PRODUCTION OF ACETALDEHYDE

SUBMITTED IN PARTIAL FULFILLMENT

OF THE REQUIREMENTS FOR THE DEGREE OF

Bachelor of Technology

In

Chemical Engineering

By

SUSHMITA SHARMA (091431)

VINAY JAISWAL (091434)

I

UNDER THE GUIDENCE OF

Dr.K. N. Gupta

SR.LECTURER

MAY, 2013

SUBMITTED TO

DEPARTMENT OF CHEMICAL ENGINEERING

JAYPEE UNIVERSITY OF ENGINEERING AND TECHNOLOGY,A.B.

ROAD, RAGHOGARH, DIST. GUNA -473226, M.P., INDIA2011-2012

i

JAYPEE UNIVERSITY OF ENGINEERING AND TECHNOLOGY

A.B. ROAD, P.B. No. 1, RAGHOGARH, DIST. GUNA (M.P.) INDIA

Phone: -7544 267051, 267310 – 14, Fax : 07544267011

This is to certify that the project work titled “PRODUCTION OF

ACETALDEHYDE”submitted by SUSHMITA SHARMA (ER. No. 091431) and VINAY

JAISWAL(ER. No. 091434)” in the partial fulfillment for the award of degree of B.Tech.in

Chemical Engineering, by Jaypee University of Engineering and Technology, Raghogarh,

Guna, M.P., has been carried out under my supervision at JUET Guna campus. This work has

not been submitted partially or wholly to any other university or institute for the award of any

other degree or diploma.

Signature of Guide

Dr. K. N. Gupta

Sr.Lecturer

Department of Chemical Engineering

Place: Guna

Date

ii

ACKNOWLEDGEMENT

We wish to express deep sense of gratitude and sincere thanks to our project supervisor Dr.

K.N.Gupta – Assistant Professor, Department of Chemical Engineering & Chemical

Technology for his valuable guidance, encouragement, suggestions, and moral support

throughout the period of this project work.

We express our thanks to Professor N. J. Rao – Vice Chancellor of Jaypee University for his

valuable suggestions. We would like to thank Professor K. K. Tiwari, who is associated with

JUET after his retirement from ICT Mumbai for his guidance and suggestions during this

project work.

We would like to thank Dr. G. K. Agrawal for his suggestions during this work. Our special

thank to Dr. Hari Mahalingam –Head of Chemical Engineering Department for providing all

the necessary facilities to complete this work.

We would like to thank Dr. B.K.Nandi, Dr. K.N.Gupta, Dr. Rajkumar Arya and other faculty

members as well, of Chemical Engineering Department for their support during this

work..We would also like to extend our thanks to Library staff for their continuous support

and all theinformation providers on the internet.

Finally we would like to thank our batch mates and family for the motivation and support

they haveprovided us.

Signature of students

Name of Students

Date

Sushmita Sharma

iii

Vinay Jaiswal

EXECUTIVE SUMMARY

The project deals with the production of Acetaldehyde. It is an organic compound with the

chemical formula CH3CHO.Acetaldehyde is a colorless, mobile liquid having a pungent

suffocating odor that is somewhat fruity and pleasant in dilute concentrations The process

technologies used for the production of Acetaldehyde is given below.

Process technologies:

Oxidation of ethylene

Oxidation of ethyl alcohol

Hydration of Acetylene

From saturated hydrocarbon

The economics of the various processes for the manufacture of acetaldehyde are strongly

dependent on the price of the feedstock used. Since 1960, the liquid-phase oxidation of

ethylene has been the process of choice. However, there is still commercial production by

the partial oxidation of ethyl alcohol, dehydrogenation of ethyl alcohol and the hydration

of acetylene. Acetaldehyde is also formed as a co product with ethyl alcohol and acetic

acid.

Process selected

Oxidation of Ethylene is selected for the production of acetaldehyde because currently, the

Wacker-Hoechst process accounts for 85 % of the worldwide production capacity for

acetaldehyde. Acetaldehyde yield almost equal (about 95%).Lower investment costs in the

single stageprocess, because of the need of only one reactor with conversion per pass: 35 45%

This method is technically simple, smooth in reaction, and high in selectivity. The favorable

economics of the process are due to the abundance of ethylene. It is regarded as the most

economic industrial process route, and has been widely used in many countries

Process Discription

There are two variations for the production of acetaldehyde by the oxidation of ethylene; the

two – stage process developed by Wacker – Chemie and the one – stage process developed

by Farbwerke Hoechst.

The single-stage manufacture of acetaldehyde by direct oxidation of ethylene in the gaseous

phase in the presence of palladium chloride and water is known. The process is generally

carried out in the following manner on an industrial scale: Ethylene is oxidized in a bubble

column reactor containing an aqueous solution of CuCl2, CuCl and PdCl2, with oxygen, in a

cyclic process at 400K. under a pressure of 3 bars (absolute pressure), By the term "singlestage manufacture" there is to be understood that the oxidation of the ethylene yielding

acetaldehyde and the reoxidation of the palladium chloride reduced in this process

(reoxidation being effected by CuCl2 which is converted into CuCl, the latter in its turn is

reoxidized by the oxygen) are carried out in one reactor. The gas current leaving the reactor

and containing steam, acetaldehyde, ethylene and small amounts of oxygen, carbon dioxide,

acetic acid, crotonaldehyde and chlorinated compounds (such as methyl chloride, ethyl

iv

chloride and chloroacetaldehydes) is cooled in a condenser to about 80° to 130° C., about.

The condensate formed thereby substantially consisting of water, small amounts of

acetaldehyde and acetic acid is generally recycled to the reactor. Small amounts of copper

oxalate and high molecular byproducts likewise formed remain persistent in the catalyst

solution whereas the volatile by-products in conjunction with the acetaldehyde and the

unreacted starting compounds leave the reactor. In order to avoid an accumulation of these

by-products a small amount of the liquid phase is withdrawn continuously from the reactor.

Next, this portion is released from pressure, whereby the dissolved low-boiling compounds

such as acetaldehyde, ethylene and carbon dioxide flash and are removed. The degassed

solution is conveyed to a regeneration vessel, where it is heated to a temperature from about

165° to 180° C.,. The regenerated solution is recycled to the reactor. The gas current leaving

the reactor, after having been cooled in the condenser, is generally cooled further to about 30°

to 80° C., in heat exchangers. Next, the acetaldehyde is washed out from the gas current in a

scrubber. The residual gas mainly consisting of ethylene, oxygen, carbon dioxide and inert

gas is recycled to the reactor, after having removed part of this gas (in order to avoid an

accumulation of carbon dioxide and inert gas) and after having added fresh ethylene. The

condensate formed in the heat exchangers and the aqueous acetaldehyde solution formed in

the scrubberare combined in a collecting vessel. This mixture designated as "crude aldehyde"

is conveyed to a two-stage distillation process. In this process the low-boiling compounds

(methyl chloride, ethyl chloride), and the dissolved gases such as ethylene and carbon dioxide

are obtained as the overhead in a first step by extractive distillation using water as an

extraction agent. The bottom product is passed to the second distillation step, where pure

acetaldehyde is obtained as the overhead product. A fraction containing mainly

crotonaldehyde is withdrawn as a sidestream. The high-boiling by-products (in particular

acetic acid and chloroacetaldehydes) and the water are withdrawn from the bottom. The

removed mixture is designated as "waste water".

v

INDEX

CONTENTS

Title page---------------------------------------------------------------------------------------------------i

Certificate-------------------------------------------------------------------------------------------------ii

Acknowledgment-------------------------------------- -------------------------------------------------iii

Executive Summary------------------------------------------------------------------------------------iv

CHAPTER 1: HISTORICAL PROFILE-----------------------------------------------------------1-2

1.1-History of acetaldehyde-----------------------------------------------------------------------------1

1.2-Natural occurrence-------------------------- --------------------------------------------------------2

CHAPTER 2: APPLICATIONS------------------------------------------------------------------------3

2.1-Traditional Applications-----------------------------------------------------------------------------3

2.2-Current Applications---------------------------------------------------------------------------------3

2.3-Acetaldehyde Grades--------------------------------------------------------------------------------3

CHAPTER 3: ECONOMIC SCENARIO----------------------------------------------------------4-7

3.1- Economic Aspect------------------------------------------------------------------------------------4

3.2-Demand and supply--------------------------------------------------------------------------------5-6

3.3-Manufacturers-----------------------------------------------------------------------------------------7

CHAPTER 4: PROPERTIES------------------------------------------------------------------------8-13

4.11-Physical properties----------------------------------------------------------------------------------8

4.2-Chemical properties------------------------------------------------------------------------------9-10

4.3-Environmental effects-----------------------------------------------------------------------------11

4.4-Health effects--------------------------------------------------------------------------------------12

4.5-Acute /fatal effects---------------------------------------------------------------------------------13

CHAPTER 5: MANUFACTURING PROCESSES -------------------------------------------14-20

5.1-Oxidation of Ethylene: ------------------------------------------------------------------------14-16

5.2-From Ethyl Alcohol----------------------------------------------------------------------------16-17

5.3-From Acetylene: --------------------------------------------------------------------------------17-18

5.4-From Saturated Hydrocarbons----------------------------------------------------------------18-19

5.5-Specifications, Analytical, and Test Methods---------------------------------------------------20

