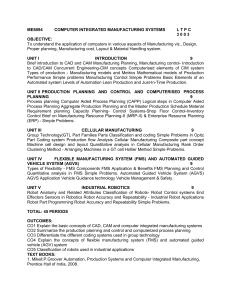

ABSTRACT Flexible production system is a system that can meet our requirements that provide variability. Recognizing the need to respond properly to rapidly changing market demands, we explain several types of flexibility that can be incorporated in our production organization to achieve this goal.Flexibility in manufacturing system is one of the most important problems of the present situation,we must to perform the desired customer's requirement & economical and high quality of the product that enforced to adopting the flexible manufacturing system for various new manufacturing enterprises.FMS consists of a combined system of computerized numerically controlled machine tools, automated material handling systems operating under the controlled computer, workstation, storage, etc. A higher level of flexible manufacturing systems is represented by the so-called intelligent manufacturing systems. Our project highlights the benefits, defects, application of flexibility manufacturing system, and also overviewed other aspects of flexibility manufacturing system. INTRODUCTION The term flexibility suggests the ease and experience bring about changes in a manufacturing environment. Business entities usually compete with one another in areas of strength. These areas of strength are usually we can be defined in terms of unique competencies, core competencies, or competing priorities.The competition is normally handled through factors like cost, quality, delivery, service, and flexibility.According to us, in tune with globalization and varying consumer demands, many companies are trying to compete in the area of flexibility. A flexible manufacturing system (FMS) is a highly automated Group Technology machine cell, consisting of a group of processing stations (usually CNC machine tools), interconnected by an automated material handling and storage system, and controlled by an integrated computer system. An FMS is capable of processing a variety of different part styles simultaneously under NC program control at the different workstations. Flexible manufacturing system (FMS) implements the manufacturing industries with the necessary flexibility and ability to cope up with the current demands defined by the market needs. Flexible manufacturing system normally includes four or more work stations that are mechanically interconnected by a unique part handling system and electronically controlled by a distributed controlled system.