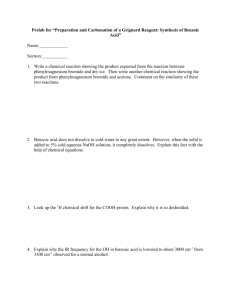

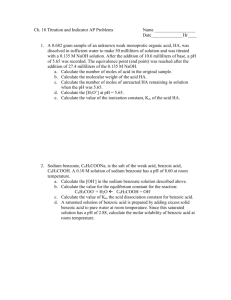

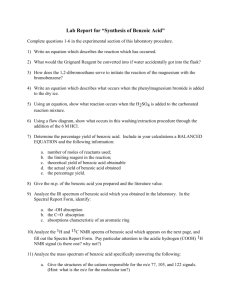

OBJECTIVE To purify benzoic acid by recrystallization To determine the melting point of pure benzoic acid ABTRACT Recrystallization was attempted in this experiment to purify the organic compound, benzoic acid. Benzoic acid crystals were collected and used to find the melting point to determine the purity of benzoic acid. Experimental melting range for benzoic acid was found to be 120 C121 C. But based on the results‚ the melting point that has obtained was 122.1°C.The percentage difference shown was 10% exceed. This finding suggests that the benzoic acid that was recovered is not really pure because of the experimental melting point that was recorded suggests that the recovered benzoic acid contain some impurities. Percent recovery of benzoic acid was found to be 35.45% that is lower than the actual one which should be 79%.The percentage difference may due to several factors that caused the loss of product. INTRODUCTION Recrystallization is a common method used to purify a solid. As the name implies a solid sample with suspect purity is dissolved into an appropriate solvent. Liquids are customarily purified by distillation, while solids purified by recrystallization; sometimes called simply “crystallization”. When heat is involved a solvent is chosen in which the solute has a low solubility at room temperature, but a higher solubility at an elevated temperature. If the are any impurities that have the same solubility as the main component, then a different solvent needs to be chosen. When organic substances are synthesized in the laboratory or isolated from plants, they will obviously contain impurities. Several technique for purifying these compounds have been developed. The most basic of these technique for the purification of organic solids is recrystallization, which relies on the different solubilities of solutes in a solvent. Compounds, which are less soluble, will crystallize first. The crystallization process itself helps in the purification because as the crystals form, they select the correct molecules, which fit into the crystal lattice and ignore the wrong molecules. Organic compounds that are solids at room temperature are usually purified by recrystallization. The general technique involves dissolving the materials to be recrystallized in hot solvent and cooling the solution slowly. The solid that crystallized out from the solution is very pure material. During the recrystallization process, solid impurities that do not dissolve in hot solution are normally eliminated through filtration. The dissolved impurities remain in cold solution while the pure compound recrystallized out of the solution. MATERIALS Chemicals : Benzoic acid Distilled water Apparatus : Conical flasks Hirsh / Buchner funnel Watch glass Filter funnel Capillary tubes Beaker FLOWCHART Part A Weight about 1.0 g benzoic acid into 100 ml volumetric flask. Add 15 ml water and anti-bumping granules (3-5 pieces ) Heat the mixture on a hot plate until the solvent boils. Filter the hot mixture of benzoic acid through a fluted filter into conical flask. Prepare the fluted filter paper and put it in the funnel. Heat 20 ml water. Add 2-3 ml water if required and continue boiling until all benzoic acid has dissolved. Add boiling water if crystallization occurs on filter paper. Add until all the crystals are dissolved. Wash crystals with cold water and dry. Place the filter paper with crystals in a watch glass and leave for 4 hour to air dry. After filtration, boil filtrate to produce more concentrated solution. Filter the crystals through a Buchner funnel. Cool the solution to room temperature. After compound has recrystallized out, place flask into ice bath for a few minutes . Concentrate the solution by heating on the hot plate and cool if no recrystallization occurs. Part B After the crystal dry completely, weight the pure benzoic acid recovered , calculated the % recovered. Break the crystal into powder, fill the powder in 3 capillary tubes. Read the melting point using BUCHI B540 Compare the result with the actual melting point of benzoic acid RESULTS 1) Data on the impure Benzoic Acid a) Mass of benzoic acid + weighing paper : 1.8632 b) Mass of weighing paper : 0.8500 c) Mass of impure benzoic acid : 1.0132 2 ) Data for recrystallized benzoic acid a) Mass of recrystallized benzoic acid + weighing paper : 1.2101 b) Mass of weighing paper : 0.8500 c) Mass of recrystallized benzoic acid : 0.3601 d) Calculation of percentage recovery : 1.0132 × 100 % 0.3601 ( show calculation ) e) Melting point of recrystallized benzoic acid 35.54 % : 122.1 3 ) Melting point of recrystallized benzoic acid ( Theory ) : The melting of the crude benzoic acid was 118-122 C , while the melting point of the recrystallized benzoic acid was 114-122 C. When recrystallized using just water as the solvent the benzoic acid appear as a white, powdery solid weighing 0.87 g. The percent recovery was 79%. DISCUSSION The percentage recovery of benzoic acid