CHAPTER 6: PROCESS SELECTION-------------------------------------------------------------21

CHAPTER 7: MATERIAL AND ENERGY BALANCE------------------------------------22-38

7.1 Material balance---------------------------------------------------------------------------------22-30

7.2 Energy balance--------------------------------------------------- ------------------------------31-37

vi

7.3 Control strategy ---------------------------------------------------------------------------------38-39

CHAPTER 8: DETAILED EQUIPMENT DESIGN---------------------------------------------------------------40-51

8.1 Process Design Of Reactor ---------------------------------------------------------------------40

8.1.1Mechanical Design Of Reactor ------------------------------------------------------------40-42

8.3 Process design of Distillation column--------------------------------------------------------42-50

8.4 Process design of scrubber-------------------------------------------------------------------------51

8.4.1 Mechanical Design of Scrubber-----------------------------------------------------------------52

CHAPTER 9 : CAPITAL COST ESTIMATION--------------------------------------------------------------------53-64

9.1.1Cost of Reactor-------------------------------------------------------------------------------------53

9.1.2Cost of Absorber-------------------------------------------------------------------------------53-54

9.1.3 Cost of Distillation Column I-------------------------------------------------------------------54

9.1.4Cost of Distillation Column II------------------------------------------------------------------54

9.1.5 Cost of ethylene storage vessel-----------------------------------------------------------------55

9.1.6Cost of heat exchanger----------------------------------------------------------------------------55

9.2 Estimation of Capital Investment-------------------------------------------------------------55-56

9.2.1Estimation of Total Product Cost------------------------------------------------------------56-57

9.2.2 Direct Production cost----------------------------------------------------------------------------57

9.2.3 Plant overhead cost-----------------------------------------------------------------------------58

9.2.4 General Expenses-----------------------------------------------------------------------------58-59

9.2.5 Gross Earning Income---------------------------------------------------------------------------59

9.3 Hazop analysis of reactor----------------------------------------------------------------------60-62

9.4 Plant layout --------------------------------------------------------------------------------------63-64

10. Conclusion & Recommendation----------------------------------------------------------------65

References-----------------------------------------------------------------------------------------------66

Appendix-1------------------------------------------------------------------------------------------67-73

vii

CHAPTER-1

HISTORICAL PROFILE

1.1-History of acetaldehyde:

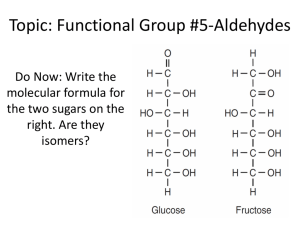

Ethanal is one of the oldest known aldehydes and was first made in 1774 by Swedish chemist

Carl Wilhelm Scheele by the action of manganese dioxide and sulfuric acid on ethanol.

Its structure was not completely understood until 60 years later, when Justus von Liebig

determined the constitution of ethanal, described its preparation from ethanol, and gave the name

of aldehydes to the chemical group. The formation of acetaldehyde by the addition of water to

acetylene was observed by Kutscherow in 1881.

Acetaldehyde was first used extensively during World War I as an intermediate for making

acetone from acetic acid. Ethanal (acetaldehyde) is the name of the shortest carbon chain

aldehyde. It has a central carbon atom that has a double bond to an oxygen atom (the carbonyl

group), a single bond to a hydrogen atom, and a single bond to another carbon atom connected to

three hydrogen atoms (methyl group). Its chemical formula is written as CH3CHO. [1]

Acetaldehyde

1.2-Natural occurrence:

Acetaldehyde is a simple, naturally-occurring, organic chemical present in many ripe

fruits,apples, grapes, and citrus fruits (up to 230 ppm). It is produced during the fermentation of

sugar to alcohol, and is a natural constituent of butter, olives, frozen vegetables, and cheese. It

forms in wine and other alcoholic beverages after exposure to air (up to 140 ppm). It even

occurs as an intermediate in the metabolism of sugars in the body and hence can be found in

human blood.

Acetaldehyde is listed as an approved food additive and is used to enhance citrus flavours,

helping to create natural, fruity tastes and fragrances. As a flavour ingredient, it can be found in

ice creams, sweets, baked goods, chocolates, rum, and wine.

1

In nature acetaldehyde is found in oak and tobacco leaves, in the fruity aromas of apple,

raspberry, strawberry, pear and pineapple. It is also found in the distillation waters of orris,

cumin, chenopodium, essential oils of Magnolia grandijlora, rosemary, clary sage, daffodil, bitter

orange, camphor angelica, fennel mustard, whiskey, rose wine and rum.

Acetaldehyde is a natural component of, broccoli, coffee, grapefruit, grapes, lemons,

mushrooms, onions, oranges, peaches, pears, pineapples, raspberries, and strawberries. It has

been detected in the essential oils of alfalfa, rosemary, balm, clary sage, daffodil, bitter orange,

camphor, angelica, fennel, mustard, and peppermint.

Acetaldehyde (systematically ethanal) is an organic chemical compound with the formula

CH3CHO, sometimes abbreviated by chemists as MeCHO (Me = methyl). It is one of the most

important aldehydes, occurring widely in nature and being produced on a large scale industrially.

Acetaldehyde occurs naturally in coffee and bread and is produced by plants as part of their

normal metabolism. It is also produced by oxidation of ethylene and is popularly believed to be a

cause of hangovers from alcohol consumption through drinking spirits. Pathways of exposure

include air, water, land or groundwater as well as drink and smoke. [2]

2

CHAPTER- 2

APPLICATIONS

2.1-Traditional application:

Traditionally, acetaldehyde was mainly used as a precursor to acetic acid. This application has

declined because acetic acid is made more efficiently from methanol by the Monsanto and Cativa

processes. In terms of condensation reactions, acetaldehyde is an important precursor to pyridine

derivatives, pentaerythritol, and crotonaldehyde. Urea and acetaldehyde combine to give a useful

resin. Acetic anhydride reacts with acetaldehyde to give ethylidene diacetate, a precursor to vinyl

acetate, which is used to produce polyvinyl acetate.

2.2-Current application:

Acetaldehyde is used as an intermediate in the production of acetic acid, acetic

anhydride, cellulose acetate, vinyl acetate resins, acetate esters, pentaerythritol, synthetic

pyridine derivatives, terephthalic acid and peracetic acid.

Other uses of Acetaldehyde include: in the silvering of mirrors; in leather tanning; as a

denaturant for alcohol; in fuel mixtures; as a hardener for gelatin fibres; in glue and

casein products; as a preservative for fish and fruit; in the paper industry; as a synthetic

flavouring agent; and in the manufacture of cosmetics, aniline dyes, plastics and synthetic

rubber (SCCNFP 2004).

Acetaldehyde is an ingredient contained used in many fragrance and flavour compounds.

It may be found in fragrances used in decorative cosmetics, fine fragrances, shampoos,

toilet soaps and other toiletries, in flavours of oral care products as well as in noncosmetic products such as household cleaners and detergents. Low levels of

Acetaldehyde are reported to occur in several essential oils.[3]

2.3- Acetaldehyde grade[4]

Table 2.1-Acetaldehyde grade

Grade

00070Acetaldehyde

Purity

anhydrous, ≥99.5% (GC)

00071Acetaldehyde

ReagentPlus, ≥99.0% (GC

W200336Acetaldehyde

natural, ≥99%, FCC, FG

W200301Acetaldehyde

≥99%, FCC

3

CHAPTER 3

ECONOMIC SCENARIO

3.1- World Economic Aspect

Acetaldehyde is produced throughout the world primarily from ethylene, although some is still

derived from ethanol and acetylene. Demand for acetaldehyde worldwide has continued to

decrease primarily as a result of less consumption for acetic acid manufacture, as the industry

continues to move toward the more efficient and lower-overall-cost carbonylation-of-methanol

process. For example, all manufacture of acetic acid from acetaldehyde in North America has

been discontinued and in Europe significant capacity for this process has been permanently shut

down. Acetaldehyde use for acetic acid manufacture in Asia continues but is under pressure from

the ongoing establishment of methanol carbonylation technology.

Demand has also significantly declined in the production of plasticizer alcohols, which has

totally switched to oxo processes. As a result of these process replacements, acetaldehyde

capacity has been shut down in Western Europe and in other areas, such as Mexico. In addition

to the disappearance of use for acetic acid and plasticizer alcohols, acetaldehyde demand has also

declined in the last few years because of mature end-use markets and the effects of the economic

downturn on these acetaldehyde-derived products. There has also been continued substitution for

acetaldehyde-based chemistries with other materials, which has further contributed to the drop in

acetaldehyde use.

The following pie chart shows world consumption of acetaldehyde:

Figure shows that China consumed 30% , Europe and Japan 20% each and Indian and rest of

world 15% a piece of the total acetaldehyde produced in year 2009.

4

Consumption in China is expected to grow over 5% annually in the next five years.

Acetaldehyde use for acetic acid production will increase, although this will be more of a

recovery back to the pre-2009 level. Actual growth might be limited because of acetic acid

production from the methanol carbonylation process. Strong growth of over 6% annually will

actually occur in pyridine production and there will be moderate growth for use in

pentaerythritol, as alkyd resin enamel and varnish production goes up. Other uses are generally

mature, such as sorbic acid production.

