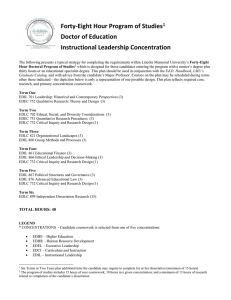

IEEJ TRANSACTIONS ON ELECTRICAL AND ELECTRONIC ENGINEERING IEEJ Trans 2009; 4: 771–778 Published online in Wiley InterScience (www.interscience.wiley.com). DOI:10.1002/tee.20479 Paper Energy Saving Speed and Charge/discharge Control of a Railway Vehicle with On-board Energy Storage by Means of an Optimization Model Masafumi Miyatake*a , Member Kunihiko Matsuda*, Non-member The optimal operation of rail vehicle minimizing total energy consumption is discussed in this paper. In recent years, the energy storage devices have enough energy and power density to use in trains as on-board energy storage. The on-board storage can assist the acceleration/deceleration of the train and may decrease energy consumption. Many works on the application of the energy storage devices to trains were reported, however, they did not deal enough with the optimality of the control of the devices. The authors pointed out that the charging/discharging command and vehicle speed profile should be optimized together based on the optimality analysis. The authors have developed the mathematical model based on a general optimization technique, sequential quadratic programming. The proposed method can determine the optimal acceleration/deceleration and current commands at every sampling point under fixed conditions of transfer time and distance. Using the proposed method, simulations were implemented in some cases. The electric double layer capacitor (EDLC) is assumed as an energy storage device in our study, because of its high power density etc. The trend of optimal solutions such as values of control inputs and energy consumption is finally discussed. 2009 Institute of Electrical Engineers of Japan. Published by John Wiley & Sons, Inc. Keywords: electric railway, rail vehicle, energy storage, electric double layer capacitor (EDLC), energy-saving operation, sequential quadratic programming (SQP) Received April 21 2008; Revised October 13 2008 1. Introduction Electrical regenerative braking has reduced total energy consumption in electric railway systems [1]. However, there are several difficulties in efficient utilization of regenerative energy, especially under DC power feeding system. One of these difficulties is that the regenerative ability closely depends on catenary voltage at the braking train. The maximum electrical braking torque is limited if catenary voltage is low. The other difficulty in utilizing regenerative energy is the need of another accelerating train or energy storage for absorbing regenerative energy. If the energy is not absorbed, catenary voltage rises, regenerative failure is occurred, and kinetic energy is disposed with mechanical friction brake. One of the ways for absorbing regenerative energy is to use energy storage. Regenerative energy is stored in the energy storage and reused in the next acceleration. The energy storage decreases the loss of circuit resistance by compensating voltage drop. It also prevents regenerative failure even if the power source cannot absorb enough energy. Energy-saving effect as well as preventing regenerative failure is expected. Energy storage devices have achieved enough energy and power density to use as on-board power sources of vehicles. There are many types of energy storage devices such as lead–acid, NiMH and Li–ion batteries, flywheel energy storage and an electric double layer capacitor (EDLC). Many research projects on the application of the energy storage devices to transportation systems have been reported. In railway applications, a few research papers can be seen in Refs [2–7]. Most a Correspondence to: Masafumi Miyatake. E-mail: miyatake@sophia.ac.jp ∗ Department of Engineering and Applied Sciences, Sophia University Kioicho 7-1, Chiyoda-ku, Tokyo 102-8554, Japan of them discussed reasonable circuit configuration and sizing of energy storage system, however, very few papers that deal with optimal charging/discharging control of the energy storage