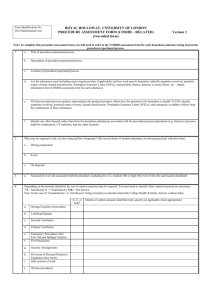

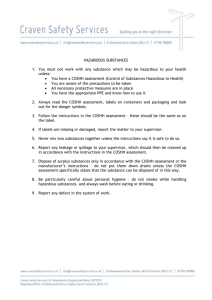

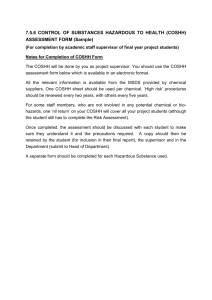

LCA / Safety Material Selection • The choice of material in any application will be affected by – – – – Availability Price considerations Life expectancy Previous performance in similar situations • The important factors in choosing a material for such applications are: – Resistance to corrosion over a wide range of operating conditions eg repeated immersion in sea water – Resistance to corrosion by air / soil – Resistance to marine bio-fouling – The mechanical properties of the material – Ability to cut, machine, bend and perform other fabrication operations Material Selection • One of the other biggest factors will be from where will the materials be sourced • In recent times, our economies have been largely a linear “once through” process The Circular Economy • However as natural resources become increasingly scarce, we are slowly moving (returning) towards a more circular economy of make – use – return wsp Consulting The Circular Economy • A circular economy is a global economic model that aims to decouple economic growth and development from the consumption of finite resources • It is about creating value for the economy, society and business while minimising resource use and environmental and social impacts via system thinking The Circular Economy • It’s not just about recycling alone! • It can be achieved by: – Taking the whole product lifecycle into account when designing products – Designing products that can be easily repaired or upgraded in order to maximise their life time – When the useful life is finished they can either be repurposed, remanufacturing or recycled • The benefits include: – Security of raw materials and reduction of exposure to supply risks and volatile commodity prices – Reduction of virgin material use – Reduction of landfill waste – Amongst others... The Circular Economy • When designing components, they should be designed primarily to last as long as possible • The notion of “throwing it away” becomes obsolete, because: – There is no away! – Everything has a value – That value can be turned into other products • The Circular Economy Strategy for Scotland has four priority areas: – – – – Food and drink (and the wider bio-economy) Remanufacture Construction Energy infrastructure The Circular Economy Sustainability • The term ‘sustainability’ generally means: • The ability to sustain something for an indefinite period of time, without depleting the resources used to sustain it, and such that it does not damage the surroundings (environment) in which it resides. Sustainability • The term “sustainable” is used for many different areas such as: • sustainable design • sustainable development • sustainable living • sustainable energy • etc.... Sustainable Engineering • If we apply the previous definition to engineering, we could say that ‘sustainable engineering’ strives to maintain sustainable principles in engineering activities such as: – Using methods that minimize environmental damage to provide sufficient food, water, shelter, and mobility for a growing world population. – Designing products and processes so that wastes from one are used as inputs to another. Sustainable Engineering • Incorporating environmental and social constraints as well as economic considerations into engineering decisions. • Sustainable engineering is the process of using energy and resources at a rate that does not compromise the natural environment, or the ability of future generations to meet their own needs. Sustainable Engineering Design • Building on the definition of “sustainable engineering”, we can define “sustainable engineering design” activities such as: – Product Design • The resources used to make a product should not be depleted • The usage and eventual disposal of the product should not damage the environment in which it operates. – Process Design • Any input resources processed by it should not be depleted • The output materials should not damage the environment into which they go. Sustainable Engineering Design • How can we incorporate “sustainable” principles and concepts, into an engineering design? • Using the “structured design process”, we can easily incorporate “sustainability”, by implementing those principles and concepts into our design process. • This is simply done by adding/including the desired “Sustainable Concepts” at the following stages of our design process: – Goal Statements – Objectives/Constraints – Selection Method for Concepts Sustainable Engineering Design (SED) • Consideration of sustainable concepts at an early stage in the design process is key. • By placing SED ideals your “goal statement”, its importance will trickle down throughout various aspects of your design. • By listing key SED Objectives, the design will be “altered/skewed” towards those objectives. • Also, by using SED ideals during concept selection activities. • NOTE: SED will significantly alter your otherwise “ideal design”. However, ideal designs may be environmentally damaging, energy intensive, or otherwise unsustainable. Hence you must find a balance between the ideal design and a sustainable design. Typical SED Objectives • Some typical SED Objectives to consider for designs include: – – – – – – Materials resources etc. Energy building construction Energy required for use Service life Environmental impact to build / use ……………. Sustainable Engineering Design (SED) • In order to incorporate sustainable concepts into Engineering Design activities, we will explore the following concepts: – – – – – Product Life Cycle Life Cycle Design Life Cycle Assessment Energy Budget Resource Budget Design for Recyclability