Indian consumption is anticipated to have moderate growth of over 3% annually in the next

several years. Acetaldehyde demand for acetic acid production will grow 3–4% per year, while

consumption for pyridines is expected to return to the 2008 level. Other uses for acetaldehyde

will also increase 3–4% annually.

Overall, the global market for acetaldehyde is expected to grow 2–3% annually during 2009–

2014. However, some of this growth is actually a recovery from the significant decline

experienced in 2009 (for example, China's use in the acetic acid market). Major regions

including Japan, Western Europe and the United States will have low growth because of no use

or no growth for acetic acid production, minimal growth in other acetaldehyde-consuming

products, or continued product replacement of materials that consume acetaldehyde. [5]

3.2-Demand and Supply

World acetaldehyde market will reach 1.26 million tons by 2012, according to new report by

global industry analysts.

With acetic acid manufacturing processes migrating from acetaldehyde based production

techniques towards carbonylation-of-methanol, the world acetaldehyde market is projected to

witness a steady deterioration in consumption. Global consumption of acetaldehyde is projected

to average to 1.26 million tons by the year 2012. Exacerbating the decline in demand and

consumption is the lack of new high-volume applications of acetaldehyde, and closures of aceticacid-from-acetaldehyde operations across the world.

The downturn in the acetic acid industry, the largest end-use market for acetaldehyde, coupled

with the phasing out of acetic acid production from acetaldehyde, is expected to result in huge

declines in consumption. In North America, acetic acid manufacturers have shut down their

operations, while in Europe; significant reductions in capacities are underway. Scaling back of

production activities is expected in Latin America and Asia Pacific in the upcoming years.

Presently however, Asia-Pacific represents the largest market for acetaldehyde with growth

stemming from the use of acetaldehyde in producing synthetic pyridines, pentaerythritol,

glyoxal/glyoxalin acid, penta-erithryte, and crotonaldehyde. Within Asia, China has emerged

into the largest consumer of acetaldehyde in the world, with the country representing the only

market where new acetaldehyde capacity installations have occurred in the recent past.

5

As stated by the recent report published by Global IndustryAnalysts, Inc., world acetaldehyde

market is dominated by Asia-Pacific, and Europe, with a combined share of 68.4% estimated in

the year 2008.

World consumption of acetaldehyde in acetane hydride end-use market, and acetic ether end-use

markets, is projected to decline by 2%, and 1.3% respectively during the period 2001 to 2010.

Positive growth is expected to stem from 1,3 butanediol end-use market , with world

consumption slated to rise of 2.7% during the period 2011 to 2015. In Asia-Pacific, consumption

of acetaldehyde in crotonaldehyde end-use market is projected to grow in excess of 3.7% over

the period 2011 through 2015.

In Europe, Germany ranks as the largest market for acetaldehyde with a 30.9% share estimated

in the year 2008, followed by France, United Kingdom and Italy. [6]

Table-3.1-Important producers and their production capacities (103 t) are listed in the

following [7]

Year

1990

1995

2000

2003

USA

283

111

155

142

W.Europ

603

668

370

212

Mexico

190

271

113

57

Japan

384

395

401

362

China

Total

1460

1845

1439

1273

400

400

500

3.3-Manufacturers

Acetaldehyde is produced by 3 companies in Germany, 2 companies in Spain & 1 company each

in France, Italy, & Switzerland. Total acetaldehyde production in western Europe on January 1,

1983 was more than 0.5 million tons, & production capacity is estimated to have been nearly 1

million tons. Most of this was based on the catalytic oxidation of ethylene; less than 10% was

based on partial oxidation of ethanol, & a very small percentage was based on the hydration of

acetylene. ... /It/ is produced (by oxidation of ethylene) by 7 companies in Japan. Their combined

production is est to have been 278,000 tons in 1982, down from an est 323,000 tons in 1981.

Japanese imports & exports of acetaldehyde are negligible.

Table-3.2-Manufacturers of Acetaldehyde in india

PRODUCT

COMPANY NAME

Ashok Organic Inds. Ltd. Ankleshwar Gujarat

Unit-II.

King Chemicals Ltd. Madras

Trichy Distilleries & Chemicals Ltd., Trichy.

Ashok Organic Inds. Ltd., Ankleshwar, Gujarat

Unit-III.

6

Acetaldehyde

CAPACITY

(TPA)

3600

Acetaldehyde

Acetaldehyde

Acetaldehyde

6000

6000

5400

Ashok Organics India Ltd. Ankleshwar, Unit-I.

Cellulose Products of India Ltd., Ankleshwar.

EID Parry (India) Ltd. Madras.

Gujchem Distillers Ltd. Ankleshwar, Gujarat.

Indian Drugs & Pharmaceuticals Ltd., Muzafarpur,

Bihar.

Indian Organics Ltd. Khopoli (M.S.)

Industrial Organics Ltd. Ludhiana.

Kapchem Ltd. Bangalore.

Laxmi Organic Industries Ltd., Maharashtra.

Pentokey Organy (India) Pvt. Ltd. Maharashtra

Polychem Ltd., Nira, Pune.

Sahakar Maharshi Shankarrao Mohite-Patil

Sahakari Sakhar Karkhana Ltd., Shankarnagar,

Akluj, Maharashtra.

Southern Organic Inds. Ltd. Bangalore.

7

Acetaldehyde

Acetaldehyde

Acetaldehyde

Acetaldehyde

Acetaldehyde

2400

3000

9000

3000

7500

Acetaldehyde

Acetaldehyde

Acetaldehyde

Acetaldehyde

Acetaldehyde

Acetaldehyde

Acetaldehyde

3000

3600

3500

4800

3600

6000

6000

Acetaldehyde

2400

CHAPTER 4

PROPERTIES

4.1-Physical properties:

Acetaldehyde is a colorless, mobile liquid having a pungent suffocating odor that

is somewhat fruity and pleasant in dilute concentrations. Some physical properties of

Acetaldehyde is given in Table 2.

Table-4.1 Physical properties [8]

Molecular formula

Chemical Structure

Physical State

Molecular Weight

Melting Point

Boiling Point

Water Solubility

Density

Vapor Density (air = 1)

Vapor Pressure

Reactivity

Flash Point

Surface tension at 20 °C,mN/ma

Coefficient of expansion per °C (0-30

°C)

Latent heat of vaporization, kJ/mol

Heat of combustion of liquid at constant

pressure, kJ/mol c

C2H4O

CH3-CHO

colorless liquid

44.05

-123.5øC

21øC at 760 mm Hg

miscible

d16/4, 0.788

1.52

740 mm Hg @ 20øC

highly reactive

-36øF (-38øC)

21.2

0.00169

Heat of formation at 273 K, kJ/mol c

Critical temperature, °C

Critical pressure, MΡa (atm)

Ignition temperature in air, °C

Explosive limits of mixtures with air, vol

%

Acetaldehyde

-165.48

181.5

6.40(63.2)

165

4.5 – 60.5

25.71

11867.9

8

4.2 Chemical properties: [9]

Acetaldehyde is a highly reactive compound exhibiting the general reactions ofaldehydes; under

suitable conditions, the oxygen or any hydrogen can be replaced.Acetaldehyde undergoes

numerous condensation, addition, and polymerization reactions.

4.2.1 Decomposition:

Acetaldehyde decomposes at temperatures above 400°C, forming principally methane and

carbon monoxide. The activation energy of the pyrolysis reaction is 97.7 kJ/mol (408.8

kcal/mol). There have been many investigations of the photolytic and radical – induced

decomposition of acetaldehyde and deuterated acetaldehydes.

4.2.2 The Hydrate and Enol Form:

In aqueous solutions, acetaldehyde exists in equilibrium with the hydrate,CH3CH(OH)2. The

degree of hydration can be computed from an equation derived by Bell and Clunie. The mean

heat of hydration is –21.34 kJ/mol(89.29kcal/mol); hydration has been attributed to hyper

conjugation. The enol form, vinyl alcohol (CH2 = CHOH) exists in equilibrium with

acetaldehyde to the extent of approximately one molecule per 30,000. Acetaldehyde enol has

been acetylated with ketene to form vinyl acetate.

4.2.3 Oxidation:

Acetaldehyde is readily oxidized with oxygen or air to acetic acid, acetic anhydride, and

peracetic acid (see Acetic acid and derivatives). The principal product isolated depends on

reaction conditions. Acetic acid is produced commercially by the liquid – phase oxidation of

acetaldehyde at 65°C with cobalt or manganese acetate dissolved in acetic acid as a catalyst.

Liquid – phase oxidation of acetaldehyde in the presence of mixed acetates of copper and cobalt

yields acetic anhydride.

4.2.4 Reduction:

Acetaldehyde is readily reduced to ethanol. Suitable catalysts for vapor-phase hydrogenation are

supported nickel and copper oxide. Oldenberg and Rose have studied the kinetics of the

hydrogenation of acetaldehyde over a commercial nickel catalyst.

4.2.5 Polymerization:

Paraldehyde,2,4,6- trimethyl – 1,3,5 – trioxan, a cyclic trimer of acetaldehyde is formed when a

mineral acid, such as sulfuric, phosphoric, or hydrochloric acid, is added to acetaldehyde.