can be found. The charging/discharging command of energy storage affects the energy consumption and may influences the optimal speed profile, the trajectory of a train in the velocity-position state space. The vehicle speed should be also controlled observing the state of charge (SOC) of energy storage in order to run the vehicle with small amount of energy. The authors pointed out that the charge/discharge command and vehicle speed profile should be optimized together based on the optimality analysis. It is difficult to discuss the optimal operation because it has many nonlinear constraints. However, there are a few papers that deal with the energy-saving vehicle operation with a kind of optimization. For example, The problem of solving optimal speed profile was developed in Ref. [8], however, the characteristics of power source cannot be considered. The papers seen in Refs [9,10] deals with some of practical conditions by using the dynamic programming (DP), however, it is difficult to apply to the system with multiple power source, because DP has a serious disadvantage that the increase of control input dimension causes explosion of computation time. The optimization of multiple-train scheduling was realized with DP in Ref. [11], however the conventional—not optimized—speed profile composed of maximum acceleration, coasting and maximum deceleration was used. Similar technique with DP was used in Ref. [12] for optimization of hybrid rail vehicles, however, the conventional speed profile was also used. To overcome the problem, the new solvable formulation with gradient method was proposed in Refs [13–15]. It was so flexible that can be applied to the optimization of not only multiple-train operation but also the train with energy storage device. However, the shortcoming of this method is the need of deep mathematical background. It has not been really applied to the train with energy 2009 Institute of Electrical Engineers of Japan. Published by John Wiley & Sons, Inc. M. MIYATAKE AND K. MATSUDA storage system, because it is not easy to develop the optimization program. The authors have developed the mathematical model characterized by the following items. Ic VT INV. Chopper DC link • The model is based on a commonly used optimization technique for easy software development. • It can be applied to the system composed of the main DC power feeder and auxiliary energy storage. • It can optimize the notch and charge/discharge commands simultaneously for minimum energy consumption. IM EDLC VC Fig. 2. Circuit model of an on-board EDLC train and Rc are the capacitance and internal resistance in the EDLC respectively. It is necessary to convert voltage by using a bidirectional chopper because the voltage difference between the DC link and EDLC is high. The motor-inverters of the train in Fig. 2 were modeled as a current load that helps solving circuit equations simply. In this study, the proposed method was assumed to apply to DC electric railway systems, however, it can be also applied to road vehicles such as hybrid electric vehicles and fuel cell electric vehicles with partial modification. In this paper, the authors intend to formulate the optimal control problem of the train operation to find notch and charge/discharge commands which minimize the amount of consumed energy, propose how to solve it, discuss the optimized results and find knowledge of the optimal operation. The knowledge extracted from the trend of optimization results will be applied to the design and parameter tuning of future charge/discharge controllers for energy storage. 