Steering & Braking System Design for Onion Harvester

advertisement

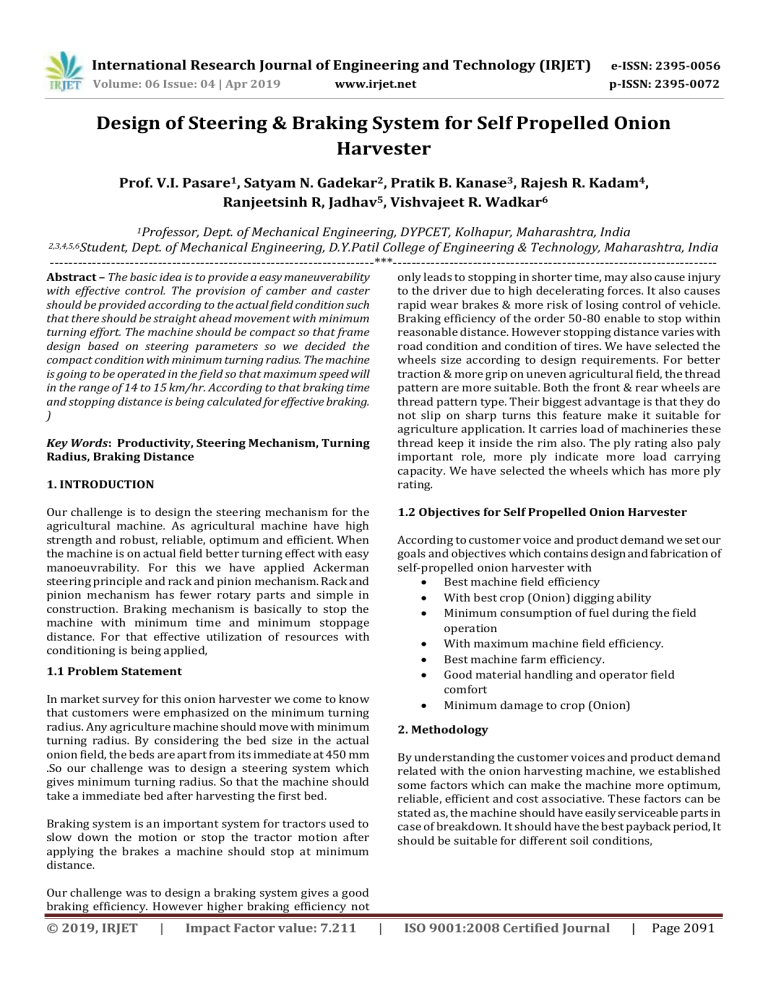

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 04 | Apr 2019 p-ISSN: 2395-0072 www.irjet.net Design of Steering & Braking System for Self Propelled Onion Harvester Prof. V.I. Pasare1, Satyam N. Gadekar2, Pratik B. Kanase3, Rajesh R. Kadam4, Ranjeetsinh R, Jadhav5, Vishvajeet R. Wadkar6 Dept. of Mechanical Engineering, DYPCET, Kolhapur, Maharashtra, India Dept. of Mechanical Engineering, D.Y.Patil College of Engineering & Technology, Maharashtra, India ---------------------------------------------------------------------***--------------------------------------------------------------------- 2,3,4,5,6Student, 1Professor, Abstract – The basic idea is to provide a easy maneuverability with effective control. The provision of camber and caster should be provided according to the actual field condition such that there should be straight ahead movement with minimum turning effort. The machine should be compact so that frame design based on steering parameters so we decided the compact condition with minimum turning radius. The machine is going to be operated in the field so that maximum speed will in the range of 14 to 15 km/hr. According to that braking time and stopping distance is being calculated for effective braking. ) only leads to stopping in shorter time, may also cause injury to the driver due to high decelerating forces. It also causes rapid wear brakes & more risk of losing control of vehicle. Braking efficiency of the order 50-80 enable to stop within reasonable distance. However stopping distance varies with road condition and condition of tires. We have selected the wheels size according to design requirements. For better traction & more grip on uneven agricultural field, the thread pattern are more suitable. Both the front & rear wheels are thread pattern type. Their biggest advantage is that they do not slip on sharp turns this feature make it suitable for agriculture application. It carries load of machineries these thread keep it inside the rim also. The ply rating also paly important role, more ply indicate more load carrying capacity. We have selected the wheels which has more ply rating. Key Words: Productivity, Steering Mechanism, Turning Radius, Braking Distance 1. INTRODUCTION Our challenge is to design the steering mechanism for the agricultural machine. As agricultural machine have high strength and robust, reliable, optimum and efficient. When the machine is on actual field better turning effect with easy manoeuvrability. For this we have applied Ackerman steering principle and rack and pinion mechanism. Rack and pinion mechanism has fewer rotary parts and simple in construction. Braking mechanism is basically to stop the machine with minimum time and minimum stoppage distance. For that effective utilization of resources with conditioning is being applied, 1.2 Objectives for Self Propelled Onion Harvester According to customer voice and product demand we set our goals and objectives which contains design and fabrication of self-propelled onion harvester with Best machine field efficiency With best crop (Onion) digging ability Minimum consumption of fuel during the field operation With maximum machine field efficiency. Best machine farm efficiency. Good material handling and operator field comfort Minimum damage to crop (Onion) 1.1 Problem Statement In market survey for this onion harvester we come to know that customers were emphasized on the minimum turning radius. Any agriculture machine should move with minimum turning radius. By considering the bed size in the actual onion field, the beds are apart from its immediate at 450 mm .So our challenge was to design a steering system which gives minimum turning radius. So that the machine should take a immediate bed after harvesting the first bed. 2. Methodology By understanding the customer voices and product demand related with the onion harvesting machine, we