9

Paraldehyde can also be formed continuously by feeding acetaldehyde as a liquid at 15 - 20°C

over an acid ion – exchange resin. Depolymerization of paraldehyde occurs in the presence of

acid catalysts. After neutralization with sodium acetate, acetaldehyde and paraldehyde are

recovered by distillation. Paraldehyde is a colorless liquid, boiling at 125.35 °C at 101 kPa (1

atm).

4.2.6 Reactions with aldehydes and ketones:

The base catalyzed condensation of acetaldehyde leads to the dimmer, acetaldol, which can be

hydrogenated to form 1,3 butandiol or dehydrated to form crotonaldehyde. Crotonaldehyde can

also be made directly by the vapor-phase condensation of acetaldehyde over a catalyst.

Crotonaldehyde was formerly an important intermediate in the production of butyraldehyde,

butanol, and 2-ethylhexanol. However it has been replaced completely with butyraldehyde from

the oxo process. A small amount of crotonaldehyde is still required for the production of

crotonic acid. Acetaldehyde forms aldols with other carbonyl compounds containing active

hydrogen atoms.

4.2.7 Reactions with Ammonia and Amines:

Acetaldehyde readily adds ammonia to form acetaldehyde ammonia. Diethyl amine is obtained

when acetaldehyde is added to a saturated aqueous or alcoholic solution of ammonia and the

mixture is heated to 50-750C in the presence of a nickel catalyst and hydrogen at 1.2 MPa

(12atm). Pyridine and pyridine derivates are made from paraldehyde and aqueous ammonia in

the presence of a catalyst at elevated temperatures; acetaldehyde may also be used by the yields

of pyridine are generally lower than when paraldehyde is the staring material. Levy and Othmer

have studied the vapor- phase reaction of formaldehyde, acetaldehyde, and ammonia at 3600C

over oxide catalysts; a 49% yield of pyridine and picolines was obtained using an activated

silica-alumina catalyst. Brown polymers result when acetaldehyde reacts with ammonia or

amines at a PH of 6-7 and temperature of 3-250C. With acetaldehyde, a primary amines can be

condensed to Schiff bases: CH3CH=NR, the schiff base rivets to the starting materials in the

presence of acids.

4.2.8 Reactions with Alcohols and Phenols:

Alcohols add readily to acetaldehyde in the presence of a trace of mineral acid to form acetals;

eg, ethanol and acetaldehyde form diethyl acetal. Similarly, cyclic acetals are formed by the

reactions with glycols and other polyhydroxy compounds; eg, the reaction of ethylene glycol and

acetaldehyde gives 2 – methyl – 1,3 – dioxolane.

4.2.9 Reactions with Halogens and Halogen compounds:

Halogens readily replace the hydrogen atoms of the methyl group: eg, chlorine reacts with

acetaldehyde or paraldehyde at room temperature to give chloroacetaldehyde; increasing the

temperature to 700-8000C gives dichloroacetaldehyde; and at a temperature of 80-900C chloral is

formed. The catalytic chlorination with an antimony powder or aluminum chloride ferric

chloride has been described.

10

4.3 Environmental effects: [10]

4.3.1 Environmental Release:

Acetaldehyde is released into air or wastewater from facilities producing or using the

chemical. Acetaldehyde is also released to the environment from the combustion and photooxidation of hydrocarbons. Acetaldehyde is an intermediate product of respiration in higher

plants and occurs naturally in many foods, such as ripe fruits that have tart tastes before

ripening, and coffee. Acetaldehyde is a component of cigarette smoke.

In 1992, releases of acetaldehyde to environmental media, as reported to the Toxic

Chemical Release Inventory by certain types of U.S. industries, totaled about 8.4 million pounds:

6.42 million pounds to the atmosphere; 1.9 million pounds to underground injection sites;

77,188 pounds to surface water discharges; and 289 pounds to land.

Concentrations of acetaldehyde measured in air samples taken from different locations vary,

depending on several conditions, including weather. The chemical has been detected in ice fog,

rain, cloud mist, and fog.

4.3.2 Transformation/Persistence:

4.3.2.1 Air

In air (at 25øC), acetaldehyde reacts with OH radicals, NO3, singlet oxygen, and NO2 The

estimated half-life for the reaction of acetaldehyde with OH produced by UV light is 6.2

hours; the products of this reaction include peroxyacetylnitrate (PAN), methyl nitrate,

methyl nitrite, and nitric acid . Acetaldehyde absorbs UV light at wavelengths of 290 to

342 nm, indicating some potential for photolysis. The photolytic half-lives for acetaldehyde

are about 34 hours in the summer and 296 hours in winter at 55ø c

4.3.2.2 Soil

Acetaldehyde will volatilize rapidly in near surface and surface soils or leach into the ground, or

undergo microbial degradation. Acetaldehyde is not expected to adsorb to soils, other than

those containing montmorillonite clay.

4.3.2.3 Water

If released to water, acetaldehyde will rapidly biodegrade or volatilize (for a typical river, the

half-life is 9.3 hours). Laboratory tests demonstrate that acetaldehyde is easily biodegraded (1)

by acclimated sludge and sewage with theoretical biological oxygen demand (BOD)

11

4.4 Health effects:

Acetaldehyde is the major metabolite of ethanol. Many of the adverse effects of ethanol are

attributed to acetaldehyde. Direct administration of acetaldehyde to rats has established alcohol

dependency.

Pharmacokinetics:

4.4.1 Absorption –

Acetaldehyde is rapidly absorbed by oral and respiratory routes. Estimated half-lives of

acetaldehyde in circulating blood have been reported as <15 minutes and 3.1 minutes.

4.4.2 Distribution –

Experimental studies indicate that, following inhalation or oral exposure, sufficient first-pass

metabolism occurs in the liver and respiratory tract to limit acetaldehyde access to the systemic

circulation. However, acetaldehyde was detectable in the liver, blood, kidney, spleen, heart, and

bone of rats exposed to the 20 mM vapor for 1 hour and in maternal and embryonic tissues

following administration (route unspecified) of >5 g/kg ethanol to pregnant mice

4.4.3 Metabolism –

Acetaldehyde is metabolized (mainly in mammalian liver) to acetic acid by aldehyde

dehydrogenase. The rate of metabolism to acetic acid varies, but it is generally considered to be

rapid. Acetic acid enters the metabolic pool of intermediary metabolism and is used in the

production of carbon dioxide and water or in cellular synthesis of cholesterol, fatty acids, and

other tissue constituents. In vitro, acetaldehyde formed adducts with cytosine- and purinecontaining nucleotides.

4.4.4 Excretion –

Because the major metabolite of acetaldehyde enters into intermediary metabolism, the excretion

of the parent compound or its metabolites may be limited. Acetaldehyde has been detected in

expired air (usually no more than 5%) but only its metabolites have been detected in the urine

.

4.5-Acute /fatal effects:

Humans exposed acutely to moderate concentrations of acetaldehyde experience irritation of the

eyes and respiratory tract and altered respiratory function. Animals exposed to moderate to high

concentrations exhibit skin and eye irritation.

4.5.1 Humans –

12

The acute irritation of acetaldehyde is characterized by the following: eye irritation in sensitive

individuals, at 25 ppm for 15 minutes; eye irritation, at 50 ppm for 15 minutes; irritation of

respiratory tract, at 134 ppm for 30 minutes.

4.5.2 Animals –

The oral LD50 value for the rat is 1.93 g/kg .The inhalation LC50 for rats exposed for 30

minutes was 20,000 ppm . Acetaldehyde elicited mild skin irritation (open test) and severe eye

irritation in rabbits.

4.6 Handling storage and shipping information: [11]

Acetaldehyde should be stored in the dark in tightly closed containers, under cool and fireproof

conditions with the addition of an inhibitor. It must be stored away from substances with which it

can react, such as halogens, oxidative substances, amines, organic substances, caustic solutions,

concentrated sulfuric acid.

It is suggested that the photo-induced atmospheric removal of acetaldehyde occurs

predominantly via radical formation. Photolysis is expected to contribute another substantial

fraction to the removal process. Both processes cause a reported daily loss of about 80% of

atmospheric acetaldehyde emissions. Reported half-lives of acetaldehyde in water and air are 1.9

h and 10-60 h, respectively.

During transport, storage and fur-ther processing, Acetaldehyde must be blanketed with

protective gas (nitrogen). It is transported in pressure containers (rail tankers). Acetaldehyde is

stored in pressure containers or at zero pressure in refrigerated containers. Acetaldehyde may be

stable in storage under these conditions.

Around 80% of the total production of acetaldehyde is made by liquid-phase oxidation of

ethylene using a catalytic solution of palladium and copper chlorides. The remainder is produced

by the oxidation of ethanol and the hydration of acetylene. Intercompartmental transport of

acetaldehyde is expected to be limited because of its high reactivity. However, some transfer of

acetaldehyde to air from water and soil is expected, because of its high vapour pressure and low

sorption coefficient.

13

CHAPTER - 5

MANUFACTURING PROCESSES

Manufacturing processes

Oxidation of ethylene

Oxidation of ethyl alcohol

Hydration of Acetylene

From saturated hydrocarbon

The economics of the various processes for the manufacture of acetaldehyde are strongly

dependent on the price of the feedstock used. Since 1960, the liquid-phase oxidation of ethylene

has been the process of choice. However, there is still commercial production by the partial

oxidation of ethyl alcohol, dehydrogenation of ethyl alcohol and the hydration of acetylene.

