Solenoid Valve Control for Internal Combustion Engines

advertisement

IFAC

Copyright C> IFAC Mechatronic Systems,

California, USA, 2002

c:

0

[>

Publications

www.elsevier.comllocatelifac

MODELING AND CONTROL OF SOLENOID

VALVES FOR INTERNAL COMBUSTION

ENGINES

Charles Robert Koch . ,1 Alan F. Lynch •• ,1

Ryan R. Chladny·

• Dept. of Mechanical Engineering, University of Alberta,

Edmonton AB, T6G 2GB Canada

•• Dept. of Electrical and Computer Engineering,

University of Alberta, Edmonton AB, T6G 2V4 Canada

Abstract: This paper considers the modeling and control of solenoid valve actuators

used for gas exchange in internal combustion engines. Solenoid valves are an

emerging technology which offers performance benefits over traditional camshaft

based valve timing. Maintaining the impact velocity of the armature and valve

is a primary performance requirement in order to minimize acoustic noise and

mechanical wear. To control this velocity, the finite element method (FEM) is used

to generate static force and flux data which is validated experimentally. A flatnessbased control provides linear tracking error dynamics assuming current control.

A reduced-order nonlinear velocity/disturbance observer ensures linear estimate

error dynamics for constant force disturbances. The estimated state feedback is

simulated using the FEM model flux and force data and acceptable impact velocity

and acceleration are achieved in face of model uncertainty disturbance. Copyright

© 2002 IFAC

Keywords: Electromagnetic Devices, Valves, Finite Element Method, Internal

Combustion Engines, Nonlinear Control, State Observers, Feedforward

Compensation

1. INTRODUCTION

mance gains have been demonstrated in laboratory settings (Barros da Cunha et al., 2000),

(Rassem, 2001), commercial success depends on

the development of accurate models amenable

to the design of cost-effective, high-performance

controllers. This paper proposes a flatness-based

nonlinear control scheme for a real solenoid valve

and demonstrates it's performance in a simulation

incorporating force and flux data derived from a

FEM model.

The use of solenoid actuators to control the gas

exchange valves of a spark ignition internal combustion (IC) engine can significantly improve engine fuel consumption and reduce hazardous exhaust emissions. Performance benefits of solenoid

actuation over a conventional camshaft engine

result from being able to optimize individual

valve timing over the complete engine load-speed

range (Pischinger et al., 2000) . Although perfor-

The development of an optimal design for solenoid

valve actuators has received recent attention and

a number of configurations have been proposed. A

common feature of the design alternatives is their

use of springs in order to reduce electrical energy

1 This research was partially supported by the Natural

Sciences and Engineering Research Council of Canada

(NSERC), under Research Grant numbers 249553-02,

249681-02.

197

input. By storing energy in the springs, rapid

motion with large strokes is possible with realistic

electrical energy requirements. The high system

energy density provided by the springs can also

help overcome the substantial combustion pressure forces acting on the valve. The use of springs

in hinged or c1apper-type actuators is discussed

in (Kawase et al., 1991), (Cristiani et al., 2002).

Here the armature is constrained to rotate about

a fixed pivot. The gas exchange valve is connected

to the armature and has linear motion. By choosing the location of the attachment point of the

valve to the armature, the mechanical force lever

ratio can be varied. The result is smaller airgap

lengths and improved force characteristics. Work

in (Pischinger and Kreuter, 1984) considers a

pre-Ioaded two-spring linear motion configuration

shown in Figure 1. This paper considers a real prototype valve provided by Daimler-Chrysler which

has this configuration.

Fig. !. Schematic of the two-spring solenoid actuator valve.

The dynamic equations which describe solenoid

valve behaviour are nonlinear and many of the

model parameters vary with operating conditions

and wear. Further, solenoid valves are usually

modeled in isolation from the complex combustion

gas force dynamics. That is, for simplicity these

forces are considered as unknown disturbances to

the valve dynamics . The development of control

schemes which provide reliable high performance

operation has received recent attention . Most control schemes attempt to limit the impact velocities of the armature on the stator using some

form of position and velocity feedback derived

from a linear approximation of the system. In

(Konrad, 1998) linear control methods are used

to design an estimated state-feedback trajectory

tracking controller. A method based on controlling kinetic and potential energy is detailed in

(Schmitz, 1995). Adaptive feed forward methods

for disturbance rejection are presented in (Koch

and Mockel, 2001). This paper is organized as

follows . Section 2 outlines the controller specifications and system performance requirements.

