed such that they can be emptied of liquid after loading. They may be left under vapor phase. Hoses on reels of mini-bulk trucks are an exception because they are constantly connected on the truck side and therefore provided with a thermal relief valve. Hard arms maybe left under liquid, however they need thermal expansion protection. 6.2.1.1 Truck Tank Level Measurement All truck tanks shall be equipped with rotary gauges. A rotary gauge is a variable liquid level gauge consisting of a small positive shutoff valve located at the outer end of a tube, the bent inner end of which communicates with the tank interior. The tube is installed in a fitting designed so that the tube can be rotated with a pointer on the outside to indicate the relative position of the bent inlet end. The length of the tube and the configuration to which it is bent is suitable for the range of liquid levels to be gauged. By a suitable outside scale, the level in the tank at which the inner end begins to receive liquid can be determined by the pointer position on the scale at which a liquid-vapor mixture is observed to be discharged from the valve. The more modern version of this device, the “Magnetel” may also be used. 6.2.2 Rail Car Loading and Unloading Rail tank car loading racks shall be designed to meet all local regulations and shall be in accordance with railroad and industry standards. Layout shall provide optimum ease in positioning tank cars. In some countries, regulatory practices allow loading/unloading a train where all cars are coupled together. Other countries require uncoupling and keeping a minimum distance between the cars. A vertical clearance from the track of not less than 6.7 meters and a horizontal clearance from center of track to loading rack Safety in LPG Design PRODUCT TRANSFER 6-13 edge of not less than 2.6 meters shall be maintained. The loading spots shall be level and on a straight section of track. New or renovated loading racks shall be equipped with swivel hard arms for liquid and vapor connections. Hard arm material shall be Schedule 80 Seamless Steel - ASTM Specification A-106, Grade B. Liquid connections shall have an emergency release as well as dry break couplings. An alternative would be a purging system for the coupling. There shall be one fail safe, remote operated emergency block valve (EBV) in the liquid and vapor lines to the plant tanks. The EBV shall be installed in the transfer pipe within 6 meters of the hose connection or loading arm, per NFPA 58. The individual lines to each rail car shall be provided with manual shut-off valves. Rail Car ESS Rail Car EBVs Melting in Fire Adequate Grounding Through Rails Manual ESS on Both Sides Releasing when Moving LOCAL EMERGENCY PUSH BUTTON TERMINAL ESS More Rail Cars Liquid EBV Vapor EBV Figure 6.2.2: Emergency block valves in rail car unloading National codes normally require that each rail car shall be equipped with an internal shut-off valve. Ideal loading rack designs incorporate the ability to close all rail car shutoff valves from the loading rack or the plant emergency shutdown system (ESS). However, this requires a special rail car design. As a minimum the individual rail carshut-off valve shall be operable at the hard arm and also operate if accident or error moves the rail car. Push-buttons to operate the ESS shall be located at strategic points, which provide ready access to operators. Where hoses are used, valves and connections are necessary between the hose headers and a vent system to allow draining the loading hose after completing loading but before disconnecting the hose from the car. Many rail tank cars are equipped with nonconductive bearings and non-conductive wear pads located between the rail car and the chassis. As a result, the resistance from the tank car compartment to ground through the rails may not be low enough to prevent the accumulation of an electrostatic charge on the tank car body. Therefore, bonding of the tank car body to the fill system piping is necessary for protection against static accumulation. In addition, because of the possibility of stray currents and to prevent an ignition hazard as a result of such currents, loading lines shall be bonded to the rails. The two rails of the siding shall be permanently bonded to the metal loading rack. The unloading rail spur shall be insulated from the main track to guard against stray currents, which might cause a spark. Often the insulation point is at the spur entering the site as shown in Figure “Spacing in marketing LPG bulk plant with cylinder filling” in Chapter 2. 6-14 PRODUCT TRANSFER Safety in LPG Design Normally a reciprocating compressor shall be provided for unloading rail tank cars. The compressor shall be sized to provide the desired volumetric liquid unloading rate by pressurization of the rail car vapor space(s). Manifolding shall be provided to allow subsequent exhausting of LPG vapor from the car(s), discharging to the bottom of the LPG tank into the liquid. It is desirable to unload rail tank cars at such a rate that the operation can be completed by one individual during a normal working period. The unloading rate will be affected by the size of the tank car and the compressor capacity available. If unloading has to be finished in shorter time unloading pumps may be used. If a manifold system is used to unload cars simultaneously, check valves shall be installed to prevent the return of product to the rail cars. Provisions shall be made so the loading assembly can be swung to one side and held out of the way of moving tank cars when not in use. Where a rack is required it shall be of steel frame construction with nonskid metal flooring. Stairs and the main walkway shall have handrails. 6.2.3 Marine Loading and Discharge The design of marine loading and discharge facilities is specific to both the individual pier and the marine transportation unit(s) selected to serve it. A number of design issues, both general for marine berths and specific to LPG berths should be considered, such as site selection, berth layout/spacing, and berth pier and pipeline design to reduce the risk of vessel collision with loading platforms, transfer lines and berthing structures. Information on such issues is available in the Marketing Engineering Standard EE.3M.86 “Marine Facilities, Design, Specification and Evaluation” and DP XV-J “Safety in Plant Design Docks, Loading Racks and LPG Storage Facilities.” It is recommended that the designer seek assistance from ExxonMobil Research and Engineering (EMRE) for guidance in LPG marine facilities matters. An existing jetty shall be inspected and approved by EMRE for operation prior to any joint venture commitment. For a new jetty, the following surveys shall be carried out to establish the design basis: 6.2.4 1. Bathymetry – to determine water depth for navigation, channels, anchorage and maneuvering areas. 2. Tidal Range – to determine tide conditions. 3. Current – to determine current velocities and directions for surface, mid-depth and bottom current. 4. Wind – to determine wind velocities and direction for wind loading consideration. 5. Wave/Swell – for terminals at exposed locations to determine wave height, direction and period. 6. Geotechnical – to determine soil conditions, extent, thickness, strength and deformation of soil layers. 7. Earthquake – to determine seismic conditions. 8. Environmental – to establish baseline data and provide environmental impact assessment. 9. Fleet Data – to establish vessel physical dimension, mooring plans and manifold details. Data can be obtained from ExxonMobil Supply. Marine Pier Installations The jetty shall be constructed of non-combustible materials. A floating pontoon jetty is not acceptable for LPG operations. The jetty design shall be certified by EMRE Engineering or approved designated consultant. The jetty design shall include but not limited to: Safety in LPG Design PRODUCT TRANSFER 6-15 1. the ability to absorb lateral load that is expected when berthing tankers mooring. 2. corrosion protection. 3. spill containment (if jetty is used for loading/unloading multiple products). 4. vehicle access to facilitate maintenance. The jetty may be used for loading/unloading multiple products other than LPG provided it is designed and constructed for LPG operations in addition to meeting relevant ExxonMobil’s standards and specifications for loading/unloading other products. Breasting facilities are required to absorb the energy of the berthing vessel, to protect other facilities and to provide points of contact for the moored vessel. Common arrangement for tanker pier is shown in Fig 6.2.4-a which shows two free standing breasting dolphins. Number of breasting dolphins may be increased to accommodate vessels of larger sizes. Breasting dolphins should be place symmetrically about the center of the loading platform piping manifold. All berths shall be deep enough and long enough so that the tanker operated at the deepest draft shall have adequate UKC (underkeel clearance) during any stage of tide. Berthing dolphins should be well lit and marked with reflective material to provide clear target for the pilot for night berthing. The berthing operations should be reviewed to establish the number of tugs and other berthing aids (bow thrusters, berthing monitoring systems). Issues related to rapid and fail safe communications, including providing the ship with a control box to shut down shore pumps and close EBVs in the event of an emergency, should be considered. Quick release mooring hooks should be considered, so that the vessel can be removed from the berth area quickly in the event of an emergency. Mooring facilities should be arranged as symmetrically as possible about the centerline of the piping manifold. Breast line mooring points shall be located so as to: 1. 2. Provide mooring line leads as near as possible to 90 degrees to the longitudinal centerline of the vessel. As far aft and as far forward as possible. Spring line mooring points should be located to provide mooring line leads as nearly parallel as possible to the vessel’s longitudinal axis. Mooring points should be located to keep all lines at vertical angle less than 25 degrees and not more than 50 m from the vessel. Mooring structure should be arranged so that all lines in the same service are approximately the same lengths. An anemometer shall be provided to monitor wind conditions, so that cargo transfer can be shut down at pre-determined wind limits. Flammable gas detectors should be installed in the berth loading/discharge manifold area to detect product leaks and sound the alarm in the berth area as well as the control center. Corrosion protection of steel structures above elevation of at least 3 m below riverbed or seabed shall be provided. Protection may be provided by coatings, increased thickness of steel member (corrosion allowance) and cathodic protection. Dock Operations Building The structure for operator on duty, if provided, shall be located such that the operator can observe the product transfer system clearly. However, the structure shall be 15 m from the most hazardous area where ignition is mostly likely to occur. It shall also be located near a safe emergency evacuation route. Layout shall provide for structural support, operating area for transfer of product, gangway access to tanker, spring mooring lines and fire protection. Lighting in all work 6-16 PRODUCT TRANSFER Safety in LPG Design areas shall have an average illumination of 100 lux and shall be suitable for both day and night operations. Pumps are generally used for loading and unloading vessels. Loading pumps are on shore and unloading pumps are normally on the ship. Piping shall not be routed below the jetty. Loading, discharge and vapor return lines from the Marine Pier to the shore shall have two emergency block valves (EBV), one at the pier manifold and one at the shore side. These valves shall be remotely operated. The valves shall either be operable for 15 minutes in the event of a fire by fireproofing power supplies or incorporate fusible elements, which will allow closure when melted. Valves, which close automatically on loss of power (fusible elements), shall be designed to limit their closure rate as a result of power failure in order to prevent hydraulic surge. Emergency shutdown buttons shall be positioned at the manifold and at the exits to the pier. Consideration shall be given to Emergency Shutdown Buttons at the Emergency Egress locations as well. Risk assessment may be used to determine whether the pier shutdown buttons should activate the pier EBVs only or activate the entire plant emergency shutdown system. Fig 6.2.4-a: Common arrangement for tanker pier Loading Platform Electrically insulating flanges are required for stray current protection on marine loading and unloading lines for both vapor and liquid. Without insulating flanges, currents could be developed by ship or dock cathodic protection systems or by galvanic potential differences between ship and shore. Installation shall be such that the pier piping is insulated from both the on-board piping and the shore piping (the latter to maintain the separation of the pier cathodic protection system). All plant flow lines (except for the dock lines as mentioned above), shall be electrically continuous. Dock lines shall have the insulating flanges as close to the presentation as possible (i.e. for loading arms the insulation flange shall be installed at the outboard arm, behind the triple swivel and any support which comes in contact with the ship; for hose strings, one hose shall be electrically discontinuous). This will ensure electrical isolation between the vessel and the pier. An insulating flange, when new, shall have very high electrical resistance, typically over 10 million Ohms. Insulating flanges in service shall have at least 1000 Ohms resistance; a lower value means that deterioration has occurred and maintenance is needed. Electrical bonding connections (bonding wire) shall not be used between the vessel and the pier piping. Because of cathodic protection systems for the dock or ship or galvanic potential differences between ship and shore, a current may exist through the Safety in LPG Design PRODUCT TRANSFER 6-17 bonding wire, which can spark on connecting or disconnecting. In circumstances where the government authority requires bonding wires, every effort shall be made to educate the authorities about the dangers of such practice. If a bonding wire is used, the wire shall include an explosion-proof switch. Before the wire is attached to the vessel, the switch shall be in the open position. After the wire is attached to the vessel, the bonding circuit can be closed using the explosion proof switch. The procedure shall be reversed to disconnect the bonding wire. All electrical equipment shall be suitable for the electrical area hazard classification where it is installed. Normally, LPG Cargo Transfer Equipment is empty when not in use. Appropriate piping for depressurizing and venting shall be included at the pier manifold. Also, depending on the operations and vessels involved, vapor return lines may be required. Critical dock services which shall be protected against fire exposure include the following: fire mains, dry pipe foam headers, systems associated with the control and actuation of emergency block valves, quick-release hooks or other emergency facilities, and any other instrumentation or communications systems which are essential during an emergency. Insulating Flanges if Pier in Salty or Brackish Water Emergency Release System EMERGENCY PUSH BUTTON ON SHORE LOCAL EMERGENCY PUSH BUTTON TERMINAL ESS VAPOR EBV EBV LIQUID EBV EBV Figure 6.2.4 b. : Emergency block valves in marine loading and unloading As far as possible, the layout of the above systems shall provide at least 7.5 m spacing from the berth manifolds to avoid fire exposure from three dimensional fires at these locations. Sections unavoidably extending within the 7.5 m distance shall be fireproofed. The critical systems shall also be protected against spill fires burning on the water surface below the dock structure, by locating these systems above the deck or by fireproofing. An alternative method for the fire main is to install a remote operated dump valve at each extremity to establish flow in the event of fire (see GP 3-2-3). 6.2.4.1 Marine Cargo Dock Hose Marine Cargo Dock Hose shall not be used for refrigerated or partially refrigerated LPG Cargo Transfer. For pressurized LPG, the use of all steel Marine Loading Arms is recommended, however, under certain circumstances, (i.e. when the throughput rate and the volumes are small and cargo transfer is infrequent) use of Marine Cargo Dock Hose may be acceptable for existing facilities. A formal LPG Cargo Transfer Risk Assessment can be of help in determining whether use of Marine Cargo Transfer Dock Hose may be used. EMRE's memorandum on “LHG Marine Cargo Transfer Fire/Explosion Risk Assessment Procedure” (93 CMS2 010) can serve as a starting point for such an assessment. Marine Loading/Unloading Hoses shall be designed as follows: Working pressure of 2,415 kPa and a Bursting pressure of 12,075 kPa GP 3-11-1 shall be used for the purchase specification of Marine Cargo Dock Hose. The ERE report EE.76E.92 provides details on the purchase specification, inspection and retirement criteria. The report EE.40E.94 “Marine Dock Hose Technology and Practice Training Video with its companion Application Guide” is also a source of useful information regarding hose purchase specification, inspection and testing, hose handling and retirement criteria. 6-18 PRODUCT TRANSFER Safety in LPG Design Marine loading (barges) arms/hoses shall be capable of accommodating the combined effects of change in draft and tidal changes. Marine barges loading arms/hoses shall be designed and tested periodically in accordance with OCIMF, Design and Construction Specification for Marine Loading Arms and United States Coast Guard (USCG) requirements (33 CFR 156) or equivalent. Test pressure shall be 125 percent of maximum operating system pressure. Hydrostatic test shall be carried out at least once a year. Figure 6.2.3.2: Emergency release coupling in marine loading and unloading 6.2.4.2 Marine Loading Arms New or renovated facilities shall conduct cargo transfer with all steel Marine Loading Arms. Hard arm material shall be Schedule 80 Seamless Steel - ASTM Specification A106, Grade B. Terminals in pressurized LPG service which use Marine Cargo Dock Hoses shall consider upgrading to Marine Loading Arms. A formal LPG Cargo Transfer Risk Assessment can be of help in determining the need for the upgrade. EMRE's memorandum on “LHG Marine Cargo Transfer Fire/Explosion Risk Assessment Procedure” (93 CMS2 010) can serve as a starting point for such an assessment. GP 3-11-2 covers the requirements for the design of Marine Loading Arms and associated equipment (such as Quick Connect/Disconnect couplers, Accessories, Range Monitor Systems and Emergency Release Systems (ERS)). Regarding ERS, reference shall be made to EEEL ERS Guidance Note for GP 3-11-2. Emergency Release Systems (ERS) are recommended for new and existing LPG arms. An ERS consists of dual isolation valves at the ship/loading arm connection. The ERS allows for rapid, automated disconnect in the event of an emergency with little loss of product. As general guidance, circumstances where LPG transfer without an ERS may be used are as follows: 1. Safety in LPG Design Facility is a loading terminal, and PRODUCT TRANSFER 6-19 2. Arm is equipped with a range monitoring system which shuts down loading pumps and closes remote operated block valve at base of loading arm in event vessel begins to approach limits of loading arm operating envelope, and 3. Total arm contents that might be spilled in the event the arm is damaged by ship motion is less than 500 liters of LPG, and 4. Surge analysis has been conducted to ensure there is minimal risk of pipe rupture in event of emergency shutdown described in item 2 above, and 5. Probability of excessive ship motions is minimal based on historical records and average wind and current conditions at the site. Relatively infrequent marine transfers. 6. The decision whether to equip LPG Loading Arms with ERS can be made after an LPG Cargo Transfer Risk Assessment. The considerations described above are assessed in detail in EMRE's memorandum on “LHG Marine Cargo Transfer Fire/Explosion Risk Assessment Procedure” (93 CMS2 010). NOTE: Vapor cannot be evacuated from the last tank to be discharged because there is no vapor line to shore. Figure 6.2.4.3: LPG ship unloading with compressor without vapor return line to shore 6.2.4.3 Discharging System without Vapor Return If a ship is equipped with two or more tanks and compressors, it can discharge through a single line without a vapor return system. This is accomplished by selectively drawing vapor from one tank in the ship and forcing it into another, causing the discharge. As liquid is exhausted from the tank, the empty tank may then be used as a vapor source 6-20 PRODUCT TRANSFER Safety in LPG Design while a loaded tank is being discharged. The piping arrangement and successive steps in the operation are shown in the schematic flow diagram in Figure 6.2.4.3. Since there is no vapor line to the shore tanks in this system, the vapor cannot be evacuated from the last tank to be discharged. Loading Arm shall conform to OCIMF publication “Design and Construction Specification for Marine Loading Arm”. Pipelines on pier shall be adequately bonded and grounded. If excessive stray currents are encountered, insulating flanges or joints shall be used. 6.2.5 Pipeline Dispatch and Receipt The designer should consult with the pipeline company and the delivery company (refinery) to establish detailed mutual agreement on design specifications, ownership, metering and operating responsibility for the pressure reducing station located in the plant. Pressure rating of receipt manifolds, type of pressure reducing valve, overpressure protection and emergency shut-down procedures shall be established. Point of transfer of product and maintenance/inspection responsibility shall be clarified. A remote operated, fail safe emergency block valve (EBV) shall be provided at the receiving/dispatching station on incoming and outgoing pipelines. This valve shall be incorporated into the plant emergency shutdown system (ESS). In addition, it may be equipped with automatic shutdown features (fusible element). Quarter turn ball valves with hydraulic or pneumatic actuators are the preferred choice. There shall be an insulating flange to separate the plant piping from the pipeline cathodic protection system. Safety in LPG Design PRODUCT TRANSFER 6-21 7 LPG CYLINDERS 7.1 Cylinder Purchasing Specifications This section describes the Purchasing Specifications of portable LPG (small) containers usually referred to as “Cylinders” or “Bottles.” Cylinders are Loan Delivery Equipment (LDE). This means that they are purchased and owned by the LPG facility, but stay mostly with the customer for LPG consumption. They are designed to be refilled at a filling plant. Safety of LPG cylinders is important, the general public as customers is in direct contact with the cylinders. It is therefore important that LPG cylinders, together with all associated fittings and controls, e.g.; valves, gas flow pressure regulators and hoses, be manufactured to the latest internationally recognized and approved design standards and correctly specified for their intended duty. This Purchasing Specification has been produced to assist in determining that the LPG equipment purchased for market place use, meets acceptable standards of safety, integrity and reliability. Primarily, this requires special attention to internal cleanliness of cylinders and quality of elastomers/rubbers, used in valves/regulators and associated hoses, for safeguarding against LPG leaks and hazardous pressure/flow conditions. 7.1.1.1 Quality Control Systems Whatever the type of equipment, all manufacturers should be formally accredited within an internationally recognized standard for product quality control. As a minimum, this would mean EN/ISO 9001/2 or BS 5750. If candidate manufacturers are not currently accredited with these standards they should show evidence of progressing towards these standards. Manufacturers should agree to Quality Assurance Auditing of their manufacturing unit(s) and Quality Control (QC) systems, to be carried out at the discretion of the purchaser by their designated employee or agent. Whenever possible, equipment should be certified for LPG service as described in “Quality Assurance” in Chapter 1. 7.1.1.2 Manufacturing Records To ensure reliable and efficient quality control, monitoring of equipment integrity and fault tracing after delivery, manufacturers shall be required to maintain full records of raw material quality laboratory analyses, or official certification of fit for purpose, for each batch of material or component used in their cylinders. Safety in LPG Design LPG CYLINDERS 7-1 Manufacturers shall also operate a recognized quality control (QC) system, when one is not specifically required within a design or manufacturing standard. QC records shall be maintained for each batch purchase. 7.1.1.3 Post Sales Equipment Batch Rejection A significant change in purchasing policy is the introduction of a means of improving market place safety by introducing Post Sales Equipment Batch Rejection Criteria. This requires all equipment found to be faulty either before or after placing into the market place, to be immediately withdrawn and examined for cause of the fault. The main concerns being LPG leaks, hazardous gas supply pressures and or any other malfunction. As part of a purchasing agreement, manufacturers shall agree to cooperating fully with the investigation and if found to be replicated or unresolved, consideration being given to replacing the whole batch. Simply replacing faulty equipment within, or reasonably beyond, a Guarantee period is inappropriate without investigating and resolving the cause of the fault. This policy applies to valves, regulators, and hoses as well. Figure 7.1.2: Typical domestic LPG cylinder 7.1.2 Cylinder Specifications As a minimum, all cylinders in use or being processed and handled shall comply with internationally recognized design standards. Where national standards are in force, these may be used, providing they are at least equivalent to, or derived from, those standards referred to in sub-section “Manufacturing Standards and Design.” A most important requirement contained within these guidelines, which is not dealt with by any of the listed standards, is that of internal cleanliness of the cylinders, not only by removal of pressure test water, but the prevention of iron oxide and mill scale and/or its removal. See sub-section “Cylinder Heat Treatment” later in this chapter. 7-2 LPG CYLINDERS Safety in LPG Design 7.1.2.1 Manufacturing Standards and Design Cylinders shall be designed, fabricated, tested and marked (or stamped) in accordance with Department of Transportation (US DOT 4B 4BW-240), equivalent industry standards or local regulations. Although some of the standards listed below permit the use of aluminum as a cylinder construction material and brazing for fabrication, neither of these materials or joining processes are recommended nor should they be used for refillable LPG cylinders. Only steel and electric arc welding specified within these standards are recommended. Examples of appropriate standards are: 1. US Standards DOT 4B/4BW - 240. 2. International Standard ISO 4706. 3. European Standard EN 84/527. 4. British Standard BS 5045 Part 2 1989. 5. French Standard NF M88-703. 6. Malaysian Standard MS 641/642. 7. Australian Standard SAA AS B239. 8. Japanese Standard JIS B 8233. Figure 7.1.2.1: Two piece and three piece cylinders For reference, the following material specification is quoted, which is used for DOT 4BA cylinders. Carbon Silicon Manganese Phosphorus Sulfur Phosphorus and sulfur 0.22% maximum 0.45% maximum 1.60% maximum 0.04% maximum 0.04% maximum 0.07% maximum The material shall be proven to be able to withstand less than 10% of permanent stretch when undergoing hydrostatic stretch test. All parts of welded cylinder bodies and all parts welded to the body shall be made of compatible materials. The cylinder can be fabricated in 2 piece or 3 piece welded design. Figure 7.1.2.1 shows the typical drawing of a two and three pieces welded cylinder. Opening on the cylinder may be provided with a boss welded onto the cylinder. Tapered internal threads of ¾” NGT shall be provided on the boss for attachment of the cylinder accessories. In case DIN 477 Safety in LPG Design LPG CYLINDERS 7-3 thread is used there shall be clear marking on the cylinder (preferably on the bung) to distinguish from NGT threaded cylinders. If delivered without valve a lug or cap shall be provided for each cylinder to cover the opening to prevent foreign material from entering the cylinder. 7.1.2.2 Manufacturing Measurement Tolerances The size of portable cylinders shall be up to a maximum of 50 kg. The service pressure of the cylinder shall be at least 1,660 kPa based on 100% commercial Propane at temperature of 54 °C. Maximum filling limits for cylinders shall be based on local standards. In the absence of local standards, or when local standards allow a higher limit, the maximum safe quantity that can be filled into the cylinder shall be such that the cylinder will not be more than 95% liquid full at a temperature of 54 °C. All cylinder dimension tolerances shall be compatible with those of cylinder valves, filling plant equipment and handling devices. This information shall be obtained from equipment suppliers and inserted into the purchasing specifications, to suit their individual circumstances. Otherwise, serious damage and possible hazardous situations may develop within the plant. The following sub-section highlights critical dimensions, which shall be established, prior to placing orders for cylinders. Following superficial dimensions shall be fixed: 1. Overall diameter. 2. Overall height. 3. Valve bung thread. 4. Height of valve filling orifice above cylinder base. 5. Maximum angle of valve from perpendicular (0.5 degrees from top of valve bung is recommended maximum). For most refillable cylinders it is not cost effective to specify both the tare weight and the internal volume, due to slight variations in diameter, height and metal thickness. Internal volume shall be specified as it is key to preventing overfilling. The internal volume specification shall have a tolerance of +1% or less of the rated nominal cylinder water capacity. 7.1.2.3 Cylinder Attachments The design of the footring shall be stable and allow the cylinder to stand firmly on a substantially level surface without any support. The bottom of the cylinder shall have a minimum clearance of 20 mm from the ground. Design of foot-rings shall comply with the following: 7-4 1. Foot rings shall be rolled from steel having equivalent strength as the main cylinder body and be designed to protect the cylinder against impact damage if it is dropped. The top of the foot-ring shall be of castellated design to permit at least six welding lugs and to provide unrestricted air circulation for the cylinder base, through rectangular apertures for a nominal 60% of the of its overall rolled length. 2. The base of the foot ring shall be rolled to at least an internal “J” or “d” section to provide additional reinforcement and a rounded surface to minimize damage to cylinder handling and standing surfaces. A flat, sharp edged finish shall not be accepted. Six equally spaced 5 mm diameter water drain holes, shall be drilled through the bottom of the “J” section. These holes shall be angled to allow trapped water to drain away from the foot-ring and not become self-blocked when the cylinder is standing on a firm flat surface. LPG CYLINDERS Safety in LPG Design Neck ring valve protection and lifting handles shall be designed as follows: 7.1.2.4 1. Preferred valve protection is by a neck-ring welded to the cylinder body, which shall be manufactured from forged or rolled steel, having equivalent strength as the cylinder body. A steel cap screwed to the bung is allowable. The disadvantage of the steel cap is that the customer or retailer needs to have the discipline to always screw it back before returning the cylinder. Valve protection caps from plastic shall not be permitted. 2. The neck-ring shall be of sufficient height to allow another cylinder to be stacked on top without contacting the valve of the cylinder underneath. It shall also have an external diameter which permits secure, tilt free stacking but with sufficient clearance for easy manual separation of the stacked cylinders. 3. The neck ring shall be open at one side to provide full access to the valve for fixing top or side connecting LPG gas flow regulators, which ever is specified. It shall allow for valve apertures, such as gas outlet connection and pressure relief valve to be positioned to an unrestricted opening in the neck ring without over stressing the valve tightening torque during its insertion. 4. For nominal 6 kg to 15 kg capacity cylinders, which may be manually lifted, the neck ring shall be designed with two handles to permit lifting with two hands for safe stacking or transporting without strain. Cylinder Markings Design Specification:DOT-4B-240 Manufacturer: Keloil Design Pressure: 1.66 MPa Year manuf.5-1999 Retst 5-2008 Serial No. E345236 Property of: Esso Tare weight: 12.5 kg LPG weight: 12 kg Water capacity: 26.2 l. Cylinder shall be marked in accordance with local regulations. Where any of the above design standards do not specify, the following shall be clearly stamped on the side of the neck ring, or on the cylinder body top, providing the cylinder body thickness is no less than 3.48 mm thick. Figure 7.1.1.4: Cylinder makings Safety in LPG Design 1. Flammable. 2. LP-Gas, LP-GAS, Propane, or Butane. 3. Design Specification number. 4. Name or identification logo of manufacturer. 5. A serial number of the cylinder. 6. Design pressure (If not included within the design specification). 7. Date of manufacture (MM/YY). 8. Tare Weight in kg to nearest 100 g including valve. LPG CYLINDERS 7-5 9. Weight capacity of Propane and Butane. 10. Water capacity in liters. 11. Owner’s logo. 12. Re-test date (for future use). 7.1.2.5 Cylinder Heat Treatment All of the above manufacturing standards require cylinders to be heat treated after welding. This may be by be stress relieving (annealing) between 625 oC to 650 oC, or by normalization at about 900 oC. The former is preferred, to reduce the tendency for internal oxidation of the cylinder surface by heat blistering of mill scale. However, if national standards require the latter, some means of preventing this phenomenon shall be employed during heat treatment. For instance, inerting with Nitrogen or providing an Oxygen reducing atmosphere within the cylinder and/or the heat treatment furnace are considered appropriate methods. Heat treatment shall be homogeneous, on either a continuous or batch basis, within a closely controlled furnace, preferably with Oxygen level control, to minimize external as well as internal oxidation. Additional safeguard against direct flame impingement on the cylinders shall also be provided to prevent over heating “hot spots,” on any part of the cylinder body. 7.1.2.6 Cylinder Finishing Following the hydraulic testing, all cylinders shall undergo several important finishing processes before they are ready for receipt for filling processes. Next , the cylinders shall be shot blasted. Shot blasting standards shall comply with US Standards SSPC SP6-63; NACE 3, or their equivalents within ISO 8501/1 depending on the type of paint finish required. It may be carried out in an air blast machine or wheel propelled using steel or iron grit only as prescribed by ISO 8503/1. Immediately after shot blasting, the paint finish for the cylinders shall be carried out. All paint regimes shall include a stove baking process. In addition the following shall be considered: 1. When local environmental conditions are highly corrosive, pre-treatment of cylinders by zinc spraying or zinc phosphating is recommended. The former is generally regarded the more durable and resistant to impact scratching etc., although it may be more expensive to apply. 2. For environmental reasons water based epoxy paints are preferred. If this is not feasible, normal epoxy paint finish in accordance with local requirements and experience. Internal cleanliness is a highly important quality control requirement for safety of cylinder LPG in the market place. LPG may suffer odor depletion, “odor fade”, in new cylinders due to reaction of certain stenching agents with cylinder contaminants. Therefore, manufacturers shall ensure and guarantee internal cleanliness of cylinders, especially with regard to free water and particulate matter such as mill scale, “weld splash” and any other form of iron oxide. Air-blowing and then vacuum cleaning shall carry out the cleaning process. Next the tare weight of the cylinders shall be determined: 7-6 1. Tare weighting of the cylinders, shall be undertaken with a full electronic load base scale, capable of an accuracy of 0.05% of its full weighing capacity. 