Acetaldehyde is also formed as a co product with ethyl alcohol and acetic acid.

5.1 Oxidation of Ethylene: [12]

5.1.1 Raw material:In this process ethylene and oxygen used as raw material. Where Ethylene is obtained from

petrochemical industry and oxygen is taken from air.

Wacker – Chemie and Farbwerke Hoechst, developed the direct liquid phase oxidation of

ethylene in 1957 – 1959. The catalyst is an aqueous solution of PdCl2 and CuCl2. In 1894, F.C.

Phillips observed the reaction of ethylene with an aqueous palladium chloride solution to form

acetaldehyde.

C2H4+PdCl2 + H2O CH3CHO +Pd +2HCl

The metallic palladium is reoxidized to PdCl2 with CuCl2 and the cuprous chloride formed is

reoxidized with oxygen or air.

Pd + 2CuCl2 PdCl2 +2CuCl

14

2CuCl+1/2 O2 + 2HCl 2CuCl2 + H2O

The net result is a process in which ethylene is oxidized continuously through a series of

oxidation – reduction reactions.

C2H4 + ½ O2 CH3CHO

∆H = -244 kJ(-57.84 kcal/kmol)

5.1.2 Process Description.

There are two variations for the production of acetaldehyde by the oxidation of ethylene; the two

– stage process developed by Wacker – Chemie and the one – stage process developed by

Farbwerke Hoechst.

The single-stage manufacture of acetaldehyde by direct oxidation of ethylene in the gaseous

phase in the presence of palladium chloride and water is known (cf. Jira, Blau, Grimm;

Hydrocarbon Processing, March 1976, pages 97 to 100). The process is generally carried out in

the following manner on an industrial scale: Ethylene is oxidized in a bubble column reactor

containing an aqueous solution of CuCl2, CuCl and PdCl2, with oxygen, in a cyclic process at

400K. under a pressure of 3 bars (absolute pressure), By the term "single-stage manufacture"

there is to be understood that the oxidation of the ethylene yielding acetaldehyde and the

reoxidation of the palladium chloride reduced in this process (reoxidation being effected by

CuCl2 which is converted into CuCl, the latter in its turn is reoxidized by the oxygen) are carried

out in one reactor. The gas current leaving the reactor and containing steam, acetaldehyde,

ethylene and small amounts of oxygen, carbon dioxide, acetic acid, crotonaldehyde and

chlorinated compounds (such as methyl chloride, ethyl chloride and chloroacetaldehydes) is

cooled in a condenser to about 80° to 130° C., about. The condensate formed thereby

substantially consisting of water, small amounts of acetaldehyde and acetic acid is generally

recycled to the reactor. Small amounts of copper oxalate and high molecular byproducts likewise

formed remain persistent in the catalyst solution whereas the volatile by-products in conjunction

with the acetaldehyde and the unreacted starting compounds leave the reactor. In order to avoid

an accumulation of these by-products a small amount of the liquid phase is withdrawn

continuously from the reactor. Next, this portion is released from pressure, whereby the

dissolved low-boiling compounds such as acetaldehyde, ethylene and carbon dioxide flash and

are removed. The degassed solution is conveyed to a regeneration vessel, where it is heated to a

temperature from about 165° to 180° C.,. The regenerated solution is recycled to the reactor. The

gas current leaving the reactor, after having been cooled in the condenser, is generally cooled

further to about 30° to 80° C., in heat exchangers. Next, the acetaldehyde is washed out from the

gas current in a scrubber. The residual gas mainly consisting of ethylene, oxygen, carbon dioxide

and inert gas is recycled to the reactor, after having removed part of this gas (in order to avoid an

accumulation of carbon dioxide and inert gas) and after having added fresh ethylene. The

condensate formed in the heat exchangers and the aqueous acetaldehyde solution formed in the

scrubberare combined in a collecting vessel. This mixture designated as "crude aldehyde" is

15

conveyed to a two-stage distillation process. In this process the low-boiling compounds (methyl

chloride, ethyl chloride), and the dissolved gases such as ethylene and carbon dioxide are

obtained as the overhead in a first step by extractive distillation using water as an extraction

agent. The bottom product is passed to the second distillation step, where pure acetaldehyde is

obtained as the overhead product. A fraction containing mainly crotonaldehyde is withdrawn as a

sidestream. The high-boiling by-products (in particular acetic acid and chloroacetaldehydes) and

the water are withdrawn from the bottom. The removed mixture is designated as "waste water".

In the two – stage process ethylene and oxygen (air) react in the liquid phase in two stages. In the

first stage ethylene is almost completely converted to acetaldehyde in one pass in a tubular plugflow reactor made of titanium. The reaction is conducted at 125-1300C and 1.13 Mpa (150 psig)

palladium and cupric chloride catalysts. Acetaldehyde produced in the first reactor is removed

from the reaction loop by adiabatic flashing in a tower. The flash step also removes the heat of

reaction. The catalyst solution is recycled from the flash – tower base to the second stage (or

oxidation) reactor where the cuprous salt is oxidized to the cupric state with air. The high

pressure off – gas from the oxidation reactor, mostly nitrogen, is separated from the liquid –

catalyst solution and scrubbed to remove acetaldehyde before venting. A small portion of the

catalyst stream is heated in the catalyst regenerator to destroy undesirable copper oxalate. The

flasher overhead is fed to a distillation system where water is removed for recycle to the reactor

system and organic impurities, including chlorinated aldehydes, are separated from the purified

acetaldehyde product.

While according to the two-stage method, the ethylene reaction and the oxidation reaction

proceed in separate reactors. However, this two-stage variant of the method requires a catalyst

circulation entailing high energy consumption and has technically been less frequently realized

than the single-stage variant.

This method is technically simple, smooth in reaction, and high in selectivity. The favorable

economics of the process are due to the abundance of ethylene. It is regarded as the most

economic industrial process route, and has been widely used in many countries.

Flow sheet-5.1- Production of acetaldehyde from oxidation of ethylene

16

5.2 From Ethyl Alcohol: [13]

Acetaldehyde is produced commercially by the catalytic oxidation of ethyl alcohol. Passing

alcohol vapors and preheated air over a silver catalyst at 4800C carries out the oxidation.

CH3CH2OH + ½ O2 CH3CHO + H2O, ∆H = 242 kj/mol (57.84 kcal / mol)

With a multitubular reactor, conversions of 74-82% per pass can be obtained while generating

steam to be used elsewhere in the process.

Acetaldehyde also, produced commercially by the dehydrogenation of ethyl alcohol.

Reaction:

C2H5OH CH3CHO + H2

Catalyst: Cu -Co-Cr2O3

Temperature: 280 – 3500 C.

5.2.1-Process Description:

The following section will describe a silver process for acetaldehyde production from ethanol

.Air and preheated ethanol goes into a saturator. The air leaving is saturated with ethanol and

overheated before entering the reactor. The main reactions that take place are:

C2H5OH + ½ O2 → CH3CHO + H2O

C2H5OH → CH3CHO + H2

The by-products are formed according to following reactions:

C2H5OH + O2 → CH3COOH + H2O

C2H5OH + ½ O2 → CH4 + CO + H2O

C2H5OH + 2 O2 → 2 CO2 + 3 H2O

Ethanol is mixed with air and passed over a silver catalyst at 500 – 650 ◦C in the reactor .The

high temperature gas (acetaldehyde and unconverted alcohol) from the outlet of oxidizer is

cooled and condensed, then sent to scrubber to absorb acetaldehyde and unconverted ethanol.

Nitrogen hydrogen, methane, carbon monoxide and carbondioxide gas and other inert gases are

discharged from the top of the tower.. The diluted acetaldehyde solution at the bottom of the

scrubber, which contains acetaldehyde, alcohol, acetic acid, and water, is sent to the distillation

tower after heating, the gas phase fraction from the tower top, after condensation, is partly

collected, which is 99% acetaldehyde and the most portion is refluxed back.The ethanol and

water solution discharged from the bottom of the distillation tower is pressed into ethanol

recovery tower. where ethanol is separated from butanol, ethyl acetate, and most of the water.

These impurities exit in bottom Stream and are sent to waste treatment. The distillate consists of

an 85-wt.% solution of ethanol, which is then recycled back in the feed.

17

Flowsheet-5.2 for Acetaldehyde production from oxidation of Ethanol

5.3 From Acetylene:

[14]

Acetylene used as raw material for producing acetaldehyde in petrochemical industries.

In theory, there are two methods for this process to take place.

.Using solid catalyst in vapour phase system for acetylene hydration.

.by using a mercury-ion(liquid) catalyst in liquid phase for hydration of acetylene.

In fact, acetaldehyde is also manufacture from vinyl ethers, ethyl alcohol and ethylene.Industrial

process of producing acetaldehyde by hydration of acetylene using mercury-iron catalyst in

liquid phase is much simpler in construction and handling the operation.

5.3.1 Process Description:

A special designed hydrator converts acetylene to acetaldehyde by managing following chemical

reactions.