3. Formulation of Optimal Control Problem Advantages: maintenance-free, long lifetime, quick charge/ discharge 3.1. Definition of variables The optimal control problem is formulated from the circuit model. Variables are defined as follows: Control inputs n and u determine the acceleration/deceleration force and charging/discharging current, respectively. Table I shows the definition of control inputs. For example, the definition of control input ‘n’ is illustrated in Fig. 3. State variables x, v and Vc indicate the train position, speed and EDLC voltage, respectively. The variable VT is the catenary voltage at the train. It is treated as an auxiliary state variable to avoid complexity in solving circuit equations analytically, although it is derived by solving circuit equations. It is derived by adding circuit equations in the optimization problem as the constraints. Disadvantages: lower energy density than that of batteries at present, wide range of terminal voltage regulation. Table I. Definition of control inputs n and u 2. Modeling of Energy Storage and DC Feeding Circuit The EDLC is assumed in the modeling of energy storage in this study. It has the following characteristics, The fact shows the difficulty in using EDLC as a main power source of high-speed vehicles. However, if it is used with other main energy sources, the EDLC is expected as one of the most promising auxiliary devices for transportation systems. The EDLC supplies large power but small energy, whereas large energy is supplied by the main power source. A DC feeding circuit is modeled with one train between substations. The model circuit appears in Fig. 1. In this figure, Vs and R0 are the supply voltage and the internal resistance at a substation respectively. The values of R1 and R2 are equivalent resistances of feeder and return circuits. These resistance values are proportional to the distance between the train and substation. The constants C R1 R0 Chopper C DS Maximum deceleration Deceleration Coasting Acceleration Maximum acceleration Maximum charging Charging Standby Discharging Maximum discharging L AS Lb fmax Vc VS −1 (a) Circuit model La −1 Negative 0 Positive 1 Maximum acceleration Train SS1 Charging/discharging command u Acceleration force f R0 RC VS Substation1 Notch command n R2 VT IS Value 0 +1 Substation2 u Control input DP:departure station SS2 AS:arrival station SS:Substation fmin Maximum deceleration (b) Location of stations and substations Fig. 1. Modeling of a feeding circuit with one train between substations Fig. 3. Definition of control input u 772 IEEJ Trans 4: 771–778 (2009) ENERGY SAVING RAILWAY VEHICLE WITH ON-BOARD ENERGY STORAGE Q 3.2. Optimal control problem The optimal control problem is described as the following mathematical formulation. Minimizing the objective function T J = Vs Is (x, VT )dt Initial state of charge Final state of charge With final state constraint (1) 0 Subject to the following equality and inequality constraints ẋ = v (2) v̇ = f (n, v, VT ) − r(v) (3) V˙c = −Ic (u)/C (4) PT (n, v, VT ) = PS (x, VT ) + PC (u, Vc ) (5) x(0) = 0, v(0) = 0, Vc (0) = Vc init (6) x(T ) = L, v(T ) = 0, Vc (T ) = Vc final (7) −1≤n≤1 (8) −1≤u≤1 (9) VT min ≤ VT ≤ VT Vc min ≤ Vc ≤ Vc (12) (13) r PT max min , Vc max Vc init , Vc final L, T vmax (x) Fig. 4. Boundary conditions of EDLC SOC R1 (x) = (La + x)r0 R2 (x) = (L − x + Lb )r0 Vc Ic (u)ηch (u ≥ 0) Pc (u, Vc ) = Vc Ic (u)/ηch (u ≤ 0) Ic (u) = uIc (16) (17) (18) max Here, ηm and ηg (v) are motor-inverter efficiency in accelerating and braking respectively. The constant M is the total weight of the train that includes on-board energy storage. The regenerative efficiency ηg must be treated as the function of speed v for considering electro-pneumatic blended braking. Equivalent resistances of feeding system R1 and R2 are given in (16) if the position of the departing station is defined as (6). The constants La and Lb indicate the distance from the departure and arrival stations to the substations 1 and 2 shown in Fig. 2 respectively. The constant r0 is the equivalent resistances of feeding system per meter. The constant ηch is the chopper efficiency. The constant Ic max is the rated value of the EDLC current. Chopper efficiency is too complicated to be examined in detail here. Therefore, the chopper efficiency ηch is assumed as the constant value. (11) 0≤x≤L Ic f Vc max Time (10) 0 ≤ v ≤ vmax (x) where Is Ps , Pc VT min , VT max Without final state constraint sum of load currents supplied from substations; EDLC current; acceleration/deceleration force influenced by the voltage VT ; running resistance per unit weight of the train; electric power supplied to motor-inverters of the train; power from substations and EDLC; lower and upper limitation of the catenary voltage at the train position; lower and upper limitation of the EDLC voltage; first and final values of the EDLC voltage; distance and running time between the departure and arrival stations; speed limitation. 