established some factors which can make the machine more optimum, reliable, efficient and cost associative. These factors can be stated as, the machine should have easily serviceable parts in case of breakdown. It should have the best payback period, It should be suitable for different soil conditions, Braking system is an important system for tractors used to slow down the motion or stop the tractor motion after applying the brakes a machine should stop at minimum distance. Our challenge was to design a braking system gives a good braking efficiency. However higher braking efficiency not © 2019, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 2091 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 04 | Apr 2019 p-ISSN: 2395-0072 www.irjet.net Sr. No Parameter Specification 1 Machine Type 4 Wheel 2 Overall dimensions (L x B x H) 2550 x 1600 x 1776 mm 3 Static Ground Clearance 300 mm 4 Machine weight 570 kg 5 Wheel Base 1550 mm 6 Wheel track width 1450 mm 7 CG location from machine mid plane & wheel Centre 367mm 8 Max. Speed 15 km/hr 9 Working Width 900 mm 10 Working Depth 100 mm 11 Volume of Material Handled 0.045 m³/sec 3. OVERALL TECHNICAL SPECIFICATIONS OF MACHINE 3.1 Design of Steering System Requirements of Steering System Table -1: Overall Machine Specifications Digging and Conveyor System Replaceable Blades Adjustable Cutting Depth with Hydraulic Jack Mechanism Effective Blade Geometry Better Separating Index Engage and Disengage Mechanism for Conveyor Drive Steering System Adjustable Camber Effective turning radius Provides better control on uneven agriculture field Power Transmission System Provide best performance on field by providing effective torque at wheel and best tractive effort. | Impact Factor value: 7.211 The effort required to steer should be minimum. The steering mechanism should also provide the directional stability. This implies that the machine should return to its original position quickly after removing hand from wheel. It should provide easy maneuverability. The design should be such that it should transfer less shocks to driving wheel. Table -2: Steering System Specifications Steering System Specifications Machine Frame Provide structural support to the machine © 2019, IRJET The steering mechanism should be effective and easy to operate. The intention of Ackermann geometry is to avoid the need for tires to slip sideways when following the path around a curve. The geometrical solution to this is for all wheels to have their axles arranged as radii of circles with a common center point. A linkage between these hubs pivots the two wheels together, and by careful arrangement of the linkage dimensions the Ackermann geometry could be approximated. This was achieved by making the linkage not a simple parallelogram, but by making the length of the track rod (the moving link between the hubs) shorter than that of the axle, so that the steering arms of the hubs appeared to "toe out". According to that we divided the machine into different subsystems according to its working principle and mechanism. Following figure gives brief introduction about each system and its features. 3.2 Selected Mechanism: Ackerman Geometry To work on the above factors we decided the strategy to design and fabricate the onion harvester which can perform effectively with most innovative and optimum features. Provides better ergonomic considerations by providing good visibility assistance, accessibility of controls and safety. | Type of Steering System Rack & Pinion type Inner Wheel Angle (Θ) 42° Outer Wheel Angle (Φ) 27.1 ° Ackerman % 70% Turning Radius (R) 2.859 m King Pin Inclination (KPI) + 80 Camber +2° Caster +6° Scrub Radius 0.11 m ISO 9001:2008 Certified Journal | Page 2092 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 04 | Apr 2019 p-ISSN: 2395-0072 www.irjet.net Furthermore, the availability of this steering box is high in the market and spare parts are easily available. Hence Maruti 800 was the best possible option. Other Parameters Track Width 1450 mm Wheel Base 1550 mm Steering Gear Box Ratio 18:1 Steering Arm 125 mm Steering Gear Box Ratio / Steering Ratio: 18:1 The requirement of the steering gear box for this particular vehicle was in the range of 10:1 to 20:1. The steering gear box of Maruti 800 was a perfect selection for it. It has a steering ratio of 18:1. 