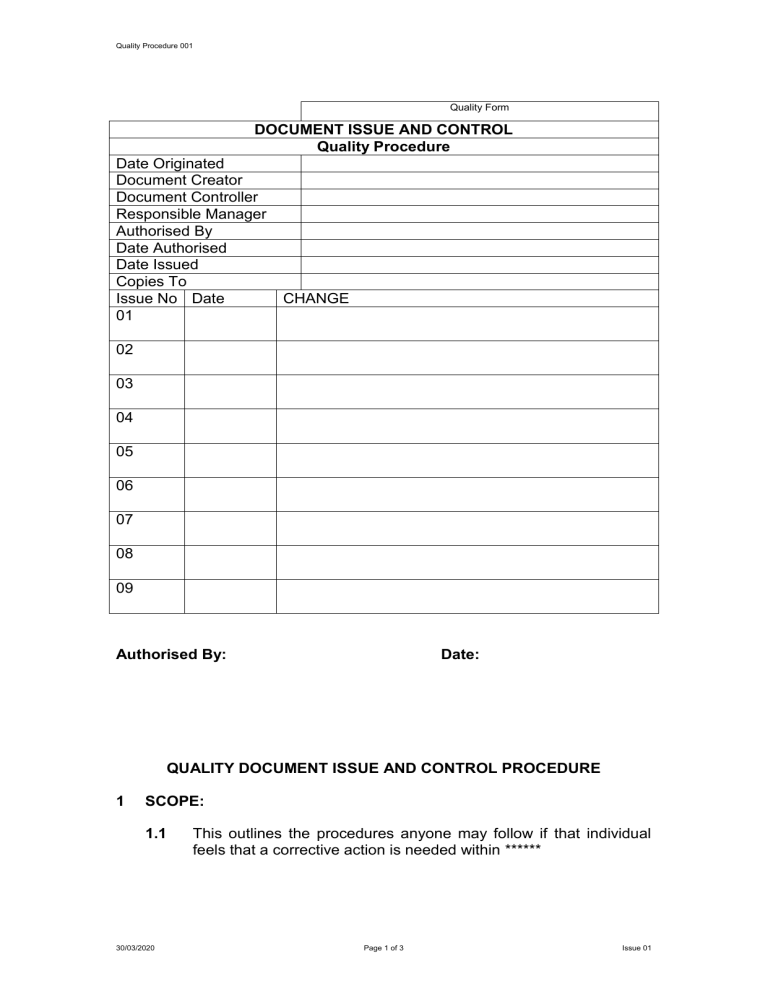

Quality Procedure 001 Quality Form DOCUMENT ISSUE AND CONTROL Quality Procedure Date Originated Document Creator Document Controller Responsible Manager Authorised By Date Authorised Date Issued Copies To Issue No Date 01 CHANGE 02 03 04 05 06 07 08 09 Authorised By: Date: QUALITY DOCUMENT ISSUE AND CONTROL PROCEDURE 1 SCOPE: 1.1 30/03/2020 This outlines the procedures anyone may follow if that individual feels that a corrective action is needed within ****** Page 1 of 3 Issue 01 Quality Procedure 001 2 RESPONSIBILITY: 2.1 . 3 REFERENCES 3.1 4 5 Managers and Directors, Quality Manager None DEFINITIONS 4.1 Requester – Anyone may request corrective action. 4.2 Responsible Person(s) – The individual(s) identified as being responsible and having the authority to eliminate the cause of the issues identified in the corrective action. 4.3 Corrective Action – Any one of a number of actions that may be taken to correct a problem within the system. Types of corrective actions include the following: Process Corrections, Internal Audit Corrections, Preventative Actions and Customer Concerns. 4.4 Feedback Centre Database – An electronic database that contains all customer DETAILS OF PROCEDURE 5.1 Documentation used in the quality system is approved prior to release according to the requirements of the document’s approval authority and this document control procedure. The approval for the issuance of documents at the start of the system implementation may be handled through approving a list in a memo. 5.2 Revisions or deletions of documents are reviewed and approved by the position(s) that originally approved the documents prior to implementing the revision or deletion. 5.3 Documentation is reviewed on an as-needed basis. The review completion is reported in the management review and any issues to be presented to the Quality Committee. 5.4 The most current documentation is made readily available to those performing the tasks defined and/or those having responsibility for the document. Availability is primarily through the Server. Any hard copy documentation is considered to be for reference only. 30/03/2020 Page 2 of 3 Issue 01 Quality Procedure 001 6 5.5 Documentation is legible and readily identifiable to ensure proper use and deployment of the quality system 5.6 Any obsolete documents are removed from the server and hard copy location to prevent unintended use. DOCUMENTATION 6.1 6.2 6.3 30/03/2020 Quality Procedure Master Quality Form Master Request For Change Form Page 3 of 3 Issue 01