PRODUCT LIFE CYCLE Product Life Cycle • The life-cycle of a “product” from its conception and design, to manufacture, to service and finally to disposal. • At each stage there are labour, energy and material inputs, and waste • Outputs create environmental and social impacts. Sustainable Product Life Cycle • In a more ideal product life cycle: resources and waste are managed in a closed-loop cycle, with products being reused, recycled and remanufacture Product Life Cycle How Long Should a Product Last? • All products have a “Life Cycle”, that is, a start, use, and disposal but how long should that be? 5 Minute Discussion • How long should a Razor last? – – – – What materials are they made from? How are they made? Can they be recycled? What are the issues? Product Life Cycle • A classic diagram showing the sales volume (or production) vs. time for a given product during it’s lifecycle: • Generally, most products that are developed follow this curve, where each stage has specific characteristics. Product Life Cycle Stage Characteristics • • Market introduction stage • • • Sales generally are low and slow to take off. Production costs tend to be high on a per unit basis Profits tend to be negative or very low because of low sales and high unit costs Competitors tend to be few in number Marketing cost needed to create customer awareness, interest and for introducing the product into the distribution channels are high Product Life Cycle Stage Characteristics • • Growth stage • • • • costs reduced due to economies of scale sales volume increases significantly profitability begins to rise public awareness increases competition begins to increase with a few new players in establishing market increased competition leads to price decreases Product Life Cycle Stage Characteristics • • Mature stage • • • • costs lowered as a result of production volumes increasing and experience sales volume peaks and market saturation is reached increase in competitors entering the market prices tend to drop due to the proliferation of competing products brand differentiation and feature diversification is emphasized to maintain or increase market share Industrial profits go down Product Life Cycle Stage Characteristics • Saturation and decline stage • • • costs become counter-optimal sales volume decline or stabilize prices, profitability diminish profit becomes more a challenge of production/distribution efficiency than increased sales LIFE CYCLE ANALYSIS Life Cycle Analysis • One tool which can be used to assist in designing products for the circular economy is a Life Cycle Analysis/Assessment (LCA) • LCA is a standardised methodology and is detailed in two international standards – ISO 14040 & ISO 14044 • The assessment is the “factual analysis of a product’s entire life cycle in terms of sustainability” • To examine how much a product impacts on the environment, it can often be a complex mix of: – Inputs – Outputs – Interactions • From the cradle-to-grave or cradle-to-cradle of a product Life Cycle Assessment (LCA) • A “Life Cycle Assessment” (LCA), also known as “life cycle analysis”, or “eco-balance”, or “cradle to grave analysis”, etc... is the investigation and evaluation of the environmental impacts of a given product or service caused or necessitated by its existence. • The purpose of LCA is to assess the full range of environmental and social impacts assignable to products or services, to be able to choose the one with the most beneficial outcome, or least impact. • LCA can be a great tool for making decisions based on quantifiable information • However, LCA can be controversial depending on its use. Since the scores assigned and the ‘scope’ of assignment can vary, some factors may be difficult to quantify and subject to interpretation. Life Cycle Assessment (LCA) • An LCA can be used for: – Assistance to regulators/government to formulate legislation – Assist manufacturers to analyze and improve their process or products – Enable consumers to make informed choices Life Cycle Assessment (LCA) Issues with LCA: • There are no “accepted standards” to perform an LCA, hence the question arises: “Who has conducted the LCA, what is their bias, and for what purpose was it conducted?” • Due to “lack of accepted standards”, government or consumers – are unsure of accuracy of LCA – cannot compare LCAs done by two different parties – hence, difficult to make choices based on LCA Life Cycle Analysis • There are typically 4 main stages involved: – – – – Goal and scope Inventory analysis Impact assessment Interpretation Paradigm Sustainability Solutions Life Cycle Analysis Goal and scope: • The most important (often subjective) choices are described, such as: – The reason for undertaking the LCA – A precise definition of the product and its life cycle – A description of the system boundaries • Used to: – Define the goal(s) of the project – Determine what type of information is needed to inform the decisionmakers – Determine the required specificity – Determine how the data should be organized and the results displayed – Define the scope of the study – Determine the ground rules for performing the work Life Cycle Analysis Inventory analysis: • Life Cycle Inventory – Data Collection – Modeling of System • All of the environmental inputs and outputs associated with the product are studied, such as: – The use of raw materials and energy – The emission of pollutants – The waste streams Life Cycle Impact/Life Cycle Inventory Impact assessment: • Life Cycle Impact Assessment – Characterization – Normalization – Weighting • Conclusions are drawn to allow better business decisions to be made such as: – The environmental impacts are classified – They are translated into themes such