Section 3 details the use of the FEM for modeling

the magnetostatics of the solenoid valve. Section 4

derives the nonlinear flatness-based control and

validates its performance using data from the

FEM model. Finally, conclusions are drawn in

Section 5.

least 5500 RPM with sufficient engine breathing

is required by modern spark ignition IC engines

to obtain reasonable engine power density. As

well, armature impact velocities must be less than

0.1 m/s to maintain acceptable levels of acoustical

noise and mechanical wear (Wang et al., 2002).

Additionally, electrical energy consumption must

be reduced to minimize engine fuel consumption

which is a main objective for electronic valve actuation. Maintaining system performance in face

of parameter variations due to wear and changing

operating conditions are also a major concern. For

example, parameter variation is inevitable with

under hood temperatures ranging from -40°C to

l60°C . Finally, stringent position sensor accuracy

requirements are imposed by the demanding motion planning constraints. These sensor requirements result from the velocity constraints and the

high accelerations just before armature impact.

For the solenoid valve considered here, this large

acceleration combined with an acceptable impact

velocity tolerance leads to a sensor accuracy of

approximately lOp-m. At present, the cost of a

sensor with this accuracy over a 8mm stroke limits commercialization potential and has prompted

research into alternate sensing methods (Roschke

and Bielau, 1995), (Rossi and Tonielli, 2001),

(Butzmann et al., 2000).

2. CONTROLLER SPECIFICATIONS

Energy efficiency and density constraints are addressed in this paper via the choice of the twospring linear actuator shown in Figure 1. To

reduce the sensor accuracy requirements which

result from high accelerations near impact, the

nonlinear flatness- based control aims to regulate

low acceleration (as well as velocity) near impact.

Due to stringent multiple conflicting performance

specifications, control design for the solenoid actuator is a challenging problem. A primary requirement due to engine RPM time constraints is a

3-4 ms travel time over a minimum 8 mm stroke.

This is because a maximum engine speed of at

198

4. FLATNESS-BASED CONTROL

1600 --,---....,-....,-....,---.----.---.---,---.

1----· FEA

I

1- - Experimental i

l

Lumped Parameter Modeling

--i

The armature position of the solenoid valve system, shown schematically in Figure 1, is denoted

by x and the origin of the x-coordinates is defined at the midpoint between the two coils. The

armature is mechanically constrained to move on

x E [-4,4J mm. Assuming there is no leakage flux,

no magnetic saturation, the E-shaped electromagnet has an inductance of the form

I

3000 Amp-turns

i

//

1500 Amp-turns

./

/

500 Amp-turns

l

i

1

~

(1)

o

246

where f3 and /\, are related to the number of turns,

area and lengths of the flux paths, and magnetic

permeabilities of the air and iron core of the coil.

Assuming no coupling between the coils, the force

F2 exerted by Coil 2 on the armature is obtained

by differentiating the coenergy function

8

Armature Displacement [mm]

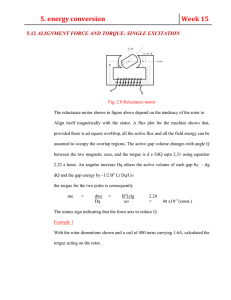

Fig. 2. Comparison of FEM model and experimental force data at three current levels.

3. FEM MODELING

with respect to position, where A2(X, i 2) =

L2(X)i2 is the flux linkage of the coil, and i2 is

the coil current. Thus, the force equation is

A FEM model is constructed in order to generate

flux and force data as a function of armature

position and coil current. This data is to be used

below in Section 4 in order to accurately simulate

the proposed control scheme. The magnetostatic

behavior of the slightly off-round elliptical coil

is analyzed using the commercial program ANSYS. Although the coils are slightly elliptical, they

are modeled approximately in two dimensions by

assuming axisymmetric geometry. Quadrilateral

elements with nonlinear capability are used to

model the actuator domain, and far field effects

are represented using infinite boundary elements.

The permeability of the magnetic material's nonlinear dependence on magnetic field intensity is

incorporated. By energizing only a single coil at a

time (i.e., assuming zero coupling between coils),

static force and flux data are computed over a

grid of airgap and current data. ANSYS uses a

magnetic vector potential A such that ~ x A = B,

where B is the magnetic flux density, and solves

the following Maxwell's equations for magnetostatics:

-f3i~

(/\,+X)2'

Assuming both coils have identical construction

and using the same reasoning as above, the inductance of the first coil is

LI(X)

= 2f3/(/\, -

x).