2. All cylinders with an LPG capacity of between 6 and 50 kg, may be tare weighted to the nearest 100 g. LPG CYLINDERS Safety in LPG Design 3. Tare weights shall be permanently punched onto the cylinder neck-ring or body. Valve fitting is the next step in the cylinder manufacturing process: 1. All valves shall comply with and be approved for their market use requirements. 2. An approved, non-hardening valve thread sealant paste or tape shall be applied. For hygiene reasons, PTFE based sealant pastes are preferred to lead base. PTFE tape may be used providing it is manufactured to a recognized national standard, e.g.: BS 4375. 3. The valves shall be tightened in accordance with the valve manufacturers specification, or to that value stipulated within an approved valve design specification referred to in Section "Cylinder Valve Purchasing Specifications." These torque maximum values shall not be exceeded even to align the valve outlet and/or pressure relief valve (PRV) to required orientation. Leak testing of all cylinders is important step in preventing leaks. 1. Following fitting of valves, all cylinders shall be leak tested by filling with air to 7 bar (0.7 MPa) gauge pressure and completely the immersing cylinder in a water bath and looking for leaks by bubble observation. Any bubbles, however small, shall result in rejection of the cylinder. 2. If the leaks are from a valve thread, the valve may be re-tightened to no more than the torque specification limit. If the leak persists, its cause shall be traced and remedied. Faulty valve bung threads may be re-tapped or require the cylinder to be scrapped. No attempt shall be made to re-tap the valve thread. Faulty valves shall be reported to the cylinder purchaser and/or valve supplier. 3. If bubbles are observed coming from the weld of a cylinder, that cylinder shall be rejected. If two or more weld leaks are observed per batch, the entire batch shall be rejected unless the source of the leaks is identified and rectified. 4. If a leak is observed coming from a cylinder body material itself, all production with the batch of steel being used, shall be stopped and the matter reported to the cylinder purchaser for deciding further action. Prior to delivery, all cylinders, shall be evacuated down to a vacuum (absolute) pressure of a nominal 10 kPa (75 torr). To prevent damage to paint work, during transport, cylinders shall be protectively wrapped, as circumstances and experience demand. Cylinders shall be labeled or otherwise signed in accordance with purchaser instructions and or local national safety requirements, but as a minimum, this shall include a durable hazard warning label. 7.1.2.7 Record Retention. To assist with any incident investigation and or cylinder re-qualification or scrapping, records shall be kept of all of the following against cylinder serial number: Safety in LPG Design 1. Cylinder batch number and order details. 2. Manufacturing steel batch analysis. 3. Tare weight. 4. Water volume capacity. 5. Test or Working Pressure. 6. In addition, full records shall be kept of all tests as required by DOT 4B/4BW240 Standard. LPG CYLINDERS 7-7 7.2 Cylinder Valve Purchasing Specifications As with cylinders, a wide range of valve designs, types and sizes are in use worldwide. LPG valves in vapor service may be (a) manually operated, side entry valves and the most widely used one is called POL (Port-O-Lite) valves with the female (CGA510) or male outlet connection or (b) automatic, self closing, top entry valves and the popular systems in the market are Compact, Jumbo and Snap-Tight. LPG valves in liquid service are always manually operated valves with a dip tube and the most widely used one is the CGA555 with male connection. Except where it is explicitly forbidden by national authorities, all cylinders irrespective of valve type shall be fitted with a pressure relief valve. 7.2.1 Manufacturing Design Standards All valves and their components, irrespective of design, shall be manufactured in accordance to a recognized international or equivalent national standard. Examples of such standards bodies and applicable manufacturing standards are as follows: 1. International Standards Organization (ISO). 2. Committee of European Normalization. (CEN/EN) TC 286 WG 2(Draft). 3. UK LPGA Code of Practice 15 1994. 4. Japanese Institute of Standards (JIS) B8245. 5. Malaysian & Singapore Standards. At the time of writing, an important new European Design Standard designation number CEN TC 286 WG 2 N67, is in late draft stage, but the forecast date of final versions preclude its inclusion within these guidelines. In the interim, it is recommended that existing standards already in use shall be retained, but shall now include the following additional requirements: Figure 7.21: Compact, POL, and liquid take-off cylinder valves 7.2.1.1 Dimensions and Materials No changes to existing valve dimensions shall be made without consulting with appropriate owner’s personnel, as changes may impact on cylinder filling operations, market place acceptance and safety. 7-8 LPG CYLINDERS Safety in LPG Design All materials shall be compatible with all commercial grades of LPG and chemically and physically resistant to possible trace contaminants such as re-active volatile sulfides and water vapor. 7.2.1.2 Valve Body A Copper/Zinc/Lead (forging brass) alloy designated Cu.Zn40.Pb2 shall be used and shall provide a tensile strength of 360 - 400 N/mm2 and a Brinell Hardness HB of 80-85. Suitable standards for the composition and properties of this brass are: 1. DIN 17 660 -Alloy 2.0402. 2. BS 2782/2784 Alloys CZ 122 or 128. 3. JIS H3250, C3771 BE. The finished valve shall not exhibit internal or external deformation following fitting to a cylinder after applying tightening torque to the maximum value stipulated within the valve manufacturing standard, or as advised by the valve manufacture. Cylinder valves shall have a minimum rated working pressure of at least 1,725 kPa. One-piece valve body design is preferred to two-piece since there is chance of failure at the threaded connection causing leakage after prolonged use. 7.2.1.3 Seals and Internal Fittings Materials All elastomer/rubbers and plastics used for internal valve seals, operation and external regulator connection seals shall be suitable for LPG at operating temperatures ranging from –20 oC to 60 oC. They shall also be manufactured in accordance with a recognized international standard, which pays particular attention to: 1. 2. Chemical resistance(Swelling/solvency) to lubricants and other normal occurring LPG components. Aging. 3. Low /High Operating Temperatures. 4. Ozone Attack (Cracking) etc. Suitable standards, which include the above requirements, are: 7.2.1.4 1. European Standard EN 549. 2. BS 6505. Pressure Relief Valves and Other Internal Fittings Except where it is expressly forbidden by national authorities, cylinder valves shall incorporate a pressure relief valve in its body. Pressure relief valves shall be designed to ensure a minimum LPG release rate and conditions in accordance with NFPA 58 1992, Appendix E. The pressure relief valve shall relief only vapor pressure. The set pressure of the relief valve shall be not less than 2,415 kPa. Although allowed by NFPA 58, fusible plugs are not recommended for LPG cylinders. All springs and other internal fittings used in valve designs shall be corrosion proof, and resistant to chemical attack, sufficient to guarantee protection for at least ten years irrespective of location. 7.2.1.5 Valve Markings Valves shall be permanently stamped and or embossed with the following information: 1. Safety in LPG Design Manufacturer's name/logo. LPG CYLINDERS 7-9 7.2.1.6 2. Date of Manufacture (Month & year). 3. Pressure Relief Valve Setting. 4. Marking of valve thread (NGT, DIN). Liquid and Dual Off-take Valves Manufacturers of liquid off-take valves, shall ensure that they are specifically designed for this duty and are manual closing type. They shall be protected against physical damage. Materials shall be metal and suitable for LPG service. Cylinder valves shall have a minimum rated working pressure of at least 1,725 kPa. Cylinder valve shall come complete with a pressure relief valve. The pressure relief valve shall relief only vapor pressure. The set pressure of the relief valve shall be not less than 2,415 kPa. Pressure relief valve shall be designed to minimize the possibility of tampering. The valves shall incorporate an excess flow check device and have outlet connecting threads which prevent them being connected to a vapor LPG system. Shutoff valve shall not be located between the excess flow valve and the cylinder. This also applies to dual purpose (Liquid or Vapor) off-take valves. In addition, such valves shall also incorporate a self closing device, which prevents liquid LPG release to the atmosphere, if the valve is accidentally opened before connecting to a sealed system. Valves used for liquid or dual off-take shall be clearly and permanently marked to indicate liquid handling. Color coding may be considered. Where pressure relief valves are fitted, they shall at all times be exposed only to the cylinder vapor space. 7.2.1.7 Records and Shipping The valve manufacturer shall keep and maintain records of valve details for each batch supplied, which include specifications and laboratory analyses of all materials used for valve manufacture. This shall be sufficient to trace any faults subsequently found, back to the specific raw material batch supplied by original equipment manufacturers (OEM). Pre-Delivery Packing - All valves shall be securely wrapped and packed to prevent damage and contamination during delivery. 7.3 Regulator Purchasing Specifications There is a very wide range of regulator designs associated with cylinder LPG. These guidelines are mainly for non-adjustable regulators, which are directly fitted to cylinders. Their general principles may be applied to those, which are remotely mounted, but otherwise directly connected to no more than one or two cylinders. Single or two stage regulators are acceptable. Cylinder regulators shall be constructed of materials suitable for LPG service. The connection of the cylinder regulator to the cylinder valve shall be compatible with the cylinder valve. Regulators, connected to multi-cylinder manifold installations are not considered within this chapter. For multi-cylinder installations, a two-stage regulator system, as discussed in “Container Regulators” in Chapter 10, is typically installed. Regulator performance characteristics shall be clearly and unambiguously stated and agreed upon with manufacturer in writing. Once fixed, such performance criteria shall only be changed by joint agreement and again in writing. Unless otherwise requested, all regulators shall be guaranteed to be interchangeable with those in existing use and in so being, provide a safe and otherwise trouble free fitting to the cylinder valves. 7-10 LPG CYLINDERS Safety in LPG Design Regulators may incorporate an excess flow check device, which is designed to cut off gas flow in event that the gas supply hose to an appliance becomes unattached or is severed. Such devices shall specifically meet the following acceptance criteria: 7.3.1 1. Gas flow shut-off is not activated within normal regulator LPG throughput rating. 2. Gas “leak-by rate”, following activation, shall not exceed that required by local/national safety authorities, or a maximum of 60 grams/h which ever is lower. 3. It will re-open automatically when the hose is re-connected, but only with gas appliance valve in the off position. Manufacturing Design Standards All regulators, shall be manufactured to an internationally approved current design standards. Examples of such standards are: 1. BS 3016. 2. UL 144. 3. JIS B8238. 4. prEN 12864 (Standard in final draft stage since 1997). Membrane Spring Pressure Control Valve Figure 7.3.1 a: Cylinder regulator principle 7.3.1.1 Materials, Regulator Body, and Internal Fittings All materials shall be compatible with all commercial grades of LPG and chemically and physically resistant to possible trace contaminants such as reactive volatile sulfides and water vapor and salt spray environment attack. Regulator bodies shall be manufactured from a generally non-corrosive metal only. If zinc alloy is used, it shall conform to ISO 301:1981. All springs and other internal fittings used in regulator designs shall be corrosion proof, and resistant to chemical attack, sufficient to guarantee protection for at least ten years irrespective of location. 7.3.1.2 Non-metallic Components All elastomer/rubbers and plastics used for internal and external components shall be suitable for LPG at operating temperatures ranging from –20 °C to +60 °C. They shall also be manufactured in accordance with a recognized international standard, which pays particular attention to: Safety in LPG Design LPG CYLINDERS 7-11 1. Chemical resistance (Swelling/solvency) to lubricants and other normal occurring LPG components. 2. Aging. 3. Low/High Operating Temperatures. 4. Ozone and Salt Attack (Cracking) etc. Use of adhesives for fixing regulator components shall not be permitted. Suitable manufacturing material standards for seals and diaphragms, which include the above protection requirements are: 1. European Standard designate pr (preliminary) EN 549. 2. BS 6505. In addition to requirements within non-metallic components, materials used for the manufacture of laminated reinforced diaphragms shall be specifically required to be tested for resistance to de-lamination in accordance with Standard Pr EN 549. However, resistance to de-lamination shall also be tested for by immersion in Propylene for 72 h at 20 (+/-5) oC. Figure 7.3.1-b: "Snap-On" two stage cylinder regulator (SRG) 7.3.1.3 Regulator Markings The minimum permanently stamped or embossed markings for regulators shall be: 7-12 1. Name of manufacturer. 2. Production date(MM/YY). 3. Designed outlet pressure. LPG CYLINDERS Safety in LPG Design 4. Grade of LPG. 5. Maximum rated gas flow. 6. Direction of gas flow. Pre-Delivery Packing. All regulators shall be securely wrapped and packed to prevent damage and contamination during delivery. Regulator packing shall include customer fitting and operating instructions. Figure 7.3.1-c: Compact Cylinder Regulator (Kosan) Figure 7.3.1-d: "Quick-on" cylinder regulator, child proof, single button, excess flow valve (Cavagna) 7.4 Hose Purchasing Specifications This section of minimum standards covers cylinder hoses used for domestic appliances, maximum working pressure of 35 kPa and industrial application, maximum working pressure of 2,415 kPa. Cylinder hoses shall be manufactured to BS, JIS, UL or Safety in LPG Design LPG CYLINDERS 7-13 equivalent standard or meets local requirements. The date of manufacture (MM/YY) shall be permanently marked on each hose. Cylinder hoses shall be fabricated of materials resistant to the action of LPG both as liquid and vapor. Hoses for industrial application shall be designed for working pressure of 2,415 kPa with a minimum of 5:1 safety factor. For industrial application, hose shall come with assembly consisting of a flexible hose, a tee-check valve and a ball valve shall be used. The hose assembly shall have a design capability of withstanding a pressure not less than 4,830 kPa. Purchased LPG hoses for customer appliances, shall meet internationally recognized approved manufacturing standards. Plastic hose shall not be used in LPG service. Manufacturers shall clearly and durably mark hoses as below and no hoses shall be purchased unless so marked: 1. Manufacturers name/logo. 2. Manufacturing standard number. 3. Current year of manufacture. 4. The words "LPG" or equivalent. Typical cylinder hose manufacturing standards are listed below. For high pressure hoses, which are pre-fitted with screw connections by the manufacturer and which are normally used for connecting cylinders to manifolds, high pressure, or wall mounted regulators. 1. BS 3121 (Hose Type 2) 1991. 2. DIN 4815 Part 2. 3. JIS K6347. 4. NF Gaz M 88-768. For low pressure hoses that are normally used to connect regulators to LPG appliances operating up to 200 mbar gas pressure. 1. BS 3212 (Hose Type 1) 1991. 2. DIN 4815 Part 2. 3. JIS K6347. 4. NF Gaz D36-161. The length of the hose shall not exceed 2 m if installed indoors and can be greater than 2 m if installed outside building. However, the length shall be as short as possible. Hoses shall not be installed with sharp bends or twists and shall be protected against physical damage. Hoses shall not be concealed from view or used in concealed locations. Hoses shall not extend from one room to another nor pass through any partitions, walls, ceilings, or floors. 7.4.1 Hose clips All hoses must be securely fixed to the connectors. For low pressure connections, tension clips or screw type clips are sufficient. For high pressure hoses the connection must be screw type with a compressed clamp which is prefabricated the hose manufacturer. High pressure hose connections must not be repaired locally but exchanged against new hose connections. The use of rubber slip ends shall not be permitted except for domestic appliances where the working pressure is less than 35 kPa. 7-14 LPG CYLINDERS Safety in LPG Design 7.5 Cylinder Filling Plant This section of minimum standards covers the LPG cylinder filling plant within ExxonMobil’s fence. The cylinder filling plant shall have manual or automatic cylinder filling capabilities, leak check equipment, weight check equipment, cylinder evacuation units, conveyors and associated motors. The LPG cylinder filling shed shall be of open shed design. The floor level shall be 1.1 meter above the road level for easy unloading/loading of cylinders from/to trucks. The area shall be well ventilated to minimize the accumulation of LPG vapors. The LPG supply from the storage to the filling plant shall be by pump. An emergency shutdown valve shall be provided on the piping system supplying LPG to the filling facility. Emergency shutdown pushbuttons shall be provided at strategic location/s to ensure that the filling plant shuts down safely during emergency. Location of the emergency shutdown pushbuttons shall be located such that they are still operable during fire situation. The electrical area classification of the filling plant shall be in accordance with Chapter 2. The LPG filling equipment shall be designed for 1,725 kPa to accommodate LPG filling with anticipated higher Propane composition. Public access to areas where LPG is stored and transferred shall be prohibited. To prevent trespassing or tampering, the LPG filling plant shall be enclosed by an industrial fence not less than 2 m high unless it is otherwise adequately protected (e.g. within a greater fenced area). Sufficient clearance shall be provided to allow maintenance to be performed. Warning signs “NO SMOKING” and “NO OPEN FLAME” shall be posted in the filling plant. Fire protection and gas detectors shall be provided in accordance with Chapter 8. 7.6 Cylinder Filling Cylinder filling may be manual, automated or fully integrated automated. Fully integrated/automated cylinder filling lines are complex, custom designed equipment and LPG supply volume and pressure requirements are likely to be specific to each individual line. The facilities provided in a plant for handling cylinder maintenance, testing, and filling will depend on the volume of product to be filled into cylinders, the type and variety of cylinder to be processed (ranging from 3.9 to 48 kg), and project economics. Total cylinder filling and storage capacity requirements shall be determined by establishing the maximum number and size distribution of the cylinders to be filled to meet average daily/seasonal demand. Then, peak daily demand shall be established in the same manner. Finally, provision for future business growth shall be added to the previous two values, since incremental equipment capacity and operating space (particularly) can be incorporated in a new plant design at a small fraction of the costs incurred in expansion of the same plant after it is constructed. All of the above information will be needed to define the number, type and layout of scales. Average and peak capacity requirement determinations shall include allowances for interruptions of normal operation by such contingencies as power failures, mechanical breakdowns, and product supply shortages. The designer shall next determine the optimum strategy for meeting peak demand, by balancing capital cost of providing additional instantaneous filling capacity against the disadvantages of filling and storing cylinders during off-peak periods. Evaluation of the latter alternative shall include: Safety in LPG Design LPG CYLINDERS 7-15 1. A risk analysis of warehousing a larger inventory of pressurized cylinders. This risk potential may be partially mitigated by providing remote/satellite storage depots for filled cylinders. Many national safety authorities regard a previously used depressurized cylinder awaiting refilling to be as hazardous as a full one. Local limits on permissible cylinder quantity transported in one vehicle load may also affect storage arrangement. 2. A financial analysis of the costs of increased filled cylinder inventory. Cylinders are usually the largest single asset item in LPG plants that have a significant filling operation. Figure 7.5.2: Cylinder filling adapter (SRG) 7.6.1 Cylinder Processing and Filling The pump supplying the product to the filling shed shall not be oversized since this would keep the automatic pressure control valve to the supply tank always wide open, which would impair control. Investment in the “carrousel” system may justify provision of an installed spare supply pump. The line feeding the cylinder filling shed shall be provided with a remote operated emergency block valve (EBV) and several local actuation push-buttons distributed at strategic locations in the shed to activate the plant Emergency Shutdown System (ESS). A fail safe, quarter turn ball valve with hydraulic or pneumatic actuators is the 7-16 LPG CYLINDERS Safety in LPG Design preferred choice. The valve shall meet API-607 fire-resistance tests. The valve shall be located outside the filling shed. The Emergency Shutdown System shall also activate a valve that closes the air supply to the filling machine. Should there be a fire, this may prevent escalation by eliminating the air, which would normally, blow through melted plastic/copper air lines. 7.6.2 Manual Filling System A Manual filling connection and a beam type scale (preferably double beam) may be adequate if small quantities of various sized cylinders are to be handled. The scale weighing range shall be such that the maximum is equivalent to approximately twice the load, which will be applied by the largest filled cylinder. The scale shall be located in a platform or within a room specifically designed for cylinder filling. The base and platform of the scale shall be set flush with the surrounding floor level. Appropriate means for transporting the cylinders are required. The scale shall be capable of providing accuracy within the limits prescribed by the local authority. A well supported manifold shall be provided, at a convenient height, to receive product from the marketing plant pumping station. The manifold shall include a lateral fitted with positive shutoff valves. The shutoff valves are fitted with hoses of convenient lengths to reach the cylinder valve without in any way applying a strain upon the cylinder. The end of the charging hose is fitted with a quick-acting, positive shutoff valve and a filling adapter or coupling suitable for attachment to the cylinder valve being utilized. A steel I-beam provides rigid support to keep all parts in correct alignment. The manifold piping is 32 mm pipe size for strength and rigidity. Restrictions are held to a minimum to allow for fast filling. The fitting at the end of the charging hose may be manually secured to the cylinder valve and in most instances can be of a type which will permit hand tightening of the connection. Devices are available where a resilient seating means is used to form a gastight seal without the use of a wrench. The quick-acting shutoff device and the adapter or coupling may be supported from above by a counter balance so the unit remains in a convenient location when disengaged and, at the same time, supports the hose end when attached to a cylinder valve. This minimizes the weight applied to the cylinder and, in turn, the scales. Units of this type may be installed singularly or with manifolds accommodating any number of scales required for a particular operation. As an alternate to the manually secured coupling or adapter at the end of the charging hose, certain valves are adaptable to the use of a device which may be secured by hooking, snapping or otherwise engaging the valve with the application of downward pressure. In other cases a connector may be utilized which engages the valve body, forcing and sealing the end of the adapter or coupling within the inlet of the valve. 7.6.3 Automated Filling System An automated filling system may be justified if larger quantities of one cylinder size have to be filled, possibly including electronic weigh scales to assure greater product control precision. Simple automatic systems may be justified for modest throughput levels and are found in many small plants worldwide. Fully-integrated, automated processing systems are justified where very large quantities of one cylinder size must be filled. These systems utilize a rotary filling head, or carrousel, similar in principle to a motor oil filling head. However, special vapor retaining connect/disconnect systems are incorporated due to high product vapor pressure. Fill weight may be checked continuously by a load cell-actuated electronic weighing system. Simple automation can be achieved by using the scales, manifold and charging hose of the manual system, but installing an automatic valve in the lateral from the manifold. A Safety in LPG Design LPG CYLINDERS 7-17 sensing device is attached to the scales and is responsive to the upward movement of the beam. A pneumatic system, using compressed air, permits the control valve at the manifold to remain in an open position until the movement of the scale beam, which closes the control valve, actuates the relay. With the poise set at the appropriate point on the beam (allowance being made for any weight, which may be exerted by the hose) the flow of incoming liquid shall be shut off when the desired weight is reached. As a modification of this system, a solenoid valve may be substituted for the control valve at the manifold with an explosion-proof mercury switch activated by the movement of the scale causing flow of incoming liquid to cease when the proper weight has been reached. 7.6.3.1 Unitized Automatic Scales Scales shall be accurate to within 1/10 of 1 percent throughout their entire range. Scales shall be of the double-beam type or constructed so that individual adjustment can be made for tare and net weights. It is recommended that scales be designed for the following adjustments: Recommended Range Tare and Net Contents Fine Adjustments 0.5 – 5.5 Kg 14 g 5 – 60 Kg 113 g NOTE: A set of check weights shall be available within each filling plant to calibrate all scales daily. Figure 7.5.3.1-a: Filling with conveyor Automated systems are also available which are "unitized" in that the scales and automatic control device are fabricated as a single unit. These units are constructed with the control mechanism completely encased within cabinetry. The accuracy of the scales is reported to be plus or minus 50 grams. In operation, larger tolerances may be necessary depending upon the fluctuation in the product pressure, speed of filling, the amount of product to be filled, and friction in hoses, pipes and fittings. The scales are provided with two roller weights representing the weight of the product to be charged and the tare weight. Further, a sliding weight for the fine adjustment of the tare is included. Higher precision is obtainable with “load cell-actuated” electronic equipment. 7-18 LPG CYLINDERS Safety in LPG Design A four scale filling plant is illustrated in Figure “Filling with conveyor” above, using automatic filling scales with a “keyboard” type of weight adjustment. The filling head attached to the individual filling hose provides an automatic means of attachment to cylinder valves with threaded outlets. A conveyor system brings the cylinders to the four stations and, likewise, removes them. A pneumatic lifting device is located under each charging position so the scale platform may be elevated through the conveyor, lifting the cylinder to a position where its weight may be determined. From Pump Manifold Approx 20% of Scale Beam Scale Frame Length Trip Valve Filler Valve Pilot Vapor Pressure from Air Compressor Pivot Point Trip Valve Filling Hose Scale Beam Beam in Raised position Beam Horizontal Beam when Cylinder is not Filled Alternate Trip Valve Installation Figure 7.5.3.1-b: Typical automatic filling for cylinders This type of system may be utilized with two or more stationary scales erected after each other on the chain conveyor. The system includes pneumatic indicators, a counting device, and stops for fully automated operation of the inlet and outlet of the cylinders. The capacities are limited by the following operator actions: 1. Fetching of cylinder from conveyor, and placing on scale. 2. Connecting of cylinder valve to filling head, adjusting scale, and starting the filling. 3. Disconnecting of filling head, removing cylinder from scale, and placing it on a transport conveyor. The figure above illustrates an automatic cylinder filling valve attached to a charging manifold, which may service any number of additional units. The automatic valve can be isolated from the manifold by a positive shutoff valve. It is necessary to connect a suitable supply of compressed air to the unit in order to operate the relay pilot and main shutoff device. The lifting of the scale beam when the desired filling amount has been reached actuates a trip or “bleed” valve installed on the scales. The manufacturer indicates that the device is designed with a positive feather-touch control, which prevents vibration or sudden jars from causing improper cutoff. Operation of the unit requires no electrical or mechanical power. The automatic cylinder filling valve is designed specifically for use with a beam scale and is not adaptable directly for use with a dial scale. When the desired amount of fuel has been put into the cylinder, the rising scale beam contacts the trip valve and shuts off the filler valve. A red button indicator appearing on top of the filler valve visually indicates this condition. 7.6.3.2 Cylinder Handling Chain conveyor systems may be utilized to eliminate manual transport of cylinders. With one system the cylinders are loaded directly on to the chain conveyor from a highway transport or from the empty cylinder storage area and conveyed directly to the Safety in LPG Design LPG CYLINDERS 7-19 filling scales. The cylinders are taken from the conveyor, placed on the scales for filling and then returned to a second conveyor, which moves the units either to the highway transport or to the filled cylinder storage area. Cylinders shall still be inspected for damage and re-inspection date prior to loading onto the conveyor or at some point in the system before filling. A second system employs a continuous conveyor configuration and is particularly adapted to the charging of 33 kg or 45 kg cylinders. The system can, however, be adapted for filling smaller cylinders. In this system the empty cylinders are carried to the filling scales on the chain conveyor and accumulate before the scales. The operator releases a group of empty cylinders, which pass on to the scales and are stopped by pneumatic equipment so that they are arranged with each cylinder in the correct position at each scale. Cylinder receipt Control Visual external control for damage, valve integrity, corrosion Accept or Reject Control of refurbishment date correct filling weight by reconciling tareweight and actual weight on independent scale Control leak from valve and bung Pass or Refurbish Read Tareweight input tareweight into scale Fix cylinder cap or seal Attach filling adaptor Wash cylinder Fill cylinder Load cylinder on truck or store in plant Stop filling Cylinder delivery move cylinder from scale Figure 7.6.4-a: Cylinder filling process 7-20 LPG CYLINDERS Safety in LPG Design A pneumatic lifting device consists of a bottom frame with bearing brackets into which the lifting table is placed. The lifting table is raised and lowered by means of a pneumatic cylinder operated by automatic controls. The charging hose is connected and the lifting table of the scale is activated in order to lift the cylinder free of the chain conveyor. After filling is completed and the charging hose is disconnected, the cylinder is lowered to the chain by releasing the control. As soon as all the filled cylinders are lowered on to the chain conveyor the “stops” are opened and a new operating cycle begins. The filled cylinders are then carried to a check scale, which is also built into the chain conveyor system. This system is ideal for heavy cylinders as it eliminates manual lifting. Figure 7.6.4-b: Automated filling plant with carrousel Safety in LPG Design LPG CYLINDERS 7-21 7.6.4 Integrated Automated Filling Plant Integrated, automated filling plants are laid out for high capacity and utilize specialized equipment. They require extensive preliminary study, and large investment. The best practice for an integrated cylinder filling process is shown in Figure 7.6.4-a “Cylinder filling process.” The designer shall rely on packaging experts, both from within the company and from equipment fabricators and vendors, to design the equipment and determine the level of automation justifiable. The designer's primary responsibility will be to provide the packaging specialists with a precise duty/performance specification for the proposed filling system. This manual confines discussion of integrated, automated filling systems to a review of the capabilities of various system components, and a summary of information needed to solicit proposals for automated systems. The schematic plant layout (Figure 7.6.4-b: “Automated filling plant with carrousel”) combines all equipment components discussed above to create an automated plant capable of continuously filling 1000 to 1200 cylinders (11-13 kg) per hour. One location operates an 800 cylinder/hour plant with one operator, one forklift driver and one supervisor. 7.6.4.1 Degree of Automation Once the filling plant throughput requirements are established, comparative investments and operating costs for various degrees of automation can be determined. These values will permit the designer to conclude whether the plant shall have: 1. Individual weigh scale filling machines. 2. Chain conveyor systems. 3. Depalletizers/palletizers. 4. Fully automated operation incorporating a filling carrousel. Key factors to be considered in justification of automation are: 1. Estimated capital cost of equipment components and installation. 2. Present and projected cost of labor at various skill levels for the life of the project. 3. Estimated equipment maintenance costs, preferably supported by actual experience with identical equipment elsewhere, and applicable local regulations at the site. Most recent designs of filling machines allow the processing of cylinders of different size. Cylinders have to be filled in batches. After one batch is finished the carrousel is stopped to adjust to the next cylinder height. 7.6.4.2 Carrousel System For higher processing capacities, the use of a carrousel filler such as shown in Figure 7.6.4.2-a “Typical Cylinder Filling Carrousel” is justified by its efficiency. A carousel is a rotating table upon which a number of automatic filling scales are equally spaced around the outer edge. The carrousel becomes an integral part of the chain conveyor system. Depending on conveyor system complexity, empty cylinders may be routed from a number of sources to the carrousel. Cylinders accumulate on the carrousel inlet section of the conveyor, and then are transferred, one at a time, to one of the multiple carrousel scales by an automatic intake device. As the carousel slowly turns, an operator places a cylinder on the platform of a scale, attaches the filling head, sets the net charge weight and tare weight on the scale and opens a valve to start filling. When the cylinder is filled, the automatic filling valve is tripped to the closed position. The cylinder may then pass over check scales. The number of scales placed on a carousel will depend upon the cylinder filling rate required within the plant. Carousels are 7-22 LPG CYLINDERS Safety in LPG Design available with 4 – 36 scales per unit. The size of the carousel shall be selected on the basis of the expected future filling rate. Figure 7.6.4.2-a: Typical cylinder filling carrousel (Siraga) Figure 7.6.4.2-b: Large cylinder filling carrousel (Crisplant) The following operating sequence is then performed by the carrousel: 1. Safety in LPG Design The filling head at the end of a charging hose is either manually or automatically connected to the cylinder valve. Manual connection may be LPG CYLINDERS 7-23 necessary with screw type fittings, while automatic connection is feasible with click-on/clamp-on type fittings. 