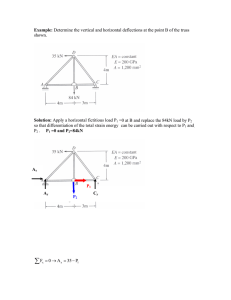

Design of Members Rui Simões Department of Civil Engineering University of Coimbra Eurocodes ‐ Design of steel buildings with worked examples Contents Introduction Design of columns Design of beams Design of beam‐columns Brussels, 16 ‐ 17 October 2014 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 INTRODUCTION Main internal forces and combinations Bending+Shear Compression+Bending+Shear Tension/Compression Torsion – less common Building – master example (Cardington - UK) Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 INTRODUCTION Member design: i) resistance of cross sections; ii) member buckling resistance. RESISTANCE OF CROSS SECTIONS Cross section classification - Class 1; Class 2; Class 3 and Class 4. Clause 6.2 of Eurocode 3, part 1.1 provides different Vz My G approaches, depending of cross section shape, cross section class and type of internal forces (N, M+V, N+M+V,….): – elastic criteria (clause 6.2.1(5)); x , Ed fy M 0 2 z , Ed fy M 0 2 NEd My,Ed x , Ed fy M 0 z , Ed f y M 0 3 Ed fy M 0 2 1 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 INTRODUCTION – linear summation of the utilization ratios – class 1/2/3 (clause 6.2.1(7)); M y , Ed M z , Ed N Ed 1 N Rd M y , Rd M z , Rd – nonlinear interaction formulas – class 1/2 (clause 6.2.1(6)). Section properties – gross section, net section (deduction for holes) or effective section (class 4 or shear lag effects) (clause 6.2.2 of EC3-1-1). MEMBER BUCKLING RESISTANCE Buckling resistance (clause 6.3 of Eurocode 3, part 1.1) must be checked in all members submitted to compressive stresses, which are: – members under axial compression N; – members under bending moment M; – or under a combination of both (M+N). Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS Column cross sections and applications Rolled open or closed sections, welded sections or built-up sections – The objective is to maximize the second moment of area in the relevant buckling plan in order to maximize the buckling resistance. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS NEd Compression resistance (clause 6.2.4 of EC3-1-1) NEd 1.0 Nc , Rd NEd is the design value of the axial compression; fy Nc,Rd is the design resistance to axial compression, given by the minimum of: i) Plastic resistance A N c , Rd A f y M 0 (class 1, 2 or 3) N c , Rd Aeff f y M 0 (class 4) Aeff - effective area ii) Buckling resistance – Nb,Rd, in general the flexural buckling resistance, which is analysed hereafter. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS Column Buckling Flexural buckling is in general the buckling mode, which govern the design of a member in pure compression. For this mode in a pinned column, the elastic critical load Ncr, defined as the maximum load supported by the column, free from any type of imperfections, is given by the well known Euler’s formula: N EI N d 2y dx 2 Ny 0 Ncr L x Ncr y(x) y(x) y (z) 0 N Buckling in a bending mode 2 E I L2 E I – Bending stiffness L – Buckling length (LE for other support conditions) In specific cases (e.g. members with cruciform cross sections) buckling may occur in other modes: torsional buckling or flexural-torsional buckling. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS Column Buckling Ncr 2 E I LE cr 2 2 E I A LE 2 2 E 2 Slenderness Critical stress 2 E f y 1 12 cr E fy LE i fy N A 1 Af y Ncr Non-dimensional slenderness 1.0 Euler’s curve I A Radius of gyration fy i Euler´s curve E fy 1 2 E 2 1.0 L E i Imperfections or real columns (geometrical imperfections and material imperfections). Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS Buckling Resistance (clause 6.3.1 of EC3-1-1) N b.Rd A f y M1 (Class 1, 2 or 3) Theoretical behaviour N b.Rd Aeff f y M1 (Class 4) is the reduction factor for the relevant buckling mode 1 2 2 but 1.0 2 0.5 1 0.2 Neglect BUCKLING if: 0.2 or NEd Ncr 0.04 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS Buckling Resistance (clause 6.3.1 of EC3-1-1) Flexural buckling A fy Ncr Lcr 1 i 1 Aeff fy Ncr 1 Lcr i (Class 1, 2 or 3) Aeff A 1 E f y 93 .9 (Class 4) ε 235 f y Torsional or flexural-torsional buckling T A f y Ncr T Aeff fy Ncr (Class 1, 2 or 3) (Class 4) - buckling in flexural buckling mode about z axis Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS EXAMPLE 1 Safety verification of a column member of the building represented in the figure. A’ A E’ C’ B C D E F 4 6.00 m 3 4.50 m 2b 2.50 m 2a 2.00 m 2 6.00 m 1 4.00 m 4.50 m 4.50 m 4.00 m Building – master example i) The inner column E-3 represented in the figure, at base level, is selected. This member has a length of 4.335 m and is composed by a section HEB 340 in steel S 355. In this column the bending moments (and the shear force) may be neglected; the design axial force (compression) obtained from the previous analysis is given by NEd = 3326.0 kN. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS EXAMPLE 1 ii) Cross section classification – section HEB 340 in pure compression. Geometric characteristics: A = 170.9 cm2, b = 300 mm, h = 340 mm, tf = 21.5 mm, tw = 12 mm, r = 27 mm, Iy = 36660 cm4, iy = 14.65 cm, Iz = 9690 cm4, iz = 7.53 cm. Mechanical properties of the steel: fy = 355 MPa and E = 210 GPa. Web in compression (Table 5.2 of EC3-1-1) c (340 2 21.5 2 27) 20.25 33 t 12 (class 1) 33 0.81 26.73 Flange in compression (Table 5.2 of EC3-1-1) c 300 2 12 2 27 5.44 9 9 0.81 7.29 21.5 t (class 1) HEB 340 cross section, steel S 355, in pure compression is class 1. c Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS EXAMPLE 1 iii) Cross section verification - class 1 in pure compression. N Ed 3326 . 0 kN N c , Rd A fy M0 170 . 9 10 4 355 10 3 6067 . 0 kN . 1 .0 iv) Buckling resistance. Buckling lengths – Assuming that the design forces were obtained by a second order structural analysis, the buckling lengths are considered (conservatively) equal to the real lengths (mid-distance between floors), given by: Buckling in the plan x-z (around y) - LEy 4.335 m Buckling in the plan x-y (around z) - LEz 4.335 m Determination of the slenderness coefficients 1 210 106 3 355 10 76.41 y z LEy iy 4.335 14.65 102 29.59 LEz 4.335 57.57 iz 7.53 10 2 y y 0.39 1 z z 0.75 1 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS EXAMPLE 1 z Calculation of the reduction factor min h 340 1.13 1.2 b 300 and flexural buckling around y curve b ( 0.34) flexural buckling around z curve c ( 0.49). As z 0.75 y 0.39 and tf 21.5 mm 100mm curve c min z curve b 340 y 300 HEB 340 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF COLUMNS EXAMPLE 1 z 0.5 1 z 0.2 z 2 z 0.5 1 0.49 0.75 0.2 0.752 0.92 z 1 2 2 0.92 0.92 0.75 z 0.69 0.69 min z 0.69 v) Safety verification λz 0.75 Nb,Rd z A fy M1 0.69 170.9 104 355 103 1.0 4186.2 kN As, NEd 3326.0 kN Nb,Rd 4186.2 kN safety is verified with the cross section HEB 340 in S 355 steel. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Beam cross sections and applications A beam may be defined as a member subjected essentially to bending and shear force. Castellated beams Hot-rolled sections (IPE, HEA or HEB, RHS,….) Welded sections Welded sections in non-uniform beams Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Cross section resistance Uniaxial bending (clause 6.2.5 of EC3-1-1) M Ed 1 .0 M c.Rd Class 1 or 2 Mc.Rd Wpl fy M 0 Class 3 Mc.Rd Wel. min fy M0 Class 4 Mc.Rd Weff .min fy M0 Bi-axial bending (clause 6.2.9 of EC3.1.1) M y , Ed M pl , y.Rd M z , Ed M pl , z.Rd 1 .0 I or H 2; 5 n CHS 2 RHS but 1 1.66 2 1 1.13 n but 6 n NEd N pl , Rd Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Cross section resistance VEd 1.0 Vc,Rd Shear (clause 6.2.6 of EC3-1-1) PLASTIC RESISTANCE Vpl.Rd Vpl.Rd Av fy ELASTIC RESISTANCE 3 M0 Ed VEd Av – Shear area fy 3 G y 6.2.6 (3) of EC3-1-1 or from tables of profiles). f y 3 M0 Vz Av (obtained from clause 1.0 My G Ed VEd S It e. n. a. f z y Shear stresses - Shear buckling for webs without stiffeners should be verified in accordance with EC3-1-5, if: hw 72 tw 235 / fy hw and tw are the height and thickness of the web and is in accordance with EC3-1-5. 3 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS My,V.Rd Cross section resistance z Bending and Shear Interaction Vz (clause 6.2.8 of EC3-1-1) My VEd 50% Vpl , Rd NO REDUCTION VEd 50 % Vpl , Rd REDUCED MOMENT fyr 1 fy fy y hm tw fyr fyr (M y) + fy (Vz ) 2 VEd Vpl.Rd 12 For I and H cross sections of equal flanges, with bending about the major axis y, the bending moment resistance My,V,Rd is given by (clause 6.2.8 of EC3-1-1): M y ,V .Rd Aw 2 Wpl , y 4 tw f y M y , c , Rd M0 AW hw tw Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Lateral-Torsional Buckling Instability phenomenon characterized by the occurrence of large transversal displacements and rotation about the member axis, under bending moment about the major axis (y axis). This instability phenomenon involves lateral bending (about z axis) and torsion of cross section. z My y Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Lateral-Torsional Buckling In the study of lateral-torsional buckling of beams, the Elastic Critical Moment Mcr plays a fundamental role; this quantity is defined as the maximum value of bending moment supported by a beam, free from any type of imperfections. For a simple supported beam with a double symmetric section, with supports prevent lateral displacements and rotation around member axis (twist rotations), but allowing warping and rotations around cross section axis (y and z), submitted to a uniform bending moment My (“standard case”), the elastic critical moment is given by: L My My C B A z x´ z´ a) Elevation E Mcr x 2 E IW G IT E I z 1 2 L L G IT Which depend mainly of: Loading and support conditions; Length between lateral braced sections (L); Lateral bending stiffness (E Iz); Torsional stiffness (G IT); Warping stiffness (E Iw). Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS z Lateral-Torsional Buckling z y CG G Elastic critical moment Mcr E I z k z C1 2 k k z L w 2 C IW k z L2 G IT C2 z g C3 z j 2 E Iz Iz 2 z g z a z s 2 0.5 C2 z g C3 z j Mcr,1>Mcr Mcr Mcr,2<Mcr P z j z s 0 .5 y 2 z 2 z dA I y A C P P C C - applicable to member with symmetric and mono-symmetric cross sections, - include the effects of the loading applied below or above the shear centre; - several degrees of restriction to lateral bending (kz) and warping (kw); - several shapes of bending moment diagram (C1, C2 and C3 in the next tables). y Eurocodes ‐ Design of steel buildings with worked examples DESIGN OF BEAMS Lateral-Torsional Buckling Elastic critical moment - Publication nº 119 do ECCS (Boissonnade et al. 2006). - LTBeam software http://www.cticm.com Brussels, 16 ‐ 17 October 2014 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Lateral-Torsional Buckling Lateral-torsional buckling resistance (clause 6.3.2 of EC3-1-1) M Ed 1 .0 M b.Rd Mb.Rd LT Wy fy M1 Wy = Wpl.y Class 1 and 2; Wy = Wel.y Class 3; Wy = Weff.y Class 4. LT is the reduction factor for lateral-torsional buckling, which can be calculated by one of two methods, depending of member cross section. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Lateral-Torsional Buckling i) General method LT 1 2 LT LT LT 2 0.5 LT 1.0 LT 0 .5 1 LT LT 0 .2 LT LT Wy fy Mcr 0.5 Mcr - Elastic critical moment 2 Table 6.4 - Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Lateral-Torsional Buckling ii) Alternative method (rolled sections or equivalent welded sections) LT 1 LT LT LT 2 2 0.5 LT 1.0 LT 1 LT 2 LT 0 .5 1 LT LT LT ,0 LT LT Wy fy Mcr 0.5 Mcr - Elastic critical moment 2 Table 6.5 - LT ,0 0.4 0.75 (may be specified in National Annexes of Eurocode 3) Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS Lateral-Torsional Buckling LT ,mod LT LT ,mod 1.0 f 2 f 1 0.5 1 k c 1 2.0 LT 0.8 f 1.0 Neglect LTB if: LT LT ,0 M Ed M cr LT ,0 2 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS EXAMPLE 2 Safety check of a beam of the building illustrated in the figure (along line E). The beam is composed by a IPE 600 with 9 m length at the central span; the lateral spans with 6 m length (the governing spans) are composed by a section IPE 400 in steel S 355. For the lateral buckling check, two cases are considered: a) a beam with 6 m length, laterally braced only at the end support sections; b) a beam with 6 m length, laterally braced at the end support sections and at mid-span section. A’ A The geometrical and mechanical properties of C D E F 6.00 m 3 A = 84.46 cm2, b = 180 mm, h = 400 mm, iy = 16.55 cm, Iz = 1318 cm4, iz = 3.95 cm, B 4 the section IPE 400 in S 355 steel are: tf = 13.5 mm, tw = 8.6 mm, Iy = 23130 cm4, E’ C’ 4.50 m 2b 2.50 m 2a 2.00 m 2 IT = 51.08 cm4 ; Iw = 490x103 cm6; fy = 355 MPa and E = 210 GPa. 6.00 m 1 4.00 m 4.50 m 4.50 m Building plan – master example 4.00 m Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS EXAMPLE 2 139.1 kN a) Beam laterally braced at supports i) The internal forces (neglecting the axial force) are represented in the figure. Vz,Ed 70.7 kN The design values are MEd = 114.3 kNm 71.6 kN 140.1 kN and VEd = 75.9 kN. 255.7 kNm 93.7 kNm ii) Cross section classification 246.3 kNm 111.4 kNm 99.2 kNm 109.7 kNm My,Ed Web (an internal part) in bending: c 331 38 .49 72 72 0 .81 58 .32 t 8 .6 Flange (outstand part) in compression: (180 2 21 8 .6) 2 c 4 .79 9 9 0 .81 7 .29 13 .5 t The cross section is class 1 75.2 kN 75.9 kN 114.3 kNm 113.6 kNm 163.0 kNm Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS EXAMPLE 2 iii) Cross section verification Bending resistance: MEd 114.3 kNm Wpl,y fy M0 1307 106 355 103 1.0 464.0 kNm Shear resistance: VEd 75.9 kN Vpl , Rd Av fy M0 3 42.69 10 4 355 103 1.0 3 875.0 kN hw 373 .0 0 .81 43 .4 72 72 58 .3 8 .6 1 .0 tw So, it is not necessary to verify the shear buckling resistance. Bending + Shear: VEd 75.9 kN 0.50 Vpl,Rd 0.50 875.0 437.5 kN So, it is not necessary to reduce the bending resistance to account for the shear force. Cross section resistance is verified. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS EXAMPLE 2 iv) Lateral buckling resistance Assuming the support conditions of the “standard case” and the loading applied at the upper flange level, the elastic critical moment can be zg=200 mm 400 obtained from the following equation, with L = 6.00 m, kz = kw = 1.0, CG IPE 400 C1 ≈ 1.80 and C2 ≈ 1.60 (Boissonnade et al., 2006) and zg = 200 mm. Mcr E I z k z C1 k z L2 kw 2 2 IW Iz k L G IT C z C z 2 z2 2 g 3 j E Iz 2 0.5 180 C2 z g C3 z j C A 3m Mcr 164.7 kNm 93.7 kNm (Using LTBeam –> Mcr = 175.64 kNm) 3m 6m 111.4 kNm My,Ed 114.3 kNm 93.7 111.4 0.84 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS EXAMPLE 2 Mcr 164.7 kNm ; Wy Wpl ,y 1307 cm3 LT Wy fy Mcr 0.5 LT 1.68 Table 6.4 - General method: Rolled cross section IPE 400 with h/b=400/180=2.2>2 - Curve b LT 0.34 LT 2.16 LT 0.28 M b, Rd 0 .28 1307 10 6 LT 0 .5 1 LT LT 0 .2 LT 355 10 3 129 .9 kNm 114.3 kNm 1 .0 So, the safety is verified (utilization ratio = 114.3/129.9=0.88). LT 1 2 LT LT LT 2 2 0.5 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS EXAMPLE 2 B A C b) Beam laterally braced at supports and mid-span i) Cross section verifications are not changed. 