3.3. Discretization of the problem The continuous time formulation must be transformed to a discrete time one in order to apply a mathematical programming to the optimal control problem. Therefore, t is defined as the constant sampling interval. Control inputs n, u are discretized as (19). Other variables such as VT , x, v, VC etc. are also discretized as (T /t + 1) dimensional vectors. n = [n(0), n(t), n(2t), . . . , n(T )] u = [u(0), u(t), u(2t), . . . , u(T )] (19) The discretized objective function is written as (20). The objective function is sum of supplied energy from two substations given as (1). Equality constraints are given as (2)–(7). Equations (2) and (3) are motion equations of the train. Gradient can be considered as including the influence to the running resistance r. If it is considered, r is also the function of x. The EDLC voltage is given as the (4). Equations (6) and (7) describe the initial and final conditions of state variables. The constraint (11) gives the terminal EDLC voltage as well as the initial one as illustrated in Fig. 4. If the constraint is not given, it is difficult to compare the solutions under various conditions with energy consumption. Inequality constraints of control inputs, state and auxiliary variables are shown in (8)–(13). The functions related with circuit equations as the following equations. Mvf (n, v, VT )ηm (n ≥ 0) (14) PT (n, v, VT ) = Mvf (n, v, VT )/ηg (v) (n ≤ 0) Vs − VT Vs − VT (15) Ps (x, VT ) = + R0 + R1 (x) R0 + R2 (x) T /t J = Vs I s = Vs (i)Is (i) (20) i=0 4. Optimization Method The optimal control problem is solved by the sequential quadratic programming (SQP) method in this study. SQP is an optimization method to solve general nonlinear programming problems. A general optimal control problem with equality and inequality constraints can be derived from the discretized formulation from (1) to (18) as Minimize : J (ω) Subject to : gi (ω) = 0 (i = 1, . . . , ng ) (21) hj (ω) ≤ 0 (j = 1, . . . , nh ) where ω = (n, u, VT , x, v, Vc ) is the vector of variables, J is the 773 IEEJ Trans 4: 771–778 (2009) M. MIYATAKE AND K. MATSUDA Table II. Specific parameters of feeding circuit and train operation Search direction ω (k+1) (k) α dopt (k) dopt ω (k) Jqp(ω) Step (2) ω (k) ψ(ω) Fig. 5. Procedures of SQP method C Vc max Vc min Vc init Vc final Ic max objective function, g and h are equality and inequality constraints, ng and nh are the numbers of equality and inequality constraints. The objective function is rewritten using the second order approximation around the feasible point ω (k) where k is the number of search iteration. Similarly, equality and inequality constraints are also rewritten as the first-order approximation around the feasible point ω (k) in problem (21). The problem is transformed into a kind of quadratic programming as Minimize : Jqp Subject to : 32.3 F 560 V 300 V 560 V 560 V 500 A weight power density energy density Rc 500 kg ≤ 560 W/kg 2.8 Wh/kg 0.3 (real) 0.03 (ideal) Table IV. Conditions of simulation in each case (22) (i = 1, . . . , ng ) hj (ω (k) ) + ∇hj (ω (k) )d(k) ≤ 0 (j = 1, . . . , nh ) where d(k) = ω − ω (k) , ∇ = ∂∂ω and Bk is positive definite matrix. In general, the solution d(k) opt of the approximated problem (22) can be easily derived by using the interior point method [16,17]. Here, the merit function is defined as: ng nh |gi (ω)| + max(hj (ω), 0) (23) ψ(ω) = J (ω) + µ i=1 250 × 103 kg 90% ≤90% 95% ∞ M ηm ηg ηch Vmax (x) Table III. Specific parameters of the EDLC bank Step (4) 1 = d(k) Bk d(k) + ∇J (ω (k) )dk 2 gi (ω (k) ) + ∇gi (ω (k) )d(k) = 0 130 s, 1 s 2000 m 0.03 1500 V 0.04 m/m 5000 m T , t L R0 Vs r0 La , Lb T [s] EDLC Case 1 Case 2 Case 3 130 130 130 Case Case Case Case 130 130 120 120 without with with Rc = 0.03 without with without with 4 5 6 7 VT max [V] ∞ ∞ ∞ 1650 1650 ∞ ∞ evaluated as 560 and 2.8 Wh/kg respectively, whose values are between the values used in the papers [18] and [4]. Paper [18] uses relatively smaller values, 260 and 0.60 Wh/kg. On the other hand, paper [4] uses larger values, 6 and 6 Wh/kg. Maximum acceleration/deceleration characteristics and running resistance are given in Fig. 6. In the characteristics, electropneumatic blended braking system with the air supplement control is assumed. Only if the regenerative braking force is not enough for the specific braking force, air brake works. In the model used in the examples, the characteristic of the squeezing control is not included in the analyses for simple implementation that can reduce the number of complicated nonlinear constraints. It is assumed to use receptive substations with pulse width modulation (PWM) converters [19] that are now in the initial state of practical application. Seven cases are prepared as tabulated in Table IV for evaluation under various conditions. The optimization program was developed with Optimization Toolbox on MATLAB software. By using such convenient toolbox, the program could be implemented with shorter development period. i=1 where µ is a large positive constant. Finally, the α in (23) is searched to minimize ψ(ω (k+1) ) where ω (k+1) = ω (k) + αd(k) opt . The optimal point d(k) opt of the problem (22) is used as the search direction. The vector ω (k+1) is the new feasible point of the next iteration. Consequently, the optimization problem (21) can be solved by iterating the following procedure. (1) Give the initial feasible point ω (0) , and set k = 0. (2) Solve problem (22), and obtain the search direction d(k) opt as in Fig. 5. −6 (3) Stop iteration if the norm ||d(k) opt || is less than 10 . (4) Find α minimizing the merit function, and obtain the next feasible point ω (k+1) as in Fig. 5. (5) Increase k by 1, and return to the step 2. 5.2. Optimization results Case 1 is the optimization 5.2.1. Base case analyses result of the train without the EDLC. Cases 2 and 3 show results of the sensitive analysis in case of the constant Rc is 0.3 or 0.03 respectively. Optimization results are shown in Table V and Fig. 7. In Fig. 7, the graphs of control inputs n and u, catenary voltage at train pantograph, EDLC voltage, train speed and train power at inverter input are drawn. Case 1: The optimal control input n without EDLC consists of the maximum acceleration, reduced acceleration by degrees, coasting and maximum deceleration. The results that are consistent with the results of previous papers [9,10] indicate the reliability of the 5. Simulations of Optimization and Their Results Specific parameters are 5.1. Conditions of simulation tabulated in Tables II and III. In the simulations, a train runs on a straight line without speed limitations and gradients for simple analyses. The final EDLC voltage is given to equal the initial one. The small size of EDLC bank is chosen taking the impact of weight on energy consumption and high cost of EDLC into account. The maximum output of the EDLC bank at the highest voltage is 560 V × 500 A = 280 kW, while the total power of the train, that depends on the catenary voltage, is roughly 2 MW. The maximum power and energy densities of the EDLC bank are 774 IEEJ Trans 4: 771–778 (2009) ENERGY SAVING RAILWAY VEHICLE WITH ON-BOARD ENERGY STORAGE Table VI. Evaluation of energy consumption 1.2 1300 [V] 1500 [V] 1700 [V] Acceleration force [N/kg] 1 Total energy consumption [MJ] Energy saving in % 28.02 27.54 — 1.71 0.8 Case 4 Case 5 0.6 Table