2. The scale is adjusted (a) manually for cylinder tare weight, using a single-dial or digital keyboard weight adjustment, or (b) automatically using selfadjusting scales programmed from a digital keyboard-programmed computer. Fill weight is predetermined when the size of cylinder to be processed is selected. 3. The cylinders are filled in less than one revolution of the carrousel. LPG supply to each cylinder is shut off automatically when the correct fill weight is reached. 4. The filling head is either manually or automatically disconnected as the carrousel revolution is completed. 5. The filled cylinders are automatically transferred to a check scale with dial or digital readout. 6. After weighing, the cylinders are automatically transferred to the outlet section of the chain conveyor. Figure 7.5.4.3-a: Unloading pallets to destacker Figure 7.5.4.3-b: Pallet feeding into the conveyor system Carrousels are produced with varying numbers of scales, or filling stations, up to a maximum of 48. Maximum carrousel filling capacity is approximately 1200 cylinders per hour. Carrousel design is adaptable to filling all sizes of cylinders. Where adequate volume demand exits, the filling carrousel permits achieving a continuous maximum production rate with minimum operating work force. In order to 7-24 LPG CYLINDERS Safety in LPG Design realize the full potential of this equipment, it shall be installed as a part of an integrated filling plant that incorporates all support facilities needed to operate the carrousel continuously at capacity. The filling method briefly described in the prior discussion is predicated upon the processing of a group or batch of cylinders of a uniform size or capacity, observing the tare weight of each cylinder, and in turn adjusting the tare weight component of the scales. Operating in this manner it, is not necessary to adjust the fuel weight component since uniform cylinders are being processed. It should be noted that by using this method, a correct filled weight may be obtained regardless of the contents of the cylinder when presented to the carrousel. In other words, this system ensures that cylinders will not be overfilled since the scales will trip when the combination of the fuel weight and tare weight is reached. Figure 7.5.4.3-c: Check weight scale A filling procedure using a predetermined quantity is not recommended since it involves time consuming procedures like cylinder emptying. Utilization of constant tare weight is also not recommended since different suppliers may manufacture cylinders over a long period. 7.6.4.3 Cylinder Filling Support Functions The support equipment items required to create a fully integrated, automated cylinder filling plant based on the carrousel are as follows: Equipment to unload cylinders to be filled from the incoming transport and place them on the conveyor system. Palletization of cylinders is desirable for high volume filling, distribution, and sales operations. Safety in LPG Design LPG CYLINDERS 7-25 Equipment to feed a conveyor system shall consist of a fork lift truck, a destacker, and a depalletizer with a ram to eject the unloaded cylinders onto the conveyor. Ready access to a second lift truck and driver is desirable in event of destacker, depalletizer, or palletizer breakdowns. Figure 7.5.4.3-a “Unloading pallets to destacker” shows a forklift unloading pallets to the destacker. Cylinder counting equipment: An automatic cumulative counter should be provided to count all cylinders remaining on the line, which will now be filled, as part of control procedures. The cylinders next enter the carrousel filling process. Carrousel Cylinder Filling: Tare weights, connection, filling and disconnection were described in section 7.5.4.2 “Carrousel System.” Figure 7.5.4.3-d: Leak detection unit Check weighing/Overfill detection equipment: The system shall next provide a device that is capable of accurately weighing moving cylinders and detecting over/underfill situations. The device shall also eject those over/underfill cylinders from the line onto a branch “decant/refill” conveyor. The Figure 7.5.4.3-c “Check weight scale” shows an overfill check weight scale to control whether filling matches correct figures for each filled cylinder as it moves along the conveyor system, automatically rejecting overfills. Weight readings are manually checked periodically on a statistical basis to guard against continuous filling error. Statistical data shall be kept for each carrousel scale as well as for the overfill check weight scale. Leak detection equipment: A leak detection device capable of detecting leaks of 0.5 grams/hour, and shunting the leaking cylinders to a reject conveyor is next required. The automatic leak detection is likely to require review and endorsement by local regulators. Figure 7.5.4.3-d “Leak detection unit.” shows such a unit, which may function on the basis of either (a) cylinder pressure drop in 3 seconds, a time interval 7-26 LPG CYLINDERS Safety in LPG Design consistent with 1200 cylinder/h. filling rate, or (b) hydrocarbon vapor detection in the same time interval. In some countries the law requires that dipping the cylinders completely under water perform leak detection. This is an effective test provided the water surface is allowed to become calm and is not disturbed by the submersion process. Figure 7.5.4.3-e “Seal leak detection unit” shows a machine that is capable of detecting seal leaks. Figure 7.5.4.3-e: Seal leak detection unit Cylinder capping equipment: Next, a machine shall be provided to apply either plastic or metal sealing caps to the cylinder valve outlet connection. Figure 7.5.4.3-f “Typical valve cap” shows such a sealing cap. If acceptable to local regulators, plastic seals shall be used because they are probably more effective than metal seals. Figure 7.5.4.3-f: Typical valve cap Cylinder washing and drying equipment: The Figure 7.5.4.3-g “Inside of a water jet washing machine” shows a high pressure jet water washing cabinet without brushes that cleans the cylinders while they continue to move along the conveyor. Wash water is Safety in LPG Design LPG CYLINDERS 7-27 freed of sediment and recycled. High pressure air jets then dry the valve area of the cylinders. After washing, the cylinders must be manually subjected to a visual inspection and transferred to a branch “reject” conveyor if they are deficient, for repair or scrapping. Figure 7.5.4.3-g: Inside of a water jet washing machine Figure 7.5.4.3-h: Cylinder stacker Re-palletizing and shipping equipment: The filled cylinders are now ready for movement into a palletizer-stacker, and then for removal by lift truck to outbound 7-28 LPG CYLINDERS Safety in LPG Design transport or a filled cylinder storage area. The integrated filling plant's conveyor system is ideally configured in a loop, so that the filled cylinder outlet is as close as possible to the empty cylinder inlet, thereby permitting a single lift truck and operator to serve both ends of the conveyor line. Figure 7.5.4.3-i: Cylinder painting cabinet 7.6.4.4 Cylinder Maintenance Facilities Generally it is preferred that cylinder maintenance and re-testing is performed by specialized third party companies outside the filling plants. Cylinder manufacturers are best equipped to perform this task. However, if this is not viable, cylinder maintenance may be performed inside the filling plant. This section of minimum standards covers the buildings, structures and equipment used for maintaining LPG cylinders. The LPG cylinder maintenance shed shall be of open shed design. The area shall be well ventilated to minimize the accumulation of vapor cloud. The shed shall be constructed of noncombustible materials. The maintenance shop typically includes a shot blasting unit, spray painting or dip painting equipment, a dry oven, conveyors and associated electric motors. Utility station such as plant air and plant water shall be provided to maintenance shop. Plant air and plant water piping shall be clearly identified either by labeling or color coding. The electrical area classification of the filling plant shall be in accordance with Chapter 2. Safety in LPG Design LPG CYLINDERS 7-29 Cylinder painting equipment: Some plants may include cylinder painting. This equipment includes a water curtain using recycled water to dispose of over spray mist. An overhead jack that rotates the cylinder while it is coated by an automatic spray gun engages cylinders on the conveyor. A protective shroud shall be incorporated into the rotating jack to protect top cylinder valves normally used in operations. If desired, a second paint station using a spray gun equipped with a stencil mask can apply a trademark or text to the cylinder after the base painting coat is applied. Typically, paint would be applied to a statistical fraction of all cylinders, say one in five. This intermittent operation would be controlled automatically. At offsite locations, subcontractors may advantageously perform several of the operations discussed above. They may include cylinder painting, cylinder depressurization, air purging, and subsequent repair and re-qualification of rejected cylinders and/or their valve assemblies. Concurrent use of the offsite subcontractor facilities to augment storage space for empty and/or full cylinders may achieve additional economic benefits. It is recommended that any design study for a new plant, or for major modification of existing facilities, include a thorough exploration of incentive for subcontracting support operations of the type discussed above at locations away from the main plant. Figure 7.5.4.3-j: Cylinder pallet storage 7.6.5 Purchasing Guidelines for Filling Plants There are three reliable filling plant manufacturers who are well established in the market and have produced a large number of safe filling plants. All vendors are deeply involved in fully automated filling plants, which rely heavily on electronics for filling/check weigh scales, leak detection and bar code or data matrix control of cylinder processing and stock control. However, the designers are primarily fabrication and conveyor systems engineers with relatively limited knowledge of LPG properties and operations. They are dependent almost entirely on third party filling plant operators for field experience for developing the practical aspects of their designs. The adverse effect of intense competitiveness between the manufacturers on quality, performance claims and guarantees needs to be very carefully safeguarded against. Consequently, it is important to specify and obtain agreement and or clarification on safety and performance guarantees etc., in writing, prior to placing orders, on items discussed in the next paragraphs. 7-30 LPG CYLINDERS Safety in LPG Design 7.6.5.1 Safety and Integrity of Equipment Design Vendors should submit designs with due consideration given to the owner’s LPG Specifications. Consideration should be given to auto- refrigeration, especially of Propane at –42 °C, irrespective of climatic conditions. The design should also maintain equipment safety and performance under all anticipated environmental conditions of the plant location. The vendor shall provide formal recognized “certification” of all materials of construction and assembly. This shall include all materials and equipment, “bought in” by the vendors, with specific attention to elastomer seals, pipe thread and flange jointing, LPG transfer hoses and electrical parts, including prevention of static electricity. All major equipment shall be designed and manufactured to approved standards acceptable to the appropriate national regulations or LPG Design Guidelines in this book, which ever are the more stringent. This applies in particular to LPG piping, flanges and fittings, pumps and compressors and the classification of electrical equipment. All main steel work, e.g.; palletizers, carrousel and conveyor chain frames, shall be fabricated from hot rolled or forged sections. Pressed and folded steel shall not generally be accepted for major frame members. Possible exceptions may be permissible for small modular constructions, which can be readily removed or replaced, if damaged. Care shall be taken to electrically ground electrically isolated metal parts around the machinery to prevent accumulation of static charge. In particular, this pertains to metal parts suspended by rubber for flexibility or metal connections attached to plastic/rubber tubing. All machines shall reset automatically. In the case of shutdown or emergency shutdown, moving parts shall automatically reset back to their starting positions. It is not recommended to install protective caging between filling machinery. Cylinders shall be accessible at all times. All services required of the vendor’s equipment should be thoroughly considered and agreed upon before signing of contracts, in particular; instrument air supply (air pressure, volume and quality), electric power (including voltage fluctuation range), and water (pressure, volume, quality). Detergents for cylinder washing (compatibility with plant water treatment system) shall be compatible with environmental requirements. Emergency shutdown system (ESS) considerations shall be included. Vendor equipment shall be specified as compatible with the existing system and fail safe, i.e.; sealed against release of LPG during emergency shut down and or failure of operating media. 7.6.5.2 Performance Criteria and Guarantees. All vendors should provide overall and specific guarantees of equipment safety as well as performance. The owner should specify and agree with the vendor’s pre- and post commissioning “acceptance” criteria, as appropriate, in writing. This is of particular importance to retrofitting equipment to an existing plant. Previous discussions with all vendors, revealed serious gaps and shortfalls in their guarantee cover. Vendors tend to be overly optimistic when making claims about their new developments. The owner should be careful to request proof of performance and reliability from case histories, i.e. proven track record. It is obviously important that the owner does not unknowingly become a proving ground for any relatively new equipment developments. Safety in LPG Design LPG CYLINDERS 7-31 Indemnity clauses differ quite markedly between vendors. The owner should clarify and agree to the details with the vendor. Such clauses range from possible incidents arising from, pre- and post-commissioning by vendor personnel, through to market place safety, unreliability of check scales and/or of leak detection equipment. Key criteria to be covered include: cylinder filling rates, and tolerances for fill weight, check weight and leak rates at the required cylinder filling and chain conveyor speeds, under normal local operating conditions. These criteria would usually require a vendor's engineer to visit the plant, to be “fully” acquainted with local operating conditions. Filling scale fill tolerances shall be geared to appropriate National weights and measurement. It is important to note that the “overall filling accuracy” mentioned in the ExxonMobil Product Control Manual should not be quoted to the vendor. The owner shall request “guaranteed” filling accuracy from the vendor, per cylinder size and filling rate. With the exception of 45 − 50 kg cylinders, most vendors can usually meet requirements of the Product Control Manual. 7.6.5.3 Pre-Delivery Testing of Equipment. All equipment shall be pre-tested by the vendor, especially pressure testing of LPG pipe work and hoses. See also “Performance Criteria and Guarantees” above in relation to required cylinder filling rates and conveyor speeds. Certification of the safety of all electric items and circuitry, especially electronic scales and computerized systems shall be checked. Many of these are now designed to be intrinsically safe, but this should specifically checked. 7.6.5.4 Installation and Commissioning The owner should be satisfied that sufficient details are agreed to with the vendor on how installation and commissioning are undertaken, without prejudicing guarantees of equipment reliability and performance. This may include direct involvement by the vendor in both installation and commissioning as well as training of owner personnel. 7.6.5.5 After Sales Service All vendors claim to provide a reliable after sales service. Vendor staffing is largely by personnel involved in equipment manufacture. However, some vendors have or are establishing local offices, so details of what services are available on a 24 hour notice, as a minimum, should be obtained. To augment their normal services, all vendors provide contract Periodic Preventive Maintenance Services. Details on these services may be obtained and compared with availability/capability of local skills. 7.6.5.6 Records, Drawings, Maintenance, Spare Parts The vendor shall provide all records of approval certification and manufacturing standards for all materials, equipment and tests as appropriate. Accurate plant drawings and operational service diagrams, especially wiring diagrams, shall also be supplied, together with maintenance and inspection schedules, with specific reference to “bought in” items. Note that all vendors are highly dependent upon boughtin materials and equipment which require instructions and recommended maintenance and inspection schedules from the original manufacturers. Spare parts shall be itemized with recommended frequency of fitting. This is particularly important for elastomer seals in liquid phase LPG use. 7-32 LPG CYLINDERS Safety in LPG Design 7.6.6 Third Party Cylinder Filling Plant This section of minimum standards covers a third party cylinder filling plant where ExxonMobil LPG cylinders are filled. Local standards shall be followed. In the absence of a local standard or if the local standard is less stringent, the following minimum standard shall apply. The structure of the LPG cylinder filling shall be of open shed design. The area shall be well ventilated to minimize the accumulation of vapor accumulation. Pumps shall be used to transfer the LPG from the storage to the filling plant. At least one emergency shutdown valve shall be provided on the piping system supplying LPG to the facility. Emergency shutdown device/s shall be provided at strategic location/s to ensure that the filling plant shuts down safely during emergency. Location of the shutdown device/s shall be such that they are still operable during fire situation. The electrical area classification of the filling plant shall be in accordance with Chapter 2. Working pressure of LPG to the filling station unit shall be a maximum of 1,725 kPa. A separate weight check scale shall be provided to check the weight of the filled cylinders before dispatching them out of the filling facility. Public access to areas where LPG is stored and transferred shall be prohibited. To prevent trespassing or tampering, the LPG filling plant shall be enclosed by an industrial fence not less than 2 m high unless it is otherwise adequately protected (e.g. within a greater fenced area). At least 2 means of emergency access from the fenced or other enclosure shall be provided. Sufficient clearance shall be provided to allow maintenance to be performed. Clearance of at least 1 m shall be provided to allow emergency access to the required means of egress. The outside storage area for filled cylinders shall be a minimum distance of 7.5 m from cylinder filling facilities. Relevant signs such as “NO SMOKING” and “NO OPEN FLAME” shall be posted around the perimeter and in the filling plant. 7.7 Cylinder Distribution 7.7.1 Distribution Center Cylinder distribution strategy may, in some cases, require the installation of distribution centers. This is typically the case where one large filling plant serves several demand centers. Large trucks transport the cylinders back and forth between the filling plant and the Distribution Center. From there, small trucks, principally pickup trucks owned by the resellers or dealers, are used for delivery to end-users. Regulatory compliance (land status, classification and zoning laws) is a basic requirement. Sites in industrial zones are preferred, housing and public areas shall be avoided. The area shall be freely ventilated (not located in a terrain depression). Size and shape of land shall be large enough to satisfy spacing requirements based on store capacity stipulated in Table 7.7.1. Safe truck access has to be included in these considerations. The area shall be preferably fenced with a 3 m high chain linked fence. LPG cylinders shall be stored upright and well ventilated, preferably in an open-air loading platform. Where inclement weather can frequently preclude work, or required by local regulations, the Distribution Center may be provided with a roof, constructed of noncombustible, lightweight, friable material that would break up quickly in a fire. Sufficient space shall be maintained between the underside of the canopy and the highest stacked cylinders to facilitate application of cooling water in the event of a fire emergency. Safety in LPG Design LPG CYLINDERS 7-33 Drains shall be avoided in the floor of the storage place. The platform floor shall be level and provided with suitable hard standing for LPG cylinder handling. Normally, the platform would be elevated, such that it is at the same level as the back of the truck. However, if the platform is at ground level, particular precautions have to be taken that, when unloading, cylinders are not damaged. Appropriate warning signs are to be prominently displayed i.e. “No Smoking or naked Flames” “Highly Flammable LPG.” Electrical fittings used on the platform and under the roof of the storage area shall be suitable for Zone 2 area classification. Other areas such as yard lighting or office lighting shall be suitable for normal service. Table 7.7.1 shows the spacing requirements for Distribution Centers: Quantity* of LPG Stored Size of Largest Stack Distance to Property Line Kg kg m < 30000 < 7000 8 < 50000 < 9000 9 < 60000 < 10000 10 < 100000 < 10000 11 < 150000 < 20000 12 < 250000 < 30000 15 > 250000 < 30000 20 Table 7.7.1: Spacing to property line in Distribution Centers *Nominally “empty” cylinders have to be considered as “full” for above calculations unless the cylinders are stored under the following conditions: 1. The “full” and nominally “empty” cylinder storage area is clearly marked. 2. Full cylinders are always stored in the “full” area, nominally “empty” cylinders are always stored in the “empty” area. 3. A gangway with a separation distance of at least 3 m is maintained between the nominally “empty” and “full” cylinders. 4. Individual unpalletized stacks (either full or empty) shall be separated by 1.5 m distance for accessibility. For palletized stacks the gangway distance shall be a minimum distance of 2.5 m. Domestic cylinders shall be stacked in the following manner: 1. Manual stack: Maximum 3-cylinder high for cylinders up to 15 kg content and maximum 2-cylinder high for cylinders above 15 kg up to 26 kg. 2. Wooden Pallets: Maximum 2-pallet high and each pallet at 2-cylinder-high. 3. Caged Steel Pallets: Filled cylinders - up to 4-pallet high and each pallet at one-cylinder high. Empty cylinders - up to 6-pallet high). Cylinders above 20 kg shall be stored upright without stacking. Fire protection facilities for the Distribution Center are designed for first aid use only. Following firewater capacities are recommended: 1. 7-34 For LPG storage up to 25 tons 800 l/min at 7 bar for at least 1 hour. LPG CYLINDERS Safety in LPG Design 2. For LPG storage exceeding 25 tons 2300 l/min at 9 bar for 1 hour and at least 2 firewater monitors. It is expected that public fire brigades would provide backup during LPG fires. Specific requirements by individual Fire Department Offices may differ and the Project Engineer will have to present his case to the fire authority for a system, which will suit the location in terms of associated fire risks. 7.7.2 Dealer and Reseller Cylinder Storage In some cases dealers or resellers may store considerable numbers of cylinders on their own premises. The preferred location for cylinders stored for resale is outside buildings. Fence and door are adequate means of control to the storage premises. Firefighting capability is normally limited to a 9 kg dry powder extinguishers but depending on conditions, the local firefighting authorities may require more protection (firewalls etc.). Storage outside of buildings shall be located in accordance with Table 7.7.2 and at least 1.5 m from any doorway in a building frequented by the public. The table reflects requirements in NFPA 58, 5.4.1. Following are the explanations for the column headings in the spacing table below: 1. Nearest important building or group of buildings. 2. Line of adjoining property that may be built upon. 3. Busy thoroughfares or sidewalks. 4. Line of adjoining property occupied by schools, churches, hospitals, athletic fields, or other points of public gathering. 5. Dispensing station. Horizontal Distance to: Quantity of LPG Stored, 1. and 2. 3. and 4. 5. Kg m m m < 227 0 0 1.5 227+ to 1134 0 3 3 1134+ to 2721 3 3 3 2721+ to 4540 6 6 6 7.5 7.5 7.5 > 4540 Table 7.7.2: Spacing in reseller cylinder storage (from NFPA 58) If cylinders are stored inside buildings or structures the buildings and structures shall be one story in height and shall have walls, floors, ceilings, and roofs constructed of noncombustible materials. Exterior walls, ceilings, and roofs shall be constructed as follows: Safety in LPG Design 1. Of lightweight material designed for explosion venting, or 2. If of heavy construction, such as solid brick masonry, concrete block, or reinforced concrete construction, explosion venting windows or panels in walls or roofs shall be provided having an explosion venting area of at least 0.1 m2 for each 1.4 m3 of the enclosed volume. LPG CYLINDERS 7-35 The floor of such structures shall not be below ground level. Any space beneath the floor shall be of solid fill or the perimeter of the space shall be left entirely unenclosed. The floor level is preferably 1.1 m above the road level for easy unloading/unloading of cylinders. The structure shall be ventilated using air inlets and outlets, the bottom of which shall be not more than 150 mm above the floor, and shall be arranged to provide air movement across the floor as uniformly as practical and in accordance with the following: Where mechanical ventilation is used, air circulation shall be at least 0.3 m3/min×m2 of floor area. Outlets shall discharge at least 1.5 m from any opening into the structure or any other structure. Where natural ventilation is used, each exterior wall [up to 6.1 m in length] shall be provided with at least one opening, with an additional opening for each 6.1 m of length or fraction thereof. Each opening shall have a minimum size of 32,250 mm2, and the total of all openings shall be at least 720 mm2/m2 of floor area. Heating shall be by steam or hot water radiation or other heating transfer medium with the heat source located outside of the building or structure or by electrical appliances listed for Class I, Group D, Division 2 locations, in accordance with NFPA 70, National Electrical Code. Walls of attached structures shall have a fire resistance rating of at least 1 hour. There shall be no openings. Common walls for attached structures used only for storage of LP-Gas shall be permitted to have doorways that shall be equipped with 1 1/2-hour (B) fire doors. Common walls at points at which structures are to be attached be designed to withstand a static pressure of at least 0.7 MPa per 0.1m shall have the following : Rooms within structures shall be located in the first story and shall have at least one exterior wall with unobstructed free vents for freely relieving explosion pressures. Fire detection and firefighting requirements shall be as per local fire authority requirements. 7-36 LPG CYLINDERS Safety in LPG Design 8 FIRE PROTECTION 8.1 Passive and Active Fire Protection In developing safety and fire protection guidelines for LPG facilities, the greatest concern is failure of tanks containing LPG whether large tanks or domestic cylinders. The probability of this type of failure can be made virtually negligible by properly engineering and operating facilities, in accordance with the guidelines in this manual. Although avoidance of such risks is of prime importance, it is necessary to protect against emergency situations that can still occur. Safety in LPG plant design is incorporated in two ways, by passive protection and by active means of mitigation. Passive protection is achieved by adequate spacing, by mounding or fireproofing, and by providing equipment with the appropriate electrical area classification. Active means of mitigation are achieved by providing emergency shutdowns, emergency block valves and an adequate firefighting system. Fireproofing and firefighting equipment is discussed in this chapter. Electrical classification is discussed in “Electrical Area Classification” in Chapter 2. Also an example of an “Emergency Shutdown System” is shown in Chapter 2. Emergency block valves on tanks and loading facilities are discussed in “Emergency Block Valves on Bulk LPG Tanks” in Chapter 3 and “Emergency Block Valves for Piping” in Chapter 5. The physical properties of LPG, which are important for understanding the safety and fire hazard implications, are discussed in Chapter 12 “LPG PROPERTIES.” Bulk LPG tanks at Refinery, Upstream, and Marketing plants shall be protected with the application of firewater and/or fireproof insulation. A deluge or fixed spray system shall protect aboveground spheres, which are discussed in this chapter. Aboveground bullets shall be protected by a fixed spray system or fixed fire monitors which are capable of reaching the whole bullet surface area. Insulation may be substituted for deluge or spray systems, provided fire water is still available by at least a hydrant system. Generally both fireproofing and a deluge/spray system are not used unless risk analysis shows a need to further mitigate the effects of fire. 8.1.1 Fireproofing, a Passive Fire Protection Fireproofing of structural supports, tanks, instrumentation and control tubing, and valve actuators shall be considered when evaluating the fire protection systems for LPG storage. The function of fireproofing is to reduce the rate of temperature increase during fire exposure. The mechanism for reducing the rate of temperature increase can be absorption of heat through chemical breakdown of the protective coating or resistance to heating using thermal insulation, depending on the nature of the fireproofing. Safety in LPG Design FIRE PROTECTION 8-1 As a passive fire protection system, fireproofing provides protection without depending on detection systems or alarms. Mechanical or electrical failures have no effect on its performance. Fireproofing also provides time to evacuate neighboring areas. On the other hand, in a fire, fireproofing provides only a finite period of protection. Without the addition of water, failure of fireproofed equipment will occur if the fire burns long enough. Further, the type of fireproofing shall be selected carefully to ensure compatibility with the storage area environment both from the standpoint of fireproofing application or installation and long-term durability of the fireproofing. Fireproofing can be used in combination with active water fire protection systems as a means of protection until the water system is activated, as a back-up in the event the supply of water is interrupted, or if the water application rate available is less than what is desirable. The fireproofing material shall provide equivalent to a fire endurance of 1.5 hours per UL 1709. The fireproofing system shall be designed to withstand exposure of direct flame impingement (as per GP-14-3-1) . It shall also be non-corrosive, inert under fire, resistant to weather and hose streams. 8.1.1.1 Fireproofing Applications Fireproofing practices for Refineries and Upstream facilities are described GP 14-3-1. In Marketing LPG storage facilities, fireproofing shall be considered for use in the following areas: 8.1.2 1. Structural Supports: Fireproofing used on steel supports for LPG tanks can prevent collapse in the event of fire. On spherical tanks and vertical cylindrical tanks, structural supports shall be fireproofed from ground level to the intersection of the support with the tank shell. 2. With horizontal cylindrical tanks (bullets), steel saddles and vertical support steel shall be fireproofed to the intersection of the saddle with the tank if the saddle is greater than 300 mm height at its lowest point. Exceptions for horizontal tanks below 7.6 m3 and vertical tanks below 0.5 m3 are discussed in NFPA 58. Thickness of the fireproofing material shall be provided per “Fire Resistant Coatings” in this Chapter. 3. Pipe Supports: Fireproofing shall be provided on all pipe supports within 15 m of a tank and on all pipe supports within the spill containment area. 4. Tank Shell: If, based on substandard spacing in existing installations, a risk assessment determines a higher risk, fireproofing of the tank shell may be the only viable solution to alleviate the risk. For new plants it is required to provide adequate spacing as per Chapter 2 “PLANT SITE.” and fireproofing shall not be applied considered a solution take credit for substandard spacing. 5. Emergency Block Valves: Actuators and cabling of Non-fail-safe valves shall be fireproofed in order to function during the first 15 minutes of an emergency. The valve body does not need fireproofing since it is fire safe by design. Fail-safe installations do not need fireproofing since by definition the fire is supposed to destroy the cabling or ducts and thereby cause short circuit or pressure loss which in turn closes the valve. Fire Resistant Coatings There is a number of fire protective or insulating coatings available that could be considered for use on an LPG tank. The factors involved in selecting such a coating include: 8-2 1. Intended application (i.e., stationary tank, tank truck or railway car). 2. Amount of fire protection time required. FIRE PROTECTION Safety in LPG Design 3. Use of water sprays and type of water. 4. Required maintenance. 5. Material's physical properties. 6. Material's application properties. 7. Atmospheric corrosivity. 8. Weight limitations. 9. Cost of economics. With these factors in mind, short descriptions of various fire protective coatings and thermal insulating systems follow. 8.1.2.1 Dense Concrete Dense concrete or gunite have been used successfully for many years and are the materials of choice in refineries, chemical plants and terminals. Concretes made with Portland cement have a density of 2220 - 2380 kg/m3. Such concrete can be formed in place or pneumatically sprayed to the required thickness using steel reinforcement such as galvanized 14 US gauge steel mesh with openings of 50 mm by 50 mm. The mesh shall be spaced the required distance from the substrate, usually half the thickness of the concrete or gunite. See ExxonMobil Engineering Report EE.50E.88 for a recommended formulation and mixture. Concrete and gunite are durable and can be satisfactorily applied by most contractors. The disadvantages of these concretes include relatively high weight, high thermal conductivity, need for steel reinforcement and the installation cost and time involved in forming them in place. The underlying steel shall be coated prior to applying the concrete or gunite, and, also, in corrosive atmospheres, it shall be top-coated. 8.1.2.2 Lightweight Concretes Non-proprietary lightweight concretes are made of lightweight aggregates such as vermiculite and perlite and cements that are resistant to high temperatures. Additionally, a number of lightweight cementitious concretes (such as Carboline's Pyrocrete 241, et. al.) are available and have been used. Chloride-containing lightweight concrete shall not be used because of their innate corrosion potential. Dry densities range from 400 to 1270 kg/m3. Pneumatically applied material is about 20 percent heavier than lightweight concrete poured in place. Lightweights are often sprayed, troweled or formed in place using reinforcing mesh. The substrate shall be coated and reinforcement shall be required. A top coat for the lightweight concretes is recommended to prevent moisture from penetrating; otherwise, corrosion may occur, along with cracking and spalling in freezing climates. Lightweight concrete materials are fairly durable and have limited maintenance requirements. They are capable of withstanding direct flame impingement up to 1090 °C; they can withstand thermal shock and high-pressure hose steams; and they can be satisfactorily applied by most contractors. The disadvantages of lightweight concrete materials include the need to maintain a good surface coating so that moisture cannot penetrate. Additionally, lightweight concretes are also more susceptible to mechanical damage than are dense concrete materials. 