3m 3m 6m ii) Lateral buckling check: 93.7 kNm As the beam is laterally braced at mid span cross section, the critical moment can be evaluated 111.4 kN 93.7 114.3 0.82 My,Ed with L = 3.00 m and a conservative hypothesis of kz = kw = 1.0. For the given bending moment 114.3 kNm shape between lateral braced cross sections, M C1 = 2.6 (Boissonnade et al., 2006) . zj C3 zg C2 2 5 . 0 zj C3 zg C2 IT G Iz 2 E L 2 kz 2 IWIz z kzkw I 2 E Lz 2 k C1 r Mc M Mcr 1778.8 kNm (Using LTBeam – Mcr = 1967.7 kNm) 1.0 2.06 1.000 0.850 0.5 2.15 1.000 0.650 1.0 2.35 1.000 1.3 1.2 f 0.5 2.42 0.950 0.77 f 1.0 2.60 1.000 0.55 f 0.5 2.45 0.850 0.35 f 1.0 2.60 f f 0.5 2.45 0.125 0.7 f 0.125 0.7 f Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAMS EXAMPLE 2 Mcr 1778.8 kNm ; Wy Wpl ,y 1307 cm3 LT Wy fy Mcr 0.5 LT 0.51 Table 6.4 - General method: Rolled cross section IPE 400 with h/b=400/180=2.2>2 - Curve b LT 0.34 LT 0.68 LT 0.89 M b, Rd 0 .89 1307 10 LT 0 .5 1 LT LT 0 .2 LT 6 355 10 3 412 .9 kNm 114.3 kNm 1 .0 So, the safety is verified (utilization ratio = 114.3/412.9=0.28). LT 1 2 LT LT LT 2 2 0.5 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS Cross section resistance (clause 6.2.9 of EC3-1-1) Class 1 or 2 – Uniaxial bending MEd MN,Rd Double-symmetric I or H sections M N , y , Rd M pl , y , Rd 1n 1 0 .5 a but M N , z , Rd M pl , z , Rd M N , z , Rd if 2 n a M pl , z , Rd 1 1 a n NEd N pl.Rd if MN , y , Rd M pl , y , Rd n a N N pl Eixo de about menor inércia Bending minor axis -- zz 1.0 Eixo deabout maior inércia Bending major axis - -y y n a a A 2 b t f A 0.50 No reduction if N Ed 0.25 N pl , Rd NEd 0.5 hw tw fy M 0 My HEA NEd hw tw fy M0 (z axis) (y axis) 0 0 M pl , y 1.0 , Mz M pl , z Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS Cross section resistance (clause 6.2.9 of EC3-1-1) M z,Ed Class 1 or 2 – Bi-axial bending M y , Ed M N , y.Rd M z , Ed M N , z.Rd I or H 1 .0 N Class 3 or 4 2; 5 n but 1 Circular hollow sections 2 Rectangular hollow sections d R , l p d NE n x , Ed fy M0 M y,Ed NEd x , Ed N Ed A 1.66 1 1.13 n2 M y , Ed Iy z 6 M z , Ed Iz y Bending, shear and axial force (clause 6.2.10 of EC3-1-1) – Similar to bending and shear interaction. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS Member stability Members with high slenderness subjected to bending and compression, may fail by flexural buckling or lateral-torsional buckling. Flexural buckling cross-section): and lateral-torsional buckling (doubly-symmetric My.Ed My , Ed M z.Ed M z , Ed NEd k yy k yz 1.0 (Eq. 6.61 of EC3-1-1) y NRk M1 LT My , Rk M1 M z , Rk M1 eN,y NEd (class 4) M y.Ed M y , Ed M z.Ed M z , Ed N Ed k zy k zz 1.0 (Eq. 6.62 of EC3-1-1) z N Rk M1 LT M y , Rk M1 M z , Rk M1 kyy, kyz, kzy and kzz - interaction factors, which are dependent of instability phenomena and plasticity – Annex A of EC3-1-1 (Method 1) or Annex B (Method 2). Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS Member stability i) Members with closed hollow sections or open sections restrained to torsion are not susceptible to torsional deformation. ii) Members with open sections (I or H sections) are susceptible to torsional deformation. Members not susceptible to torsional deformation – checking of flexural buckling against y-axis and z-axis, considering eqs. (6.61) and (6.62) with LT = 1.0 and interaction factors kyy, kyz, kzy and kzz in members not susceptible to torsional deformation. Members susceptible to torsional deformation – checking of lateral-torsional buckling, considering eqs (6.61) and (6.62) with LT according to 6.3.2 of EC3-1-1 and interaction factors kyy, kyz, kzy and kzz in members susceptible to torsional deformation. Eurocodes ‐ Design of steel buildings with worked examples DESIGN OF BEAM‐COLUMNS Member stability Method 2 (Annex B of EC3-1-1) Interaction factors for members not susceptible to torsional deformations (Table B.1 of EC3-1-1). Brussels, 16 ‐ 17 October 2014 Eurocodes ‐ Design of steel buildings with worked examples DESIGN OF BEAM‐COLUMNS Member stability Method 2 (Annex B of EC3-1-1) Interaction factors for members susceptible to torsional deformations (Table B.2 of EC3-1-1). Brussels, 16 ‐ 17 October 2014 Eurocodes ‐ Design of steel buildings with worked examples DESIGN OF BEAM‐COLUMNS Member stability Method 2 (Annex B of EC3-1-1) Equivalent factors of uniform moment Cmi (Table B.3 of EC3-1-1) Brussels, 16 ‐ 17 October 2014 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 Safety check of a beam-column of the first storey of the building illustrated in the figure. The member, composed by a HEB 320 cross section in steel S 355, has a length of 4.335. The relevant geometric characteristics of HEB 320 cross section are: A = 161.3 cm2; Wpl,y = 2149 cm3, Iy = 30820 cm4, iy = 13.82 cm; Iz = 9239 cm4, iz = 7.57 cm; IT = 225.1 cm4 and IW = 2069 x 103 cm6. The mechanical characteristics of the material are: fy = 355 MPa, E = 210 GPa and G = 81 GPa. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 The design internal forces obtained through the structure analysis (second combinations are order) for illustrated the in the various figure. load z 65.5 kNm y Two simplification are assumed for the subsequent design verifications: i) the shear force is sufficient small so can 53.0 kN 201 kN 417 kN 72.3 kNm 29.8 kNm 41.1 kN 58.6 kNm 32.0 kNm 41.1 kN 57.1 kNm 29.3 kNm 40.2 kN 55.9 kNm 27.9 kNm 39.3 kN 53.8 kNm 29.0 kNm be neglected; ii) the shape of the bending moment diagram is linear. Design values are: NEd = 1704 kN; My,Ed = 24.8 kNm 630 kN 841 kN at the base cross section. 1053 kN i) Cross section classification 43.2 kN 1262 kN 54.5 kNm 68.6 kNm As the compression force is high, the cross section is As the section HEB 320 is a stocky section, even under this load condition, is class 1. 50.5 kN 1496 kN classified under compression only (conservative approach). 29.4 kN 1704 kN NEd Vz,Ed 10.6 kNm 73.5 kNm 24.8 kNm My,Ed Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 ii) Cross section resistance The design internal forces: My,Ed = 24.6 kNm and NEd = 1704 kN (compression). N pl ,Rd A fy M0 161.3 104 355 103 1.0 5726.2 kN NEd My,Ed As, NEd 1704 kN N pl ,Rd 5726.2 kN, the axial force resistance is verified. Since, NEd 1704kN 0.25 Npl, Rd 1431.5 kN , in accordance with clause 6.2.9.1(4) of EC3-1-1, it is necessary to reduce the plastic bending resistance (to MN,y,Rd): M pl ,y ,Rd Wpl ,y fy Mo MN,y , Rd M pl , y , Rd As, 2149 106 355 103 A 2 b tf 161.3 2 30 2.05 762.9 kNm a 0.24 1.0 A 161.3 1n 1 0.30 762.9 606.9 kNm NEd 1704 n 0.30 1 0.5 a 1 0.5 0.24 N pl ,Rd 5726.2 M y , Ed 24 .8 kNm M N , y , Rd 606 .9 kNm , the bending resistance is verified. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 iii) Verification of the stability of the member In this example the Method 2 is applied. As the member is susceptible to torsional deformations (thin-walled open cross section), it is assumed that lateral-torsional buckling constitutes the relevant instability mode. Since Mz,Ed = 0, the following conditions must be verified: My , Ed NEd k yy 1.0 y NRk M1 LT My ,Rk M1 M y , Ed N Ed k zy 1 .0 z N Rk M1 LT M y , Rk M1 Step 1: characteristic resistance of the cross section NRk A fy 161.3 10 4 355 103 5726.2 kN M y , Rk Wpl , y f y 2149 10 6 355 10 3 762 .9 kNm Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 z Step 2: reduction coefficients due to flexural buckling, y and z h 320 1.07 1.2 b 300 and y 320 tf 20.5 mm 100mm 300 flexural buckling around y curve b ( 0.34) flexural buckling around z curve c ( 0.49). HEB 320 Plane xz - LE,y = 4.335 m. y LE,y 1 4.335 1 0.41 iy 1 13.82 102 93.9 0.81 y 0.62 y 0.92 Plane xy - LE,z = 4.335 m z LE , z 1 4.335 1 0.75 2 93.9 0.81 i z 1 7.57 10 z 0.92 z 0.69 0 .5 1 0 .2 2 1 2 2 0.5 Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 Step 3: calculation of the LT using the alternative method applicable to rolled or equivalent welded sections (clause 6.3.2.3 of EC3-1-1) The length between braced sections is L = 4.335 m. The critical 5 kNm 10.6 kNm moment Mcr assuming a linear diagram, in this example obtained just by LTBeam software, is given by: Mcr 5045.1 kNm LT 2149 10 6 3 Rolled I or H sections with h b 320 300 1.07 2 curve b, and LT 0.34 Taking LT ,0 0.4 and Table 6.4 - 0.75 LT 0 .5 1 0 .34 0 .39 0 .4 0 .75 0 .39 2 0 .56 LT 1 2 0.56 0.56 0.75 0.39 2 0.5 355 10 5045.1 0.99 0.5 0.39 24.8 kNm My,Ed Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 Step 3: calculation of the LT using the alternative method applicable to rolled or equivalent welded sections (clause 6.3.2.3 of EC3-1-1) The correction factor kc, according to Table 6.6 of EC3-1-1, with = 10.6/(-24.8) = - 0.43, is given by: kc 1 1 0.68 1.33 0.33 1.33 0.33 (0.43) 2 f 1 0.5 1 kc 1 2.0 LT 0.8 1 0.5 1 0.68 1 2.0 0.39 0.8 0.89 2 The modified lateral-torsional buckling reduction factor is given by: LT ,mod 0.99 0.89 1.11 1.00 So, LT ,mod 1.00 must be adopted. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 Step 4: interaction factors kyy and kzy. The equivalent factors of uniform moment Cmy and CmLT are obtained based on the bending moment diagram, between braced sections according to the z direction in case of Cmy and laterally in case of CmLT. Assuming the member braced in z direction and laterally just at the base and top cross sections, the factors Cmy and CmLT must be calculated based on the bending moment diagram along the total length of the member. Since the bending moment diagram is assumed linear, defined by: My,Ed,base= -24.8 kNm; My,Ed,top = 10.4 kNm, from Table B.3 of EC3-1-1, is obtained: My,Ed,top My,Ed,base 10.6 24.8 0.43 5 kNm 10.6 kNm C my C mLT 0.60 0.4 0.43 0.43 ( 0.40) 24.8 kNm My,Ed Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 DESIGN OF BEAM‐COLUMNS EXAMPLE 3 Because the member is susceptible to torsional deformations, the interaction factors kyy and kzy are obtained from Table B.2 of EC3-1-1, through the following calculations: NEd 1704 k yy C my 1 y 0.2 0.43 1 0.41 0.2 0.46; 0.92 5726.2 1.0 y NRk M1 NEd k yy 0.46 0.54 , then As k yy C my 1 0.8 y NRk M1 NEd 0.1z k zy 1 CmLT 0.25 z NRk M1 0.1 0.75 1704 1 0.82 0.43 0.25 0.69 5726.2 1.0 As k zy 1 NEd 0.1 0.76 C mLT 0.25 z NRk M1 then k zy 0.82 Step 5: Finally, the verification of equations 6.61 and 6.62 of EC3-1-1 yields: 1704 24.8 0.46 0.34 1.0 0.92 5726.2 1.0 1.00 762.9 1.0 1704 24.8 0.82 0.46 1.0 0.69 5726.2 1.0 1.00 762.1 1.0 Section O.K. Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 Free software for design of steel members in accordance with EC3-1-1. Beam-columns design Design of cellular beams http://www.constructalia.com http://www.steelconstruct.com Eurocodes ‐ Design of steel buildings with worked examples Brussels, 16 ‐ 17 October 2014 Thank you for your attention rads@dec.uc.pt