as carbon reductions or human health effects Life Cycle Analysis Interpretation: • This is forms a check that the study conclusions are well substantiated: – ISO 14044 describes a number of validation tests to ensure any conclusions are adequately supported by the data and by the procedures used • Sensitivity analysis (SA) is a significant tool for studying the robustness of results and their sensitivity to uncertainty factors in life cycle assessment (LCA). – It highlights the most important set of model parameters to determine whether data quality needs to be improved, and to enhance interpretation of results. Energy /Resources…… • An Energy/Resource Budget can also be done on its own. To create one, you can consider: – – – – – – – Material usage Material source Transportation Renewable? Manufacturing of Product Use of Product Disposal of Product. Life Cycle Design • Life Cycle Design, is an activity whereby the designer recognizes and takes into account the various phases of a product’s life cycle, during the design of that product. • If all phases of a product’s life are recognized and considered during the design phase, the final product is likely to ‘integrate better’ into our environment, and be produced, used and disposed of in a more sustainable manner. • In other words, we should strive to consider life-cyclebased criteria during our concept generation and design selection activities. For example, for design selection, we can assign appropriate weighting to life-cycle based criteria for decision making purposes. Life Cycle Design • Some Life Cycle “Design Objectives” that could be used during the design process include: – – – – – Transportation Usage Energy consumption Safety Recyclability Design for Recyclability • How do we incorporate “Recyclability” principles, into an engineering design? • Using the “structured design process”, we can easily incorporate “Recyclability”, by implementing those principles and concepts into our design process, at the following stages: – Goal Statements – Objectives/Constraints Selection – Method for Concepts Design for Recyclability • Typical Objectives for Design for Recyclability – – – – – – Materials resources etc. Energy to recycle By products of the process Disassembly , separation etc. Reuse? ……………. It could take up to 20 and 100 uses for a reusable cup to make up for the greenhouse gas emissions of a single-use cup. https://www.artsthread.com/portfolios/designinginfographics/ https://www.artsthread.com/portfolios/designinginfographics/ 5 Minute Discussion Should we wrap a cucumber in plastic? HEALTH & SAFETY Health & Safety • You should have received a copy of the student safety guide – And hopefully you have looked at it! • Page 14 – Control of Substances Hazardous to Health (COSHH) – Risk assessments – HAZOP assessments Health & Safety • The “Control of Substances Hazardous to Health (COSHH) Regulations 2002 (as amended)” is the law that requires a risk assessment is carried out on any work activity that involves the use of hazardous substances • For all project work that involves the use of either: – A Hazardous material – An activity involving potentially hazardous processes • A COSHH and/or risk assessment must be carried out and recorded • The details of the assessment(s) are recorded on the COSHH/risk assessment forms which are available from your project supervisor Health & Safety • COSHH is primarily concerned with hazardous materials, i.e.: – – – – Chemicals Reactions Interactions (including materials compatibilities) Products • Risk Assessments are focused more on the process, i.e.: – The experimental method – The techniques that are going to be used – This therefore includes non-chemical hazards • So, before starting any experimental work, you must undertake an assessment of what you are proposing to do and how you propose to do it COSHH COSHH What is a hazardous material? • Generally speaking any product that is marked by the supplier with a hazard statement or symbol should be regarded as hazardous • Hazards for each chemical will be detailed in a safety sheet (MSDS) • Hazard statements will be listed on the MSDS along with the appropriate symbols COSHH Flame: • Flammable materials or substances liable to self ignite when exposed to water or air (pyrophoric), or which emit flammable gas. COSHH Corrosion: • Materials causing skin corrosion/burns or eye damage on contact, or that are corrosive to metals. COSHH Exploding Bomb: • Explosives, including organic peroxides and highly unstable material at risk of exploding even without exposure to air (selfreactives). COSHH Flame Over Circle: • Identifies oxidizers. • Oxidizers are chemicals that facilitate burning or make fires burn hotter and longer. COSHH Skull and Crossbones: • Substances, such as poisons and highly concentrated acids, which have an immediate and severe toxic effect (acute toxicity). COSHH Environmental Hazard: • Chemicals toxic to aquatic wildlife COSHH Health Hazard: • A cancer-causing agent (carcinogen) or substance with respiratory, reproductive or organ toxicity that causes damage over time (a chronic, or long-term, health hazard). COSHH Exclamation Mark: • An immediate skin, eye or respiratory tract irritant, or narcotic. COSHH Gas Cylinder: • Gases stored under pressure, such as ammonia or liquid nitrogen COSHH COSHH • Hazard statements have a code beginning with H • Precaution statements have a code beginning with P Code H200 H201 H202 H203 H204 H205 H220 H221 H222 H223 H224 H225 H226 H227 H228 H240 H241 H242 H250 Physical hazard statement Unstable explosive Explosive; mass explosive hazard Explosive; severe projection hazard Explosive; fire, blast or projection hazard Fire or projection hazard May mass explode