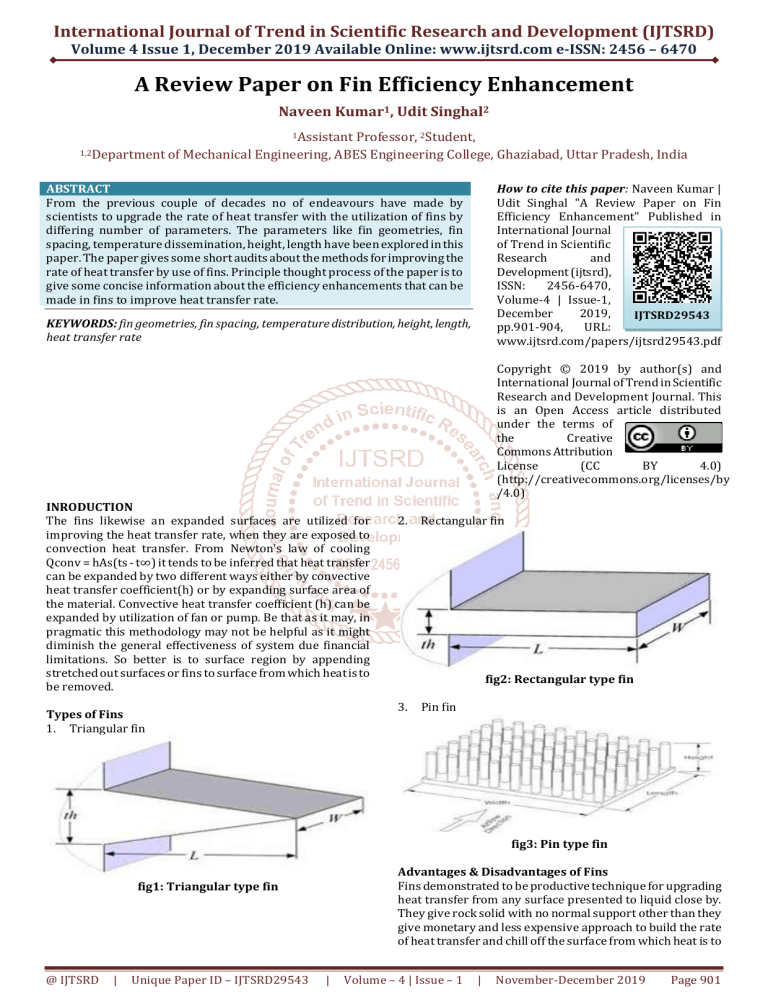

International Journal of Trend in Scientific Research and Development (IJTSRD) Volume 4 Issue 1, December 2019 Available Online: www.ijtsrd.com e-ISSN: 2456 – 6470 A Review Paper on Fin Efficiency Enhancement Naveen Kumar1, Udit Singhal2 1Assistant Professor, 2Student, 1,2Department of Mechanical Engineering, ABES Engineering College, Ghaziabad, Uttar Pradesh, India How to cite this paper: Naveen Kumar | Udit Singhal "A Review Paper on Fin Efficiency Enhancement" Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-4 | Issue-1, December 2019, IJTSRD29543 pp.901-904, URL: www.ijtsrd.com/papers/ijtsrd29543.pdf ABSTRACT From the previous couple of decades no of endeavours have made by scientists to upgrade the rate of heat transfer with the utilization of fins by differing number of parameters. The parameters like fin geometries, fin spacing, temperature dissemination, height, length have been explored in this paper. The paper gives some short audits about the methods for improving the rate of heat transfer by use of fins. Principle thought process of the paper is to give some concise information about the efficiency enhancements that can be made in fins to improve heat transfer rate. KEYWORDS: fin geometries, fin spacing, temperature distribution, height, length, heat transfer rate Copyright © 2019 by author(s) and International Journal of Trend in Scientific Research and Development Journal. This is an Open Access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0) (http://creativecommons.org/licenses/by /4.0) INRODUCTION The fins likewise an expanded surfaces are utilized for improving the heat transfer rate, when they are exposed to convection heat transfer. From Newton's law of cooling Qconv = hAs(ts - t∞) it tends to be inferred that heat transfer can be expanded by two different ways either by convective heat transfer coefficient(h) or by expanding surface area of the material. Convective heat transfer coefficient (h) can be expanded by utilization of fan or pump. Be that as it may, in pragmatic this methodology may not be helpful as it might diminish the general effectiveness of system due financial limitations. So better is to surface region by appending stretched out surfaces or fins to surface from which heat is to be removed. 2. fig2: Rectangular type fin 3. Types of Fins 1. Triangular fin Rectangular fin Pin fin fig3: Pin type fin Advantages & Disadvantages of Fins Fins demonstrated to be productive technique for upgrading heat transfer from any surface presented to liquid close by. They give rock solid with no normal support other than they give monetary and less expensive approach to build the rate of heat transfer and chill off the surface from which heat is to fig1: Triangular type fin @ IJTSRD | Unique Paper ID – IJTSRD29543 | Volume – 4 | Issue – 1 | November-December 2019 Page 901 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 be separated. With favourable circumstances there are somewhere in the range of few disadvantages as well, appending fins to any surface expands the weight and may now and again decline the general effectiveness. They can be utilized just where a surface is in direct contact with the liquid close by. Applications 1. They are used in IC engines where engine is exposed to air like two wheelers and aircraft. 2. They are used in compressors as well. 3. Fins are also used in the Evaporators and condensation components of the refrigeration and air conditioning. 4. They are also used in the electric motors. Literature Review S. A. Nadaa et al. [1] Free type convection heat transfer in a level annulus with fins and without fins were numerically examined for rectangular fins and longitudinal fins annular fins. The effect of Rayleigh constant number, annulus profundity, fin number and measurement the heat stream pattern, isotherms, transfers and compelling warm conductivity were contemplated. Correlation between the heat transfer upgrades of the annular fins and the longitudinal fins was directed. Omer Sarfraz et al. [2] This paper displays the improvement of a point by point model with the cross-fin conduction type heat transfer convenience. This apparatus is differentiated by exploratory data and without thought of cross-fin heat conduction for two of the cooling and heating cases. As impact of the cross-fin heat conduction upon the general heat transfer was viewed as under 10 % of by and large heat transfer, when two of the water