VII. Evaluation of energy consumption 0.4 0.2 Running resistance 0 0 5 10 15 Velocity [m/s] 20 25 30 Case 6 Case 7 Total energy consumption [MJ] Energy saving in % 37.56 35.43 — 5.67 1.2 Maximum braking force the EDLC when the train coasts. Deceleration force [N/kg] 1 It is found from the result that the EDLC is utilized effectively. The total energy consumption is 26.40 MJ. Compared with case 1, the total energy consumption is reduced about 4.17%. The result indicates that energy-saving effect is higher if the internal resistance of the EDLC is reduced by future technical development. The percentage of saved energy compared with case 1 is evaluated as 0.35 and 4.17% in cases 2 and 3 respectively. In the voltage graphs in Fig. 7, the voltage recovery by larger discharge from EDLC in acceleration phase of case 3 is very slight. That is because the maximum output power of the EDLC is much smaller than the train power itself. If larger EDLC bank is installed, more voltage recovery can be realized, however, heavier train weight may cause larger energy consumption. 0.8 0.6 0.4 Electrical braking force 0.2 0 1300 [V] 1500 [V] 1700 [V] 0 5 10 15 20 Velocity [m/s] 25 30 Fig. 6. (a)Acceleration (b) deceleration characteristics and running resistance 5.2.2. Simulation of weak regenerative condition In the simulation, receptive substations are assumed and squeezing control is omitted. In such conditions, regenerative failure cannot be simulated properly. However, weaker regenerative condition can be imitated with limiting the upper catenary voltage VT max . In cases 4 and 5, VT max is set to 1650 V. The regenerative current is reduced so as to keep the catenary voltage within the upper limit. The results are shown in Table VI and Fig. 8. The trend of control input n in cases 4 and 5 is different from that in base cases in braking. The braking force is reduced in running higher speed by the limitation VT max because such operation finally increases total regenerative energy. The EDLC voltage Vc in case 5 is slightly lower than that in case 2 for collecting more regenerative energy under the limited voltage. Table V. Evaluation of energy consumption Case 1 Case 2 Case 3 Total energy consumption [MJ] Energy saving in % 27.55 27.45 26.40 — 0.36 4.17 proposed method. Case 2: Very little difference of the optimal control input n can be seen in cases 1 and 2. Regarding the control input u, the higher the absolute value of power to the train is, the larger the absolute value of current is. Qualitatively, this trend is proper, because the energy loss by current through the feeder reduced. Despite the lower limit value of the EDLC voltage Vc min is set to 300 V, the EDLC stops discharging when the EDLC voltage drops to about 480 V. This result is attributed to the higher internal resistance of the EDLC. The efficiency of the EDLC itself is reduced according to the voltage drop of the EDLC. Consequently, the availability of EDLC for energy-saving operation is low. However, it should be noted that the availability is not always increased even if a smaller EDLC bank with fewer cells is used, because the internal resistance is increased by reducing the number of parallel connection of cells. Case 3: In this case, there is also little variation in control input n. However, optimal charging/discharging command includes the following two significant difference compared with the case 2. 