8.1.2.3 Pre-formed Inorganic Panels Pre-formed inorganic panels are pre-cast or compressed fire-resistant panels made of a lightweight aggregate and a cement binder or a compressed inorganic insulating material such as calcium silicate and perlite. The panels are attached to the substrate by mechanical fasteners that are designed to withstand exposure to fire without appreciable Safety in LPG Design FIRE PROTECTION 8-3 loss of strength. An example of this type of material is COROC II and Hubilite insulating panel boards. When panels are used outdoors, an external weatherproofing system is usually required to prevent moisture from penetrating. All joints shall be caulked or sealed with mastic. Pre-formed materials have several advantages including: they can be applied cleanly; there is no curing time; and they have low conductivity. One disadvantage of preformed materials is the necessity for labor-intensive application when these panels must be fitted to tanks because of their diameter; therefore, they may not be practical. 8.1.2.4 Masonry Blocks and Bricks Masonry blocks of lightweight blast-furnace slag (used as coarse aggregate) are sometimes used. These units are laid up with staggered joints not more than 6 mm thick. The joints shall be made using fire-resistant mortar, such as a mixture of 1 part lime, 4 parts Portland cement, and 12 parts perlite. Brick and block are no longer commonly used because of their high installation cost and fairly extensive maintenance requirements. Brick-and-block assemblies tend to crack and admit moisture, which can lead to serious corrosion and spalling. They should provide adequate protection where currently installed, but should not be used in new installations. 8.1.2.5 Subliming, Intumescent, Ablative Organic Coatings Organic coatings (such as “Chartek” or “Pittchar”) can provide fire resistance through one or more of the following mechanisms: 1. Intumescent epoxies expand to several times their volume when exposed to heat and form a protective insulating ash or char at the barrier that faces the fire. 2. Subliming mastics absorb large amounts of heat as they change directly from a solid to a gaseous state. 3. Ablative mastics absorb heat as they lose mass. Organic coatings are sprayed on the substrate in one, two or more coats, depending on the required thickness. Reinforcing fabric or wire is needed for application to LPG tanks, tank trucks and railroad cars. The main advantage of organic fire resistant coatings is that they are lightweight. They are suitable for use on existing equipment supports that may not be able to handle additional weight or are located in less accessible areas. Because of complex application characteristics, the need for adequate film thickness and proper bonding to the substrate, only vendor-approved, experienced applicators should be employed. A disadvantage is that they may tend to shrink while curing; specifications should therefore indicate the wet thickness that will yield the required dry thickness. To ensure proper application and thickness, a qualified inspector should frequently check the applicator's work. A manufacturer's representative is frequently used to supervise the application and to serve as the inspector. Substrate preparation and priming of the steel is important to adequate bonding. Intumescent coatings require a top coat to prevent moisture from penetrating and causing failure. The surface coating should be inspected and renewed according to the vendor's recommendations. The use of fire hoses on an intumescent coating during a fire may be detrimental; part of the protective char may wash away. Also, coatings may be less durable than more 8-4 FIRE PROTECTION Safety in LPG Design traditional concrete materials when subjected to mechanical impact and abrasion. Several coatings should not be used where equipment or piping must be steam cleaned. See also GP 19-1-1 “Paints & Protective Coatings.” 8.1.2.6 Thermal Insulating Systems Two thermal insulating materials are recommended not only as insulating materials but also as fire resistant coatings. Suitable materials are listed in GP 14-3-1. A material like foamed glass block is applied in two layers, each 50 mm thick, with staggered joints. A steel jacket is also required. This steel jacket serves two purposes: 1. In the event of a fire it holds the insulation in place and prevents it from shattering and failing structurally. 2. It provides protection from fire hose impingement during fire fighting functions. These systems are frequently used where thermal energy conservation is required; foam glass can be designed and used for both cold and hot service. Poor fitting of the cladding over any porous insulation or gaps in insulation blocks can lead to corrosion under insulation discussed below. Sphere Watertight cover to protect column insulation Figure 8.1.2.7: Corrosion protection of sphere columns 8.1.2.7 Corrosion Prevention behind Coatings Experience has shown that improper protection of the steel under fireproofing or improper application of the fire proofing can lead to corrosion behind fire protective coatings. Concrete has been used extensively, and corrosion has been found frequently behind concrete and gunite coatings. The causes for such corrosion have been determined in several applications and include: Safety in LPG Design FIRE PROTECTION 8-5 1. Improper surface preparation and application. 2. Protective steel coating not applied when required. 3. Inadequate concrete mixes (compressive strength as low as 103 - 138 bar). 4. Inadequate rain shedding designs employed. 5. Little or no maintenance after application. 6. No external protective coating applied to fire resistant coatings. Each of these factors in its own way can be applied to each of the insulating or fire protective coating discussed above. It is important that each fire protective system be properly applied and maintained. Special care shall be taken when designing fireproofing for sphere columns. The upper end of the sphere column shall have an inclined watertight steel girder which positively prevents the ingress of water between concrete and column. 8.1.2.8 Selection of a Fire Resistant or Insulating Coating For stationary LPG bullets or spheres the system of choice as noted previously is dense concrete or gunite. Others have been used but, if an insulating system is required, then it is recommended that foam glass block be applied. To protect foam glass from flame and fire hose impingement, it shall be jacketed with a steel jacket. Alternatives to concrete are lightweight cementitious coatings or proprietary lightweight concretes such as Pyrocrete 241, which has been used successfully within the company for a number of years. These require no protective jacket. Coatings on tank trucks or rail cars are normally provided only when required by local regulations. Intumescent epoxy coatings have been applied successfully on over-theroad tank trucks in some Far East locations for several years. When required for tank trucks or railway cars, an intumescent epoxy “Chartek III” or PPG's “Pittchar” shall be used, mainly because of their ability to absorb road shock damage. 8.1.2.9 What Thickness Is Required? There is no easy answer to this question and it pertains to each of the fire protective coatings discussed previously. There are several guidelines including the following: 1. The most conservative guideline is API 2510 which states that the fire resistant coating must give 1-1/2 hours protection in a UL 1709 fire when exposed on a 10W49 steel beam. There is no indication if it is to be exposed in a contour or box design, but for organic coatings and lightweights the contour design is recommended. 2. Global Practice 14-3-1 recommends that for a critical application to a 19 m3 capacity or greater tank, fireproofing with 38 mm of high density concrete or gunite shall be used. 3. Independent testing facilities, such as Germany's BAM F90 where test requirements are less demanding than API 2510, require 90 minutes protection for an LPG tank using venting LPG as coolant in a non-controlled fire. 4. Other National laws (in US and overseas) regarding both rail and truck transportation require various criteria affecting thickness. It is recommended that for LPG tanks or other stationery storage API 2510 be followed. For truck tanks, there are no clearly defined procedures; therefore, it is recommended that national rules be followed. Do not follow the advice of proprietary coating manufacturers unless there is documented laboratory testing that such coating thickness meets local or national law. Additionally, consider long term durability (10-20 years) in 8-6 FIRE PROTECTION Safety in LPG Design the atmosphere, resistance to mechanical damage, need for thermal insulation, corrosion of the underlying steel, ease of repair, and others. 8.2 Fire Protection System Design Philosophy Most LPG fires originate as smaller fires that have the potential to become larger and more hazardous. Such fires may not occur as a result of tank failure, but because of pump or piping leaks, or tank overfills. Human failure, such as overfill or improper water draining, can also lead to an LPG release. Unless controlled, the leak can ignite and the fire can escalate rapidly. A primary objective of the features described in this section is to break that chain of events and control incidents at an early stage. See also API Standard 2510A “Fire-Protection Considerations for LPG Facilities.” Design for optimum safety of LPG facilities varies with differences in the size and type of operations and in plant operating environments. The greatest concern is fire, and the fundamental philosophy is as follows: 1. Prevent releases and fires by proper design, sound operating practices, and regular training of personnel. 2. Provide a system of valves (Emergency Block Valve) that can be operated locally or remotely, to isolate storage tanks and transfer equipment in case of a leak, fire or other emergency. 3. Provide a means of protecting LPG tanks and tanks from overheating in case of fire. The properties of LPG are such that a small release, if not controlled, can escalate very quickly into a major event. Therefore, fire protection equipment shall be designed for rapid actuation and for the largest credible scenario. The first step in determining fire protection requirements is to divide the plant into risk areas. DP XV-G, “Equipment Spacing” defines areas separated by 15 m of relatively open space as separate risk zones. Fire can normally be contained to one risk area. Spacing, firewalls, drainage, and emergency block valves are design elements that will limit the spread of a fire and allow firefighting access. For example, in a large plant the marine piers, truck loading, and cylinder filling areas may be separated by spacing and segregated drainage. The figures for spacing given in Chapter 2 “PLANT SITE” are considered adequate for this separation. A small redistribution center would be considered one risk area. Cooling by firewater is the basic fire protection for LPG distribution facilities. The extent and capacity of the firewater system is based on the assumption that only one major fire will occur at one time. Thus, the sizing and layout (Design Practices XV-J) of major components of the system is based on the fire contingency at the risk area having the largest requirements. The system shall be sized to provide firewater for the fire area and for cooling all equipment in the vicinity of the fire area. Sizing guidelines for Refining and Upstream facilities are discussed in Design Practices XV-I and GP 3-23. For Marketing terminals and bulk plants, the system configuration and spacing is outlined in Chapter 2 “PLANT SITE” and sizing of the firefighting facilities is discussed below. While the main purpose of the firewater system is to provide cooling in case of fire it shall be mentioned that monitor and hose streams, and water spray systems, can also be used to disperse vapor releases. The maximum firewater flow requirement is generally for the LPG tank area. Required water rates for these and other risk areas are in “Firewater Pumps in Plant.” Safety in LPG Design FIRE PROTECTION 8-7 Fire protection for redistribution centers, for bulk customer and dealer installations, shall be designed as required by local law. However, a risk assessment may require higher than normal protection. This has to be decided case by case. Guidelines for emergency planning can be found in the ExxonMobil Marketing Operations Guide (Grey Book) “PLANT EMERGENCY PLANNING.” Requirements in this chapter cover the basic needs of most facilities, but modifications may be necessary for specific situations. Local regulations shall always be followed. Equally important, fire protection equipment shall be suitable for the response capability of the plant itself and of public emergency agencies and mutual aid partners. Emergency planning shall reflect all of these factors. Development of those plans and testing them with practice drills will often show where improvements can be beneficial. 8.2.1 Firewater System, an Active Fire Protection Reliability is a primary consideration in the design and layout of the firewater system. The system shall be designed for easy testing to assure dependability, adequate flow rate, and adequate coverage of the protected equipment. In a plant handling other products in addition to LPG, an integrated system is normally provided. Firefighting foam may be available for gasoline or other fuels, but it shall not be used on an LPG spill or fire. Application of foam will not control vapors or extinguish an LPG fire; in fact, by adding heat, it is likely to increase the vaporization rate with unpredictable and undesirable consequences. Provisions for fire protection shall comply with the requirements of API STD 2510 and API Publication 2510 A. 8.2.1.1 Firewater Source A large body of unlimited water such as the sea, a lake, or a river is the preferred firewater source. The suction pipe shall designed such that it is always fully submerged irrespective of tidal conditions. Where this is not available, wells or a municipal supply can be used if sufficient capacity and reliability are available. Municipal sources used for drinking water shall be protected against contamination by positive means, such as a break tank with the water inlet at the top above the maximum level. The fire water system shall be suitably protected from freezing where necessary. Where the source is limited, water storage shall be provided, sufficient to provide full design flow for a minimum of 4 hours for Marketing Terminals and 6 hours for Refining and Upstream Facilities without interrupting other essential users at the plant. The difference between both is based on experience and the complexity of units. Also, the water source must be capable of supplying one half the maximum firewater demand on a continuous basis after the storage capacity has been used. Storage can be in tanks, ponds, or reservoirs. Refining or Upstream facilities shall have a connection between the cooling water system and the firewater system as an emergency back-up. 8.2.1.2 Firewater Pumps in Plant The main firewater pumps shall have a total capacity no less than the demand of the largest risk area. At least two pumps shall be provided, with independent power sources for drivers. This may consist of one diesel plus one electric or, two diesel powered pumps. Alternatively, the drivers of all firewater pumps may be electric motors provided a backup diesel generator system capable of supporting all firewater pumps’ drivers is available. The decision should be based on reliability of electrical supply. 8-8 FIRE PROTECTION Safety in LPG Design Rated capacity of any single pump normally does not need to exceed 50% of the total requirement. For small terminals where the pump size is the same or smaller than local fire trucks, consider providing connections so the fire truck can operate in parallel in the event of failure of one of the pumps. RAILWAY RAIL CARS Spray Water Spray Water Spray Water Remote Impoundment Hydrant Hydrant Bullets Deluge System MOUNDED TANK Sphere Spray Water MOUNDED TANK Earth Mound Pumps M o n i t o rH y d r a n t Monitor Hydrant Propane Loading Spray Water Spray Water Spray Water Butane Loading FIRE Firewater Main Grid WATER TANK FILLED CYLINDERS FIRE PUMPS Hose Reel Spray Water EMPTY CYLINDERS OFFICE BUILDING CYLINDER FILLING GATE Figure 8.2.1: Typical Firewater system in a Marketing Terminal Where support by local fire brigade is weak or questionable, three pumps, each providing 50 percent firewater design capacity, would normally be considered to provide sufficient reliability. The third pump would be available when one of the first two is down for maintenance or fails in service. Likewise, two 100 percent pumps may be specified. One would be "primary" while the other would serve as a spare. Pumps are normally sized no larger than 568 m3/h but can be larger if a single firewater demand exceeds this. When two 50% pumps are provided, the site shall have a plan for backup protection during maintenance downtime of one pump. Upstream, due to the remote nature of many facilities, requires 100% coverage at all times, i.e. two 100% pumps or three 50% pumps. Diesel drivers shall match the power requirements of the pump. Engines shall be equipped with a closed-circuit cooling system employing a water- Safety in LPG Design FIRE PROTECTION 8-9 cooled heat exchanger or a radiator with fan. It shall be noted that the horsepower requirement is greater for a radiator with fan cooling system than for a water-cooled heat exchanger system. This shall be carefully considered when determining the size of engine needed. Water quality (hardness, corrosivity, sludge content) shall be evaluated when determining the type of cooling system provided. Heat exchangers are prone to plugging and failure under conditions of poor water quality and may prove to be unreliable under such conditions. Enough fuel shall be on hand at the Diesel pumps to operate at maximum fuel use capacity for four hours in Marketing and six hours in Refining and Upstream Facilities. The pumps shall have remote and local start capability. Primary fire pumps shall be sequentially and automatically started by a drop in fire main pressure. Further pressure drop shall automatically start the secondary fire pumps. Manual starting of the primary and secondary fire pumps is acceptable provided that the facility is manned 24 hours and proper procedure for fire water startup has been established. The staged pre-set timers are typically set at 5 – 10 second delays. Care shall be taken to ensure that the chosen system allows pumps to be tested with minimal impairment of the total fire protection system. Additionally, the flowmeasuring device shall be located for accurate testing throughout the pump capacity curve. Figure 8.2.1.2-a: Firewater Diesel System design depends on the combination of pumps and pipe sizing to deliver proper pressure to spray systems, hydrants, and other users. At least 5.5 bar gauge pressure shall be available at design rate at the farthest point in the mains from the pumps. Handheld hoses are difficult to control above 8 bar gauge. To stay within this operating range, pump discharge pressure shall not be less than 8.6 bar gauge at rated capacity; 10 bar gauge is a reasonable maximum. A flat pump curve is necessary because a wide range of flow rates will be needed for different contingencies. The pressure rise at shutoff shall not exceed 20%, and at 150% of rated capacity the head shall not be less than 65% of design. The firewater rate will depend on the exposure. Following rates from NFPA 2510A are used to calculate the firewater requirements: 8-10 FIRE PROTECTION Safety in LPG Design Tank Cooling (radiation): Tank Fire Engulfment: Jet Fire Impingement: 4.2 liters per minute per m2; 10.5 liters per minute per m2; 1000 - 2000 liters per minute; at point of contact For a three sphere (20 m diameter) installation, the basis for the firewater rate would be as follows: assume the central tank on fire. The two adjacent tanks would need cooling. The calculation would be: Tank area: π x 202 = 1256 m2 Tank on fire would need: 1256 x 10.5 = 13188 liters per minute Adjacent tanks would need: 2 x 1256 x 4.2 = 10550 liters per minute For potential jet fires add: 2000 liters per minute Total firewater demand: 25783 liters per minute For larger tanks credit may be taken for tank areas not under direct flame radiation. System pressure shall be controlled at the pump discharge by a pressure controller, bypassing excess flow back to the water source. Higher pressures, and additional controls, may be needed if the plant is very large or there are significant differences in elevation. Figure 8.2.1.2-b: Firewater pump Continuous positive pump suction shall be provided. Priming devices are not recommended because of concerns about reliability. This means that submerged vertical centrifugal pumps are needed to lift suction from the sea or other waterway. Horizontal centrifugal pumps are suitable only if the source is above the pump; for example, from a tank. Suction screens or strainers shall be provided if foreign material is present which could plug the suction lines or pumps. Either traveling or double removable screens, cleanable with the pump in service, shall be used. A flow meter is recommended, such as an averaging type pitot tube, to permit testing the performance of each pump. The instrument can be located in the main firewater grid piping, where it can also be used to measure flow to deluge and spray systems. It can also be located in the bypass line back to the source. A jockey pump shall be provided on a pressurized wet pipe firewater system to maintain water pressure. The jockey pump shall be sized such that it will pressurize the Safety in LPG Design FIRE PROTECTION 8-11 firewater system to 690 kPa gauge in 2 minutes. Firewater main pressure shall be monitored at a continuously manned location and alarm upon low pressure in the system. The jockey pump is not considered as part of the overall plant firewater capacity, although it may be used for other utility purposes. Shutoff valves shall be provided on each pump discharge to permit maintenance work without disrupting the firewater system. Shutoff valves shall be positive shut-off valves. 8.2.1.3 Firewater Distribution Piping in Plant A grid or looped pressurized firewater system shall be provided, capable of supplying water at the required rate to any part of the plant. The fire mains enclose each risk area in a loop, and the loops are interconnected to form a grid. Isolation valves shall be provided so that in the event of any single piping failure: 1. No more than 300 m of pipe containing users (hydrants, hose reels, sprays, monitors, etc.) can be lost; and 2. The piping to only two adjacent sides of any risk area can be lost. Piping within a risk area supplying more than two users shall be connected to two separate sections of the fire main separated by a valve in the main. Lines to two or more users shall also be valved at each end where they connect to the main. Fire mains shall be sized by hydraulic calculations to supply required rates. A minimum 150 mm nominal pipe size is recommended. Pipe flow velocities shall not exceed 6 m/s in any area of the distribution system piping. In freezing climates, all sections of the piping system that are normally filled with water shall be buried 300 mm below the frost line. Firewater connections to monitors, hose reels, sprays etc. in freezing climates shall be winterized. Above-grade sections shall normally be dry per GP 3-2-3 para. 3.17. Piping material shall preferably be welded steel; flanged cast iron may also be used, except in Upstream applications. Buried steel pipe shall be suitably coated and wrapped for corrosion protection. Cement lined pipe shall be required for salt water service, and is recommended for fresh water, to minimize corrosion. The residual pressure at the hydrant outlet shall be the basis for determining the hydraulics for the firewater piping system. The minimum residual pressure shall not be less than 690 kPa gauge. Pipe which is one size larger than calculated required pipe NPS shall be used in designing firewater piping system to deliver the specific flow rates since internal corrosion and scale formation in unlined steel pipe may reduce the flow capacity over time. 8.2.1.4 Firewater Deluge for Tanks A water deluge is a system where water is applied at the top of a tank and allowed to run down. Lines shall be at least 75 mm in size. In addition, a fixed spray system shall be used to wet the lower hemisphere of the sphere. Where monitors are available which can fully wet the lower hemisphere, they may be substituted for the lower spray system. This type of system is most effective for spheres because the tank geometry assists in evenly distributing the water. It can be built from large diameter piping that is not prone to plugging and is more likely to survive an explosion. A disadvantage is that soot and carbon from a fire may inhibit wetting the surface, particularly the underside of the sphere. The lower spray systems, or monitors, are used to protect the underside. A recent change in the GP-3-2-3 requires now firewater coverage of the lower hemisphere If necessary, weirs shall be used to improve water distribution and prevent “dry spots.” Especially the area behind columns needs careful ducting of deluge water. The adequacy of the water coverage shall be determined by means of performance tests. If water could accumulate behind weirs they shall be provided with drain holes to prevent corrosion. 8-12 FIRE PROTECTION Safety in LPG Design Water is usually applied over the tank by a single large nozzle at least 38 mm diameter, with inverted bowl deflectors to direct the flow downward. Manholes, piping connections, and ladders often interfere with uniform coverage, so weirs and baffles can be used to improve distribution. The system shall be manually operated from a safe location outside the spill containment area and at least 15 m from the tank being protected. The location of the actuating valve shall be prominently marked. In locations with limited manpower, the system shall be remotely operable from a manned location. Deluge valves shall be designed to be easily reset without removal of faceplate or other disassembly of the valve. Deluge valves shall be designed to fail in the open position on loss of control power. 8.2.1.5 Firewater Sprays Water spray systems consist of a network of small spray nozzles, arranged in rows or grids over the tank or equipment being protected. This type of system is more susceptible to plugging, which results in reduced and unequal water application. Water spray systems are also more susceptible to damage from an explosion than deluge systems or monitors. Figure 8.2.1.5-a: Large bore firewater vortex spray nozzle A spray system is normally dry, with open nozzles, and is operated by a single valve. The system shall be manually operated from a safe location outside the spill containment area and at least 15 m from the equipment being protected. The location of the actuating valve shall be prominently marked. In locations with limited manpower, the system shall be remotely operable from a manned location or may be activated automatically. A skilled and experienced specialist, using hydraulic calculations should design systems; otherwise it is likely that flows will not be uniformly distributed. Several features are needed to minimize plugging. A strainer with a valved 50 mm blow-off connection shall be installed in the main feeder pipe to the sprays. Mesh size shall be 50% or the spray nozzle diameter. Nozzles shall have a minimum orifice diameter of 13 mm; diffusers or deflectors to form the spray pattern shall be external. The maximum openings of the strainer shall be 6 mm and the ratio of free screen area to pipe crosssectional area shall be no less than 3:1. Water distribution within the nozzle discharge Safety in LPG Design FIRE PROTECTION 8-13 pattern shall be uniform; hollow-cone patterns shall not be used. The pattern shall be reasonably unaffected by changes in water flowing pressure within the anticipated pressure range. Nozzles shall spray well-dispersed droplets throughout the discharge pattern, with approximately 85 percent of the droplets ranging from 200 – 400 microns in diameter. A waterspray nozzle pressure of not less than 414 kPa is acceptable. Carbon steel piping downstream of the strainer shall be internally galvanized, and flushout connections shall be provided. Corrosion-resistant stainless steel and copper-nickel alloy is preferred to galvanized pipe, although they are more expensive. Spray systems shall be designed as shown in Figure 8.2.1.5-b. If at all possible flush valves should be installed at the end of the header which can be opened before each test. In cold climates the system must be self draining. Spraywater Settling rust and debris Figure 8.2.1.5-b: Spray nozzle design minimizing plugging Spraywater Settling rust and debris Figure 8.2.1.5-c: Unfavorable spraywater design leading to plugging. 8.2.1.6 Hydrants in Plant A sufficient number of hydrants shall be installed to supply the required water rate to each risk area. They provide backup protection in case a primary system such as a deluge or water spray is disabled. Hydrants can provide water to pumper trucks, mobile monitors or hand-held hoses, directly from the plant firewater system. Depending on the number and size of hoses, a hydrant can supply 130 to 170 m3/h of water. When a pumper truck is used, it can boost the pressure, increasing flow to 250 m3/h. Hydrants shall be located within 50 m of any point where water will be required. However, they shall be accessible in emergencies, and shall be along roadways and not 8-14 FIRE PROTECTION Safety in LPG Design within risk areas. Maximum spacing between hydrants is 90 m, measured along roads or accesses ways. Hydrants shall be located on at least two sides of each LPG tank so the tank can be reached by at least 3 streams of water from hose lines not longer than 90 m. Hydrants shall be 102 mm diameter with two 65 mm hose connections. Each hydrant shall have two valved and capped hose connections, and a larger valved and capped connection to supply a pumper truck. The length of suction hose required shall not exceed 7.5 m. Connections shall be compatible with municipal and mutual aid firefighting equipment. Hydrants shall be self-draining in freezing climates. The steel hydrant barrels shall be hot-dip galvanized after welding. Unless a local fire department hose connection is specified male hose thread, 65 mm to NST (refer to NFPA 194) may be used. 8.2.1.7 Firewater Monitors may be Fixed or Mobile Fixed monitors provide practical and flexible firewater coverage, and shall be considered if emergency response forces are limited. A monitor can be quickly aimed, activated and locked in position by a single person, who is then free for other tasks. A monitor has an effective range of about 30 m, and if strategically placed can protect two or more risk areas. Monitors can be bolted directly to hydrants with no additional piping. They shall be accessible in an emergency, between 15 and 30 m from the equipment protected. Depending on ship size, monitors on piers may have to be remotely operated. Monitors shall be of brass or bronze construction, with double ball bearing swivels and a locking device. Nozzles shall be about 110 m3/h capacity, adjustable for fog or straight stream type. In terminals, tank truck and tank car loading and unloading positions shall be protected by fixed water monitors with adjustable fog-to-straight-stream nozzles located on each side of the loading and unloading installations. Installation of fixed water monitors shall be considered at large or high-risk consumer installations. Mobile monitors shall have the same capabilities as described above but are more flexible because they can be moved around to cover larger areas. However, they require more time and manpower to deploy. The monitor shall be furnished with two hose connections, and two 15 m lengths of hose, which can be stored on the trailer. Each connection requires a check valve to protect against a burst hose. For rapid deployment, hoses shall remain connected to a hydrant or valved outlets from a firewater main. 8.2.1.8 Internal Firewater Flooding of Tanks Pressurized LPG storage at refineries and upstream gas plants shall be provided with water flooding facilities to inject water and displace LPG in the lower portion of LPG tanks, in the event of a tank leak, per GP 3-2-3 para 9.4. Marketing facilities may provide connections if required by risk considerations. The key to such an installation is to have water pressure available to overcome the sphere pressure. In the case of Propane or Propane rich storage, or sometimes Butane storage, higher pressure water is provided via a pumper truck. 8.2.1.9 Hoses and Hose Reels Fire hoses are for use by plant or municipal brigades, usually as backup for deluge and spray systems and monitors. Two to four men may be needed to handle a typical 65 mm size hose. The time needed for deployment can be reduced if hoses and nozzles are available at the plant. Hoses shall be stored in cabinets because they can be deteriorated by solar radiation. Nozzles shall be constant-volume, adjustable combination straight Safety in LPG Design FIRE PROTECTION 8-15 stream/fog types, made of brass. Live hose reels shall be permanently connected to the fire main system. One person can put hose reels into action more quickly than the larger hoses where a team is required. Fixed hose reels typically hold 30 m of 32 to 38 mm hose of the firm type that can be stored on the reel without collapsing. 8.2.1.10 Drainage Against Area Flooding During Firefighting Spills of LPG liquid (and heavier-than-air vapor releases) shall drain away from product storage, transfer areas, and buildings. It is also important to avoid accumulation of water where it could interfere with emergency actions. The drainage system for each individual risk area shall be sized for the maximum rate of rainfall, or design firewater rate, whichever is greater. Plant-wide drainage capacity is usually set by the maximum rainfall rate, assuming this exceeds the firewater requirement for the largest risk area. 8.2.1.11 Dry Powder Fire Extinguishers The preferred strategy for fighting an LPG fire is to isolate the fuel at its source and to cool exposed equipment. LPG fires shall not be extinguished unless the fuel supply can be isolated; otherwise a vapor cloud may form and create a greater hazard. However, portable fire extinguishers shall still be provided in LPG plants, primarily to protect against fires involving other materials. In plant areas outdoors, type BC or ABC dry chemical extinguishers are most suitable. Portable extinguishers with about 9 kg of agent can readily be carried and used by one person. Typically two extinguishers shall be provided at strategic locations throughout plants. Examples for such locations are: marine piers, truck and rail racks, cylinder filling sheds, pumps, compressors; and redistribution centers. Larger wheeled units with about 70 kg of agent are more powerful, but normally two people are needed for handling and maneuvering. They shall be placed near truck loading racks, and can be considered on piers unless congestion would limit their mobility. Dry chemical extinguishers are also effective indoors, but the agent is messy and can damage electrical and electronic equipment. Carbon dioxide extinguishers are recommended for substations, computer rooms, and similar locations with sensitive instruments and switch gear. Halon extinguishers (type BC) are no longer recommended because of environmental concerns. Pressurized water extinguishers can be considered for offices where combustible materials such as wood, paper, and plastic are the main sources of fuel. Extinguishers for use indoors shall be mounted near exit, and shall be of a size that can readily be carried around in the building. 8.2.2 Protection Requirements 8.2.2.1 Aboveground Tanks – Bullets and Spheres Spheres shall be protected with either a water deluge system, per GP 9-2-1 (preferred), or a fixed spray system discussed later in this chapter. Water deluge systems are not recommended for horizontal bullets, or for protection of transfer operations which shall use firewater sprays. Although fireproof insulation may be substituted for deluge or sprays provided fire water is also available, generally deluge and sprays are preferred. Spray systems shall be used on horizontal LPG bullets, cylinder filling and storage areas, and truck and rail loading/unloading areas. For horizontal bullets, a fire water monitor system capable of wetting the whole bullet surface may be substituted for sprays. If three or more tanks are closely spaced, less than 15 m shell-to-shell, they shall 8-16 FIRE PROTECTION Safety in LPG Design be fireproofed if a fire water monitor system is used, per GP 14-3-1. This is because the close spacing will make fire water coverage more difficult. At least two portable fire extinguishers each having a minimum capacity of 9 kg of dry chemical with a B: C rating shall be provided. Emergency controls, if provided, shall be conspicuously marked, and the controls shall be located so as to be readily accessible in emergencies. 