is only 35.54% but the actual one should be 79%.The percentage difference may due to several factors that caused the loss of products. One of the factor is that the volume of water added to the solution is too much which making the solution not saturated enough to produce maximum yield of benzoic acid after cooling. Normally‚ larger volume of water used will tend to the products to dissolve more easily. The benzoic acid crystallized on the filter paper during the hot filtration. The additional hot water need to be added to dissolve the benzoic acid crystals on the filter paper which causes the solution to be more dilute so that the products is lost in the solution. In this experiment‚ the benzoic acid is dissolved in hot water while only a little amount of benzoic acid is able to dissolve in cold water. The benzoic acid cannot dissolve well in cold solution because of its hydrophobic benzene ring. However the carboxyl group –COOH that attached to the benzene ring allows some of the benzoic acid soluble in water. In hot solution‚ the increase in temperature causes the water molecules to has more kinetic energy and move faster. As a result‚ it allows the water molecules to penetrate through the benzoic acid solid and hence solubilisation of benzoic acid occurs. In addition‚ other impurities present in mixture cannot dissolve in water. So‚ water is a good solvent to be chosen in the experiment. The bumping granules were added in the experiment. The bumping granules are small insoluble and porous stones made of calcium carbonate or silicon carbide. There are a lot of pores inside the bumping granules in which it provides nucleation site to trap air and creates space to allow the bubble of solvent to form. When the bumping granules are heated‚ it will release tiny bubbles which can prevent bumping and boiling over of the mixture so that the loss of solution can be avoided even it is boiled. The adding of bumping granules must be added before boiling of the solution instead of after boiling. This is because adding of bumping granules to a solution near its boiling point will induce flash boiling point as well. The bumping granules are not soluble in the solvent and hence they can be filtered out by using filter paper but they are not reusable. During the hot filtration most of the residue was removed and stay on the filter paper while the benzoic acid solution pass through the filter paper and goes into the conical flask. During cooling process‚ the hot solution was allowed to cool slowly to the room temperature and then only immersed in an ice-bath. The solution should be protected from the contaminants by covering with a piece of filter paper. Fast cooling always produces relatively small crystals because the particles do not have sufficient time to arrange themselves in proper conformation so it is not advisable to cool down the hot solution immediately in ice-bath. The small size of crystal form may trap impurities easily. Oppositely‚ slow cooling allowed the molecules to interact and arrange themselves properly and hence they form larger size of crystals. But large particles may causes some solvent being trapped inside the crystals. During cool filtration the water soluble impurities that might dissolve in water which was filtered out through the suction filtration. However‚‚ some of the impurities might be trapped on the surface of the benzoic acid crystals so small volume of ice cold water should be used to wash the benzoic acid crystals dissolve the particular impurities. The crystal was dried in the oven at 100°C.A fresh piece of filter paper can be used to place under the filter paper with benzoic acid crystals. The purity of a crystal can be determined by its melting point. A narrow range of melting point indicates high purity of the sample otherwise broad range of melting point indicates the presence of impurities in the crystal. The melting point of the recovered benzoic acid obtained experimentally is 122.1°C but the actual one should be 122°C. The percentage difference of the melting point recovered by benzoic acid is about 10%.The percentage difference is little bit high because the presence of impurities in the crystal. Maybe the filtration that has conducted was not in the proper way causes the impure substance flow into the solution that has separated in the conical flask. Sometimes the impure substance maybe in the form of tiny particle and cannot observed with the naked eyes causes the error in this experiment will happen. CONCLUSION Theoretically the melting point of recrystallized benzoic acid was 114 oC – 122oC . Organic compounds in the form of solids are purified by recrystallization. In this experiment , benzoic acid was used for a recrystallization process. The melting point of the recrystallized benzoic acid obtained experimentally is 122.1oC . The result shows that the benzoic acid was not really pure due to some possible sources of error done during this experiment. Thus , the percentage recovery of the purified benzoic acid for this experiment is just 35.54%. The result really show a very large