5.2.3. Simulation of shorter running time The cases 6 and 7 are simulated with reduced margin time by 10 s. Other condition is the same as cases 1 and 2 respectively. Optimization results are shown in Table VII and Fig. 9. The trend of control input n is the same as the results of base cases. On the other hand, the EDLC voltage Vc , in case 7, drops much lower than that in case 2. The stored energy in EDLC is more effectively used in case 7. The trend of Vc in case 7 is similar to that in case 3. In train coasting, the train collects small current for charging the EDLC. Regarding energy consumption in Table VII, the energy-saving effect by introducing EDLC is 5.67% that is evaluated much higher than that in cases 1 and 2. The EDLC enables obvious energysaving operation when the train runs with less margin time. 6. Conclusion (1) The EDLC voltage drops to the lower limitation Vc min when control input n changes from acceleration to coast at time 50 s. (2) Substations supply the power with a small current for charging This paper presents the optimal train operation with EDLC minimizing energy consumption. SQP can be applied to the formulated optimal control problem with discretization with easier 775 IEEJ Trans 4: 771–778 (2009) M. MIYATAKE AND K. MATSUDA Speed [m/s] 20 0.5 0 −0.5 −1 0 20 40 Case 2 −0.5 −1 Voltage at pantograph [V] Case 3 0 0 20 40 60 80 100 120 Time [s] 1800 Train power [W] Control input u 1 0.5 1600 1400 1200 0 20 40 15 10 5 0 60 80 100 120 Time [s] Capacitor voltage [V] Control input n 1 60 80 100 120 Time [s] 0 20 40 500 60 80 100 120 Time [s] Case 2 400 Case 3 300 5 0 20 40 60 80 100 120 Time [s] 40 60 80 100 120 Time [s] x 106 0 −5 0 20 Fig. 7. Graphs of optimal control inputs and state variables 20 0.5 Case 2 0 Case 5 −0.5 −1 Case 4 0 20 40 60 Speed [m/s] Control input n 1 15 10 5 0 80 100 120 0 20 40 Control input u 1 0.5 Case 5 0 Case 2 −0.5 −1 0 20 40 60 80 100 120 500 Case 2 450 Case 5 400 350 300 0 20 40 Train power [W] Voltage at pantograph [V] Case 4 Case 5 1600 1500 1400 1300 0 20 40 60 80 100 120 Time [s] Case 2 1700 80 100 120 550 Time [s] 1800 60 Time [s] Capacitor voltage [V] Time [s] 60 80 100 120 Time [s] 4 x 106 2 0 −2 −4 0 20 40 60 80 100 120 Time [s] Fig. 8. Graphs of optimal control inputs and state variables discharged if margin time between stations is expected enough. The EDLC current should be kept low if the consumed power is low. Regarding the acceleration/deceleration command, very few differences between with and without EDLC are observed. These trends of results may be found with qualitative investigation or trial and error. However, it is significant that such study can be investigated quantitatively. The quantitative results implementation. As a result, it is found that the energy consumption can be reduced by using on-board energy storage device. Compared with the train without EDLC, the total energy consumption is reduced by 0.36–5.67%. If rectifier substations that cannot absorb regenerative energy are assumed, the energy-saving effect will be evaluated much higher. The optimal EDLC control strategies are also clarified. For energy-saving operation, the EDLC should not be deeply 776 IEEJ Trans 4: 771–778 (2009) ENERGY SAVING RAILWAY VEHICLE WITH ON-BOARD ENERGY STORAGE 25 Speed [m/s] Case 6 0.5 0 −0.5 −1 Case 7 0 20 40 60 80 Time [s] 0.5 0 −0.5 −1 Voltage at pantograph [V] Case 7 0 20 40 60 80 Time [s] 100 120 1800 Train power [W] Control input u 1 1700 1600 1500 1400 1300 0 20 40 60 80 Time [s] 20 15 10 5 0 100 120 Capacitor voltage [V] Control input n 1 100 120 0 20 40 60 80 Time [s] 100 120 0 20 40 60 80 Time [s] 100 120 40 60 80 Time [s] 100 120 550 500 450 400 350 300 x 106 4 2 0 −2 −4 0 20 Fig. 9. Graphs of optimal control inputs and state variables will be used as ideal models for evaluating the design of online control used in actual rail vehicles. A further direction of this study will be to optimize the train operation problem, which has more complicated conditions, for example, rectifier substations, speed limitations and gradients. (8) Khmelnitsky E. An optimal control problem of train operation. IEEE Transactions on Automatic Control 2000; 45(7):1257–1266. (9) Ko H, Koseki T, Miyatake M. Numerical study on dynamic programming applied to optimization of running profile of a train. IEEJ Transactions on Industry Applications 2005; 125-D(12):1084–1092. (in Japanese). (10) Ko H, Koseki T, Miyatake M. Application of dynamic programming to optimization of running profile of a train, Computers in Railways IX, WIT Press; 2004, 103–112. Acknowledgments This