8.2.2.2 Buried/Mounded Drums Mounding or burial of storage drums shall be considered as adequate protection without further need of firewater for these tanks. For mounded drums, the sand shall be stabilized with a layer of grout or other material to prevent erosion from rain or firewater hose streams. At least two portable fire extinguishers each having a minimum capacity of 9 kg of dry chemical with a B: C rating shall be provided. Emergency controls, if provided, shall be conspicuously marked, and the controls shall be located so as to be readily accessible in emergencies. 8.2.2.3 Pump and Compressor Stations A live hose reel shall be provided covering the entire area of the pump and compressor area with 30 m long hose. Live hose reel shall be permanently connected to the fire main system and the nozzles shall be complete with shutoff ball valves. Adjustable fogto-straight- stream nozzles shall be provided on live hose reels equipped with 30 m of 32 or 38 mm fire hoses. At least one portable fire extinguishers having a minimum capacity of 9 kg of dry chemical with a B: C rating shall be provided. Emergency controls, if provided, shall be conspicuously marked, and the controls shall be located so as to be readily accessible in emergencies. 8.2.2.4 Truck Loading and Unloading Facilities Tank truck and tank car loading and unloading positions shall be equipped with dry chemical fire extinguishers as follows: one 15 kg dry chemical extinguisher for each four positions. Since the only safe way to extinguish an LPG fire is to shut off the product supply, dry chemical fire extinguishers are required for other purposes, such as small spills or burning materials after the product has been shut off. At consumer locations, tank truck unloading positions shall be equipped with dry chemical fire extinguishers. Either a water spray system or fixed water monitors shall be designed for truck loading and unloading area. Sufficient number of 30 m long live hose reel shall be provided to cover the entire area of the truck loading/unloading area. Live hose reel shall be permanently connected to the fire main system and the nozzles shall be complete with shutoff ball valves. Adjustable fog-to-straight-stream nozzles shall be provided on live hose reels equipped with 30 m of 38 mm fire hoses. At least two portable fire extinguishers each having a minimum capacity of 9 kg of dry chemical with a B: C rating shall be provided for the truck loading/unloading area. Emergency controls, if provided, shall be conspicuously marked, and the controls shall be located so as to be readily accessible in emergencies. 8.2.2.5 Vaporizer At least one portable fire extinguisher having a minimum capacity of 9 kg of dry chemical with a B:C rating shall be provided. This requirement is optional if the vaporizer is installed near LPG tanks where fire extinguishers are already provided. Safety in LPG Design FIRE PROTECTION 8-17 8.2.2.6 Cylinder Filling Plant Water spray system shall be designed for filled cylinder storage area. Sufficient number of 30 m long live hose reels shall be provided to cover the entire area of the cylinder filling plant. The hose reels shall be permanently connected to the fire main system and the nozzles shall be complete with shutoff ball valves. Adjustable fog-tostraight- stream nozzles shall be provided on live hose reels equipped with 30 m of 32 to 38 mm fire hoses. At least two portable fire extinguishers each having a minimum capacity of 9 kg of dry chemical with a B: C rating shall be provided for the LPG filling plant. Emergency controls, if provided, shall be conspicuously marked, and the controls shall be located so as to be readily accessible in emergencies. 8.2.2.7 Cylinder Storage All storage areas shall clearly display a warning notice with the words “LPG STORE.” Warning signs “STOP MOTOR”, “NO SMOKING”, “FLAMMABLE GAS” shall be posted at all LPG cylinder storage area. The locations of the signs shall be determined by local conditions, but the lettering shall be large enough to be visible and legible. Sufficient number of 30 m long live hose reel shall be provided to cover the entire area of the cylinder storage area if the water capacity of the total LPG cylinders stored exceeds 15 m3. Live hose reel shall be permanently connected to the fire main system and the nozzles shall be complete with shutoff ball valves. Adjustable fog-to-straight-stream nozzles shall be provided on live hose reels equipped with 30 m of 38 mm fire hoses. Fire-fighting foam shall not be used for LPG fire. At least two portable fire extinguishers each having a minimum capacity of 9 kg of dry chemical with a B: C rating shall be provided for the cylinder warehouse. 8.2.2.8 Cylinder Maintenance Shed Sufficient number of 30 m long live hose reels shall be provided to cover the entire area of the cylinder maintenance. At least two portable fire extinguishers each having a minimum capacity of 9 kg of dry chemical with a B: C rating shall be provided for the cylinder maintenance shed. 8.2.2.9 Firewater at Marine Piers Firefighting monitors shall be installed at the berth, primarily to provide coverage/cooling for the berth manifold area and the cargo transfer equipment. They may also provide a method for dispersing LPG vapors in the event of an accidental release. Berth monitors shall provide assistance to the vessel's firefighting system and shall be able to cover the vessel's manifold area. In addition, berths receiving vessels in the international trade shall have ISGOTT fire water connections installed at the berth to provide the vessel with fire water in the event of an emergency. Fire water connections for a fire boat to connect and increase the berth's firewater capacity shall be considered. If firewater connections are installed, they shall be located at least 60 m away from high risk areas. Detailed description of the firewater requirements and firefighting equipment requirements for marine terminals are provided in EMRE's report EE.5TT.81 “Fire Protection and Safety Guidelines for Marine Terminals.” 8-18 FIRE PROTECTION Safety in LPG Design The following fire protection shall be provided: 8.2.3 Installation Requirements (Minimum) Barge pier or wharf for transfer of Class I products, or any product heated above its flash point, and Class I products in drums Fire main and hydrants with firewater supply of at least 340 m3/h Portable fire protection including monitors and portable fire extinguishers Flammable Gas Detectors Flammable gas detectors may be provided as early warning. Installations shall be based on risk considerations. Plants close to housing that may be unmanned during the night would need higher protection than plants in uninhabited areas. A minimum level of leak detection is already called for on all new pump seals. The integrity of the pump seal can be further upgraded to one of the higher sealing categories described in Chapter 4, “Shaft Sealing,” to both reduce the chances of pump seal failure and provide better containment should the pump seal fail. In addition to pump seals, new compressor seals, depending on risk considerations may also be provided with a leak detection device. Leak detection may also be provided around loading/unloading locations, which do not have continuous surveillance, and around LPG tanks, through the use of flammable gas detectors. Decisions to provide this additional monitoring would typically be made as a result of a risk analysis. The analysis would typically consider local conditions, the proximity of the storage to the fence line and populated areas or to process equipment and ignition sources, and the volume of storage or frequency of loading/unloading operations. When flammable gas detectors are applied to loading/unloading points, the design shall be tolerant of hydrocarbon that will be present around the transport vessel due to breaking connections. If not, false alarms will render the system ineffective by frequent nuisance alarms. Additional detail on flammable gas detectors is provided in Design Practices Section XV-K, “Flammable Gas, Toxic Gas, and Fire Detection Systems.” LPG detection system shall be designed as “PRE-FIRE” early warning system. As such, automatic water application system (i.e. deluge, water spray) shall not be activated by LPG detection system alone. Open path detectors are now reliable and a few instruments can cover large areas. To detect leaks from groups of equipment or facilities within the same line of sight, openpath gas detects shall be installed. For example, open path gas detectors can be used to detect release of LPG from a row of pumps or compressors. Their signal may be used to activate the Emergency Shutdown System. An audible alarm is needed at the control room and, if the control room is not permanently manned, also a local audible alarm. Some local regulations always require local alarm. During times when the plant is not manned, the alarm may be transmitted to a security company. Also point detectors are acceptable. They may be installed to detect leaks from individual release sources. Individual release sources includes pump seals, compressor seals, flanges, safety relief valves venting to atmosphere, sewer vents and small pipes/connections which are prone to failure due to vibration or corrosion. One point detector may be used to detect gas leaks from several individual release sources which are located nearby. However, the coverage or sensing area of the point detector must not exceed those specified by the manufacturer. If coverage area is too large for one detector, additional point detectors shall be installed. Safety in LPG Design FIRE PROTECTION 8-19 Detectors shall initiate an alarm at the following: 1. A measurement of 20 –2 5 percent LEL - at least 100 decibels audible and visual alarms. The alarm condition shall not be considered cleared until the specific detector reading has dropped below 20–25 percent LEL. Operator response shall be required to clear the audible and visual alarms. 2. A measurement of 50 – 60 percent LEL – activate an emergency ALARM and at least 100 decibels audible / visual alarms. The alarm condition shall not be considered cleared until the specific detector reading has dropped below 20 – 25 percent LEL. Operator response shall be required to investigate cause of emergency, take corrective action before clearing the audible, visual alarms and resetting the emergency ALARM system. These detector shall sound alarm at the site and at a constantly attended location if the site is not continuously manned. The detectors shall be installed not more than 100 mm above grade level. At least one gas detector shall be installed at each of the following locations: 1. LPG tanks. 2. Truck loading/unloading rack. 3. Cylinder filling shed. 4. Jetty - near manifold flanges. Gas detectors shall be positioned based on site conditions and requirement taking into account of manufacturer’s recommendation. 8.2.4 Fire Detectors Minimum requirements can be supplemented with additional fire protection, depending on each plant's situation. Factors which may make this desirable include limited emergency response capability; proximity to populated areas or public roads; risk from adjacent facilities; future development of the area; availability of utilities; and topography of the site. Fire detectors are an appropriate design feature to provide early warning thus reducing risks. Additional fire detector details are provided in Design Practices Section XV-K “Flammable Gas, Toxic Gas, and Fire Detection Systems.” Numerous mechanical and electronic devices are available to detect the environmental changes created by a fire. The most sophisticated type is the optical flame detector, which “sees” a fire directly, without depending on air currents to transport smoke or hot gases to a sensor. This is a significant advantage outdoors. Flame detectors can be useful in emergency response by reducing the time interval between the outbreak of a fire and its control, which is important in an LPG installation. When an optical device is desired, the infrared (IR) detector designed specifically for hydrocarbon fires is recommended. IR detectors are more reliable and less vulnerable to false alarms than ultraviolet (UV) detectors. The ability to discriminate between fires and false alarms can be improved by adding a second sensor, either IR or UV. Considerable care and expense are needed in design, installation, and maintenance if flame detectors are to be beneficial. A detector can only save time in identifying an emergency, and there may be better ways to do it. Flame detectors shall be considered if all the following conditions exist: 8-20 1. Continuous surveillance not feasible with available personnel. 2. Early warning by other means not feasible: gas and seal leak detectors. 3. Capability exists for prompt response: fire suppression, shutdown, and isolation, whether automatic or manual. FIRE PROTECTION Safety in LPG Design 4. Available technical expertise for equipment selection, design, installation. 5. Ongoing maintenance support available. All flame detectors have a wide field of view, typically around a 90° angle. This suggests a small number of detectors could cover a large area, but there are other factors to consider. Response is not instantaneous, because the detector to satisfy its design criteria for a fire must accumulate enough information. The sensitivity and response time of a detector depend on fire size, distance, and the position of the fire in its field of view. And as distance increases, obstructions become more of a problem, and false alarms become more likely. Requirements for audible alarms are as discussed under “Flammable Gas Detectors.” Heat sensing detectors, also discussed in DP XV-K, are an alternative to optical flame detectors. Response from heat sensing detectors is slower, but false alarms are reduced compared with optical detectors. Two types of point heat sensing devices, pilot heads with fusible plugs and nylon tubing, have been used with success to automatically actuate deluge or spray systems. When fire detectors are deployed at locations with spray or deluge systems, the site shall evaluate automating the deluge/spray system with the fire detection. In the case of LPG tanks, prompt actuation of deluge/spray systems will reduce any BLEVE potential. Safety in LPG Design FIRE PROTECTION 8-21 9 TRANSPORTATION 9.1 Means of Product Movement This chapter discusses the various types of equipment used to convey product between refineries and marketing terminals, from terminals to distributors, or from terminals to end users. Ship or rail car normally transports large quantities while road transportation dominates transportation in smaller parcels. The LPG is transported in pressure tanks, which are mounted to ship, rail car or truck. Ships are also often equipped with refrigerated tanks. The discussion in this section cites basic, generally accepted standards for equipment design that will provide satisfactory LPG transportation if more specific national standards do not exist. Need for “custom design” can be avoided since vendors have standardized equipment designs for tank trucks, portable containers and rail tank cars. General guidelines are defined to assist in selecting the most efficient truck power trains and suspensions for various types of service. 9.2 Road Bulk Transportation Equipment Two classifications of road transport are considered: 9.2.1 1. Large capacity transports for point-to-point product delivery from a supply source to a single destination. 2. Smaller route delivery trucks (Mini-bulk) designed to load at a terminal and deliver product to a number of end users efficiently grouped on a periodically served loop route. Truck Design and Procurement As a guide for the design, fabrication, testing, and inspection of a road transport unit, reference DOT (ICC) Specification MC331, “Cargo Tanks Constructed of Steel Primarily For Transportation of Compressed Gases” and NFPA 58, Section 6 “Vehicular Transportation of LP-Gas” shall be referenced. All welded piping on truck transports shall be fabricated and tested in accordance with ASME Code for pressure piping, Section 3, Petroleum Refinery Piping B31.3. LPG road transport units may be in the form of a single tank mounted on a semi-trailer with the motive power and a portion of the load being carried by a tractor. In certain areas, motor vehicle restrictions and/or road conditions may necessitate the use of a unit consisting of a tank mounted directly on to a truck frame. The primary design goal is transportation of the maximum legal payload safely and efficiently by minimizing the weight of the vehicle and tank. Local regulations will determine the configuration that Safety in LPG Design TRANSPORTATION 9-1 best achieves this objective. To select the most efficient and safest vehicle for a given location, procurement has to consider terrain, weight regulations, road characteristics, frequency of stops, round trip mileage and local tax structures, and speed limits as follows: 1. Hilly terrain and steep grades will require comparing the advantages of larger engines versus transmissions with more forward speeds, considering total drive train cost and vehicle weight effects. Engine weight will affect payload. Two-speed rear axles are another (somewhat costly) possible design solution. More braking capability will also be required. 2. Stringent weight limits may justify high cost light weight components such as fiberglass cabs and aluminum wheels; however, rough road surfaces may make affect light weight components such that they fail prematurely. 3. Rough road surfaces may warrant investing in more sophisticated tractor suspensions, and shock absorber-mounted orthopedic seats for drivers, to reduce driver fatigue and maximize driver safety and efficiency. 4. In congested traffic conditions with a high percentage of stop and go driving, engine speed versus torque characteristics will affect the amount of gear shifting required, and correspondingly, driver efficiency. This may warrant truck automatic transmissions, but their advantages should be weighed against increased unit cost, lower fuel efficiency, and loss of some payload capacity. 5. Cost and spare parts availability, and the ability to provide adequate maintenance should also be considered. 6. In several countries Diesel engine powered trucks are mandatory. However, with all the electronics now built-in modern Diesel trucks they may serve as ignition sources as do gasoline driven vehicles. The vendor should offer at least two power train options for each truck proposal, and these should be supported by geared speed versus engine speed charts. 9.2.2 Basic Design Considerations Before selecting a specification for an LPG road transport unit, local regulations shall be explored thoroughly since regulations from the following authorities may have to be taken into account: 1. Authority concerned primarily with pressure tanks. 2. Motor vehicle authority. 3. Weights and measures authority. 4. Agency primarily concerned with the transportation of a hazardous commodity. 5. Authorities responsible for the operation of bridges and tunnels. It is recommended that Specification MC 331 and Division III of NFPA 58 be utilized as a guide for the design, construction, inspection, and testing of road transports in the event that a mandatory specification does not exist. Specification MC 331 embodies a tank designed and constructed fulfilling the requirements of the ASME Boiler and Pressure Vessel Code, Section VIII for unfired pressure vessels. Tanks intended for static storage must not be used for deliveries. Tanks shall have metal tank data plates welded to the tank in a conspicuous and accessible place with vessel code and class to which it is made, manufacturer name and tank serial no, water capacity, minimum and maximum working and design pressures, date of original and subsequent tests, operating temperature ranges. 9-2 TRANSPORTATION Safety in LPG Design 9.2.2.1 Working Pressure on Truck Tanks According to Specification MC 33,1 the design pressure shall not be less than 6.9 bar gauge nor more than 34.5 bar gauge. NFPA 58 limits are more restrictive. It is recommended that a working pressure of 17.25 bar gauge be adopted for all LPG road transport units. This working pressure would allow use of the vehicle for Propane, Butane and their mixtures. If there is a long range use for a transport vehicle exclusively for Butane it may be designed for 10.75 bar gauge. In addition, the design is to take into account the allowance for vehicle acceleration and deceleration both horizontally and vertically. Acceleration and deceleration shall be assumed as 1 g (9.81 m/sec2)in direction of travel, and 2 g in the transverse horizontal direction, vertical acceleration both upwards and downwards at 5 g. 9.2.2.2 Tank Openings and Valves Tank nozzles and valves are fitted internally, recessed into the tank shell or positioned so to minimize the risk of impact damage and to prevent unauthorized access. NFPA 58 requires that tank fittings and appurtenances be protected against damage by either: their location, e.g. behind the vehicle frame or bumper, a protective housing or recessing. The following indicates the opportunities available. Pressure relief valves may be of a recessed type in which working parts of the valve do not extend beyond the shell of the tank. As an alternate, an internal spring-type safety relief valve may be installed within a well or recess lowering all working parts below the surface of the shell. PRVs on transportation tanks shall be tested or replaced every 5 years. Where local codes explicitly permit longer testing times, they may be followed, up to 10 years. In some countries (Central Europe) the installation of PRVs on trucks is prohibited and the tanks are designed for the maximum pressure specified by local codes. Gauging devices, such as visible float gauges, rotary gauges, fixed liquid level gauges, and pressure indicators, may be installed within recesses. The pressure gauge must be connected to the vapor phase. Liquid or vapor connections necessitate the use of pipe, valves, etc. to extend beyond the primary valve installed within the tank flange or coupling. Internal Excess Flow Valves on all liquid outlet lines and vapor return lines The accidental removal of the exterior portion of the valve will, in most cases, permit the valve element within the tank to remain closed, or if open at the time of an accident, will effect automatic closure. The liquid inlet line shall be protected by a backflow check valve. All filling and discharge connections to tank to be provided with quick closing internal valves, and a manual or automatic shut-off valve. All inlets and outlets must be labeled to designate function. All liquid and vapor lines shall be capable to be closed by a Truck Emergency Shutdown System. Shutoff shall be manual at two points at the front and rear end of the truck tank and by a remote handheld device carried by the driver. Activation maybe electrical or by radio. NFPA 58 also requires certain valve arrangements on vapor and liquid openings to prevent excessive discharge of gas in the event a connection is accidentally broken. For vapor and liquid withdrawal openings either a shutoff valve located as close as possible to the tank in combination with an excess flow valve in the tank, or an internal valve with excess flow protection shall be required. For vapor and liquid inlet openings either a shutoff valve located as close as possible to the tank in combination with a back-flow check valve or an excess flow valve in the tank, or an internal valve with excess flow protection shall be required. From all the NFPA options, liquid inlets are recommended to have only back-flow check valves and not excess flow valves. Vapor inlets are recommended to have excess flow valves, as check valves would not allow for liquid withdrawal in the event of an overturn. Safety in LPG Design TRANSPORTATION 9-3 The control mechanism for self-closing internal valves shall be arranged with an interlock so the forward motion of the vehicle will release the valve holding mechanism and cause the valve to close shall the valves be accidentally left in the open position. This may be accomplished through an interlock with the brake system or the ignition system. An interlock with the brake system is recommended. There are a number of packaged control devices available for this application. 9.2.2.3 Piping, Tubing, and Fittings on Truck Tanks It is recommended that only Schedule 80 pipe be utilized if the joints are welded or welded and flanged. This shall conform to ASTM Specification A-106, Grade B, or equal. This is more stringent than section 3.3 of NPFA 58, which permits Schedule 40 piping. All valves, fittings, pumps, pipework and accessories to be located behind under-run protection bars or be located as such, that they are protected to minimize risk of damage, or leakage in a vehicle accident or roll-over. Installations where the pump is not mounted directly on the liquid discharge connection shall be arranged with a minimum length of suction pipe sloping downward from the outlet to the pump suction without irregularities or pockets. Figure 9.2.2.3: Lifting lugs on tank trucks will help should recovery be needed Threaded joints shall be minimized. On any vehicle the use of threaded joints shall be reduced to an absolute minimum. The maximum size thread tolerated on a truck installation is 32 mm. All welding fittings (welded fittings to be socket weld) shall be compatible with Schedule 80 pipe. All threaded fittings shall be extra heavy forged steel (3000#). All threaded connections shall be secured with pipe joint compound specifically approved for liquid LPG. The use of Teflon tape is discouraged since during a fire it will melt and create additional leakage and add fuel to the fire. Note that this recommendation is different from that given for cylinder valves since those are of low melting material anyway. All welded piping shall be fabricated and tested in accordance with ANSI Code for pressure piping, Section 3, Petroleum Refinery Piping B31.3. 9-4 TRANSPORTATION Safety in LPG Design Ideal designs minimize the need for flexible connections by attaching as much piping/equipment to the tank as possible. If piping or equipment is attached to the truck chassis provisions shall be made to compensate for stresses and vibrations in the piping system. The piping system configuration and its restraints shall provide flexibility. The filling connection shall lead directly into the vapor space of the tank. Spray filling will lower the pressure in the tank and does not have the adverse effects associated with fuels spray loading. If two filling connections are utilized, at least one connection shall be fitted with a tube to the top of the tank in order to facilitate the final filling of the tank. The manhole in the tank shall have least 610 mm in diameter. Tank must have the lowest possible center of gravity which when fully loaded, does not exceed 1.75 meters. Overall stability is important and a static tilt angle of 25 degrees must be possible when fully loaded. 9.2.2.4 Anti-Surge Baffles in Truck Tanks An LPG tank, when in transit, is only partially filled with liquid; therefore, relatively severe “loading” may develop as a result of the movement of the cargo. The possibility of including anti-surge baffles within the tank shall be reviewed with the transport supplier, considering local operating conditions before a specific design is finalized. 9.2.2.5 Safety Controls on Trucks Interlocks: In the operation of a tank truck delivery unit, there are a number of procedures which are repeated several times in the course of a working day; therefore, the possibility of an error and in turn a potential hazard is always present. These can be eliminated as there are safety controls available, which either program the operator's activities or act as an override to correct any inappropriate action on the part of the operator. The following is an indication of the operations which may be monitored or which may be automatically performed: 1. An interlock may be applied to the truck braking system to prevent movement while product is being transferred. 2. A lock may be placed on the vehicle so it is incapable of being moved until the dispensing hose has been returned to the vehicle and attached in an appropriate location. 3. A lock may be placed on the vehicle until the filling hose has been disconnected from the liquid filling connection. 4. A lock may be placed on the vehicle until the liquid discharge valve or any other quick closing internal valve has been released and closed. 5. A lock may be placed on the movement of the vehicle until the power take off has been disengaged and the pump has ceased to function. 6. A safety control is available which can be programmed for a tank truck delivery unit depending upon the type of equipment used. As an example, the device can be programmed so it is necessary to set the brakes first, open the main liquid discharge valve, engage the pump, then, complete the discharge operation. The hose shall be returned and secured, the pump disengaged and the main liquid discharge valve closed before the vehicle can be moved. The tank, when on truck, shall not exceed maximum allowed overall height (in the country) and not to be closer than 150 mm to prime mover/tractor cab. Chassis and running gear to have local statutory approval and meet local axle load limits. Turntable coupling (where fitted) in good condition, meeting manufacturers specification and design. Safety in LPG Design TRANSPORTATION 9-5 Suspension to be appropriate for local terrain, bushings in compliant with relevant statutory regulations and meeting Braking system to be fully compliant with relevant statutory working order. All tires (including spare) to have minimum of of sizes and type on same axle. good order, and fully manufacturers design. regulations and in full 3 mm tread, no mixing Landing legs are optional (i.e., weight consideration) but if not fitted, trailer to have pads on underside of trailer for portable landing legs, designed and capable of supporting a fully loaded trailer. Drive shaft Protection: Consideration shall be given to protecting the tank from being struck by the vehicle drive shaft in event of a universal joint failure. Housings or baffles can be used. Figure 9.2.3.3-a: Typical single tank semi-trailer instrumentation Truck lights: Trucks, trailers, and semi-trailers transporting LPG shall not be equipped with any artificial light other than electrical. Lighting circuits shall have suitable overcurrent protection (fuses or automatic circuit breakers). All wiring shall have sufficient current carrying capacity and mechanical strength, and shall be secured, insulated and protected against physical damage. Tank/Trailer side clearance lights and rear traffic indicator, brake lights to be fitted and in working order, and comply with local statutory regulations. Electrical wiring to be installed and protected (i.e., in conduit) to avoid fire or short circuit in normal conditions of use. Semi trailer to be in electrical continuity with prime mover/tractor. Connectors for air and electrics to be in good condition and mounted on the trailer such that the cables will not be fouled by prime mover mounted equipment. Under-run bar shall be fitted to rear of rigid or trailer, across width of the tanker. The bar to be secured to the subframe. Near and off side under-run protection shall be fitted and secured to the subframe. All wheels shall be fitted with mudguards. Minimum of 4 brass earthing pins to be fitted (2 each side), connections the body to be free of paint, dirt and grease. An earthing cable (15 m) to be fitted adjacent to pump outlet. Delivery hoses to be fitted with “pull away couplings”(either on truck or at all plant side) and to be in good condition and fit for purpose, and securely stored on trailer/tank during driving. Trailers to have 2 x 9 kg dry chemical fire extinguishers (one on each side), in addition to prime mover 2 x 9 kg dry chemical fire extinguishers. Capacity of tank/trailer to be clearly labeled (50 mm letters) near fill point of trailer. All wheel hubs to be equipped with full complement of bolts, correctly tightened. 9-6 TRANSPORTATION Safety in LPG Design Toolbox (lockable) to be fitted to appropriately store tools/adapters/fittings. 9.2.3 LPG Truck Discharge System 9.2.3.1 Pumps on Trucks While LPG pumps at the refinery or terminal fill the tank trucks relatively quickly the discharge of product from the truck will take longer since it has to be done via the pump installed on the truck. A truck tank may be fitted with a pump flanged directly to the liquid outlet. At the completion of the operation, the vapor contents will remain within the tank as the pump is incapable of transferring vapor. Truck pumps are operated through a power take-off by the truck engine. Mostly positive displacement sliding vane pumps are used on trucks and therefore shall be equipped with a suitable pressure actuated bypass valve permitting flow from the discharge to the suction or to the tank. Centrifugal pumps are not suitable for outboard, power take-off, transport unloading. After selecting a pump, the manufacturer's recommendation shall be observed in selecting a strainer. A pump shall be specifically designed for liquid LPG and preferably be flanged. It shall also be designed and recommended for use on a delivery truck. Figure 9.2.3.2-a: Bypass valve The capacity of the pump should be selected considering the average volume of each individual delivery or discharge and the rate at which the product can be received. The following is offered as examples for selecting pumps on trucks typically used for customer delivery. Pumps for tank truck delivery service are available with a discharge capacity of 380 liters per minute. This type of pump is suited to filling relatively large fixed storage tanks with high capacity filler valves. When the average tank being filled is approximately 760 liters capacity and the filler valve has a relatively low capacity, a pump capable of 110 to 190 liters per minute may be adequate. A pump should also be analyzed from the standpoint of maintenance as it is important that the wearing parts can be replaced with minimum effort. A pump, which requires removal from the installation in order to be repaired, is not desirable. Safety in LPG Design TRANSPORTATION 9-7 The unit shall also be capable of evacuating the same tanks, which it normally would be charging. In normal operation, it may be necessary to evacuate the contents of a fixed field LPG tank because of a defect in the unit or because of the necessity of moving the unit. With the inclusion of the evacuation feature in the tank truck delivery system, the liquid can be withdrawn from a supply tank and discharged into the delivery tank; therefore, the unit has the capability of charging or fueling without depending upon a pump or compressor at the plant. Selection of a pump establishes the maximum discharge rate and an appropriate meter can be selected. The meter shall have a sufficiently high range so it can accurately measure the maximum anticipated discharge rate through the system. Various accessories may be added to the meter depending upon the type of dispensing procedure desired. 