(2)

The force exerted by the first coil on the armature

is

FI(x, id = f3ii!(/\, - x)2.

Newton's law for the armature gives

..

x

(ii

= -mf3 (/\'-x )2

i~)

- (/\,+x )2

.

+ A(x, x),

(3)

where A(x,x) = -(k.x + Bx)/m, k.x is the

restoring force due to a spring of stiffness k s , Bx

is viscous frictional force of the mechanism, and m

is the mass of the armature. To simplify notation,

ks is the combined stiffness of both springs_

The dynamics of the coils are

dAk (X,2k

.) = Vk Tt

~xH=J

R'2k,

k

= 1,2,

(4)

where Vk is the input voltage applied to Coil k,

and R is the resistance of each coil. Taking ik as

a state, the state-space form of (4) is

~·B=O,

where H is the magnetic field intensity and J is

the current density.

dik

1

dt

= Lk(X)

The force data from the FEM model is shown in

Figure 2 as a function airgap at three current

values (79 coil turns). In order to validate the

FEM model, experimentally measured force data

is also plotted for comparison. The FEM data

agrees within 10% of the experimental results

indicating the high fidelity of the model.

(

Vk -

R'

2k -

dLk ( ) ..2 ) k

1 2

dx x X k , = , .

Substituting (2) and (1) into this expression gives

di l

xi}

/\, - X

= --(VI - Rid - - dt

2f3il

/\, - X

di2

/\, + X (

R.)

xi2

- = - - V2 - 22 + - -.

dt

2f3i2

/\, + X

-

199

The parameters R = .48 n, m = .1558 kg, B =

6.59 Ns/m ks = 174 N/mm can be readily measured. The parameters K, = 4.07 mm and /3 =

1.45 . 10- 6 Nm 2 / A2 are obtained by taking a least

square fit to the force data obtained from the FEM

model described in Section 3.

Setting i2 = 0 in (6d) and substituting the righthand side of (8) gives

i l = /;(K,-Ylh/Yld - kltl - kOYl - A(YI.lil),

(9)

which is real-valued for YI - A(YI, YI) ~ O. Writing

out (3) in terms of YI with il = 0 gives the

expression for i2 :

Flatness-based Control

A flatness-based static state-feedback current control which makes the armature position converge

exponentially to a desired trajectory is derived

assuming both coil currents can be directly controlled. As well, in order to reduce energy loss,

a complementary current condition is imposed to

ensure only one coil current is nonzero at any

time. Work in (Levine et al., 1996) provides a convenient differential flatness framework for solving

this trajectory tracking problem. Two differences

between the magnetic bearing system considered

in (Levine et al., 1996) and the solenoid valve

considered here are the presence of a spring force

and the absence of gravity.

i2

if YI - A(YI, yd ~ 0

if YI - A(Yl, yd ::; 0

(11)

The above condition compares the acceleration

due to the spring plus viscous friction with the actual acceleration. If this difference is positive then

Coil 1 is activated, otherwise Coil 2 is activated.

(5a)

X

i2

In the simulations below, the control (9) and

(10) is modified in two ways. First, condition

(11) is regularized to an "almost complementary

condition" in order to avoid singularity problems.

Secondly, a high-gain voltage feedback is used to

track (9) and (10). That is,

//3 .

(5b)

m

Note that -y~ is the armature acceleration due

to current in Coil 2. Using (5) and (3), the inputs

and states can be expressed as functions of the

independent flat outputs YI and Y2 and a finite

number of their time derivatives:

Y2 =

K,+X

x = YI

i2 = / ; Y2(K,

Vk = -Kk(ik - ikd),

+ yd

k = 1,2,

where Kk > 0 are chosen sufficiently large and ikd

are the desired currents given by (9) and (10) .

A singular perturbation argument can be used

to show tracking of position can be recovered for

sufficiently large gains Kk (Levine et al., 1996).

(6a)

(6b)

X=YI

YId + kltl + kOYI,

(10)

which is real-valued for Yl - A(Yl, yd ~ O. The

sign of YI - A(YI, YI) determines which current

should be used to:',ensure YI converges exponentially to its desir~d '~~lue. This current complimentary condition car{'be stated in terms of a

condition on YI and Y2

Two fictitious so-called flat outputs YI, Y2 are

defined as

YI =

= / ; (K,+YdVA(YI, YI) -

(6c)

·2 m(K,-x)2( "

2

A(

.))

tl =

/3

YI + Y2 YI , YI

i l = / ; (K, - Ylhjih

+ y~ -

Disturbance and velocity observer

A(YI, YI) '

(6d)

In practice, the force equation (3) contains disturbance terms which are due to cylinder pressure

transmitted from the valve, complex frictional

forces which are difficult to model, and model

assumptions such as no magnetic saturation. Assuming a constant disturbance force, (3) becomes

where (6d) is real-valued if iit + y~ - A(YI,YI) ~

o which is equivalent to ih - A(YI, YI) ~ O.