systems were dynamic (water stream in other compartments of heat exchanger). Regardless, cross-fin type conduction ends up imperative for instance a most outrageous differentiation of more important than 20% by the general heat transfer was found when only one arrangement of the heat exchanger was inactive (without any water stream in the chambers). The cross-fin heat conduction was moreover found to increase by extended difference in the air and water temperatures under heat exchanger channel especially when heat exchanger system(s) is inactive. By and large, the model without any cross finconduction have an extended tendency to under predict the breaking point right when one structure is inert and extension of cross fin conduction to the model lessens that proportion of tendency. Thus, disregarding cross-fin conduction when heat exchanger system(s) is inert may achieves less precise desire for all in all heat exchanger limit. Shwin-Chung Wong et al.[3] This examination numerically explores the normal convection from level cylinder with circular type fins. These parameters incorporate fin diameter, tube diameter, fin material, and fin dispersing, under a permanent temperature distinction by 50 K and the fin thickness by 0.5 mm . Saroj Yadava et al.[4] The present work revealed is the correlation of numerical information with experimental information. After the experiment it has been inferred that the heat transfer from fin increments by increment in inlet speed and along these lines here is a decent understanding of observational and the numerical outcomes have found. By the contextual investigations, This has been discovered that kite @ IJTSRD | Unique Paper ID – IJTSRD29543 | and curved shape has more prominent impact on Nusselt number and heat transfer coefficient. Pulkit Sagara et al.[5] The example of round and hollow bodies, body surface harshness 400 micron and 300 micron, 250 micron taken into thought. A progression of temperature is about equal in each of the Three bodies. By the harshness of body increments from 240 to 400 micron the heat motion increments. Which implies the rate of heat dissemination increments as the harshness increment for same zone and volume. The examination of body reason that as the increment the unpleasantness of body the heat transfer increments by the group of same region and volume. Partner L. Ndlovua et al. [6] We have effectively done warm investigation of outspread fins. In this subsequent differential conditions have comprehended utilizing He's VIM and the explanatory arrangements have benchmarked by the value arrangements. These effects of thermo physical parameters were illustrated with clarification. The radiation type heat transfer has expected to happen at higher temperatures as depicted against the type of coefficient of heat transfer. We have likewise demonstrated that investigative arrangements may significant upon depicting the thermo physical properties of heat transfer conditions. The unequivocal arrangements give a simple method for assessing fins bases warm conductance and the fins proficiency, this will be troublesome utilizing value plans. Besides, this incorporated shift in weather conditions term on spiral model of fin, which by consequence of constant fin development. The expansion in velocity of flowing actuates an even stream field which thus expands heat dissemination from non uniform fin. We see that temperature in abatements with expanding estimations of Peclet number and thermo-geometric fins parameters. When cooling is necessary, More estimations of Peclet number and thermo-geometric parameters will be required. Xiaoming Huanga t al. [7] A heat pipe sink with a fin exhibit the inconsistent and ceaselessly non uniform heights were predicted to increase regular convection heat transfer against decreasing stream opposition. A presentation examination of the heat pipe sink with VHFA was completed dependent on numerical reproduction. To explain stream and the heat transfer attributes, parameter examines and multi-target advancement examination were led. Mr. Vibhav Sawant et al. [8] This paper is focussed on accomplishing higher heat transfer rate and higher film coefficient. The system for accomplishing this target can be extraordinary. The heat transfer rate may be expanded against altering geometry of the fins as concentrated in this paper as on account of vehicle radiators. Additionally the sensational change in the heat transfer coefficient by