9.2.3.2 Bypass Valve for Truck Pumps The selection of a bypass valve is dependent upon the capacity of the pump and shall be sufficient to prevent the overpressuring of the system and, in turn, excessive wear on the pump. A bypass valve, which is capable of sensing complete closure of the discharge line and opening for full pump capacity, is desirable. The Figure “Installation of bypass valve in truck piping system” below illustrates where to install it in the system. A typical bypass valve is designed to bypass full pump capacity when the valve at the hose end is closed. Figure 9.2.3.2-b: Installation of bypass valve in truck piping system 9.2.3.3 Hoses and Hose Reels on Trucks LPG tank trucks may be able to utilize plant hoses when discharging at the plant. With this arrangement the plant hose can be equipped with a positive shutoff valve at its outer end, thereby eliminating the necessity of bleeding or venting the hose upon completion of the operation. If the discharge operation is performed using a hose or hoses provided with the road transport, a suitable venting arrangement shall be included in the transport piping system so the hose can be safely vented after the unloading has been completed (see sections 6.1.5 and 6.1.6). A tubing vent may be run from a point just downstream of the outboard transport shutoff valve to the top of the tank. The hose, complete with plugs or caps, shall be suitable for liquid LPG and shall be rated for a minimum working pressure of 17.25 bar gauge or, preferably, 24.2 bar gauge. When carried on a transport, hoses shall be contained within a tube designed for the purpose and attached to the vehicle or tank with closures at both ends. 9-8 TRANSPORTATION Safety in LPG Design The marketing plant loading facility provides hoses or conduits for the tank truck delivery loading. Swivel hard arms are recommended for this purpose. An evacuation hose approximately 10 to 20 meters in length shall be provided to connect the suction connection on the tank truck delivery unit with a fixed storage tank from which the liquid contents are to be withdrawn. The hose shall be approximately 25 mm nominal size and be rated for a working pressure of 17.25 bar gauge. A dispensing hose, 19 mm or 25 mm nominal size shall be employed. The length of the hose shall be determined considering the maximum distance from a safe convenient discharge location for the tank truck delivery unit to the most remote fixed storage tanks. The hose, as in all cases, shall be specifically designed for LPG service and be rated for 17.25 bar gauge working pressure. Figure 9.2.3.3: Typical single tank semi-trailers Where necessary, a vapor return hose shall also be provided with the length being equal to that of the dispensing hose; the size shall be 13 mm or 19 mm nominal. A hose reel is recommended as an accessory on a tank truck delivery unit since it reduces wear and tear on the hose, ensures that the hose is properly stored when the vehicle is in motion and can aid in developing a more efficient delivery operation. 9.2.3.4 Shutoff Valves on Truck Tanks and Hoses A shutoff valve utilized as the primary valve in any mobile tank connection shall be of a quick closing internal type with a means of remote control whenever possible. Limitations regarding the use of these valves are usually dependent upon size. Some relatively small connections cannot be fitted with this type valve as they are not commercially available. The mini bulk distribution system requires the driver operator to watch the tank while being filled but also requires him to be able to shut down the LPG flow on short notice. This is generally done by a handheld remote wireless connection to the truck valves. In case the button on the instrument is released, the valve on the truck closes and the pump stops. Safety in LPG Design TRANSPORTATION 9-9 Figure 9.2.3.4: Typical retail cargo vehicle LPG transfer system 9.2.3.5 Liquid Meters When liquid meters are used, they shall be selected to operate within the manufacturer's recommended minimum/maximum rated capacity. Materials used in the construction of meters shall be suitable for use with LPG and maintain suitable performance over the range of operating conditions the meter will be subjected to. Cast iron shall not be used unless the material is of an approved grade having adequate ductility and impact resistance over the full pressure and temperature range of the system. Liquid meters shall have the following accessories installed, either as part of the meter assembly or externally, to enable accurate meter readings. A fine mesh strainer at the meter inlet. The typical coarse mesh strainer used in the pump suction is not adequate for the meter. A differential valve to provide a back pressure against the meter and the pump and to maintain the system pressure above the product vapor. This prevents vaporization of the liquid as it passes through the meter. 9-10 TRANSPORTATION Safety in LPG Design A vapor eliminator to remove vapor from the liquid before it passes into the meter. The eliminator consists of a small tank with either a float-operated mechanism or a constant bleed orifice to circulate LPG vapors back to the LPG tank. Consideration shall be given to the requirements for a temperature compensator. A temperature compensator converts the measured meter volume reading at the temperature of the product as it passes through the meter so the meter will register the equivalent volume at a standard temperature of 15.6 °C. When liquid meters are used to measure the volume of LPG being transferred from one tank to another or from a pipeline, meters and accessory equipment shall be installed in accordance with the procedures stipulated in the API MPMS 5.1. Meters shall be protected from accidental damage either by their location or by other structural means. Meters shall be accessible to personnel for operational purposes and taking meter readings. Inlet and outlet piping shall be arranged and supported so an excessive load is not imposed on the meter. Figure 9.2.3.5: Liquid meter installation at rear side of mini-bulk truck (Sasso) 9.3 Road Cylinder Transportation Similar requirements discussed above under “Truck Design and Procurement” also apply for cylinder transportation trucks. The road conditions, grades, etc., which the vehicle must traverse shall be determined first, then the loading which will be applied to the vehicle shall be analyzed. The vehicle shall possess adequate capacity for the “pay load” and be sufficiently powered to negotiate the roads over which it must travel, at a reasonable speed. To properly handle industrial cylinders during unloading, trucks should be equipped with mechanical or hydraulic tail-gates. Dual axle trucks and tractor-trailers (articulated trucks), purchased for the transport of cylinders, shall be carefully analyzed to determine that they are capable of handling current or future pallet designs. The bed, together with sideboards or stakes, shall be of sufficient strength to support and retain the maximum number of filled cylinders expected. The height of the bed shall be considered in relation to the loading or Safety in LPG Design TRANSPORTATION 9-11 unloading dock. A tractor-trailer shall be equipped with a “landing gear”, of sufficient strength to support a full load, so that the tractor may be utilized for purposes other than supporting the tractor-trailer during loading or unloading operations. Following are international codes, which may be referenced for information on road cylinder transport: 1. The Australian Standard 1678 “Emergency Procedure Guide - Transport of Compressed and Liquefied Gases.” 2. The Australian Code for “Transport of Dangerous Goods by Road and Rail.” Figure 9.4: Typical rail LPG unloading site 9.4 Rail Tank Cars There is limited value in a detailed discussion of LPG rail tank car design in a manual intended for international use. Pressure tank cars have long been used extensively for LPG transport. However, their capacity and external dimensions, as well as external fittings and running gear, are determined by the widely varying characteristics of the various national railways (e.g. rail gauge, quality of roadbed, minimum allowed radius of main line rail curvature, banking of curves, and maximum design train speed). Therefore the designer of rail receiving or loading facilities or the purchaser of rail tank cars is best advised to seek the guidance of rail transport regulatory authorities and equipment suppliers in the jurisdiction where the facility is to be constructed or modified. 9-12 TRANSPORTATION Safety in LPG Design LPG rail car appurtenances are arranged such that they are protected in case of accident or derailment. One way of doing this is to concentrate all tank penetrations in a vertical cylindrical protective dome, with a hinged top cover, located at the top center of the horizontal tank. Another way is to provide a recess on the side of the tank and locate appurtenances therein. In countries (Central Europe) where risk from derailments is considered low, the appurtenances have been installed below the tank. 9.5 1. Pressure Relief Valves are installed in the vapor space and are of the internal spring type. The fabricators will determine the start-to-discharge pressure setting and flow capacity of the devices. Certain countries do not permit the installation of pressure relief (Central Europe). Tanks on such rail cars are designed to contain the maximum pressure. 2. Liquid Outlet: Usually there will be two liquid outlets provided within the recess/dome. Each shall be fitted with a manually controlled positive shutoff valve under which is fitted an excess flow check valve. The intake of the liquid draw-off is located at the bottom of the tank. 3. Vapor Connection: A single vapor connection is provided, fitted in a similar manner to the liquid outlet except that the excess flow check valve terminates in the vapor space. 4. Gauging Device: A gauging device in the form of a slip tube gauge is utilized to determine the liquid level within the rail car. 5. Sampling System: Some rail cars have a tube extending to the bottom of the tank and fitted with an excess flow check valve connecting to a positive shutoff valve within the dome. This installation may be used to take a sample of the cargo to verify the contents or to confirm that the tank has been completely unloaded. Marine Barge or ship either as a containerized shipment or as bulk cargo may transport LPG. As a containerized shipment, cylinders or portable containers may be utilized provided the cylinders or containers meet basic requirements. Care should be exercised in preparing the shipment so it will meet the regulatory and safety requirements, which may be applicable to the vessel, the waterways traveled and the ports at which the cargo is loaded and unloaded. As bulk cargo, non-refrigerated LPG may be transported by barge or by tank ship. Barges may be constructed with containers mounted directly to the deck or may be integrated within the structure. The decision should be dependent upon the anticipated condition of the waterways traveled. As a tank ship cargo, the product may be refrigerated in order to use low pressure tanks, which reduce containment weight and increase cargo weight. The design of a tank ship should be developed considering the condition of the product at the loading point, the facilities available at the delivery point, the volume of product available when loading and the storage or receiving capacity at the delivery point. In particular, if a refrigerated LPG cargo ship is designed to supply pressurized storage terminals the ship shall have sufficient heat exchange equipment to increase the temperature of the product downstream of the unloading pump to ambient levels. While heating could be accomplished on shore or the receiving tank may be designed to accept low temperature LPG, designing the ship without heat exchange equipment would limit its delivery capabilities. When selecting marine transportation for LPG, ships with vertical multistage onboard pumps units should be preferred. The ships pumps will have to provide sufficient head to overcome the pressure in the ambient temperature LPG tanks. Safety in LPG Design TRANSPORTATION 9-13 Design of marine LPG transportation equipment is a specialized endeavor, which benefits from technical experts in the field. ExxonMobil Research and Engineering Company and ExxonMobil marine transportation specialists should be consulted when in selecting designers and constructors. In addition EMRE has published extensive design guides, and can offer assistance in the design and construction of marine pier facilities for LPG. The basic design code for the cargo containment and transfer systems on bulk LPG ships is the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (referred to as the “IGC Code”) published by the International Maritime Organization (IMO). This code conforms to the requirements of most countries of registry, exporting countries and importing countries. A notable exception is the United States, which has regulations for both U. S. flag ships, and foreign flag ships that call at U. S. Ports. These regulations, administered by the U. S. Coast Guard, are defined in the Code of Federal Regulations, Title 46, Chapter I, Part 38, Liquefied Flammable Gasses, Part 153, Ships Carrying Bulk Liquid, Liquefied Gas, or Compressed Hazardous Materials and Part 154, Safety Standards for Self-Propelled Vessels Carrying Bulk Liquefied Gases. In addition to requirements for the liquefied gas containment and transfer systems, ships should meet numerous other national and international standards specified by the ship's country of registry, classification society, and intended port states. These standards will usually be established at the outset of a project to suit the ship's intended service. 9-14 TRANSPORTATION Safety in LPG Design 10 CUSTOMER INSTALLATIONS 10.1 Cylinder Bank Installations This section of minimum standards covers the cylinder bank installation requirements for industrial and commercial areas where ExxonMobil LPG is supplied. Public access to areas where LPG is stored and transferred shall be prohibited. To prevent trespassing or tampering, every LPG storage place shall be enclosed by a fence or cage or ventilated cabinet. Sufficient clearances shall be provided to allow maintenance and safe exchange of cylinders. Figure 10.1.1: Multiple cylinder installation 10.1.1 Design of Cylinder Banks LPG cylinders are preferably located outside of buildings and in well ventilated surrounding. The cylinders shall be installed under shade whenever possible. They shall not be installed directly under windows or adjacent to doors. They may be positioned against walls and secured by chains against tumbling. Where unavoidable, cylinders may be located inside buildings. Locations shall be carefully chosen such that Safety in LPG Design CUSTOMER INSTALLATIONS 10-1 leaking LPG could not accumulate in basements and that the location would not impact on escape routes. If necessary, PRV outlets must be piped to a safe location outside the building. At a safe location the gas will be allowed to dissipate to a concentration below lower flammable limits. Mechanical ventilation, air-conditioning intakes, openings of buildings or sewer system openings shall not be close (less than 1.5 m) to such locations. Local regulations may govern cylinder group installations. In the absence of local regulations, typically, 20 industrial 50 kg LPG cylinders may be installed in one group. Depending on customer needs it could be less but the total number must not be more than 30 industrial cylinders. If more LPG is used (requiring more than 30 cylinders to be installed) a container may be a better (safer and more economic) solution. If this is not feasible a second group of cylinders may be installed but a minimum distance of 7.5 m from the first group must be kept. The cylinders are all connected to a manifold which is divided at the center by an automatic switchover regulator. 50% of the cylinders are in use while the other 50% are in reserve. 10.1.2 Installation of Cylinder Banks LPG cylinders shall be installed at location least frequented by personnel and necessary precautions shall be taken to prevent tampering. Cylinders shall be installed aboveground and set upon a firm foundation which shall be substantially level. Flexibility shall be provided in the connecting piping. Cylinders shall be positioned so that the pressure relief valve is in direct communication with the vapor space of the cylinder. Cylinders shall not be stacked one above another when in use. Loose or piled combustible material and weeds and long grass shall not be permitted within 3 m of any cylinder. Fire protection shall be provided in accordance with local regulations and local authority shall be consulted for final approval. As a minimum, there shall be one 9 kg dry powder fire extinguisher located at a safe distance from the cylinder bank. 10.1.3 Vaporization Rate in Cylinders In order to maintain a sufficient flow of vapor to a user, it is important to properly estimate or calculate the vaporization rate. Depending on local code requirements for customer controlled piping; insufficient vapor rates could result in either a trip of the vapor supply or a loss of flame and continued feeding of vapor. In the latter case, continued flow of LPG may result in gas accumulation and a potential for explosion. The vaporization rate of an LPG container or cylinder is influenced by many factors. Precisely calculating the vaporization rate of a given cylinder is difficult. In the majority of cases when 11 kg or 12 kg domestic cylinders are used, the required vaporization rate is sufficiently low so that problems do not arise. Typically, regulators for domestic cylinders allow a take-off rate of 1 to 1.5 kg/h. In the event that larger cylinders are utilized, the vaporization rate from a single cylinder may not be sufficient to meet customer demand. In this case, multiple cylinder installation can be used. If there is any doubt regarding the vaporization capacity within a cylinder or a bank of cylinders, the pressure within the cylinder(s) may be monitored and, in this way, a substantial decrease in cylinder pressure may be interpreted as an indication that additional vaporization capacity is required. By so doing, the lack of available vapor or a shutoff of the vapor supply may be prevented. For customer comfort two cylinder banks may be installed. Such installations may permit automatic switch-over from one bank to the other if the first bank is empty. However, in that case the customer should get an alarm so that a new set of filled cylinders can be ordered. If a mixture of Propane and Butane is used, the former will vaporize preferentially. At the end of the vaporization process the liquid heel in the cylinder will consist only of 10-2 CUSTOMER INSTALLATIONS Safety in LPG Design Butane. As a result the vapor pressure in the cylinder will keep dropping throughout the vaporization. The Figure 10.1.3-a: shows how approximately a 70% Butane, 30% Propane mixture evaporates. At the end of the evaporation process all Propane is vaporized. In the calculation it was assumed that the temperature in the cylinder was constant at 25 °C. Of course, this assumption is for very little consumption and may therefore not be realistic, but it serves to demonstrate the effect. Weight Fraction Butane 1 Composition of Liquid 0,8 0,6 Composition of Vapor 0,4 0,2 0 11 10 9 8 7 6 5 3 2 1 0 1 0 Mass Re m aining in Cylinder, kg Pressure in Cylinder, bar g Figure 10.1.3-a: LPG composition as cylinder is emptied 4 3.5 3 2.5 2 1.5 1 0.5 0 10 9 8 7 6 5 4 3 2 Mass Re m aining in Cylinder, kg Figure 10.1.3-b: LPG pressure change as 10 kg cylinder is emptied The Figure 10.1.3-b: shows the pressure drop during the above vaporization process. If the temperature would be allowed to drop, the pressure may drop even lower. Safety in LPG Design CUSTOMER INSTALLATIONS 10-3 Estimates of vaporization capacity for one 45 kg cylinder filled with Propane, based on experience, are given in the Figure 10.1.3-c. When necessary, variations from the conditions in the table should be considered when sizing a specific installation. 7,0 full Vaporization, kg/h 6,0 75% 5,0 4,0 50% 3,0 25% 2,0 1,0 0,0 -20 -10 0 10 20 Ambient Temperature, C Figure 10.1.3-c: Vaporization from 45 kg Propane cylinder depending on ambient temperature and % of fill. Note that 1 kg/h of Propane equals 13.8 kW The German “Flüssiggas Handbuch” (TRF1996) suggests the following sizing criteria for cylinder vaporization: Offtake Characteristic Cylinder Size 5 kg 11 kg 33 kg Short Term up to 1.0 kg/h up to 1.5 kg/h up to 3.0kg/h Periodical up to 0.5 kg/h up to 0.8 kg/h up to 1.8 kg/h Continuous up to 0.2 kg/h up to 0.3 kg/h up to 0.6 kg/h Table 10.1.3: Vaporization from different size cylinders depending on gas use. Short term = 15 min, Periodical = 30 min on, 30 min off. 10-4 CUSTOMER INSTALLATIONS Safety in LPG Design 10.1.4 Icing or Sweating on Cylinders. Any indication of “icing” or “sweating” on the cylinder is an indication that the vaporization capacity is being exceeded and additional cylinders should be installed. As the vaporization capacity is exceeded, ice will form on the exterior of a cylinder in relationship to the humidity within the surrounding atmosphere. During periods in which the air is relatively dry, icing or sweating may not occur; however, the surface of the cylinder will be noticeably chilled and, with an increase in humidity, ice or water dew accumulation may be anticipated. As ice forms on the exterior of a cylinder it provides an additional barrier to the transfer of heat; therefore, the overall efficiency of the cylinder as a vaporizing unit is diminished. Dew on the exterior of the cylinder has the same effect. It will tend to vaporize and take heat of vaporization from the cylinder cooling it further down. As noted above, insufficient vaporization rates may lead in certain situations to a loss of flame with subsequent accumulation of LPG vapor. 10.2 Containers at Customer Sites This chapter covers the spacing and site requirements and the design of aboveground and underground or mounded LPG containers for domestic and commercial storage which are refilled on site. It does not cover cylinders connected in use in banks, or cylinders in storage awaiting use or distribution. Typically these containers are between 1 and 300 m3 in size. Containers for domestic storage and commercial storage containers should be fabricated to conform to ASME codes, or an equivalent standard when recognized by local regulations. The code followed shall be acceptable to the regulatory authority where the container is to be used. Procedures to establish Design Pressure, Design Temperature, and Critical Exposure (Minimum Design) Temperature are the same as explained in the section “Bulk Storage” in Chapter 3. When the LPG supplier (ExxonMobil) owns containers, the responsibility for the containers remains with the supplier. Therefore, the use of an inspection service is recommended to assure continuing quality assurance oversight throughout the contract with a container manufacturer. Each container shall be completely identified by the nameplate, which is permanently attached to the container. Nameplate requirements may vary based on local codes. Typical commercial or domestic containers with fittings are shown in Figure: 10.2.7. They are designed for horizontal installation, with dual lifting lugs for deployment. Four steel feet permit setting the container on a pre-poured concrete foundation slab. Where there is potential for flooding, the container shall be fixed to the foundation slab. The foundation must be heavier than the total buoyancy of an empty tank. 10.2.1 Spacing and Location of Containers Spacing of containers to the nearest important building, property line, or other containers at customer sites shall be in accordance with requirements in the country. In absence of any local requirements spacing as per Table 10.2.1 is suggested. The number of containers in a group is limited to 6 containers. If more than one such installation (group of 6 containers) is made, each installation shall be separated from any other installation by at least 7.5 m. Do not apply the minimum distances between containers to such installations. The designer shall not install multiple containers simply for the purpose of reducing spacing to the property line. The need for multiple containers shall be justified based on operating requirements. Safety in LPG Design CUSTOMER INSTALLATIONS 10-5 Maximum water capacity (m3 ) Minimum separation distances (m) Aboveground container Of any single container in a group Of all containers in a group Underground or mounded containers From buildings, prop. line or fixed source of ignition From buildings, property line, etc. to Between containers Valve assembly Container shell Between containers Less than 0.5 1.5 2.5 1 2.5 0.3 0.3 0.5 to 2.5 7.5 3 1 3 1 1.5 2.5 to 9.0 27 7.5 1 7.5 3 1.5 9.0 to 135 450 15 1.5 7.5 3 1.5 135 to 337.5 1,015 22.5 11 3 3 Above 337.5 2,250 30 ¼ of sum of diameters of adjacent containers 15 3 3 Table 10.2.1: Spacing of containers at customer sites The following shall apply to above ground containers installed along side of buildings: 1. ASME containers shall be located and installed so that the discharge from the container pressure relief device is at least 1 m horizontally away from any building opening that is below the level of such discharge. And not less than 1.5 m in any direction away from any exterior source of ignition, openings into direct-vent (sealed combustion system) appliances, or mechanical ventilation air intakes. 2. The filling connection and the vent from liquid level gauges on ASME containers filled at the point of installation shall be not less than 3 m in any direction away from any exterior source of ignition, openings into direct-vent (sealed combustion system) appliances, or mechanical ventilation air intakes. LPG containers, whether aboveground or underground or mounded, shall be installed in the open air outside buildings. Containers to be located downgrade and downwind from possible ignition sources. LPG containers shall not be stacked one above the other. The area including LPG containers and related equipment shall be enclosed by an industrial type fence at least 2 m high unless it is otherwise protected, e.g. being within a larger fenced area or otherwise isolated from public access. Unless the area is smaller than 50 m2, there shall be at least two means of exit at adjacent sides of the fence. The gate shall open outwards, shall not be self-locking and shall open into an unobstructed open space. An exception to the above is when the container is provided with a positive means of denying access to valves and fittings other than pressure relief valves, e.g. by a ventilated hinged cover that can be locked, or by a blank flange or plug on drain connections. Where damage from vehicular traffic is a possibility, means of protection shall be provided, e.g. by the use of crash barriers, bollards or non-continuous toe walls. 10-6 CUSTOMER INSTALLATIONS Safety in LPG Design No permanent source of heat shall be located within 1.5 m of an LPG container. LPG containers shall not be located directly beneath electrical power cables. For cables carrying less than 1.0 kV, the LPG container shall be sited at least 1.5 m from a line drawn vertically downwards from the power cables. For cables carrying 1.0 kV or greater voltage, the distance shall be increased to 7.5 m. No horizontal separation shall be required between an aboveground LPG container and underground containers containing flammable or combustible liquids installed in accordance with NFPA 30. Fire protection of LPG containers at customer sites shall follow requirements of the local fire services. 10.2.2 Designing Customer Storage Systems 10.2.2.1 Piping Arrangement for Customer Installation Storage containers at consumer locations shall be designed for 100 percent Propane to provide for future flexibility of product mix. Figure 10.2.2: Consumer LPG Facility Figure 10.2.2 illustrates a consumer LPG facility. This figure shows container connections and service line for a permanently mounted container at a consumer location. If transport hoses can reach the storage container, piping from connections (1) and (2) can be eliminated. Valve outlets shall be fitted with hose adapters. The liquid volume between the block valve at the unloading vehicle and the block valve of the plant must be minimized. Vent line valves at unloading connections shall be equipped with spring-loaded actuators that must be manually held open. Thermal relief valves shall be located between all shutoff valves. LPG vapor piping systems downstream of the first-stage pressure regulator shall be sized so that all appliances operate within their manufacturer’s specification. The container valving may be different in case a vaporizer is required. In such cases, a liquid off take to a vaporizer may be installed, with a pressure regulator on the Safety in LPG Design CUSTOMER INSTALLATIONS 10-7 container vapor outlet itself. This pressure regulator system would serve as a back-up during vaporizer shut-down. 10.2.3 Sizing Of Containers and Vaporization Rates Sizing of containers involves two aspects. One is the maximum consumption per hour required by the customer. The other is the supply and shipping logistics. Maximum consumption can be satisfied by natural or enforced vaporization. Containers for the former need to be larger than for the latter. According to supply logistics containers shall be sized to receive incoming shipments while maintaining a minimum reserve of the number of days demand equal to one-half of the shipping time from the supply source. LPG is commonly shipped to consumer locations in bulk in trucks or rail tank cars 10.2.3.1 Natural Vaporization An important characteristic of LPG is that, when in a storage container, it can use the heat from the surrounding air to change from a liquid to a vapor. When withdrawal starts, heat is taken initially from the liquid itself, resulting in a drop of liquid temperature. Because the product is at a lower temperature, heat starts to flow from the surrounding air through the container wall into the product. The rate at which this heat flows depends primarily on the temperature difference between the air and the product. The greater this difference, the larger the rate of heat transfer. Normal Butane will remain a liquid at atmospheric pressure when ambient temperatures are below its boiling point of 0 °C. Propane will remain a liquid at atmospheric pressure when ambient temperatures are below its boiling point of – 42 °C. At temperatures above these boiling points, rapid vaporization will take place as long as the pressure is at or slightly above atmospheric. Figure 10.2.3.1: Vapor pressures of Butane and Propane mixtures 10-8 CUSTOMER INSTALLATIONS Safety in LPG Design LPG is typically stored as a liquid under pressure. Under inactive conditions, each product in a closed container has a defined pressure versus temperature relationship i.e. the vapor pressure (see Figure 10.2.3.1). Regardless of the amount of liquid in a container and provided some vapor space exists, the internal pressure will correspond to the vapor pressure of the product at the temperature of the liquid. When the liquid stored is 100 percent Butane or 100 percent Propane, the vapor conditions will be uniform. However, when the product is a mixture of Butane and Propane, the vapor above the liquid mixture will always have a higher percentage volume of the lighter product (Propane), regardless of the proportion in the liquid state. Since Propane will vaporize at a faster rate than Butane, the first quantity of vapor taken from such a container will have a higher content of Propane than the succeeding vapor. As vapors are withdrawn, both the vapor and the liquid will have increasingly higher Butane content. When vapor is being withdrawn from a container, the internal pressure is lowered until the rate of conversion from liquid to vapor is equal to the rate of vapor withdrawal. If too much vapor is withdrawn the pressure drops to dangerously low levels which may lead to flame-out or other undesirable situations. For such installations a vaporizer may be needed, which is described later in this chapter. The size and the shape of a container are important when vaporization must take place within the container. Given the same volume a long container brings more vaporization as compared to a short one. The container surface area that is in direct contact with the liquid is an important factor known as the wetted surface area. The liquid surface area in contact with the vapor has very little effect on vaporization. More heat will be transferred for vaporization when a container is full than when it is nearly empty. In addition, the following factors will have an influence on the container vaporization rate: 1. Ambient temperature of the atmosphere. 2. Size and color of the container. 3. Exposure to solar radiation. 4. Amount of frost, ice or insulation on the container wall. 5. Circulation of air around the unit and wind conditions. Precise calculations can be developed in order to determine vaporization rates, however, due to the variation in various factors mentioned in the above list, reliance upon the estimated formula will usually suffice in the selection of a container for Propane only. 10.2.4 Sizing Containers for Vaporizing Liquid Certain factors must be known in order to determine the proper size for a container when it is to be used to vaporize the liquid stored in it to replace vapor being withdrawn from the space above the liquid. These include: 1. Maximum quantity of LPG to be vaporized per hour. 2. Number of hours per day that vapor is required. 3. Minimum allowable container pressure or minimum allowable inlet pressure to first-stage regulator. Type of product or percentage of mixture. 4. Safety in LPG Design 5. Minimum anticipated ambient temperature during period of maximum vaporization. 6. Relative humidity of atmosphere at time of minimum ambient temperature and maximum vaporization. 7. Minimum liquid level in container at time of maximum vaporization. CUSTOMER INSTALLATIONS 10-9 There is quite some experience with company engineers to calculate or estimate container sizes. The following is not meant to replace those methods or experiences. The methods described below shall help the inexperienced engineer to understand container sizing. These methods in this guideline are conservative in sizing LPG containers for natural vaporization, i.e. they will be rather on the large side than too small. 10.2.4.1 Sizing Small Containers for Natural Vaporization. Calculation Example 1: The customer needs 9 kg/h at a pressure of 1 bar. The coldest outside temperature is 20 °C. The LPG mixture is 30% Propane and 70% Butane. First determine the maximum possible temperature differential. According to Figure 10.2.3.1 at 5 °C the pressure of a 30/70 mixture would be just above 100 kPa (1 bar). With a minimum outside temperature of 20 °C the usable temperature differential would be 20 – 5 = 15 °C. Entering the x-axis of Figure 10.2.4.1 at 15 °C temperature differential and going to the next container size above 9 kg/h it turns out that a 1.75 ton container would be sufficient for the purpose. Calculation Example 2: The customer has a 5 ton container and needs LPG at a pressure of 0.5 bar. Can he run on 100% Butane if the coldest outside temperature is 19 °C? How much LPG can be taken off? According to Figure 10.2.3.1 the pressure of 100% Butane at 19 °C is about 90 kPa (0.9 bar). The temperature at 50 kPa (0.5 bar) is 10 °C. So, the usable temperature differential would be 9 °C. Entering the x-axis of Figure 10.2.4.1 at 9 °C shows that Butane in a 5 ton container could still vaporize Butane at a rate of about 12 kg/h. 25 5 ton Vaporization, kg/hr 20 3,5 ton 15 1,75 ton 10 1 ton 5 0,5 ton 0 0 5 10 15 Usable Temperature Differential, C Figure 10.2.4.1: Vaporization of LPG in 0.5 to 5 ton container (remaining container volume 25%) 10-10 CUSTOMER INSTALLATIONS Safety in LPG Design 10.2.4.2 Sizing Larger Containers to Satisfy Natural Vaporization Requirements Often, containers larger than 25 tons are equipped with vaporizers. However, in tropical climates with almost constant temperatures customers may prefer to save the operational cost of the vaporizer. When using LPG mixtures the designer must anticipate that the pressure in the container decreases as the liquid level drops. This is due to the fact that Propane boils off first (see Figure 10.1.3-b). In Figure 10.2.4.2 the vaporizing capacity at a container level of 25% volume is shown for a 10 ton, a 25 ton and a 50 ton container, containing 100% Propane. The minimum pressure anticipated is 0.5 bar. If the container contains more volume obviously the vaporization will be higher but this is not taken into account since only the lower vaporization is of interest. Depending on vaporization requirements, such containers may need a refill once they reach 25%. If only LPG at certain mixtures is available (and not pure Propane) the customer must be aware that the pressure in the containers drops as the container level decreases (see Figure 10.1.3-b) since first the Propane components vaporize. 250 50 ton Vaporization, kg/hr 200 25 ton 150 100 10 ton 50 0 -20 0 20 40 Ambient Temperature, C Figure 10.2.4.2: Vaporization of Propane in 10 to 50 ton containers (at a container volume of 25% and a delivery pressure of 0.5 bar) 10.2.4.3 Sweating, Ice or Frost Formation The formation of ice or frost will reduce the flow of heat into the liquid. Water present in the air will condense onto the container’s outer surface when the surface temperature is below the dew point of the air. The dew point temperature of the air varies with the degree of humidity and the dry bulb temperature of the air. When the surface temperature of the container is at or below 0 °C, any water on the surface will freeze to frost or ice. Frost or ice on the container surface will act as insulation and reduce the rate of heat transfer from the air to the liquid. Therefore, the withdrawal of vapors from a container shall be limited to that volume which can vaporize without reducing the product and container shell temperatures to below the dew point whenever that temperature is below 0 °C. Safety in LPG Design 11 CUSTOMER INSTALLATIONS 10- Typically, in tropical climates ice or frost formation is not a problem. However, sweating can often be seen on containers. This is a sign of too high vapor load for this container. Often there are multiple container installations which were designed properly but not operated properly. The users or fillers often leave only one container on line (which is then sweating). All containers must be opened such that the pressure in the system is as high as intended by the designer. Continuously withdrawing LPG vapor from an underground or mounded container is not recommended since the gas supply would not last long and serious sweating on the container surface would accelerate corrosion Such containers installations typically have vaporizers. 