The implication of (6) is that the coil system

is differentially flat and convenient methods for

solving trajectory tracking problems exist (Fliess

et al., 1995; Fliess et al., 1999) .

..

Letting YId denote the desired trajectory for the

armature and YI = YI - YId denote the tracking

error, the objective is to achieve linear error

dynamics

/3

X=

m

d=

0,

(ii

K,-X )2 (

.

i~) +A(x, x)+d

( K:+x )2

where d denotes the disturbance acceleration. The

velocity x required for state feedback is not directly measured. Hence, a reduced-order nonlinear observer is proposed to generate estimates of

the disturbance and armature velocity which are

denoted by d and £ respectively. The observer

(7)

Provided ko and kl are positive, YI converges to

YId exponentially. Solving (7) for ih gives

(8)

200

uses current and position measurements which

are denoted by

= (6 6 6 f = (x i l i2f ·

The following second order system describes the

reduced-order non linear observer:

The force data derived from the FEM model was

used in a 2-D Simulink lookup table to get an

accurate measure of coil force as a function of

airgap and current . The flux data from the FEM

model was inverted to get a 2-D lookup table for

current as a function of flux and airgap. This

table was used directly with (4) to simulate the

coil dynamics (i.e., flux linkage was taken as the

state in simulation). We take ko = 2.10 10 s-2 and

kl = 3 . 10 5 S-I and Kk = 105 V/A . The current

is limited to 40 A and the voltage to 2000 V.

The Simulink simulation results are shown in

Figures 3-5. Figure 3 shows that the armature

reaches Coil 1 with a velocity and acceleration

close to zero. Figure 5 shows fast convergence

of the the velocity and disturbance estimates.

A nonzero steady-state disturbance estimate is

due to the difference between FEM data and the

lumped parameter model.

e

ZI

=+

(!

+C I ) ZI

/3~~

( (11:-6)2

+

Z2 -

(!

+C I )

/3~§

- (11:+6)2 -ks~1

)

CI~I

1

m +C2~1

Z2 = -G 2z 1 - CIC2~1'

where the observer gain G = (Cl C 2 )T is such

that the zero solution of the linear error dynamics

i~ expon~ntially stable, and where i = ± - i and

d = d - d. The state estimate is computed from z

using (i d)T = Z+G~I where G = (Cl C 2 )T and

Z = (ZI Z2)T . Estimated state feedback is used

in the simulations below, i.e., the desired currents

(9) and (10) are modified to include d and i .

Simulation Result

We consider the problem of opening the valve ,

i.e., moving the armature from x = -4 mm at

t = 0 s to 4 mm at tf = 4 ms . As discussed in

Section 2, it is critical that velocity at x = 4 mm

be below .1 m/so Meeting this specification while

using acceptable electrical input power depends

on an appropriate choice of the desired trajectory

YId. Choosing YId amounts to designing the openloop compensation. One choice for YId is to wait

until t = to which is the time for the armature

to reach it's closest position to Coil 1 with no

currents applied to either coil. At t = to the

armature has zero velocity and it is then steered to

rest at x( t f) = 4 mm. This choice of YId makes full

use of the energy stored in the spring to achieve

acceptable opening times. In order to keep openloop currents continuous, the third derivatives

of YId are interpolated at trajectory endpoints.

Hence, YId satisfies the interpolation conditions

YId (to) = 0,

y~~)(to) = X(k) (to),

Yld(tf) = 4 mm,

y~~) (t f) = 0,

Time (5)

Fig. 3. Armature position, velocity. Position and

velocity tracking error.

k = 0,2,3

k

= 1,2,3.

(12)

Since the coils are not active until to, the armature

position and its first, second, and third derivatives

can be computed from the uncontrolled motion

mx + B± + ksx = 0, x(O) = -4 mm, ±(O) = O.