project has been supported by MEXT.KAKENHI (19760290). (11) Albrecht T. Reducing power peaks and energy consumption in rail transit systems by simultaneous train running time control. Computers in Railways IX 2004, 885–894. (12) Ogawa T, Yoshihara H, Wakao S, Kondo K, Kondo M. Design estimation of the hybrid power source railway vehicle based on the multiobjective optimization by the dynamic programming. IEEJ Transactions on Electrical and Electronic Engineering 2008; 3(1):48–55. (13) Ko H, Koseki T, Miyatake M. A numerical method for optimal operating problem of a train considering DC power feeding system. IEEJ Transactions on Industry Applications 2006; 126(8):1104–1112. (in Japanese). References (1) Sone S. Optimisation of regenerative train operation Pt.1 contents of “Optima”. Proceedings of IEEJ JIASC2001 2001; 3:1281–1284. (in Japanese). (2) Ogasa M. Energy saving and environmental measures in railway technologies: example with hybrid electric railway vehicles. IEEJ Transactions on Electrical and Electronic Engineering 2008; 3(1): 15–20. (3) Taguchi Y, Hata H, Ohtsuyama S, Funaki T, Iijima H, Ogasa M. Simulation results of novel energy storage equipment series-connected to the traction inverter. Proceedings of EPE2007, No. 554, Aalborg, Denmark, 2007. (4) Steiner M, Klohr M. Energy storage system with ultraCaps on board of railway vehicles. Proceedings of EPE2007, Aalborg, Denmark, 2007. (5) Taufiq J. Power electronics technologies for railway vehicles. Proceedings of PCC-Nagoya 2007, No. LS5-5-5, Nagoya, Japan, 2007. (6) Sone S, Sato T, Kouyama J. Proposal and discussion of high-speed regenerative braking for realizing genuine pure electric braking. IEEJ Technical Meeting on Transportation and Electric Railway, No. TER05-26, 2005, 71–74. (in Japanese). (7) Sekijima Y, Inui M, Aoyama I, Monden Y. A trial of regenerated energy storage with an electric double layer capacitor for rolling stock. Proceedings of IEEJ, JIASC2006, vol. 1, IEEJ: Nagoya, Japan, 2006, 125–128. (in Japanese). (14) Miyatake M, Ko H. Numerical optimization of speed profiles of inverter trains considering DC feeding circuit, PCC-Nagoya 2007, No.DS8-3-9, Nagoya, Japan, 2007. (15) Miyatake M, Ko H. Numerical analyses of minimum energy operation of multiple trains under DC power feeding circuit. Proceedings of EPE 2007, No. 102, Aalborg, Denmark, 2007. (16) Nejdawi IM, Clements KA, Davis PW. An efficient interior point method for sequential quadratic programming based optimal power flow. IEEE Transactions on Power Systems 2000; 15(4):1179–1183. (17) Irisarri G, Kimball LM, Clements KA, Bagchi A, Davis PW. Economic dispatch with network and ramping constraints via interior point methods. IEEE Transactions on Power Systems 1998; 13(1):236–242. (18) Konishi T, Hase S, Nakamichi Y, Nara H, Uemura T. Verification test of energy storage system for DC 750V electrified railway. Proceedings of RTS 2007, No. 7-5, 2007. (19) Nogi M, Takagi R, Sone S. A study of PWM substation real-time control for the improvements in the utilisation of capacity of power installations at substations. Proceedings of RTS 2007, No. 1–5, 2007. 777 IEEJ Trans 4: 771–778 (2009) M. MIYATAKE AND K. MATSUDA Masafumi Miyatake (Member) received the B.S. and M.S. degrees in electrical engineering from the University of Tokyo in 1994 and 1996, respectively. He received the Ph.D degree in information and communication engineering from the University of Tokyo in 1999. In 1999, he was a research associate in Tokyo University of Science. In 2000, he joined Sophia University. From 2004, he has been an associate professor in Sophia University. His research interests include energy management control, renewable energy generation and their applications to transportation systems. Kunihiko Matsuda (Non-member) received the B.S. and M.S. degrees in electrical and electronics engineering from Sophia University in 2005 and 2007, respectively. He is now working at Denso Corporation. 778 IEEJ Trans 4: 771–778 (2009)