in fire Extremely flammable gas Flammable gas Extremely flammable aerosol Flammable aerosol Extremely flammable liquid and vapour Highly flammable liquid and vapour Flammable liquid and vapour Combustible liquid Flammable solid Heating may cause an explosion Heating may cause a fire or explosion Heating may cause a fire Catches fire spontaneously if exposed to air Code P201 P202 P210 P211 P220 P221 P222 P230 P231 P232 P233 P234 P235 P240 P241 P242 P243 P250 P251 General Precautionary Statement Obtain special instructions before use. Do not handle until all safety precautions have been read and understood. Keep away from heat/sparks/open flames/hot surfaces. - No smoking. Do not spray on an open flame or other ignition source. Keep/Store away from clothing/.../combustible materials. Take any precaution to avoid mixing with combustibles/.. Do not allow contact with air. Keep wetted with ... Handle under inert gas. Protect from moisture. Keep container tightly closed. Keep only in original container. Keep cool. Ground/bond container and receiving equipment. Use explosion-proof electrical/ventilating/lighting/.../equipment. Use only non-sparking tools. Take precautionary measures against static discharge. Do not subject to grinding/shock/.../friction. Pressurized container: Do not pierce or burn, even after use. COSHH What is the difference between a hazard and a risk? • Hazard: – Something which is potentially dangerous • Risk: – The chance of a dangerous event occurring if the hazard is not properly controlled Risk Assessments • The other form that may be required is the Risk Assessment Risk Assessments Risk Assessments • 5x5 Risk Assessment Matrix (others are available e.g. 3x3) can be used as a guide • • • • Multiply likelihood of hazard causing an incident with consequence Should an incident occur to produce risk level Likelihood: 1 = Very unlikely 5 = Very likely Consequence: 1 = Little consequence 5 = Severe consequence (death or permanent/severe disability) Risk Assessments Risk Assessments Risk Control Hierarchy Risk Control Hierarchy • Elimination – Redesign the job or substitute a substance so that the hazard is removed or eliminated. – Staff not allowed to work at height • Substitution – Replace the material or process with a less hazardous one. – use a small MEWP to access work at height instead of step ladders – Care should be taken to ensure the alternative is safer than the original • Engineering controls – Use work equipment or other measures to separate the hazard from operators – Install equipment to prevent falls where you cannot avoid working at height. – Install or use additional machinery such as local exhaust ventilation to control risks from dust or fume. – Enclosing or guarding dangerous items of machinery/equipment – Give priority to measures which protect collectively over individual measures. Risk Control Hierarchy • Administrative controls – Identify and implement the new procedures to be able to work safely – i.e. reduce the time workers are exposed to hazards • Personal protective clothes and equipment – After all the previous measures have been tried and found ineffective in controlling risks to a reasonably practicable level – The use of personal protective equipment (PPE) must be implemented – i.e. where the risk of a fall cannot eliminate, use work equipment or other measures to minimise the distance and consequences of a fall – Workers must be trained in the function and limitation of each item of PPE. HAZOP Hazard and Operability Studies (HAZOP) • For more complex experimental work you might need to carry out a HAZOP study in addition to the usual risk and COSHH assessments • HAZOP studies should always used when designing new plant and industrial processes • Depending on the complexity of the process, this could involve a large multidisciplinary team of people and several days, weeks or months of work • The purpose of the study is to investigate how the plant or process might deviate from the intended design and any results HAZOP The overall process of a HAZOP is: • The plant or process is broken down into various “nodes” – This could be discrete areas or process flow lines shown on the P&ID (Piping & Instrumentation Diagram) • At each of these study nodes, deviations in the process parameters are examined using various guide words – The guide words are used to ensure that the design is explored in every conceivable way – This allows the potential causes and consequences of deviations to be identified HAZOP • Guide words generally tend to follow: – – – – High Flow, Low Flow, No flow, Reverse Flow High pressure, Low pressure, No pressure High temperature, Low temperature Change in composition / Change in concentration / Two phase flow / Reactions – Etc, etc... • Quite often many guide words will not apply and can be excluded. • Occasionally some additional specialist conditions need to be considered HAZOP • The outcome of the study is a report detailing amongst other things a list of actions • The actions should highlight potential situations that could be hazardous to plant personnel, public or the environment or have the potential to jeopardise the operability of the plant • There should also be a clear statement on modifications that will be made to the design or operational procedures together with a timetable for implementation • Justification as to why no action was chosen for any actions identified should also be made • Nominated people should be given ownership of required actions and this would be detailed Summary • • • • • • • • • • Circular Economy Sustainability Sustainable Engineering Design Product Life Cycle Life Cycle Analysis Design for Recyclability Health and Safety COSHH Risk Assessments HAZOP