3.5 Inner Wheel Angle: 42o The inner angle is the angle of the inner wheel taking a right or a left turn by locking the steering wheel to the extreme position. The turning radius to be met was below 3.5m. Hence after permutation and combination of all the factors, we selected 40o which was sufficient in all terms. 3.6 Outer Wheel Angle: 27.1o The outer angle according to assuming the inner angle to be 40 degree is calculated by the following formula as follows, 420 1450 𝑐 27.10 𝑐𝑜𝑡∅ − 𝑐𝑜𝑡𝜃 = 𝑏 𝑐 𝑐𝑜𝑡∅ = Fig -1: Ackerman Steering Geometry + 𝑐𝑜𝑡𝜃 𝑏 3.3 Selected Gear Box Type: Rack And Pinion The rack carries the full load of the actuator directly and so the driving pinion is usually small, so that the gear ratio reduces the torque required. This force, thus torque, may still be substantial and so it is common for there to be a reduction gear immediately before this by either a gear or worm gear reduction. 3.4 Selected Steering Ratio and Steering Gear Box: Ф= 27.1° Steering Ratio 3.7 Turning Radius: 2.859m Considering the vehicle to be partially a prototype of tractor and partially an ATV, the steering ratio had to be in between the 10:1 to 20:1. The steering effort had to be less, looking at the different operation a driver has to do while driving the vehicle and also while harvesting the onions. Various gear box of tractors as well as cars were studied. The most suited to ratio is between 15:1-20:1 for this vehicle. The diameter of the smallest circle which the outer front wheel of the car can traverse and obtain when the wheels are at the extreme position is known as turning radius. Requirement: The turning radius for this onion harvester was to be kept below 3.5 m. This was for easy maneuverability of the vehicle from onion bed to bed. Steering Gear Box Now Why MARUTI 800? The reason for fixing this particular gear box it that, it is a proven gear box for almost all the ATV’s. The structure of its entire steering system is rugged and has strength to handle weight of about 1 tonne. © 2019, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 2093 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 04 | Apr 2019 p-ISSN: 2395-0072 www.irjet.net Actual turning radius of the vehicle is an average of RIF and ROF. 3.8 Calculations R = (RIF+ROF)/2 R= 2.859 m CASTOR: +6° The caster angle or castor angle is the angular displacement of the steering axis from the vertical axis of a steered wheel in a car, motorcycle, bicycle or other vehicle, measured in the longitudinal direction. It is the angle between the pivot line (in a car an imaginary line that runs through the center of the upper ball joint to the center of the lower ball joint) and vertical. For agricultural vehicles there is no castor implemented. But considering the ATV condition and requirement of the vehicle for running it in the onion field castor of 30 was decided to be implemented to attain the straight motion of the vehicle while plucking the onions. The recommended range is between 3-6 0 Fig -2: Steering Geometry CAMBER: +2° Camber angle is the angle made by the wheels of a vehicle; specifically, it is the angle between the vertical axis of the wheels used for steering and the vertical axis of the vehicle when viewed from the front or rear. The positive camber angle gives greater stability on uneven surfaces. Tractors ordinarily designed with considerable amount of camber as they frequently required to operate on uneven surface largely counteracts the tendency of cambered wheels to turn outwards though they were large cones turning around there apexes . The correct camber for this vehicle was in between the range of 1.570.. Turning