10.2.5 Enforced Vaporization by Means of Vaporizers The alternative method to obtain vaporization of the LPG liquid uses separate vaporizers. The LPG liquid is piped directly from the bottom of the storage container to the vaporizer. Heat required for vaporization is provided by electricity, steam, hot water or water-glycol solution. A direct-fired vaporizer is not allowed. Vaporizers offer advantages even when the expense of providing the heat for the vaporization is considered. If the size of the container required for natural vaporization is larger than the volume required for receipt and reserve volumes, it may be possible to install smaller storage capacity and save in total investment by using a vaporizer. Also, the gas from a vaporizer will match the characteristics of the entering liquid and will be nearly uniform throughout the withdrawal of liquid from the storage container. While the pressure during natural vaporization drops as the liquid level is lowered during consumption it will remain constant when using a vaporizer installation. One drawback of the vaporizer installation is the fact that all components, also the Oily Residue will pass the vaporizer. Therefore provisions must be made (KO drum) to collect oily condensate after the vaporizer. Vaporizers shall be designed, constructed, installed and tested in accordance with a recognized and appropriate pressure container code, NFPA 58, 59 and manufacturer recommendations. LPG vaporizers supplied shall be from reputable manufacturers approved by ExxonMobil. Supply Supply High Pressure Regulator Low Pressure Regulator Vaporizer Commercial/Domestic Supply where Vaporizer is not Required Feedback System Supply Supply Vaporizer Vaporizer Pump Semi Feedback System Pump Direct Feed-out System Figure 10.2.5: Typical container and vaporizer installations 10-12 CUSTOMER INSTALLATIONS Safety in LPG Design The Figure 10.2.5 “Typical container and vaporizer installation” illustrates container supply installations schematically. The installation on the upper left side of the figure shows a typical Propane container. Because of its high vapor pressure, a vaporizer is normally not required. A first stage high pressure regulator is usually installed in the container dome. A second stage regulator is installed in the supply line immediately before distribution to the consuming appliances. Two stage regulators are recommended for maximum operating reliability by virtue of more uniform gas pressure, and enhanced safety in the event of a regulator failure. The remaining three installations on Figure 10.1.3 show frequently used configurations for vaporizers and containers. These are typical of commercial and domestic Butane supply systems. The liquid supply line shall preferably originate in a supply valve with dip tube located in the dome, rather than as shown (for simplicity). If there is a remote possibility that the stored liquid temperature could fall as low as the –7 °C, the boiling point of liquid Butane, the arrangement shall be a “feedback” or “semi-feedback” system. Then, the container would not be subjected to a vacuum, which might compromise it structurally or affect gas supply pressure at appliances. The “direct feedout” system would be suitable for Propane in situations where a vaporizer is needed to provide comparatively large instantaneous gas capacity from limited storage. Need for the indicated optional pump will depend on the relative elevations of the container and the vaporizer, line pressure drop, and the operating pressure range in the container. When designing the system the minimum possible ambient temperatures have to be taken into account so that vapors are not subjected to dew point conditions (see Table 10.2.5). Press Propane Mix Mix Mix Mix Mix Mix Mix Mix Mix Butane 100 90/10 80/20 70/30 60/40 50/50 40/60 30/70 20/80 10/90 100 Bar (g) Dew Point in ºC 1.0 -43.0 -36.0 -30.0 -25.0 -20.0 -15.5 -12.0 -9.0 -6.0 -3.0 0.0 1.5 -33.5 -26.0 -18.5 -14.0 -9.5 -5.0 -1.5 2.0 5.0 8.0 11.0 2.0 -26.5 -19.0 -11.0 -6.0 -1.5 3.0 6.0 10.0 13.0 16.0 19.0 2.5 -20.0 -13.5 -5.0 0.0 4.5 9.0 12.0 16.0 19.0 22.6 25.5 3.0 -14.0 -6.0 0.0 5.5 10.0 14.0 17.5 21.5 24.5 28.0 31.0 3.5 -9.0 -2.0 4.6 9.5 14.0 19.0 22.0 26.0 29.5 33.0 36.0 4.0 -5.5 2.0 8.5 13.5 18.0 23.0 26.5 31.0 34.0 37.5 40.5 4.5 -2.0 5.5 12.0 17.5 22.0 27.0 30.0 34.5 38.0 41.5 45.0 5.0 1.0 9.0 15.5 21.0 25.5 30.0 34.0 38.0 42.0 45.5 49.0 6.0 7.0 16.10 21.5 27.0 32.0 36.5 40.5 45.0 49.0 52.5 56.5 7.0 12.0 20.0 27.0 32.5 37.5 42.0 46.5 51.0 55.0 59.0 62.5 8.0 17.0 25.0 31.5 37.0 42.5 47.0 52.0 56.0 61.0 65.0 68.0 9.0 22.0 29.5 36.0 42.0 47.0 52.0 57.0 61.0 65.0 69.5 73.0 10.0 26.0 33.5 40.0 46.0 51.5 56.0 61.5 65.5 69.0 73.5 78.0 Table 10.2.5: Dew points in different LPG mixtures in relation to pressure Sizing of a vaporizer is not complicated. The basis figure to be known is the peak consumption. For a single appliance this is the hourly consumption (kg/h). If the unit is started up daily add 50% for accommodating the additional consumption during start-up. If there are multiple consumers (multiple restaurant kitchens) consumption for all appliances shall be added up since the may all consume at the same time (lunch and evening peak hours). Choice of the vaporizer is optimum if two or three units would cover multiple consumers. Depending on required reliability one single consumer may be adequately served by one single vaporizer. It shall be borne in mind that vaporizer installations typically have an emergency back-up with an natural vaporization line Safety in LPG Design 13 CUSTOMER INSTALLATIONS 10- directly from the container. The use of a vaporizer is indispensable for underground/mounded container installations It is important that there be a clear understanding as to where the designer's responsibilities end in the system leading to the point of end use. Generally, the point of demarcation is at the outlet of the high pressure regulator for non-vaporizer systems, or at the container's liquid and vapor connections in the case of vaporizer systems; however, this demarcation shall be confirmed formally in a written document executed by supplier and customer. 10.2.5.1 Installations of Vaporizers This section of minimum standards covers indirect fired LPG vaporizers to be installed in end user facilities using ExxonMobil supplied LPG. Local standards shall be followed. In the absence of a local standard or if the local standard is less stringent, the following minimum standard shall apply. Vaporizer houses shall not have drains to sewers or sump pits. A strainer shall be installed in the liquid inlet to the vaporizer. A knockout pot shall be installed at the outlet of the vaporizer to remove heavy hydrocarbons. Vaporizers shall be located in accordance with the minimum distances from other equipment in accordance with Table 10.2.5.1. Exposure Minimum Distance Required (m) Aboveground LPG Container 3 Relief Valve of Underground LPG Container 3 Point of Transfer (Truck) 3 Nearest Important Buildings or Adj. Property Line 1.5 Table 10.2.5.1: Minimum Distance Required for LPG Vaporizers 10.2.6 Installation of Containers 10.2.6.1 Aboveground Installation Aboveground containers shall be placed on concrete foundations. If the location could be flooded the container shall be fixed and the foundation shall provide adequate anchors or weighting such that the container would not float, even if empty. Product identification and safety signs shall be installed at the container. The “NO SMOKING” sign shall be clearly legible at the safety distance applicable and from points of access to the storage site. Grounding requirements are defined in “Grounding Connections for Tanks” in Chapter 3. 10.2.6.2 Underground Installation Underground containers shall be protected from superimposed loads, e.g. vehicular traffic loads, either by fencing or protecting them with a reinforced concrete slab or other load-bearing means. If the area for the container is not fenced off, the container manhole cover and container fittings shall be protected against damage and tampering. Mounded containers shall be protected either by fencing off the area around the mound or by other adequate means. Underground containers shall be surrounded by sand that is not aggressive in terms of corrosion. Minimum coverage on top is 0.3 m of sand. A concrete slab may be added. If traffic moves over the slab, no load shall be conveyed to the tank. Mounded tanks 10-14 CUSTOMER INSTALLATIONS Safety in LPG Design shall be covered similar to the requirements (0.9 m) mentioned in Chapter 3. For smaller tanks the cover may be less provided the cover cannot be eroded by rain or firewater. Underground installation greatly reduces fire risk and security problems. Where spacing is tight or not available, underground installation may be chosen. Figure 10.2.6.1: Typical container Underground containers and their fittings, valves, pressure relief valves, gauging devices and regulators shall be adequately protected against corrosion. Proper drainage shall be provided for the housing dome to eliminate accumulation of water. The following guidelines shall be observed when installing underground containers: Safety in LPG Design 15 1. Only ASME containers constructed for underground service and marked accordingly shall be installed underground. 2. All fittings, including any plugged openings, are plugged tight and free from leaks. Containers may be pressurized with air or LP-gas vapor to make certain there are no leaks. 3. The container is purged in accordance with generally accepted industry practices. (See NPGA Safety Bulletin 133 and the LPG Safe Operations Guide). 4. Rust, dirt and other foreign matter have been cleaned from the surface of the container, and the container has been visually inspected for gouges, dents, pits or other defects. 5. The external surface of underground tanks shall be Grit blasted to SA 2½ standard or chemically treated and coated with an adequate paint system with specialist advice. Shop applied coatings are preferred, but field applications are also acceptable. Irrespective of type and application method of coatings, a holiday test on the coating shall be carried out immediately prior to installation on site. 6. All points of contact shall be protected while the container is being loaded and transported. Damage to the protective coating shall be prevented. 7. All underground containers and piping shall be cathodically protected unless written tests of soil samples indicate that it is not required. Failure to provide cathodic protection can cause hidden corrosion and leaks as well as weakening of the tank wall over time. 8. The bottom of the hole shall be level and free of rock. If rocks are present, a 150 mm bed of sand shall be used. For completely buried tanks, the hole CUSTOMER INSTALLATIONS 10- shall be dug to a proper depth to provide for the housing dome to extend far enough above ground level to prevent entrance of water (50 to 150 mm is common practice), allowing for grading away from the dome. Figure 10.2.6.2: Underground installation 9. The top of the container shall be at least 150 mm below grade, unless the container might be subject to abrasive action of physical damage from vehicular traffic or from other causes such as in LP-gas service stations. In this case, it shall be placed not less than 600 mm below grade or equivalent protection shall be otherwise provided (such as by the use of a concrete slab) to prevent imposing the weight of a loaded vehicle directly on the container shell (NFPA 58- Par.3.2.4.8 a). 10. For mounded systems, the same general procedure shall be followed, except that the housing dome would be above ground, and the above ground surface area of the tank shall be covered with at least 300 mm of earth or sand. 11. In the flood plain and high water level areas, provisions shall be made to adequately secure the container to the ground, or to a concrete slab, to prevent flotation. Local soil conditions may require other provisions to allow proper drainage from within the housing dome. 12. Precautions shall be taken to prevent damage to the tank coating while lowering the tank into the hole and while back filling. Any damage to the coating shall be carefully repaired. Any small unprotected areas of a coated, wrapped and cathodically protected tank and piping system will be subject to concentrated corrosive action resulting in the possibility of severe metal loss and ultimately a leak. 13. Back fill shall be free from rocks or similar abrasives. Clean, dry sand is preferred. See Figure 10.2.6.2. 14. Because the installed container should be adequately anchored if flotation is a possibility and shall be leak tight with a slight positive nitrogen pressure, it could be maintained empty. However, it is preferred that the container be filled immediately after installation is complete. 15. Where underground containers are installed in locations subject to infrequent vehicular movement, sufficient provision shall be made to prevent the weight of such vehicular traffic from damaging the container or appurtenances. The top of the tank shall be at least 600 mm below grade or be protected by a concrete slab or equivalent. 16. Barriers shall be provided to protect the housing dome, relief valve discharge stacks, filling risers and any appurtenances that extend above grade level. 10-16 CUSTOMER INSTALLATIONS Safety in LPG Design 17. Product identification and safety signs shall be installed adjacent to the housing dome and filling risers. The “NO SMOKING” sign shall be clearly legible at the safety distance applicable and from points of access to the storage site. 18. For underground tanks that are embedded in watertight concrete casings and sand-bed, observation wells with PVC casing of at least diameter 50 mm with 0.5 mm slots shall be installed. Observation wells shall be installed at two diagonal corners of the underground tank(s) and shall extend to a depth of 600 mm below the bottom of the tank(s). 10.2.7 Container Fittings and Piping Figure10.2.7: Typical fittings needed on containers Containers, regardless of size, shall be equipped with the following: 1. pressure relief valve (PRV). 2. fixed level dip tube. 3. filling connection. 4. level indicator. 5. pressure gauge. 6. drain valve. 7. inspection nozzle. 8. multivalve. 9. bottom liquid off take (optional). 10. vapor offtake connection. 11. Regulator. All directly connected appurtenances shall be closely grouped on the top center of the horizontal container shell, and protected against mechanical damage by a steel dome with a hinged cover. On larger containers all the nozzle connections may be installed on the manhole cover if possible. The pressure relief valve shall not be installed under the dome, as this would interfere with discharge. Piping requirements for customer installations vary widely from country to country. Therefore, it is recommended that local codes and requirements be followed. If there are no local codes, NFPA 58 Section 3.2 shall be followed. Safety in LPG Design 17 CUSTOMER INSTALLATIONS 10- 10.2.8 Container Valves and Accessories 10.2.8.1 Filler Valve For new fill line installations, an isolation valve (preferably a ball valve) shall be located at the tank with a single back check filler valve adjacent to it. When it is necessary to locate the filling connection at a point remote from the filler valve, the filling connection shall be fitted with a single back check filler valve. A positive shutoff valve can be installed immediately behind the single back check filler valve in order to provide maximum safety. Double back check filler valves shall not be used in place of an isolation valve and single check valve in new installations. Figure 10.2.8.1: Double back check filler valve 10.2.8.2 Vapor Service Valve A vapor service valve may be provided as a separate unit or may be incorporated as part of the combination valve. The valve shall preferably incorporate a back seating feature. An excess flow check valve shall not be incorporated with the inlet of the device, unless local regulations ask for it. With an excess flow check valve installed there is a possibility of an interruption in service to gas-consuming devices due to high demand. This could cause a flameout followed by resumption of flow when local codes do not require safety shutdowns on loss of gas supply. 10.2.8.3 Liquid Service Valve An internal positive shutoff valve shall be installed for liquid off take service from the bottom of the container. For liquid off take service from the top of the container, an excess flow check valve shall be installed within the container, and a positive shutoff valve installed immediately adjacent. All containers 475 liters or more in capacity shall be fitted with a connection for the purpose of emptying the container of liquid. This requirement may be satisfied by the use of a bottom mounted lock type excess flow check valve installed within the container, which shall normally be plugged. Removal of the plug and the installation of a nipple or adapter to which a positive shutoff device is attached can activate the connection for the withdrawal of liquid. In order to ensure the proper procedure in activating the valve, an instruction tag shall be attached to the plugged excess flow check valve. 10-18 CUSTOMER INSTALLATIONS Safety in LPG Design 10.2.8.4 Excess Flow Check Valve In domestic storage containers, excess flow check valves shall be included as integral parts of vapor return valves. They shall also be installed either as an integral part of the liquid service shutoff valve or within the liquid outlet of the container with a separate shutoff valve installed immediately adjacent. Excess flow valves permit the flow of liquid or vapor in either direction. Excess flow is controlled in only one direction (the direction of the arrow stamped in the valve). If flow in that direction exceeds a predetermined rate the valve automatically closes. Figure 10.2.8.4: Excess flow check valve 10.2.8.5 Liquid Level Measurement Visible Float Gauge: A visible float gauge is the first choice for level measurement in customer containers. It shall be installed under the valve guard or hood for protection. The liquid level can be observed without discharging LPG vapor or liquid, however, accuracy may not be always adequate. Rotary Gauge: A rotary gauge may be used in customer containers if there is no hazard in connection with the LPG discharge necessary for the measurement. Fixed Level Gauge: Each container shall be fitted with a fixed liquid level gauge. The gauge shall be fixed to indicate an 85% filling level. Slip Tube Gauge: A slip tube gauge is not recommended on containers of 10,000 liters or lower capacity. A slip tube gauge shall only be installed when there is a strong need for greater measurement accuracy than float gauge or rotary gauge can provide, and when electric power is unavailable to operate a servo-gauge or radar gauge which was discussed in Chapter 3. 10.2.8.6 Pressure Indicator Each container in excess of 10,000 liters capacity shall be fitted with a pressure indicator (PI), which may be part of a combination valve. In containers 10,000 or less in capacity, a pressure indicator is an optional feature; if used, there shall be a shutoff valve between the container and the PI. 10.2.8.7 Regulators All regulators shall be designed and installed in accordance with NFPA 58 or equivalent. Regulators for outdoor installations shall be designed, installed, or protected so their operation will not be affected by freezing, sleet, snow, ice, mud, or debris. This protection is permitted to be integral part of the regulator. All materials used to construct the regulators shall be resistant to the action of LPG under service condition. Safety in LPG Design 19 CUSTOMER INSTALLATIONS 10- Regulator shall be designed for outdoor installation. Regulators shall be incorporated with an integral relief valve. or shall have a separate relief valve to limit the regulator outlet pressure. An integral or separate overpressure shutoff device shall be provided to shutoff the flow of LPG vapor when the outlet pressure of the regulator reaches the overpressure limits. Regulators with an overpressure protection device and a rated capacity of more than 147 kW (10.6 kg Propane per hour) shall be permitted to be used in two-stage systems where the second-stage regulator incorporates an integral or separate overpressure protection device. Figure 10.2.8.5: Visible float gauge Integral two-stage regulators shall be provided with a means to determine the outlet pressure of the high pressure regulator portion of the integral two-stage regulator. Exception: Automatic changeover regulators shall be exempt from this requirement. Integral two-stage regulators shall not incorporate an integral pressure relief valve in the high pressure regulator portion of the unit. Regulators shall be designed so as to drain all condensate from the regulator spring case when the vent is directed down vertically. At low flow rates, a single stage system may be suitable. Check with manufacturers. At higher flow rates it is typical to use two stage pressure regulation. The first regulator reduces the pressure to about 1.5 bar gauge (150 kPa) and the second regulation step lowers it to about 30 millibar gauge (3 kPa). For multiple tank installations only one set of regulators shall be installed as opposed to individual sets on each tank. This is to prevent “pressure cycling” of the system, which would be caused by slight differences in regulator adjustment or different heat input or vaporization. Aluminum or zinc is permitted for approved regulators. Zinc used for regulators shall comply with ASTM B86, specification for zinc-alloy die casting, or equivalent standards. Nonmetallic materials shall not be used for upper or lower casings of 10-20 CUSTOMER INSTALLATIONS Safety in LPG Design regulators. Regulators shall have the manufacture date (MM/YY) permanently marked on the body. First-stage and second stage regulators shall be installed outside of buildings. The first stage regulator shall be as close to the storage as practical. First-stage or high-pressure regulators shall be directly attached or attached by flexible connectors to the vapor service valve of a container or to a vaporizer outlet. The regulators is permitted to be installed with flexibility in the interconnecting piping of manifolded containers or vaporizers. Figure 10.2.8.7: Container regulator The point of discharge from the required pressure relief device on regulating equipment installed outside of buildings in fixed piping systems shall be located as follows: 1. More than 1 meter horizontally away from any building opening below the level of discharge. 2. More than 1.5 meter in all directions from any source of ignition, opening into direct-vent appliances or mechanical ventilation air intakes. 3. Not beneath any building unless the space is well ventilated. Installation of the regulator shall minimize accumulation of LPG condensate. Regulator inlet piping shall be cleaned at the time when the regulator is installed as foreign particles that entered the regulator may cause it to malfunction. The pressure regulators shall be installed in location where tampering of the regulator by unauthorized personnel is prevented. 10.2.8.8 Multivalve The multivalve combines the double back check filler valve, vapor equalizing valve with excess flow, pressure relief valve with protective cap and chain, service line shutoff valve, fixed liquid level gauge, float gauge opening and plugged pressure gauge opening in one unit. Using various available combination valves that combine all of the fittings required can reduce the number of shell penetrations. This Single Outlet System creates a higher and more congested equipment profile within the dome, and is likely to increase maintenance time. The disadvantages should be weighed against the reduction in shell penetration achieved. Safety in LPG Design 21 CUSTOMER INSTALLATIONS 10- 10.2.8.9 Pressure Relief Valves All LPG tanks, vaporizers, positive displacement pumps’ discharge shall be provided with one or more spring loaded or pilot operated pressure relief valves. Sizing of the valves will depend on the container surface and is described under: “Pressure Relief in Marketing Terminals” in Chapter 3. Suitable thermal relief valves shall be provided on liquid lines that can be blocked between two shutoff valves. Other equipment that can be blocked between shutoff valves shall be provided with protection from overpressure due to thermal expansion of the liquid. Figure 10.2.8.8: Multivalve for vapor and liquid withdrawal The pressure relief system shall be protected from the closure of any block valves installed between the tank and the pressure relief valve or between the pressure relief valve and its discharge vent outlet. This protection may be achieved by one of the following procedures: 1. Installing the pressure relief valve without block valves. 2. Providing excess pressure relief valve capacity with multiway valves, interlocked valves, or sealed block valves arranged so that isolating one pressure relief valve will not reduce the capacity of the system to below the required relieving capacity. 3. Locking or sealing the block valves open with a lock. The key must be in possession of an authorized person. Multiple pressure relief valves can cover total required relief valve capacity. These shall be installed with a manifold that includes provision for selectively closing off any particular relief valve to permit removal for inspection while the remaining valves provide for the discharge capacity required for the container. Alternatively, Multiport relief valve may be used. Weep holes on the bottom of pressure relief valve stacks shall be equipped with a 90 degree elbow to deflect a discharging vapor stream away from any container shell or piping. 10-22 CUSTOMER INSTALLATIONS Safety in LPG Design Discharge vents shall lead to the open air or to a flare system. Positive design and operational steps shall be taken to prevent the discharge of liquid LPG from atmospheric vents. Such steps include automatic shutdown of filling operations prior to overfilling. Discharge vents shall be protected against mechanical damage. If discharge vents relieve to the atmosphere, they shall be designed to prevent entry of moisture and condensate. This design may be accomplished by the use of loose-fitting rain caps and drains. Drains shall be installed so that the discharge will not impinge on the tank or adjoining tanks, piping, equipment, and other structures. Discharge vents shall terminate a minimum of 3.0 m above grade with a final discharge vertically upward. Discharge shall be to an area that has the following characteristics: 1. 2. 3. The area prevents flame impingement on tanks, piping, equipment, and other structures. The area prevents vapor entry into enclosed spaces. The area is above the heads of any personnel on the tank, adjacent tanks, stairs, platforms, or the ground. Pressure relief valves on equipment within buildings shall be piped to a point outside the buildings and shall discharge vertically upwards. Pilot operated pressure relief valves shall be designed so that the main valve will open automatically and protect the equipment if the pilot valve fails. Pilot operated valves shall be provided with a backflow preventer. 10.2.8.10 PRV Testing Requirements Pressure relief valves in LPG service normally operate in a clean, non-corrosive environment. Furthermore, PRVs are constructed of corrosion resistant materials, and are installed so as to be protected against the weather. Because of added odorization, a leak around a PRV is likely to be discovered during inspection. Pressure relief valves in LPG service have shown a good reliability over the years. However, since no mechanical device can be expected to remain in operative condition indefinitely, it is recommended that the PRV be replaced when the container is tested/reconditioned, or more frequently if required by local regulations. Safety in LPG Design 23 CUSTOMER INSTALLATIONS 10- 11 AUTOMOTIVE LPG 11.1 Automotive LPG Stations 11.1.1 Design of Automotive LPG Equipment This section sets out the minimum design standards for the LPG facilities in a service station for the refueling of motor vehicles running on LPG. The general minimum standards for bulk installations and for different components as laid down in the other sections shall apply except where specifically modified by this section. Local standards shall be followed. In the absence of a local standard or if the local standard is less stringent, the following minimum standard shall apply. LPG tanks at Retail Outlet Stations may be mounded or buried to eliminate the risk of a BLEVE. Furthermore, there are limited requirements with regard to minimum distances to buildings in the neighborhood. A mounded or buried system will require an internal, submerged pump. External inspection for corrosion damage is not easy, cathodic protection is recommended. Since there is no formal formula to calculate the LPG tank capacity the following should be considered. The frequency of unloading operations shall be minimized since each additional unloading operation constitutes an increased risk. The tank shall be sized to allow for a weekly supply pattern, e.g. 2% of annual sales volume. Aboveground tanks shall be installed with sufficient liquid head as required by the design of the pump. Underground tanks situated below driveway shall be adequately protected by reinforced concrete slabs or chamber designed by a qualified structural engineer. The manhole cover and the tank fittings open to access from the top shall be protected against damage and tampering. For underground tanks, submersible pumps of a reputable make specifically approved by ExxonMobil shall be installed. Installation shall be in strict accordance with the manufacturer’s instructions. Submersible pumps must be installed in barrels such that the pump unit can be taken out for servicing without having to gas free the whole tank. Following are international Codes on Automotive LPG: 11.1.1.1 1. Autogas, CPR 8-1, CPR 8-1s, Netherlands (in Dutch). 2. The Australian Standard 3509 “LP Gas Fuel Vessels for Automotive Use.” Remote Operated Emergency Block Valves The Emergency Shutdown System (ESS) shall be designed and executed as a fail safe system. All valves with a diameter larger than 1.6 mm shall be part of the Emergency Safety in LPG Design AUTOMOTIVE LPG 11-1 Shutdown System. There are 3 types of motive energy to operate the Emergency Block Valves: Hydraulic, Air and LPG vapor. The valve shall be a fail safe, spring loaded, quarter turn valve meeting API 607 fire-resistant testing. 1. Systems driven by LPG vapor: This type of motive energy is recommended. It has the advantages of sufficient vapor always being available and a relatively simple system layout. 2. Air driven system: This type of motive energy is recommended if reliable air supply is readily available. Air supply should be separate from air used for pressuring tires since the latter may be emptied by users. Also air for Emergency Block Valves may need drying since condensed water can cause internal corrosion in the valve actuators. Hydraulic system: This type of motive energy is not recommended since even small leaks influence its reliability. Emergency shutoff valves shall be installed as close as practicable to the liquid and vapor inlet/outlet connections on the tank, except where a back flow check valve is installed and except on the drain connection. A master emergency switch shall be provided to shut off the power to the pumps and dispensers and to close off all the emergency shutoff valves installed on the tank connections and at the dispensers. This emergency switch shall be so positioned as to be readily visible to the public and within easy reach for quick operation in cases of emergency. It shall be clearly identified by signage. 11.1.1.2 Layout LPG tanks shall be located such that the minimum separation distances shown in Table 11.1.1.2-a are not exceeded. Storage Minimum Separation Distance (meters) From Site Boundary, Buildings, Fixed Sources of Ignition, etc. Between Tanks Underground Water Capacity of 3 Tank ( m ) Above Ground Buried Portion Valve Assembly, Filling Point, etc. Aboveground Above Ground Under Ground 0.5 to 2.5 3 3 3 1 1.5 2.5 to 10 7.5 3 7.5 1 1.5 10 to 150 7.5 3 7.5 1.5 1.5 Table 11.1.1.2-a: Minimum separation distances for LPG tanks Separation distances of LPG facilities from each other and from other features of the service station shall not be less than that given in Table 11.1.1.2-b. LPG dispensers may be installed adjacent to other LPG, petrol or Diesel fuel dispensers as long as they are of flameproof construction. Pumps other than submersible pumps shall be installed as close to the tank liquid outlet valve as possible, but not underneath an aboveground LPG tank. 11-2 AUTOMOTIVE LPG Safety in LPG Design Safety relief valves shall be fitted with vents with outlets at least 1.8 m above the top of the tank and not less than 3m above ground level. The vent outlets shall be at least 4.5 m away from the property line or any fixed source of ignition. LPG dispensing facilities shall not be permitted in service stations built underneath buildings. LPG Tank LPG Tank Fill Conn. LPG Pump LPG Dispen ser M Vehi. LPG Fill Conn. 1 diameter Nil Not below TK 3m 3m Nil - Nil 3m 3m Not below TK Nil - Nil Nil LPG Dispenser 3m 3m Nil - Nil Motor Vehicle LPG Fill Connection 3m 3m Nil Nil - Undergr. petrol TK, manhl. or fill conn. 1.5 m 3m 3m 3m 3m Aboveground petrol tank 6m 6m 6m 6m 6m Petrol tank vent 3m 3m 3m 3m 3m Flameproof fuel pump / dispenser 3m 3m Nil Nil Nil 4.5 m 4.5 m 4.5 m 1.5 m 1.5 m 1.5 m 4.5 m 4.5 m 4.5 m LPG Tank LPG Tank Fill Connection LPG Pump Non-flameproof fuel pump / dispenser Parked cars As Table 11.1.1.2-a for fix. source of ign. 1.5 m Site bound. buildgs, fix. sources of ign. 3m As Table 11.1.1.2-a Table 11.1.1.2-b: Separation distances of LPG facilities from each other and from other features of the service station 11.1.1.3 Overfill Protection All tanks shall be equipped with an overfill protection device. A variety of overfill protection devices are available. The available systems range from high-tech electronic capillary measuring systems to simple mechanical systems with a floater or a mechanical meter. When the maximum filling level is reached, the system shall transmit a signal to the filling valve and then close the valve within a predetermined time lapse (approx. 15 seconds). 11.1.1.4 Piping System To avoid excessive pressure in the liquid lines, a thermal relieve valve shall be installed between two block valves. Safety in LPG Design AUTOMOTIVE LPG 11-3 Excess flow valves or non-return valves shall be installed in all LPG lines from/to the tank. The type of valve to be used depends on the flow direction of the LPG. Install excess flow valves in both underground liquid and vapor lines at the dispenser. A vapor release valve shall be installed at the filling point to enable the tank truck driver to release the vapor in the filling hose before and after the filling operation. The maximum quantity to be released is 1 kg. The quantity sets limits for the size/length of the filling hose. The liquid capacity of the filling line shall not exceed a volume of 200 liters. Underground pipes conveying liquid LPG shall be either: 1. Installed in a concrete lined duct which is subsequently filled with clean sand, or 2. Buried at a depth below ground of at least 1 m. The route shall be indicated by markers on the ground surface. Underground LPG vapor or liquid pipes shall not be embedded in concrete. Figure 11.1.1: Piping and instrument diagram of automotive LPG installation 11.1.1.5 Dispensing Equipment The dispensing system shall consist of the following essential components: 11-4 1. A vapor separator to separate vapor from the liquid before metering. 2. A meter to measure the volume of liquid delivered. AUTOMOTIVE LPG Safety in LPG Design 3. A differential valve to prevent the formation of vapor beyond the vapor separator and in the meter. 4. A flexible hose and filling nozzle. An excess flow valve as near as practicable before the inlet of the flexible hose. Hydrostatic relief valves. 5. 6. 7. 