scores and in this way the expansion in heat transfer rate was seen in this paper. Utilizing a covering of yttrium oxide expands the fin effectiveness and has focal points over the traditional fins. Tehmina Ambreen et al. [9] The pin fin shape-subordinate heat transfer and liquid stream attributes of water and nanofluid cooled heat sink by the stunned micropin- fin course of action were researched by actualizing the Lagrangian-Eulerian model. The stick fin designs of square, Volume – 4 | Issue – 1 | November-December 2019 Page 902 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 roundabout and triangular cross-areas can broke down for the parametric weight scope of 570 Pa ≤ ΔP ≤ 2760 Pa. For the nanofluid coolant, the watery arrangement are enhanced with a 0.5% volume division of alumina nanoparticles by a normal measurement of 20 nm. Heat transfer traits are communicated as far as warm obstruction and nearby and normal Nusselt number, though the stream and speed forms are plotted to appreciate the stream dispersion within the heat sinks of variable stick fin designs. A.M. González et al. [10] The present investigation proposes a half and half test/numerical strategy to get the normal convective type heat transfer coefficient what's more, general fin surface proficiency of the cylinder column plate finned heat exchanger with in-line course of action. This method joins exploratory information got from wind burrow estimations and value recreation of heat transferred by fins to decide a traditional in general fin effectiveness, η0, and found the middle value of convective heat transfer coefficient, h0. This idea has demonstrated against testing the gadget of various fins materials (aluminum AL, CS and Cu) and wind current rate (4.9 10. ≤ ue 0 m/s). This procedure was approved with some looking at outcomes for Nusselt number by connections proposed by Kaminski and Gross and ESCOA for the aluminum fins. The parametric report has demonstrated that Nusselt number relating to the finned surfaces depends principally on the geometrical and wind stream parameters. For Prandtl number Pr= 0.7 and scope of Reynolds number 102 ≤ ≤× ReDh .510 4, a connection can be approximated as Nu Pr Re Dh = 0.2617 Dh 1/3 0.6318 (coefficient of assurance R2= 0.993). Contrastingly, the general fin surface proficiency, η¯0, and worldwide parameter Nu η Dh × ¯0 (Nusselt number dependent upon general heat transfer coefficient, U) rely on the material of fin and were found bigger for larger conductive materials. Besides, evaluation of the mass and cost proficiency shows that aluminium fins give the most elevated heat conversion standard per unit mass, and steel fins yield the littlest expense per unit heat transfer rate. Khoshvaght-Aliabadi el al.[ 11] This paper talks concluded that different parameters like shape(rectangular, roundabout, tapered, cone like, parabolic) , geometry and material(copper, aluminium, mellow steel, metal and stainless steel) of pin fin were thought about in ANSYS. The results demonstrated copper roundabout empty pin balance and copper rectangular fin balance to be ideal fin balances. It was discovered that copper and aluminium pin balances with same shape have about equivalent heat transfer. So it was presumed that aluminium to be ideal material for pin balance because of economic imperatives. Dipankar Bhanja et al.[12] This paper examined the heat transfer improvement by permeable pin fins in a free convection. For answer for administering fin condition Adomian disintegration technique was utilized. It was discovered that with increment in nusselt number and porosity proportion fin productivity diminishes and with increment in sweep to length proportion fin proficiency increments. The parameters like porosity proportion, Raleigh number warm conductivity proportion improves heat transfer. Pandit et al.[13] In this paper, different geometries and pin fin stature proportion to the channel of thermoelectric @ IJTSRD | Unique Paper ID – IJTSRD29543 | generator for vehicle applications were inspected to improve the proficiency. It was discovered that precious diamond molded pin fins demonstrated to be superior to different shapes for warm proficiency. It was additionally discovered that pin fin to channel stature proportion at 0.5 demonstrated greatest proficiency. Younghwan joo et al.