C2H2 + H2O → CH3CHO + 151 KCal

The hydrator is operated at 1.5 to 2.5 atm pressure and 80-100 oC temperature. Acetylene is fed

continuously through the liquid catalyst. The temperature is maintained by steam, it is injected

at the bottom of the column. The hydrator is made of stainless steel or with ferrosilicon. The top

stream of the hydrator is sent to a cooler. All the water vapour is condensed and recycled. The

second cooler takes the outlet from the first one. Acetaldehyde is condensed along with trace of

water. Unreacted acetylene and non-condensable vapour is feed to a water scrubber. The water

scrubber is operated at temperature of 10 oC. Traces of acetaldehyde and water-soluble

compounds are scrubbed down. Remaining gases are used as fuel or recycled to the dehydrator.

18

The liquid catalyst is a solution made of mercury (II) sulphate dispersed in sulphuric acid. As

acetaldehyde is good reducing agent it reduces Hg(II) to Hg(I) and finally reducing Hg(I) to Hg.

2Hg2SO4 + H2O + CH3CHO → Hg2SO4 + H2SO4 + CH3COOH

Hg2SO4 + H2O + CH3CHO → 2Hg + H2SO4 + CH3COOH

Fluidized bed type equipment is used as hydrator. Even zinc oxide, magnesium oxide and iron

oxide are used in place of mercury.

In general, calculations 680 kg of acetylene, 0.1 kg of mercury are consumed to produce one ton

of acetaldehyde. The conversion of this process is about 50-60% per pass. Catalyst is regenerated

through the process.

Flow sheet-5.3 Production of acetaldehyde by liquid phase reaction of acetylene

5.4 From Saturated Hydrocarbons: [15]

Acetaldehyde is formed as a co product in the vapor – phase oxidation of saturated

hydrocarbons, such as butane or mixtures containing butane, with air or, in higher yield, oxygen.

Oxidation of butane yields acetaldehyde, formaldehyde, methanol, acetone, and mixed solvents

as major products; other aldehydes, alcohols, ketones, glycols, acetals, epoxides, and organic

acids are formed in smaller concentrations. This is of historic interest. Unlike the acetylene route,

it has almost no chance to be used as a major process. From synthesis Gas: A rhodium-catalyzed

process capable of converting synthesis gas directly into acetaldehyde in a single step was

reported in 1974 (84-85).

CO + H2 CH3CHO + other products.

19

The process comprises passing synthesis gas over 5% rhodium on SiO2 at 3000C and 2.0 Mpa

(20 atm). The principal co products are acetaldehyde, 24% acetic acid, 20%; and ethanol, 16%.

In the years 1980 and beyond, if there will be a substantial degree of coal gasification, the

interest in the use of synthesis gas as a raw material for acetaldehyde production will increase.

5.5 Specifications, Analytical, and Test Methods: [16]

Commercial acetaldehyde has the following typical specifications: assay, 99% min; color, waterwhite; acidity, 0.5% max (acetic acid); specific gravity, 0.790 at 200C; bp, 20.8 at 101.3 kPa (1

atm). Acetaldehyde is shipped in steel drums and tank cars bearing the ICC red label. IN the

liquid state, it is noncorrosive to most metals; however, it oxidizes readily, particularly in the

vapor state, to acetic acid. Precautions to be observed in the handling of acetaldehyde have been

published by the manufacturing chemists association.

Analytical methods based on many of the reactions common to aldehydes have been developed

for the determination of acetaldehyde. In the absence of other aldehydes, it can be detected by

the formation of a mirror from an alkaline silver nitrate solution (Tollens’ reagent) and by the

reduction of Fehling’s solution.

It can be determined quantitatively by fuchsin-sulfiur dioxide solution (Schiff’s reagent) or by

the reaction with sodium bisulfite, the excess bisulfite being estimated iodometrically.

Acetaldehyde present in mixtures with other carbonyl compounds, organic acids, etc. can be

determined by paper chromatography of 2,4 – dinitrophenylhydrazones polarographic analysis

either of the untreated mixture or of the semicarbazones, the color reaction with thymol blue on

silica gel (detector tube method) mercurimetric oxidation, argent metric titration, microscopic

and spectrophotometric methods, and gas – liquid chromatographic analysis.

With the advent of gas – liquid chromatographic techniques, this method has superseded most

chemical tests for routine analysis. Acetaldehyde can be isolated and identified by the crystalline

compounds of characteristic melting points formed with hydrazines, semicasrbazides, etc.; these

derivatives of aldehydes can be separated by paper and column chromatography.

Acetaldehyde has been separated quantitatively from other carbonyl compounds on an ion

exchange resin in the bisulfite form; the aldehyde is eluted from the column with a solution of

sodium chloride. In larger quantities, it may be isolated by passing the vapor into ether and

saturating the ether with dry ammonia; the product, acetaldehyde – ammonia, crystallizes from

the ether solution. The reactions of acetaldehyde with bisulfite, hydrazine’s, oximes,

semicarbazones, and 5, 5–dimethyl – 1, 3 cyclohexanedione (dimedone) have been used to

isolate acetaldehyde from solutions.

20

CHAPTER-6

SELECTION OF PROCESS

Table- 6.1 Comparison between most likely used method and other method

Parameters

Cost

Conversion

Environmental effect

By

oxidation

ethylene

Cost effective

of By

oxidation

of

ethanol

Comparatively

less

cost effective

35-45%

25%

Ethylene is produced No harmful effect on

in the petrochemical environment

industry and is hence

not classified as a

green product

From acetylene

High cost

50-50%

The production of

acetaldehyde

from

acetylene includes a

catalyst

containing

mercury which is

toxic

So, Oxidation of Ethylene is selected for the production of acetaldehyde because currently, the

Wacker-Hoechst process accounts for 85 % of the worldwide production capacity for

acetaldehyde. Acetaldehyde yield almost equal (about 95%).Lower investment costs in the single

stageprocess, because of the need of only one reactor with conversion per pass: 35 - 45%

This method is technically simple, smooth in reaction, and high in selectivity. The favorable

economics of the process are due to the abundance of ethylene. It is regarded as the most

economic industrial process route, and has been widely used in many countries

In both processes the aqueous crude aldehyde is concentrated and byproducts such as acetic acid

crotonaldehyde and chlorine-containing compounds are removed in a two-step distillation. The

selectivities are almost equal (94%).

other remaining process can not be selected because While passing ethyl alcohol over a copper

or silver gauze catalyst about a 25 percent conversion to acetaldehyde and The production of

acetaldehyde from acetylene includes a catalyst containing mercury, as mercuric complex which

is a toxic material hence this method is discarded

21

CHAPTER-7

MATERIAL & ENERGY BALANCE

7.1 MATERIAL BALANCE

The amount of Acetaldehyde to be produced = 2500 ton/year

Basis: 2500 tons of Acetaldehyde per annum.

Working day=300days

Total acetaldehyde to be produced=2500 TPD

=347.22 kg/hr

=7.89kmol/hr

7.1.1Material Balance across reactor

We haveSelectivity=94%

Conversion=35%

Total weight of Acetaldehyde is to be produced=347.22 kg/hr

Assuming 1.34% of acetaldehyde is lost during production

Total acetaldehyde to be produced=351.56 kg/hr=7.99694kmol/hr

Selectivity = (Moles of desired product formed)/(Moles of reactant reacted)

0.94 = 7.99694 kmol/hr/Moles of C2H4 reacted

Moles of C2H4 reacted=7.99694 kmol/hr/0.94 = 8.5073

Conversion = (Moles of C2H4 reacted)/(Moles of C2H4 fed)

0.35=8.5073/(Moles of C2H4 fed)

Moles of C2H4 fed=8.5073/0.35=24.3 kmol/hr=680.568kg/hr

Moles of C2H4 reacted to produce acetaldehyde=7.99 kmol/hr

Remaining moles = 8.5073-7.99694=0.51036 kmol/hr

Chemical reactions:Main reaction:1.C2H4+1/2O2CH3CHO

Side Reactions:2.C2H4+3O22CO2+2H2O

3. C2H4+ O2CH3COOH

4.2CH3CHOCH3CH=CHCHO

5. C2H4+HClC2H5Cl

6.C2H4+HCl+1/2O2CH3Cl+H2O

From the data we have the moles of 22

Acetic acid=0.0907 kmol/hr=5.4456 kg/hr

Methyl chloride=0.0709 kmol/hr=3.545 kg/hr

Ethyl chloride=0.0549 kmol/hr= 3.5136 kg/hr

Crotonaldehyde=0.05349 kmol/hr =3.7443 kg/hr

From reactions1 mole of C2H4 reacted=2 mol of CO2 produced

=1/2*0.5876 = 0.2398 kmol/hr

1Mole of C2H4 reacted=1Mole of CH3COOH produced

=1*0.09076=0.09076 kmol/hr

1Mole of C2H4 reacted = 1Mole of CH3Cl produced

=1*0.0709 = 0.0709 kmol/hr

1Mole of C2H4 reacted= 1Mole of C2H5Cl produced

=1*0.0549 =0.0549 kmol/hr

Total C2H4 reacted =7.99694+0.2398+0.09076+0.0709+0.0549 = 8.5073

Now, O2 reactedFrom (1) reaction7.99694/2 = 3.99847 kmol/hr

From (2) reaction3/2*0.5876 =0.8814 kmol/hr

From (3) reaction1*0.09076=0.09076 kmol/hr

From (6) reaction1/2*0.0709 =0.03545 kmol/hr

Total O2 reacted= 3.99847+0.8814+0.09076+0.03545 = 5.00608 kmol/hr=160kg/hr

HCl reactedFrom (5) reaction1Mole of HCl reacted = 1Mole of CH3Cl produced

=0.0709 kmol/hr

From (6) reaction

1Mole of HCl reacted = 1Mole of C2H5Cl produced

=0.0549 kmol/hr

Total HCl reacted = 0.0709+0.0549=0.1258 kmol/hr=4.5917 kg/hr

H2O producedFrom (2) reaction= 0.5876 kmol/hr

From (4) reaction= 0.05349 kmol/hr

From (6) reaction= 0.0709 kmol/hr

Total H2O produced = 0.5876+0.05349+0.0709 = 0.71199 kmol/hr=12.81582 kg/hr

From reaction (4)2 moles of Acetaldehyde reacted = 1mole of crotonaldehyde produced