8. A pump switch to control any remotely located electric pump. features to prevent unauthorized use or tampering. A driveaway protection coupling on the hose. Security An emergency shutoff valve at the base of the dispenser that will close off the liquid supply upon being hit, in addition to the normal means of closure as an emergency shutoff valve. The driveaway protection “beak-away” coupling shall be shall be able to disconnect in the event of a force of no greater than 600 N. It shall be capable of being re-assembled without the need for draining the hose, the use of special tools, or the replacement of parts. The filling nozzle shall be of the low emission transfer type. It shall mate with the filling connection on the receiving container on the vehicle such that, when they are disconnected after refilling, no more than 4 milliliters (cm3) of liquid shall be released to the atmosphere. It shall not be possible to discharge LPG unless connected to a fill connection on the vehicle. It shall not have any latching device. 11.1.1.6 Hose Requirements All hoses for tank filling shall be approved for LPG services. The responsibility for the filling hose stays with the transportation company. The flexible delivery hose (dispenser) shall be manufactured to a recognized standard such as BS 4089, AS 1869, UL 21 or equivalent. It shall be of stainless steel wire braid or nylon reinforced synthetic rubber and shall have a design working pressure of not less than 25 bar and a burst pressure of not less than 100 bar. The length of a delivery hose may vary from 3 to 5 meters. In the delivery hose a “break away” coupling shall be installed. It is important to follow manufacturers’ installation requirements for the break away installation. It is recommended to perform an initial test to ensure that the break away connection works as installed. The delivery hose shall be so secured on the dispenser that it cannot lie on the ground with potentials of being run over by vehicles. Damaged hoses shall be replaced. Authorized contractor firm may only carry out replacement. 11.1.1.7 Bulk Filling System Prior to starting any discharge operation, an earth connection shall be made between the tank truck and the LPG installation at the Service Station. The earth connection shall be independent of the hose connection. A 24 volt signal from the tank truck will open the filling valve. When the maximum filling level is reached this 24 Volt signal will be interrupted by the overfill protection system and will close the filling valve. This means that the filling valve is always in a closed position during idle times. The Emergency Shutdown System (ESS) on the tank truck is part of this 24 volt signal system. Activating the push button of the truck ESS will also close the filling valve. In cases where the bulk truck cannot come close to the LPG tank, a remote unloading point may be installed. 11.1.1.8 Fire Protection Fire protection shall be designed in accordance local authority which has to be consulted for final approval. Safety in LPG Design AUTOMOTIVE LPG 11-5 Warning signs with the words such as “STOP MOTOR”, “NO SMOKING”, “FLAMMABLE GAS” shall be posted at all LPG handling areas. The locations of the signs shall be determined by local conditions, but the lettering shall be large enough to be visible and legible from each point of transfer. Emergency controls, if provided, shall be conspicuously marked, and the controls shall be located so as to be readily accessible in emergencies. At least one 20 mm hose reel shall be provided. Water supply shall be at least from hydrants not more than 100 m away. Firewater piping system shall be constructed of metallic material. Plastic material is not allowed. Fire-fighting foam shall not be used for LPG fire. At least one 9 kg portable dry chemical with a B: C rating fire extinguisher shall be available at strategic locations around the station premises. Minimum shall be one at each LPG dispenser and one in the sales office attendants’ kiosk. These are in addition to whatever is required for the fuel dispensers and fuel storage at the same station. Figure 11.1.1.7: Remote unloading point 11.1.1.9 Crash Barriers The filling point shall be protected by means of crash barriers. The crash barriers can be made of steel pipes filled with concrete. The minimum diameter of the steel pipes is 100 mm and the pipes shall extend at least 0.6 m above ground level. The customer dispenser shall also be protected by means of crash barriers. Valves and Instruments on Automotive LPG Tank 11.1.1.10 Security Around Tank The LPG storage installation shall be fenced in. The minimum distance from the fence to the LPG installation is 3 meters. The fence shall be equipped with two exit doors, the doors shall be placed opposite of each other. The doors shall be kept closed and only be opened by authorized persons. The area inside the fence and at a suitable distance from 11-6 AUTOMOTIVE LPG Safety in LPG Design LPG tank shall be kept free of vegetation. The following text or pictograms shall be placed on the fence: Entry by unauthorized persons is prohibited. Smoking & open fire prohibited Safety in LPG Design AUTOMOTIVE LPG 11-7 12 LPG PROPERTIES 12.1 Product Properties LPG consists of light hydrocarbons, including Propane, Propylene, normal Butane, Isobutane, and Butylenes. The most common LPG components are Propane and normal Butane or mixtures of these. At ambient temperature and atmospheric pressure, LPG is a gas. It can be liquefied under moderate pressure or by cooling to temperatures below its atmospheric boiling point, but will readily vaporize upon release to normal atmospheric conditions. This property permits LPG to be transported as a liquid, and used in the vapor form. Property Commercial Commercial Propane Butane Molecular Weight 44 58 Liquid Density, (kg/m3), 15 °C @ Vapor pressure 505 580 Vapor Density, (kg/m3), 15 °C @ Vapor pressure 15.3 5.62 Liquid Specific Volume, (m3/ton), 15 °C @ Vapor pressure 1.96 1.73 Vapor Specific Volume, (m3/ton), 15 °C @ Vapor pressure 65.4 178 Vapor Density, (kg/m3), 15 °C @ Atmospheric pressure 2.0 2.6 Vapor Specific Volume, (m3/ton), 15 °C @ Atmospheric press. 500 400 0.510 0.575 1.5 2.0 - 42 -2 Liquid Specific Gravity 15/15 °C Specific gravity of vapor (air = 1.0) Atmospheric boiling point, (°C ), @ Atmospheric pressure Table 12.1-a: Properties of Commercial Propane and Commercial Butane Safety in LPG Design LPG PROPERTIES 12-1 Commercial Propane Commercial Butane Ignition energy, (mJ) 0.1 0.1 Flash point, (°C ) -104 -60 450 - 580 420 - 550 1970 1975 Combustion air, (m3/m3 gas) @ stochiometric 24 30 Lower flammable limit(LFL), % in air 2.0 1.8 Upper flammable limit(UFL), % in air 10 9 Motor Octane Number 100 95 Expansion factor at transition from liquid to vapor at 15 °C 270 240 0.003 0.002 Property Auto-ignition temperature range, (°C) Flame temperature in air, (°C ) Cubic Expansion Coefficient of Liquid per °C Table 12.1-b: Properties of Commercial Propane and Commercial Butane Common properties for Propane, Isobutane and Normal-Butane are shown in Table 12.1a and 12.1-b. Selected properties as a function of temperature for Propane, Isobutane and Normal Butane, and commercial mixtures are shown in Figures 12.1-a,-e. Figure 12.1-a: Vapor Pressures for Butane-Propane Mixtures 12-2 LPG PROPERTIES Safety in LPG Design 650 N - Butane Density, kg/m3 600 ISO - Butane 550 500 Propane 450 400 -40 -30 -20 -10 0 10 20 30 40 50 60 Temperature, C Figure 12.1-b: Liquid density at vapor pressure as a function of temperature 2.90 Density, kg/m3 2.70 2.50 Comm. Butane 2.30 2.10 1.90 1.70 1.50 Commercial -40 -30 -20 -10 0 10 20 30 40 50 60 Temperature, C Figure 12.1-c: Vapor density at atmospheric pressure as a function of temperature Safety in LPG Design LPG PROPERTIES 12-3 60 Density, kg/m3 50 Propane ISO - Butane 30 20 0 -30 -20 0 10 30 40 60 Temperature, C Figure 12.1-d: Vapor density at saturation pressure as a function of temperature 450 Latent Heat, kJ/kg 430 390 370 Propane 330 310 Butane 270 250 3 5 9 11 15 17 Vapor Pressure, bar 12-4 LPG PROPERTIES Safety in LPG Design 12.2 LPG Hazards LPG produces certain hazards unique to this fuel. Concentrated LPG vapor is heavier than air and tends to stay close to the ground. It drifts downwind and collects in low spots, and disperses less readily than lighter-than-air gases. Since LPG is mostly stored under pressure and vaporizes readily, it is difficult to control leaks once they occur. Once LPG is released, it mixes with air to form a flammable mixture. Leakage of a small amount of liquid produces a much larger volume of vapor, as shown in Table 12.2. This makes it important to prevent leaks, keep ignition sources at a safe distance, and disperse vapor from leaks before it is ignited. Property Liquid Volume Resultant Vapor Volume Volume of Flammable Mixture at LFL Propane Butane 1 1 270 230 12600 12200 Table 12.2: Vapor volumes for Propane and Butane A leak ignited near its source produces a jet flame, which can endanger nearby equipment and enlarge the incident. If ignition is delayed and the release is large, enough flammable mixture can accumulate to produce a large Vapor Cloud Explosion (VCE). The magnitude of a VCE incident depends on the amount of LPG involved. It has been conservatively estimated that release of as little as 500 kg of LPG may produce conditions under which a VCE might occur. Blast damage from a large VCE can extend beyond 200 meters and is almost certain to cause secondary effects as tank fragments impact additional piping and equipment. Fireball diameter, m 1000 100 10 1 0,001 0,01 0,1 1 10 100 1000 Mass in Tank, tons Figure 12.2-a: BLEVE fireball diameter Safety in LPG Design LPG PROPERTIES 12-5 Potentially more serious is a Boiling Liquid Expanding Vapor Cloud Explosion (BLEVE). Such an event typically starts with a fire near an LPG pressure storage or transportation tank. The fire heats the tank contents and the internal pressure rises. If there is direct flame impingement on the top (vapor) part of the tank at the initial stage of the fire, BLEVE may happen before the PRV activates. If the tank is still intact, the pressure relief valve may open and continue to discharge. The lower part of the tank is “wetted” and cooled by boiling product inside, but the metal temperature of the upper “dry” area rises. The “dry” steel may be overheated and weakened until it can no longer withstand the internal pressure, and the tank fails catastrophically. Depending on conditions, failure of a tank may happen from five minutes to one hour after the fire begins. If the tank fails, the boiling LPG in the tank is released resulting in massive vaporization. The vapors will ignite immediately, though there is little or no mixing with air, and burning occurs at the surface in the form of a large fireball. The size of the fireball can be taken from Figure 12.2-a “BLEVE fireball diameter” above. A 1 kg disposable LPG container will create a fireball diameter of about 5 m diameter, whereas a 1000 ton sphere BLEVE will result in a fireball of 500 m diameter. Heat radiation from the fireball will cause serious damage within a sizable radius. Wood and other combustible items will ignite spontaneously at considerable distances. The damage produced by the blast wave of a BLEVE is less serious because its radius is usually smaller than that for radiant heat from the fireball. Another hazard is fragments produced from the tank failure. This is most serious with horizontal tanks, which tend to behave as rockets and have traveled over 1000 meters in actual incidents (Mexico City). A BLEVE is possible for a pressurized container of any size. Failure of a large tank will be destructive for hundreds of meters. Even a small domestic cylinder can BLEVE; initially, the affected area is limited, but other nearby cylinders and facilities are likely to become involved. The probability of a BLEVE or VCE is very low, but because of the potential severity, it is important to provide sufficient fire protection. In addition to fire and explosion hazards, LPG also presents personnel hazards including the potential for asphyxiation and cold burns. These are described in the LPG Safe Operations Guidelines manual. Release Rate, kg/s 100 10 Liquid 1 Vapor 0,1 0,01 1 10 100 Pipe Diameter, mm Figure 12.2-b: Propane release rates from guillotine pipe failure 12-6 LPG PROPERTIES Safety in LPG Design 1000 Distance, m Very Stable, 2 m/s 100 Neutral, 5 m/s 10 1 1 10 100 Release Rate, kg/s Figure 12.2-c: Propane cloud dispersion to lower flammable limit Release Rate, kg/s 100 10 Liquid 1 0,1 Vapor 0,01 1 10 100 Pipe Diameter, mm Figure 12.2-d: Butane release rates from guillotine pipe failure 1000 Distance, m Very Stable, 2 m/s 100 Neutral, 5 m/s 10 1 1 10 100 Release, kg/s Figure 12.2-e: Butane cloud dispersion to lower flammable limit Safety in LPG Design LPG PROPERTIES 12-7 13 Glossary of Terms ACTIVE FIRE PROTECTION Active fire protection is provided by firewater, sprays, monitors, dry powder, fire brigade etc. Passive fire protection is provided by spacing, fireproofing etc. ANSI American National Standards Institute. API American Petroleum Institute. ASME American Society of Mechanical Engineers. ASTM American Society for Testing and Materials. AUTO-REFRIGERATION The chilling effect from vaporization of LPG when it is released or vented to a lower pressure. BAR GAUGE Since bar is always absolute the term bar gauge is used to indicate pressures above atmospheric inside systems i.e. the pressure read on the gauge. It is often impractical to use absolute pressures. In this manual some pressures are in bar (absolute), some in bar gauge (bar gauge is bar minus one). BLEVE Boiling Liquid-Expanding Vapor Explosion. A BLEVE occurs if a tank that is exposed to fire disintegrates suddenly because the tank metal was overheated. This usually happens if cooling by firewater is insufficient. Safety in LPG Design Glossary of Terms 13-1 BONDING Bonding means electrically connecting two pieces of equipment that do not have metal to metal contact. Typically this is done during truck loading/unloading. Bonding straps around flanges are not needed as the flange studs and nuts provide adequate conductivity. BULK PLANT A facility that receives LPG by tank car, tank truck, marine vessel (barge), or piping. It distributes this gas to the end user by cylinder (package) delivery, by tank truck, or marine vessel (barge). Such plants have bulk storage of 7.6 m3 water capacity or more and usually have either container filling or truck loading facilities or both on the premises. BULK STORAGE Bulk storage includes LPG storage in plants or at large industrial customer sites. BULLET A bullet is a large above ground horizontal tank containing LPG. It is typically used for bulk storage at plants and industrial customers. Fireproofing may protect it. CAR SEALED OPEN Term used to define a position of a valve during normal operating condition. Car seal wires or other devices should indicate that this position has been maintained at all times. Car sealed valves may be closed for maintenance purposes but then re-opened for operations. CATHODIC PROTECTION Cathodic protection is a technique to reduce corrosion of a metal surface by passing sufficient protective Direct Current to cause the anodic dissolution rate (corrosion caused by electrolytic properties of the soil) to become negligible. CAVITATION If the Net Positive Suction Head at the suction of the pump falls below its (correct) design value the liquid starts boiling and forms bubbles. This occurs in the high velocity zones of the pump, especially at the rotating impeller. The bubbles are unstable and collapse in zones of higher pressure. The collapsing bubbles impact the metal and erode metal surfaces, ultimately damaging the pump. CENTRIFUGAL PUMP In a centrifugal pump the fluid flows through a rotating impeller where centrifugal force increases kinetic energy, which is later converted to a static pressure rise as the fluid velocity is reduced in a diffuser. CET See Critical Exposure Temperature. 13-2 Glossary of Terms Safety in LPG Design CGA Compressed Gas Association. CHATTERING Pressure relief valve chattering is a condition in which the valve opens and closes rapidly. This can lead to leakage or valve destruction. It may be caused by too large a PRV capacity, too high a pressure drop in the connection to the PRV or by a faulty setting of the PRV. CHECK VALVE Valve designed to permit flow only into one direction. COMMERCIAL BUTANE (OR PROPANE) Have typical specifications that are available from the manufacturing plants. Commercial Butane or Propane contains percentages of other petroleum fractions of about the same volatility, such as propylene and Isobutane. COMMISSIONING, DECOMMISSIONING Taking a tank, container or cylinder into LPG service or out of service. This happens during initial filling or before scrapping and before and after any maintenance or test activity. COMPRESSED GAS Any material or mixture having, when in its container, an absolute pressure either exceeding 276 kPa (2.76 bar) at 21.1 °C, or exceeding 717 kPa (7.17 bar) at 54.4 °C. CONTAINER A container is a small tank containing LPG. Such containers are typically used at customer sites for heating, cooking or small industry consumption. They may be installed above ground, mounded or below ground. CONTAINER APPURTENANCES Items connected to container openings needed to make a container a gas-tight entity. These include, but are not limited to, pressure relief devices; shutoff, back-flow check, excess-flow check, and internal valves; liquid level gauges; pressure gauges; and plugs. CONTINGENCY A contingency is a normal or abnormal event during plant operation that could lead to overpressuring. The magnitude of the contingency will have a direct impact on the sizing of the pressure relief valve. Safety in LPG Design Glossary of Terms 13-3 CRITICAL EXPOSURE TEMPERATURE The Critical Exposure Temperature (CET) is the minimum steel temperature at which a component will be subjected to a pressure greater than 25% of the design pressure. If a component is exposed to lower temperatures it may fail through brittle fracture. The possibility of auto-refrigeration and the lowest one day mean temperature will be of influence when determining the CET for LPG tanks. CSO See Car Sealed Open. CYLINDER A cylindercontains LPG for customer consumption. It is normally portable, may be reusable or disposable. Cylinders are also often called “Bottles.” CYLINDER FILLING Cylinder filling is a manual, semi-automatic or fully automatic process to fill cylinders with LPG. Most important in this process are prevention of overfilling and leak control. CYLINDER FILLING SHED A well ventilated building in which the filling of cylinders takes place. CYLINDER VALVE A valve, used on LPG cylinders, which normally incorporates a shutoff valve and a pressure relief valve in one unit. A fusible plug, incorporated in the same valve may be required while PRV may not be allowed in some countries. DESIGN PRESSURE The design pressure is the maximum internal (or external) pressure used to calculate the minimum permissible wall thickness of tanks, drums, containers or cylinders. It is always higher than the operating pressure. For vacuum conditions the external pressure is the maximum difference in pressure between the atmosphere and the inside of the equipment. DESIGN TEMPERATURE The design temperature is the temperature corresponding to the most severe condition of coincident pressure and temperature. The design temperature may include both a maximum and a minimum (CET) condition. DFT Dry Film Thickness is the thickness of a surface coating once the coating has dried or cured. 13-4 Glossary of Terms Safety in LPG Design DIFFERENTIAL SETTLEMENT Differential settlement occurs after a structure has been erected. As a result of structure size and uneven compressibility of the ground, parts of the foundation may sink into the ground to different depths and cause stress in the structure. DIFFERENTIAL VALVE A special valve actuated by the difference between two pressures. It is usually used to control the higher pressure at a desired amount over the lower pressure. DIP PIPE, DIP TUBE A pipe extension from a tank opening or from a valve which extends into either the liquid or vapor space of the tank. It is used to locate the tank liquid level. DOT Department of Transportation, US government. DRY BREAK COUPLING A dry break couplingworks on the principle that only a negligible amount of product is released to atmosphere when the coupling is disconnected. This is achieved by displacing the product inside the coupling with two pistons. ELECTRICAL AREA CLASSIFICATION The concept of electrical area classification has been introduced to control electrical ignition sources around equipment that contains flammable materials. Certain areas in a plant require higher quality electrical equipment to take account of the fact that flammable mixtures may be present at some time during plant operations. ELT See LDE below. EMERGENCY BLOCK VALVE An Emergency Block Valve (EBV) is a manual or remote operated valve that is installed upstream of a source of potential leak and can provide tight shutoff. Sources of potential leaks are pumps, compressors, loading arms, hoses, cylinder filling, etc. Remote operated valves are activated by the Emergency Shutdown System (ESS). EMERGENCY RELEASE SYSTEM An Emergency Release System is provided at certain marine unloading piers. Under emergency conditions it will release the loading arm automatically to prevent damage and product leakage. EMRE ExxonMobil Research and Engineering Co., Fairfax, Virginia, USA. Safety in LPG Design Glossary of Terms 13-5 ERE Former Exxon Research and Engineering Co., Florham Park, New Jersey, USA EXCESS FLOW VALVE A device designated to close when the liquid or vapor passing through it exceeds a prescribed flow rate as determined by pressure drop. An excess flow valve allows flow to pass in either direction, but protects against excess flow in only one direction. The valve reopens when the design pressure differential is restored. FAIL SAFE A device or system “fails safe” if on loss of energy it automatically moves to the safest position. For valves on LPG tanks this would mean the closed position. FILLING DENSITY The percent ratio of the weight of liquefied gas to the weight of water at 15.6 °C, which a container will safely hold at a specific temperature. FIRE IMPINGEMENT Fire impingement occurs if in a fire situation the flames come into direct contact with tanks, containers, cylinders, piping etc. See also jet flames. Flame impingement is one of the overpressure contingencies since the external heat leads to a temperature and pressure increase inside equipment. FLEXIBLE CONNECTOR A short (not exceeding 1 m overall length) component of a piping system fabricated of flexible material (such as hose) and equipped with suitable connections on both ends. FLOAT (OR MAGNETIC) GAUGE A gauge constructed with a float inside the container resting on the liquid surface that transmits its position through suitable leverage to a pointer and dial outside the container, indicating the liquid level. Normally the motion is transmitted magnetically through a non-magnetic plate so that LPG cannot be released to the atmosphere by a seal failure. FUSIBLE LINK A link or section in a support, rod, shaft, or cable which will melt at a predetermined temperature and cause a valve or fire door to close, or will effect another action for fire protection purposes. FUSIBLE PLUG A low melting temperature metal plug designed to melt and release the pressure in a cylinder or piping system at a predetermined temperature. A fusible plug may be included in the cylinder valve when specified. 13-6 Glossary of Terms Safety in LPG Design GP / BP ExxonMobil Global Practices (previously International Practices and before that Basic Practices). Engineering Practices for facility installation. GROUNDING (EARTHING) Grounding means electrically connecting major equipment parts (tanks, pumps) to the ground. This is to provide quick dissipation of lightning or stray currents. HARD ARM A hard piping connection to unload or load LPG on trucks, rail cars or ships. Swivel joints provide flexibility. HAZARD A threat which could cause an accident HAZOP Hazard and Operability Analysis is a hazard identification analysis used during the design phase of a project. An independent HAZOP team studies all aspects of process related hazards to verify that adequate controls are included in the design to control or mitigate those hazards. HEAT RADIATION Heat radiation is the transfer of thermal energy from a fire by radiation to equipment. It is one of the contingencies that create overpressure inside equipment. HOSE TRACKING PROGRAM A hose tracking program provides information on the origin of hoses, their age, their test results, and their anticipated date of retirement. HYDROCARBON Organic compounds of hydrogen and carbon whose densities, boiling points, and freezing points increase as their molecular weights increase. ICC US Interstate Commerce Commission. INERT GAS A noncombustible, non-reactive gas that renders the combustible material in a system incapable of supporting combustion by virtue of displacing air. Safety in LPG Design Glossary of Terms 13-7 INSULATING FLANGE An insulating flange has to be installed to achieve electrical isolation of a piece of equipment for cathodic protection purposes. Typical application of insulation flanges are around mounded drums, at pipeline terminals and at marine piers. Insulating flanges at piers also prevent any sparking upon disconnecting. INTERNAL VALVE A primary shutoff valve for containers that has adequate means of actuation and that is constructed in such a manner that its seat is inside the container and that damage to parts exterior to the container or mating flange will not prevent effective seating of the valve. ISGOTT International Safety Guide for Oil Tankers and Terminals. JET FLAME If fluid escapes at a leak under high pressure it usually takes the shape of a long plume. If this plume ignites it forms a jet flame. KNOCK OUT DRUM A Knock Out Drum (KO Drum or Liquid Trap) is a container provided at the suction side of a compressorto prevent intake of liquid, which could damage the compressor. LEVEL HIGH CUT OFF A level high cut off is a means to prevent the liquid level from rising too high. This is provided on tankage or knock out drums on compressors. LDE Loan Delivery Equipment. Also called ELT in Mobil heritage, Equipment Loaned to Trade. Tanks or cylinders owned and maintained by the Company but operated by third parties (customers). LOWER FLAMMABILITY LIMIT Lower Flammability Limit (LFL) is the lowest concentration of flammable vapor in air that will result in a mixture, which can be ignited. For Propane this is 2.0 volume % and for n-Butane it is 1.9 volume % in air. If temperature or pressure of the mixture are increased the LFL will decrease (i.e. will be more dangerous). LIQUEFIED PETROLEUM GAS (LPG OR LP GAS) Propane and Butane are called Liquefied Petroleum Gas (LPG) because they will liquefy if subject to higher pressure at atmospheric temperature. They will also liquefy if refrigerated at atmospheric pressure. They may be composed predominantly of any of the following hydrocarbons or mixtures of them: Propane, Propylene, Butane (n Butane or Isobutane), and Butylene. 13-8 Glossary of Terms Safety in LPG Design MAGNETIC GAUGE See Float Gauge. MAXIMUM ALLOWABLE WORKING PRESSURE The maximum gauge pressure permissible in a tank or container during normal operation at design temperature. MERCAPTANS A family of chemical compounds similar to alcohol in which sulfur replaces oxygen. Many mercaptans have an offensive odor and are used for odorization of LPG. MEP Mobil Engineering Practices. MINIMUM VAPOR SPACE The minimum space in a tank, above the liquid level, which is necessary to ensure that the tank does not become hydraulically full under normal operating conditions. MOUNDED TANK Large horizontal tank containing LPG which is installed above ground level but is covered by an earth mound which protects it from fire. These tanks need a high quality corrosion protection. NET POSITIVE SUCTION HEAD Net Positive Suction Head (NPSH) is the pressure at the impeller of a pump. In order for the pump to function properly, the NPSH must always be above a certain level specified by the pump manufacturer. The pumped product, the product temperature, the product vapor pressure, and the suction piping arrangement will influence this. NFPA National Fire Protection Association. NPGA National Propane Gas Association. NPSH See Net Positive Suction Head. Safety in LPG Design Glossary of Terms 13-9 NPQC Non Process Quality Control is used to ensure that materials of construction and equipment will perform as required per specifications and design. NPQC is often done at manufacturers sites and may involve tests. OVERFILLING LPG expands its volume with a temperature increase. If a tank, container or cylinderis overfilled an increase in ambient temperature may lead to opening of the pressure relief valve and a discharge of LPG. To avoid this, the filling level is limited. Normally tanks, containers or cylinders are filled to 85%, however, this figure may vary depending on conditions (e.g. if LPG is already at a higher temperature during filling, it cannot expand much more). OVERPRESSURE PROTECTION Equipment containing pressurized fluids by design is limited to a maximum pressure. This maximum pressure is determined by operating conditions and economical considerations. Overpressure protection in form of automatic pressure relief should be provided to ensure that the pressure inside the equipment remains within safe limits. PASSIVE FIRE PROTECTION Passive fire protection mitigates the impact of a fire without relying on rapid detection, alarm, or response. Mechanical or electrical failures have no effect on its performance. Passive protection includes spacing, mounding or burying a tank, or providing fireproofing. These passive measures increase the time available to provide active response, i.e. firefighting response. POSITIVE DISPLACEMENT PUMP In a positive displacement pump the fluid is aspirated into a cavity and than expelled by decreasing the volume of the cavity. The pressure rise is created by displacement force. For LPG, sliding vane, internal gear or crescent pumps are used. In case the discharge side can be blocked, such pumps should be protected against overpressure by a relief valve between the pump discharge and any block valve. POST-WELD HEAT TREATMENT Post-Weld Heat Treatment is heating of equipment to a temperature that will reduce the stress that originates from welding on the equipment. PRESENTATION FLANGE Dock side flange which makes contact with the ship flange. PRESSURE RELIEF VALVE A pressure relief valve (PRV) is a mechanical device that is designed to open automatically once a certain pressure upstream of the PRV is reached. By this feature it provides overpressure protection for the equipment. 13-10 Glossary of Terms Safety in LPG Design PUSH-BUTTON The Emergency Shutdown System may be activated by push-buttons placed in strategic locations. PWHT See Post-Weld Heat Treatment. REFRIGERATED STORAGE A tank artificially maintained at a temperature below the nominal ambient temperature. REGULATOR Device to reduce and control pressure at a defined level. Usually regulators are installed between tankage or cylinders and end users. RELIEF VALVE MANIFOLD A piping manifold that may hold two or more relief valves with only one connection to the tank. Some manifolds, such as the Multi-port manifold manufactured by RegO, are designed to permit the removal of one relief valve without disturbing the others or impairing the relieving capacity required for the tank. RISK Probability of an accident occurring within a certain time, together with consequence for people, property and environment. ROLLOVER The spontaneous and sudden movement of a large mass of liquid from the bottom to the top surface of a storage reservoir as a result of an instability caused by an adverse density gradient. REMOTE IMPOUNDMENT In the case of LPG leakage under a bullet or sphere a certain amount of LPG may remain in the liquid phase. By inclining the ground surface and diverting the liquid to a shallow pool, which is located away from the tank, it is possible to divert a part of the liquid to a safer location. Should the vapors ignite the fire exposure to the tank will be lower. SET PRESSURE The set pressure is the pressure at which a pressure relief valve opens. This is identical to the design pressure of the equipment. SELF SEALING COUPLING A coupling that automatically closes when disconnected and opens when connected. It is also known as a dry break coupling. Safety in LPG Design Glossary of Terms 13-11 SHUTOFF PRESSURE Shutoff pressure is the highest pressure that a pump can reach, i.e. the pressure when the discharge valve is closed. SLIP TUBE GAUGE A variable liquid level gauge in which a relatively small positive shutoff valve is located at the outside end of a straight tube, normally installed vertically, that communicates with the container interior. The installation fitting for the tube is designed so that the tube can be slipped in and out of the container so that the liquid level at the inner end can be determined by observing when the shutoff valve vents a liquid-vapor mixture. SPACING The concept of spacing has been adopted to prevent fire from quickly spreading in a plant or at a customer site. By experience the industry has suggested minimum distances between LPG containing equipment and a variety of other locations. Such locations are the fence, the control house, firefighting equipment or other LPG containing equipment (loading/unloading etc.). Spacing requirements are incorporated in most codes. SPHERE Large above ground spherical LPG tank. It is typically used for bulk storage at refineries and large terminals. It may be fireproofed. TANK In this Manual the term tank is used for bullets, spheres and mounded drums. The term container is used for smaller customer tanks. TANK IDENTIFICATION PLATE Each tank, drum, or container needs to be permanently identified by a name plate indicating all relevant data. TARE WEIGHT Weight of cylinder, or any container, before filling. Cylinders are stamped with their empty tare weight plus weight of valve to be fitted when manufactured. THERMAL EXPANSION RELIEF VALVE LPG inside equipment expands under the influence of solar or other external heat. If LPG is subject to elevated temperatures and it is enclosed inside piping sections that are blocked on both sides, the pressure may rise above design and rupture the piping. Therefore, Thermal Expansion Relief Valves (Hydrostatic Valves) should be provided. THREAD National Gas Taper (¾” NGT ) threads are used on cylinderconnections and National Pipe Taper (NPT) threads are used in other LPG service. Some countries use DIN 477 13-12 Glossary of Terms Safety in LPG Design thread. Both NGT and DIN threads look similar. recommended on cylinder bungs and valves. Therefore, marking of DIN is UL Underwriters Laboratory. US organization for quality controls. ULLAGE The space in a tank or container above the liquid level. Ullage is necessary to allow a minimum vapor space above the LPG. UNDERGROUND TANK A tank in which all parts are completely buried under the general grade of the facility. VAPOR CLOUD EXPLOSION A Vapor Cloud Explosion (VCE) occurs if a large amount of LPG vaporizes (usually after a leak), mixes with air and finds an ignition source. In case all LPG is within the flammable limits the VCE can be severe. The degree of LPG/air mixing is largely governed by weather conditions. VAPOR PRESSURE The pressure developed over a liquid in a closed container. The vapor pressure of LPG depends on the temperature of the liquid and the composition of the primary hydrocarbons present. VAPORIZER A heat exchanger designed to supply the heat required to convert LPG from liquid phase into vapor. VESSEL Ship. In the text of this manual the term vessel is not used for tanks, drums etc. but the titles of codes use the word vessel for tanks, drums or towers. VOLATILE LIQUID A liquid that will readily vaporize at a relatively low temperature, such as normal ambient temperature. WATER CAPACITY The amount of water, in either weight or volume, at 15.6 °C required to fill a container full of liquid water. Safety in LPG Design Glossary of Terms 13-13 ZONE 0 Zone 0 is an electrical area classification. Zone 0 is an area where an explosive gas atmosphere is continuously present, or present for a long period. There is no equivalent US classification, although Zone 0 would fall under Class 1 Division 1. ZONE 1 Zone 1 is an electrical area classification. Zone 1 areas are defined as locations where an ignitable concentration of flammable gases or vapors are likely to occur in normal operations. It is equivalent to the US Class 1 Division 1. ZONE 2 Zone 2 is an electrical area classification. Zone 2 areas are defined as locations where ignitable concentrations of flammable gases or vapors are not likely to occur in normal operation, but may occur under abnormal operation. It is equivalent to the US Class 1 Division 2. 13-14 Glossary of Terms Safety in LPG Design