The eight conditions (12) are met with the seventh

degree polynomial

Time (5)

Fig. 4. Coil currents and voltages

7

Yld(t) = x(to)

+ L Ck(t -

5. CONCLUSION

to)k

(13)

k=4

The non linear uncertain dynamics of solenoid actuators and stringent performance requirements

where Ck are coefficients.

201

,([" Si: I

JI" ;&: :

3

3.2

3.4

3.6

3.8

4

3

3.2

3.4

3.6

3.8

4

:1

Time (5)

Fig. 5. Disturbance estimate, velocity estimate

error

make modeling and control of this device a challenging problem. In this paper an FEM model is

used to generate experimentally accurate static

force and flux data for a real prototype actuator.

A non linear flatness-based estimated state feedback control is derived from an ordinary differential equation model. The force and flux data of the

FEM model is coupled to the lumped parameter

model, and Simulink simulation results show low

impact velocities in the face of model uncertainty

disturbances.

Future work will concentrate on more accurate

lumped parameter models which include eddy

current and magnetic saturation effects. Also of

importance for improved robustness to parameter variation and sensor drift, is the development

of stability results for adaptive nonlinear voltage control coupled with velocity/disturbance observers. Further, investigation of open-loop trajectory planning which incorporates limits on voltage

and current would be useful. Finally, experimental

validation of the proposed control scheme will be

performed on a test bed which is under development.

6. ACKNOWLEDGMENTS

The authors wish to thank Kurt Maute and his

colleagues at Daimler-Chrysler for the donation

of the solenoid valve actuator and their technical

assistance.

REFERENCES

Barros da Cunha, S., J . Hedrick and A. Pisano

(2000) . Variable valve timing by means of a

hydraulic actuation. SAE 2000-01-1220.

Butzmann, S., J . Melbert and A. Koch (2000) .

Sensorless control of electromagnetic actuators for variable valve train . SAE 2000-011225.

202

Cristiani, M., D. Cannone and N. Moreelli (2002).

Electromagnetic actuator for the control of

the valves of an internal combustion engine.

US Pat. 6,427,650.

Fliess, M., J. Levine, P . Martin and P. Rouchon

(1995) . Flatness and defect of non-linear systems: Introductory theory and examples. Int.

J . Control 61(6), 1327- 1361.

Fliess, M., J. Levine, P. Martin and P. Rouchon

(1999) . A Lie-Backlund approach to equivalence and flatness of non linear systems. IEEE

Trans. Auto. Contr. 44(5), 922- 937.

Kawase, y '. , H. Kikuchi and S. Ito (1991). 3D nonlinear transient analysis of dynamic

behavior of th~.clapper type DC magnet.

IEEE Trans. Mag~tics. 27(5),4238-4241.

Koch, C.R. and H. M3ckel (2001). Verfahren

zur Regelung des Bewegungsverlaufs eines

Ankers. German Pat. Appl. 10010756 Al.

Konrad, R. (1998) . Verfahren zur Bewegungssteuerung fUr einen ankers eines elektromagnetishen Aktuators. German Pat. Appl.

19834548 Al.

Levine, Jean, Jacques Lottin and Jean-Christophe

Ponsart (1996). A nonlinear approach to the

control of magnetic bearings. IEEE Trans.

Contr. Syst. Technol. 4(5), 524-544.

Pischinger, F. and P. Kreuter (1984). Electromagnetically operating actuator. US Pat.

4,455,543.

Pischinger, M., W . Salber, F . van der Staay,

H. Baumgarten and H. Kemper (2000). Benefits of the electromechanical valve train in

vehicle operation. SAE 2000-01-1223.

Rassem, H. (2001) . Single-cylinder engine tests of

a motor-driven variable-valve actuator. SAE

2001-01-0241 .

Roschke, T. and M. Bielau (1995) . Verfahren

zur modellbasierten Messung und Regelung

von Bewegungen an elektromagnetischen Aktoren. German Pat. Appl. 19544207 Al .

Rossi, C. and A. Tonielli (2001). Method and device for estimating the position of an actuator

body in an electromagnetic actuator to control a valve of an engine. European Pat. Appl.

EP 1152129 Al.

Schmitz, G. (1995). Verfahren zur Regelung

der Ankerauftreffgeschwindigkeit an einen

elektromagnetischen Aktuator durch extrapolierende Abschatzung der Energieeinspeisung. German Pat. Appl. 19807875 Al.

Wang, Y., T. Megli, M. Haghgooie, K. Peterson

and A. Stefanopoulou (2002) . Modeling and

control of electromechanical valve actuator.

SAE 2002-01-1106.