23

= 2*0.05349=0.10698 kmol/hr

Acetaldehyde reacted = 7.99694-0.10698 = 7.88996 kmol/hr=347.15 kg /hr

If 20% excess O2

Then, O2 required in kmol = 160.19*1.20 = 192.228 kg/hr

Moles of air = 192.228/0.21 = 915.37 kg/hr

Moles of N2=915.37*0.79=723.16 kg/hr

O2 unreacted= O2 fed-O2 reacted = 192.228-160.19=32.038 kg/hr

C2H4 unreacted = C2H4 fed-C2H4 reacted=680.568-238.2044 = 442.36 kg/hr

Input to the reactor in kg/hr

C2H4 = 680.568kg/hr

O2 = 192.228 kg/hr

HCl = 4.5917 kg/hr

N2 = 723.16 kg/hr

Total=1600.53

Output from the Reactor

CH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443 kg/hr

Water=12.81852 kg/hr

Total =1599.628 kg/hr

Input=Output

24

Outlet

Kg/hr

InletKg/hr

C2H4 =

680.568kg/hr

O2 = 192.228 kg/hr

HCl = 4.5917 kg/hr

N2 = 723.16 kg/hr

REACTOR

Total =1600.53

kg/hr

CH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443 kg/hr

Water=12.81852 kg/hr

Total =1599.628

kg/hr

Fig-7.1.1 Material balance around reactor

7.1.2 Material Balance around condenser

Input to the condenser in kg/hr

CH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443 kg/hr

Water=12.81852 kg/hr

Total =1599.628 kg/hr

All water is condensed

Condensate= Water=12.81852 kg/hr

Non condensateCH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

25

Crotonaldehyde =3.7443 kg/hr

Total=1587.71 kg/hr

Feed = Condensate+ non condensate

1599.628=12.81852 +1587.71

1599.628=1599.628

Input=Output

CH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443 kg/hr

Water=12.81852 kg/hr

Condenser

Non condensateCH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443 kg/hr

Total=1587.71 kg/hr

Condensate=

Water=12.81852

kg/hr

Fig-7.1.2 Material balance around condenser

7.1.3 Material Balance on Scrubber

Input to the Scrubber in kg/hr

CH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443 kg/hr

Total=1586.8

The solubility of Acetaldehyde in water is infinity. So the amount of water

required for the absorption of Acetaldehyde is the equal amount of water.

Water used for absorption = 347.15*1.10 = 381.865 kg/hr

(10 % of extra water is used to scrub all the EO produced.)

Total Acetaldehyde scrubbed = 347.15 Kg/ hr

Solubility data:

Component Solubility (Kgs/ Kgs of water)

Nitrogen- 1.3462 X 10^-5

26

Carbon dioxide -1.379 X 10^-3

Oxygen- 2.87 X 10^ -5

Ethylene -1.482 X 10^-2

CH3COOH -1.42*10^-2

CH3Cl- 9.28*10^-3

C2H5Cl- 9*10^-3

Crotonaldehyde-9.8*10^-3

CO2 absorbed = (1.379*10^-3)*(381.865) = 0.52659 kg/hr

C2H4 absorbed = (1.482*10^-2)*(381.865) = 5.6592 kg/hr

CH3COOH absorbed = (1.42*10^-2)*(381.865) = 5.4456 kg/hr

CH3Cl absorbed = (9.28*10^-3)*(381.865) = 3.545 kg/hr

C2H5Cl absorbed =( 9*10^-3) *(381.865)= 3.5136 kg/hr

Crotonaldehyde absorbed = (9.8*10^-3)*(381.865)=3.7443 kg/hr

C2H4 recycle = 442.36-5.65592=436.70 kg/hr

O2 recycle =32.038 kg/hr

N2 purged=723.16 kg/hr

CO2 purged=25.32781

Water out=381.856 kg/hr

Input to the Scrubber in kg/hr

CH3CHO=347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443 kg/hr

Water in=381.856 kg/hr

Total=1968.668 kg/hr

Output from the Scrubber

Acetaldehyde absorbed=347,15 kg/hr

CO2 absorbed = 0.52659 kg/hr

C2H4 absorbed = 5.6592 kg/hr

CH3COOH absorbed = 5.4456 kg/hr

CH3Cl absorbed = 3.545 kg/hr

C2H5Cl absorbed = 3.5136 kg/hr

Crotonaldehyde absorbed = 3.7443 kg/hr

C2H4 recycle = 442.36-5.65592=436.70 kg/hr

O2 recycle =32.038 kg/hr

N2 purged=723.16 kg/hr

CO2 purged=25.32781

Water out=381.856 kg/hr

Total=1968.668 kg/hr

Input = Output

27

C2H4 recycle = 436.70 kg/hr

O2 recycle =32.038 kg/hr

N2 purged=723.16 kg/hr

CO2 purged=25.32781

Outlet

Kg/hr

InletKg/hr

SCRUBBER

CH3CHO =347.15 kg/hr

O2 unreacted=32.038 kg/hr

C2H4 unreacted= 442.36 kg/hr

Acetic acid =5.4456 kg/hr

Methyl chloride =3.545 kg/hr

Ethyl chloride= 3.5136 kg/hr

Crotonaldehyde =3.7443

kg/hr

Water in=381.856 kg/hr

Acetaldehyde absorbed=347,15 kg/hr

CO2 absorbed = 0.52659 kg/hr

C2H4 absorbed = 5.6592 kg/hr

CH3COOH absorbed = 5.4456 kg/hr

CH3Cl absorbed = 3.545 kg/hr

C2H5Cl absorbed = 3.5136 kg/hr

Crotonaldehyde absorbed = 3.7443

kg/hr

Total=1968.668 kg/hr

Total=1968.668

kg/hr

Fig-7.1.3 Material balance around Scrubber

7.1.4Material Balance on Distillation Column

Input to the Distillation Column in kg/hr

Acetaldehyde =347.15 kg/hr

CO2 = 0.52659 kg/hr

C2H4 = 5.6592 kg/hr

CH3COOH = 5.4456 kg/hr

CH3Cl = 3.545 kg/hr

C2H5Cl = 3.5136 kg/hr

Crotonaldehyde = 3.7443 kg/hr

Water =381.856 kg/hr

Total Feed = 751.44 kg/hr

Overhead contain:C2H5Cl=3.5136 kg/hr

C2H5Cl = 3.5136 kg/hr

CO2 = 0.52659 kg/hr

C2H4 = 5.6592 kg/hr

Total Overhead=13.24439 kg/hr

Bottom Contain

CH3COOH = 5.4456 kg/hr

28

Crotonaldehyde = 3.7443 kg/hr

Water =381.856 kg/hr

Acetaldehyde =347.15 kg/hr

Total bottom=738.19 kg/hr

Feed=Overhead+Bottom

751.44 kg/hr =13.24439+738.19

751.44 kg/h = 751.44 kg/h

Input = Output

C2H5Cl=3.5136 kg/hr

CH3Cl = 3.545 kg/hr

CO2 = 0.52659 kg/hr

C2H4 = 5.6592 kg/hr

Total=13.24439 kg/hr

Inlet-Kg/hr

Acetaldehyde =347.15 kg/hr

CO2 = 0.52659 kg/hr

C2H4 = 5.6592 kg/hr

CH3COOH = 5.4456 kg/hr

CH3Cl = 3.545 kg/hr

C2H5Cl = 3.5136 kg/hr

Crotonaldehyde = 3.7443

kg/hr

Water =381.856 kg/hr

Outlet

Kg/hr

DISTILLATION

COLUMN

TOTAL= 751.44 kg/hr

CH3COOH = 5.4456 kg/hr

Crotonaldehyde = 3.7443 kg/hr

Water =381.856 kg/hr

Acetaldehyde=347.15 kg/hr

Total=738.19 kg/hr

Fig-7.1.4 Material balance around Distillation column

7.1.5Material Balance around Distillation Column

Input to the Distillation Column in kg/hr

Acetaldehyde =347.15 kg/hr=7.8897 kmol/hr

CH3COOH = 5.4456 kg/hr = 0.09076 kmol/hr

Crotonaldehyde = 3.7443 kg/hr = 0.05349

Water =381.856 kg/hr = 21.21 kmol/hr

Total Feed=738.19 kg/hr=29.24 kmol/hr

For DistillateDistillate contain CH3CHO (99.88%),CH3COOH (0.1%),H2O

Distiilate347.15*0.9988 = 346.7 kg/hr=7.879 kmol/hr

346.7*(0.02/100) = 0.069 kg/hr = 3.83*10^-3 kmol/hr

346.7*(0.1/100) = 5.76*10^-3 kmol/hr

Total distillate=347.115 kg/hr = 7.8885 kmol/hr

F=D+W

29

W=F-D

W=29.24-7.8885 = 21.35 kmol/hr=391.075 kg/hr

FXf = DXd+WXw

xF = mole fraction for Acetaldehyde in feed

xF=7.8897/29.24=0.2698

xD = mole fraction of ethylene oxide in the distillate.(commercial grade

Acetaldehyde)

xD =0.9988

29.24*0.2698=7.8885*0.9988+21.35*Xw

Xw=4.64*10^-4

Acetaldehyde = 346.7 kg/hr

Water= 0.069 kg/hr

Acetic acid =0.346 kg/hr

Total distillate=347.115 kg/hr = 7.8885 kmol/hr

Inlet-Kg/hr

Outlet

Kg/hr

Total=738.19 kg/hr

CH3COOH = 5.4456 kg/hr

Crotonaldehyde = 3.7443

kg/hr

Water =381.856 kg/hr

Acetaldehyde=347.15

kg/hr

DISTILLATION

COLUMN

Crotonaldehyde =

3.7443 kg/hr

Total=738.19 kg/hr

CH3COOH = 5.4456 kg/hr

Water =381.856 kg/hr

Fig-7.1.5 Material balance around distillation column

30

7.2ENERGY BALANCE:

7.2.1Energy balance around reactor

Empirical heat capacity equation

C=a+bT+cT2+dT3;

C= heat capacity in J/Mole*K

T= absolute temp in K

S.No. COMPONENT A

B

C

D

15.69*10^-2

-8.318*10^-5

17.55*10^-9

1.

Ethylene

3.806

2.

Oxygen

28.106 -3.68*10^-6

17.459*10^-6 -1.06*10^-8

3.

Carbon Dioxide

19.795 71.43*10^-3

-5.602*10^-5

17.153*10^-9

4.

Methyl Chloride 13.875 10.140*10^-2 -3.889*10^-5

25.66*10^-10

5.

Acetaldehyde

7.716

18.22*10^-2

-1.007*10^-4

23.80*10^-9

6.

Ethyl Chloride

-.553

26.06*10^-2

-1.840*10^-4

55.475*10^-9

7.

Nitrogen

31.150 -1.357*10^-2

26.796*10^-6 1.168*10^-8

8.

Acetic Acid

4.840

-1.756*10^-4

49.48*10^-9

9.

Water

32.243 19.23*10^-4

10.55*10^-6

-3.59*10^-9

25.48*10^-2

Q= -HR+Hp+∆HR

H=m*CP*∆t

Consider feed to enter at 25oC

Tref =25oC

(m*Cp*∆T)reactants = 0

Heat capacity data for product and unreacted components at 400 K

Component

Cp*dT

J/Mole*K

6118.352

5010.481

Acetaldehyde

Unreacted

31

;

Ethylene

Unreacted

Oxygen

Nitrogen

Acetic acid

Methyl Chloride

Ethyl chloride

Carbon Dioxide

Water

3037.96

3081.16

7589.8

4549.7

7192.09

6479.6

3473.3

(m*Cp*dT)products = (6118.352*7.889*10^3) + (5010.48*15.7985*10^3) + (1.001*10^3*3037.96)

+ (0.5876*10^3*6479.6) + (0.09076*10^3*7589.8) + (25.827*10^3*3081.16) +

(0.0709*10^3*4549.7) + (0.0549*10^3*7192.09) + (0.7119*10^3*3473.3)

(m*Cp*dT)products = 2.35*10^8 J/hr = 65.27 KW

∆HR = -57.84 Kcal./Kmole = 571.87 KW

Q= -HR+Hp+∆HR = 0 - 571.87 + 65.27 = -506.53 KW

Q = (m*Cp*∆T)water ; ∆T = 35oC-25oC = 10oC

m = 506.53/4.184*10 = 12.106 Kg

7.2.2 Energy Balance of Condenser

Heat capacity data for product and unreacted components

Component

Acetaldehyde

Unreacted

Ethylene

Unreacted

Oxygen

Nitrogen

Acetic acid

Methyl Chloride

Ethyl chloride

Carbon Dioxide

Water

(m*Cp*∆T)noncondensate

(1.001*10^3*1410.47)

=

+

Cp

*dT;

J/Mole*K

2974.9

2442.602

1410.47

1477.31

3691.37

2139.47

3497.6

1863.82

1610.78

(2974.3*7.889*10^3)

+

(2442.602*15.7985*10^3)

(0.5876*10^3*1863.82)

+

(0.09076*10^3*3691.37)

32

+

+

(25.827*10^3*1477.31)

(0.7119*10^3*1610.78)

+

(0.0709*10^3*2193.47)

+

(0.0549*10^3*3497.6)

+

(m*Cp*dT)products =1.028*10^8 J/hr. = 28.57 KW

Heat given out by water which is condensate

Q=(m*Cp*T)Water = (12.81852*4184*50)

Q = 2681634.384J/hr= 0.744 KW

Therefore heat removed in the condenser = 28.57+0.744 = 29.314 KW

Utility require

Q = m*Cp*∆T where ∆T=10oC

29.314 = m*4.814*10

M=0.60 kg/s

7.2.3 Energy Balance around Heat Exchanger

Heat capacity data for product and unreacted components:

Component

Acetaldehyde

Unreacted

Ethylene

Unreacted

Oxygen

Nitrogen

Acetic acid

Methyl Chloride

Ethyl chloride

Carbon Dioxide

Cp

J/Mole*K

2873.38

2344.7

;

1482.42

1500.12

3563.71

2151.65

3352.95

1889.72

(m*Cp*∆T)products = (2873.38*7.889*10^3) + (2344.7*15.7985*10^3) + (1.001*10^3*1480.42) +

(0.5876*10^3*1889.72)

+

(0.09076*10^3*3563.71)

+

(25.827*10^3*1500.12)

+

(0.0709*10^3*2151.65) + (0.0549*10^3*3352.95)

(m*Cp*∆T)products =1.01*10^8 J/hr. = 28.2 KW

Heat entering = 29.314 KW

Therefore heat removed in heat exchanger = 29.314-28.2=1.114KW

7.2.4 Energy Balance around Absorber

33

In the absorber acetaldehyde, acetic acid, methyl chloride, and ethyl chloride are completely

absorbed in water at 25 degree C. The only energy lost is from gases which are not absorbed in

the absorbing liquid.

Heat entering in the absorber = 1.114 KW

Heat capacity data for recycled and purged streams at 25 degree C

Component

Cp

J/Mole*K

183.332

219.46

Carbon Dioxide

Unreacted

Ethylene

Unreacted

Oxygen

Nitrogen

;

146.96

148.72

Energy lost from the absorber is = (0.5756*10^3*183.332) + (15.53*10^3*219.46) +

(1.001*10^3*146.96) + (25.827*10^3*148.72)

= 7.51*10^6 J/hr. = 2.086 KW

Therefore, energy leaving the absorber with the products= 1.114 KW-2.086 KW=-0.972KW

34

Energy balance around Distillation column

Antoine equation[22]

1. P=(A−(B/(T+C))

2. P=vapor pressure(mmHg)

o

3. T = temperature( C)

TABLE-8

component

Acetaldehyde

Acetic acid

Water

A

8.00552

7.18807

8.10765

B

1600.017

1416.7

1750.286

Crotonaldehyde

7.28193

1460.08

C

291.809

225

235

227.632

Dew point –

For dew point calculation

[(Yacetaldehyde*760)/p*acetaldehyde]+ [(Yacetic acid*760)/p*acetic acid]+ [(Ywater*760)/p*water]-1=0

Yacetaldehyde=0.998

Yacetic acid =7.30*10^-4

Ywater=4.85*10^-4

And calculate ( p*components) at different temperature

And then check [Xacetaldehyde+Xacetic acid+Xwater]=1

By trial and error method we got dew point at 21.45o C (294.45K)

Bubble point calculation

(X acetic acid*p acetic acid) +(X water*p water)+ [(X crotonaldehyde * p crotonaldehyde)+]-760mmHg = 0

X acetic acid = 3.98*10^-3

X water = 0.993

X crotonaldehyde =2.507*10^-3

And calculate ( p*components) at different temperature

And then check [Y acetaldehyde +Y acetic acid +Y water]=1

By trial and error method we got bubble point at 99.89 o C (372.89K)

Latent Heat of Vaporization of Acetaldehyde at dew pt. (294.45)=566.04 KJ/kg =24.90 J/mol

Latent Heat of Vaporization of Acetic acid at dew pt. (294.45) =467.38KJ/kg=28.04 J/mol

Latent Heat of Vaporization of Water at dew pt. (294.45)=2485.15KJ/kg = 44.73 J/mol

Molar flow rate of Acetaldehyde=7.8897Kmol/hr

Molar flow rate of Acetic acid =0.09076 Kmol/hr

Molar flow rate of crotonaldehyde= 0.05349 Kmol/hr

Molar flow rate of water =21.21 Kmol/hr

Total feed=29.24 Kmol/hr

35

Molar flow rate of Acetaldehyde=7.879Kmol/hr

Molar flow rate of Acetic acid =5.76*10^-3Kmol/hr

Molar flow rate of water = 3.83*10^-3 Kmol/hr

Total Distillate =7.8885 Kmol/hr