radius for inner front wheel, RIF Turning radius for outer front wheel, ROF Parameters taken from the actual prototype, King Pin Inclination: +80 b= 1550 mm c= 1200 mm a= 1450mm 𝜃 = 420 On most modern designs, the kingpin angle is set relative to the true vertical line, as viewed from the front or back of the vehicle. It helps to reduce road shocks such as those caused by holes, stones & high spots. A king pin inclination tends to reduce. ∅ = 27.1 Turning radius for inner front wheel, SCRUB RADIUS: 0.11m RIF = The scrub radius of your car can be altered with different wheel offset and suspension design. A positive scrub radius tends to be beneficial while braking into a turn. A negative scrub radius tends to better for braking stability in the event of brake failure or split-mu braking. Typically, the scrub radius is configured to be as small as possible to minimize the effects under braking, but squirm (from zero scrub radiuses) is also undesirable. The Scrub radius is calculated by graphical method as follows, RIF=2.191m Turning radius for outer front wheel, ROF = Steering Arm Angle / Ackerman Angle: 30.220 ROF=3.527 sin (∝ +𝜃) + sin(𝛼 − ∅) = 2 sin 𝛼 © 2019, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 2094 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 04 | Apr 2019 p-ISSN: 2395-0072 www.irjet.net sin (∝ +42) + sin(𝛼 – 27.1) direction stability & to get more grip on uneven agriculture field. From we selected the front tires of 12”.The Dimensions of the FRONT TIRES is as follows: (sin ∝× cos 42+ cos ∝× sin 42) + (sin ∝ × cos 27.1 − cos ∝× sin 27.1) = 2 sin ∝ Tire type =TT 0.2136cos ∝=0.3667 sin ∝ Outer Diameter = 588 mm ∝= 30.22° Tire Size = 6”- 12” Ackerman Percentage: 70% Understeer PLY Rating = 4 Ply Ackerman percentage decides how much your inner tire turns compared to outer tire. 100 % Ackerman condition is when the turning circles of both inner and outer tire are concentric while 0 % means both circles are the same i.e. inner tire turns the same angle that of outer tyre. In 100 % Ackerman condition the steering arms meet at the center of rear axle. When the Ackerman % is below 100%, the condition is under steer and when the Ackerman percentage is above 100% the condition is over steer. Rim Size = 12” Pattern =AS504 Tire pressure = 55 psi 4. Design of Braking System Ackerman Percentage = current distance / distance for 100 % × 100 % We have used the disc brakes on the front wheel which provides easy breaking with minimum stoppage distance. 4.1 Objectives for Braking System = 1085/1550 × 100 % = 70% UNDERSTEER To obtain high operational speed during rapid braking and compatibility of tractor. Taking into account traffic safety and maintenance. To achieve minimum braking distance. The weight distribution and large rear tires of the machine have enable to generate sufficient braking effort from the rear wheels alone. 3.9 Wheels and Tires Rear Tire Selection:Selection of rear wheels were according to specification given in the rule book , provided by SAE-TIFAN . these wheels are used where drive is given , here are the specification 4.2 Calculations Dynamic axle load- Tire Type = TT Fzf = (1-ψ+x*a) W ………….front axle rear force Outer Diameter = 818mm Ψ= Tire size = 7.5”- 16” Where, = = 0.3 …………….static axle load distribution Mf = static front axle load in kg Pattern =AS504 M = total vehicle mass in kg Pressure = 65 psi x= = = 0.228 …………..relative C.G. Ply rating = 8 ply Where, Rim size = 16” h= height of C.G. Front Tire Selection:- Wb = wheel base By considering the ground clearance which was to be maintained 300mm above the ground, according to the requirements on agriculture field, for better traction, © 2019, IRJET | Impact Factor value: 7.211 Fzf = (1-0.3+0.228*0.25)*460 = 348.22 kg | ISO 9001:2008 Certified Journal | Page 2095 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 04 | Apr 2019 p-ISSN: 2395-0072 www.irjet.net Front axle braking force – = 2390.028 * 0.11 Fxf = uf * Fzf * g = 262.903 Nm = 0.4 * 348.22 * 9.81 