[14] This paper looked at the heat transfer of plate fin with pin fin heat soaks in free convection. They gave an approved new connection of heat transfer coefficient for the advancement of stick fin heat sinks. This has discovered that for all out heat dissemination plate fin heat sinks demonstrated to superior to anything pin fin heat sinks, while for heat dispersal per unit mass the turn around is valid. Conclusion Subsequent to experiencing some of research papers on fins, the end turned out that proficiency of fin can be expanded in a few different ways relying on parameters. A few different ways and systems have been created by specialists so as to upgrade the heat transfer by fins. It was discovered that in materials of fins aluminium demonstrated to be more proficient than others. Including dividing and interferences can likewise improve the efficiency. Prologue to scores and openings can likewise be valuable to improve the productivity of fins. By expanding Reynolds number heat transfer by fins can be expanded. Likewise fins of curved geometry can likewise improve the rate of heat transfer when contrasted with different geometries like annular and unusual fins. Adding covering to fins can likewise improve heat transfer. A fin exhibit with dimples is another instance of improving heat transfer through fins. REFERENCES [1] S. A. Nada, M.A.Saida, 2018. “Effects of fin geometries, arrangements, dimensions and numbers on natural convection heat transfer characterstics in finned horizontal annulus", International Journal of Thermal sciences. [2] Omer Sarfraz, Christian, K. Bach Craig R. Bradshaw, 2019, “Discrete Modeling Of fin and tube Heat Exchangers With cross-fin Conduction functionality”, International Journal Of Refrigeration. [3] Shwin-Chung Wong, Wei-Yi Lee, 2018, “Numerical study on the natural convection from horizontal finned tubes with small and large fin temperature variations”, International Journal of Thermal Sciences. [4] Saroj Yadava, Krishna M. Pandeya, 2016, "A Comparative Thermal Analysis of Pin Fins for Improved Heat Transfer in Forced Convection", Department of Mechanical Engineering, National Institute of Technology Silchar, Assam. [5] Pulkit Sagara, Puneet Teotiab, Akash Deep Sahlotc, H. C Thakur, 2016, "Heat transfer analysis and optimization of engine fins of varying surface roughness", International Conference on Advancements in Aeromechanical Materials for Manufacturing. [6] Partner L. Ndlovua, Raseelo J. Moitshekia, 2019,"Analysis of temperature distribution in radial moving fins with temperature dependent thermal conductivity and heat transfer coefficient, International Journal of Thermal Sciences. Volume – 4 | Issue – 1 | November-December 2019 Page 903 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 [7] Xiaoming Huanga, Chunyu Shia, Junhe Zhoub, Xiaojian Lua, Guoliang Xua, 2019,"Performance analysis and design optimization of heat pipe sink with a variable height fin array under natural convection", Applied Thermal Engineering. [8] Mr. Vibhav Sawant, Mr. Suprabhat Mohod , Archana Gaikwad , Parth Shah, 2017,"Review Paper on Optimisation of Fins by Modifying Geometry and Materials used for Production", International Journal of Innovative and Emerging Research in Engineering. [9] Tehmina Ambreen, Arslan Saleem, Cheol Woo Park, 2019, "Pin-fin shape- dependent heat transfer and fluid flow characteristics of water- and nanofluid-cooled micropin-fin heat sinks: Square, circular and triangular fin cross-sections", Applied Thermal Engineering. [10] A. M. González, M. Vaz Jr., P.S.B. Zdanski, 2018, " A hybrid numerical- experimental analysis of heat transfer by forced convection in plate-finned heat @ IJTSRD | Unique Paper ID – IJTSRD29543 | exchangers", Applied Thermal Engineering. [11] Khoshvaght-Aliabadi, M., Deldar, S., & Hassani, S. M., 2018, “Effects of pin-fins geometry and nanofluid on the performance of a pin-fin miniature heat sink”, (PFMHS), International Journal of Mechanical Sciences. [12] Bhanja, D., Kundu, B., & Mandal, P. K. , 2013, “ Thermal analysis of porous pin fin used for electronic cooling”, Procedia Engineering [13] Pandit, J., Thompson, M., Ekkad, S. V., & Huxtable, S. T. , 2014, “Effect of pin fin to channel height ratio and pin fin geometry on heat transfer performance for flow in rectangular channels”, International Journal of heat and mass transfer [14] Joo, Y., & Kim, S. J. , 2015, “ Comparison of thermal performance between plate-fin and pin-fin heat sinks in natural convection”, International Journal of Heat and Mass Transfer. Volume – 4 | Issue – 1 | November-December 2019 Page 904