Validation of satisfaction of braking torque = 1366.42 N Table -4: Validation of Braking Torque Braking torque – Txf = Fxf * Rr = 150.306 Nm Requirement Generated 150.306 262.903 Where, Stopping time – (T) Rr = radius of disc of rotor Txf = 1366.42 * 0.11 T= = 150.306 Nm = = 2.12 sec Validation of brake torque requirements – Stopping distance = (S) Master cylinder bore = 19.05 mm Area of master cylinder = * (19.05)2 = 285.023 mm2 S= = = 2.17 m Pedal force = 350 N = Fp Pedal ratio = 5:1 = m 5. CONCLUSIONS: Leverage efficiency = 0.8 = η The main objective was to make simple, compact, efficient and low cost small scale harvester for small land holders. This machine fulfilled all objective and following conclusion were drawn on based of work. Force acting on master cylinder = Fmc = m * Fp* η = 5 * 350 * 0.8 = 1400 N With this design we can easily achieve the objectives which have set. By this steering is effective and easy to operate. The effort required for steering is less and provide directional stability. It will provide easy maneuverability and less transfer of shocks to the driver. Pressure acted in master cylinder = (Pmc) Pmc = = = 4.912 * 106 Acp = *(bcp)2 = * 442 = 1520.53 mm2 By efficient braking we have obtained high operational speed during rapid braking. We also have taken into account traffic and safety rules. The overall objective of machine was fulfilled by our design. Which can help to fabricate simple, compact, efficient and low cost harvester. Force applied by caliper: REFERENCES Pmc = 4.912 bar Area of caliper piston = (Acp) Fp = Pmc * Acp * η = 4.912 * 106 * 1520.53 * 0.8 [1] Thomas D. Gillespie, Fundamentals of vehicle dynamics, Society of Automotive Engineers, Inc. 400 commonwealth drive, Warrandale, PA 15096- 0001 [2] Joseph Heitner, Elements of Automotive Mechanics (2nd Edition). [3] R. S. Khurmi & J. K. Gupta - Machine Design- Eurasia publishing house New Delhi,14th Edition, 2008 [4] Theory of Machine –Rattan S.S Tata - McGraw Hill Publishing Company New Delhi,2nd Edition,2006 = 5975.07 N Total force applied – FPT = fp* u = 5975.07 * 0.4 = 2390.028 N Torque generated Tf = FPT * R © 2019, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 2096 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 04 | Apr 2019 p-ISSN: 2395-0072 www.irjet.net [5] http://www.economicsdiscussion.net/agriculture/ problems-agriculture/indian-agriculture-problems7-major-problems-of-indian-agriculture/12859. [6] V.B. Bhandari “DESIGN OF MACHINE ELEMENTS” 3rd edition [7] Dr. Kirpal Singh, “AUTOMOBILE ENGINEERING” VOL. 1 by 13th edition 2012, Standard publication, Delhi 13th edition 2013. [8] Strength of Machine Element, Prof.R.K.Rajput S.Chand Publication edition 2008. [9] Laukik P. Raut, Vishal Dhandare, Pratik Jain, Vinit Ghike, Vineet Mishra, “Design, Development and Fabrication of a Compact Harvester”, International Journal for Scientific Research & Development| Vol. 2, Issue 10, 2014 | ISSN (online): 2321-0613 [10] Government of India, “Indian agricultural statistics 2015-16”, Ministry of Agriculture & Farmers Welfare, Department of Agriculture, Cooperation & Farmers Welfare, Directorate of Economics & Statistics, New Delhi Mr. Rajesh R. Kadam Student, Dept. of Mechanical Engineering, D.Y.Patil College of Engineering & Technology, Maharashtra, India Mr. Vishvajeet R. Wadkar Student, Dept. of Mechanical Engineering, D.Y.Patil College of Engineering & Technology, Maharashtra, India BIOGRAPHIES Prof. V.I.Pasare Professor, Dept. of Mechanical Engineering, DYPCET,Kolhapur, Maharashtra, India Mr. Satyam N. Gadekar Student, Dept. of Mechanical Engineering, D.Y.Patil College of Engineering & Technology, Maharashtra, India Mr. Pratik B. Kanase Student, Dept. of Mechanical Engineering, D.Y.Patil College of Engineering & Technology, Maharashtra, India Mr. Ranjeetsinh R. Jadhav Student, Dept. of Mechanical Engineering, D.Y.Patil College of Engineering & Technology, Maharashtra, India © 2019, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 2097