gap between the value from the theory. Therefore , some possible sources of error had been identified such as the loss of products , this experiment does not follow the steps as the crystal was break into the powder first before weighing it resulting the fine powder fall or flown by the air . Moreover, fast cooling of the solution generally produced more crystals of relatively small dimensions. Besides, the compound is slightly contaminated with impurities which included the water molecules that trapped inside the benzoic acid crystals. RECOMMENDATIONS In order to obtain accurate results, there are a few recommendations that should be taken during conducting the experiment. The solution should be protected from the contaminants by covering with a piece of filter paper. Next, the filtration process should be done properly as the filter paper must be fold in the right way to avoid the solid impure mixed with the solution. Thus , the cooling process should be done slowly allowed the molecules to interact and arrange themselves properly. Moreover , if the filter paper was torn on the corner to snug fit in the funnel, the torn corner side must be weighed with the benzoic acid to avoid any errors. Once the suction filtration process is completed, the collected crystals should be washed with a little more ice-cold solvent to remove final soluble impurities which would otherwise be left on the surface of the crystals. TUTORIALS 1. What is the purpose of the recrystallisation process ? Recrystallization, also called fractional crystallization, is a process that involves dissolving an impure compound in a solvent at a high temperature to create a concentrated solution and then cooling the solution slowly. The drop in temperature decreases the solubility of both the chemical compound and the impurities it contains. The pure portion of the compound crystallizes, leaving behind the impurities in the solution. Filtering out the pure crystals separates them from any impurities, and repeating the recrystallization process creates an even purer compound. For the recrystallization process to be successful, there must be only a small quantity of impurities in the chemical compound, and they must be soluble. It is possible to predict the outcome of the process by using a solubility curve, which is a graphical representation of how the solubility of a substance in a solvent varies with temperature. For the best outcome, the solubility curve should rise rapidly as the temperature rises. Performed correctly, the recrystallization procedure is a highly effective way to obtain a pure sample of a compound. However, it can take a long time because the slower the rate of cooling, the larger the pure crystals, which makes filtering easier. 2. Explain why anti-bumping are added before any solution is heated ? Because a heated solution is likely to boil, probably sooner than later. For a liquid to boil smoothly, small bubbles have to nucleate on the bottom and rise to the top. The boiling stone (aka anti-bumping granule) allows the small bubbles to form. 3. Why is suction filtration favoured over gravitational filtration when separating pure crystals from its supernatant liquid after the recrystallisation ? By comparison, suction filtration has more efficiency than gravitational filtration. More unneeded water can be removed through suction filtration. The time taken of pure crystals to dry is shortened. 4. In general, water is not a good solvent for the recrystallization. Explain this statement. Water is known as a universal solvent and can dissolve almost anything especially salts or anything else with a hydrogen bond like sugar. Since water dissolves so many things, it would be a poor choice to use in recrystallisation. The crystals would not form as well to be filtered out because the water would keep them in solution. For recrystallisation we need to find a solvent that has very little attraction for the crystals and one that would allow them to come out of solution. 5. Provide the probable reasons of low or high melting point of your experimental benzoic acid when compared to theoretical result. The melting point of the recovered benzoic acid obtained experimentally is 122.1°C but the actual one should be 122°C. The percentage difference of the melting point recovered by benzoic acid is about 10%.The percentage difference is little bit high because the presence of impurities in the crystal. Maybe the filtration that has conducted was not in the proper way causes the impure substance flow into the solution that has separated in the conical flask. Sometimes the impure substance maybe in the form of tiny particle and cannot observed with the naked eyes causes the error in this experiment will happen. 6. List the usages of benzoic acid in industry. Food preservative Medicinal Feedstock Biology and health effects 7. State the class/family of benzoic acid in organic chemistry. Benzoic acid, C6H5COOH, is a colourless crystalline solid and a simple aromatic carboxylic acid 8. Draw the structure of benzoic acid. 9. How is benzoic acid been synthesized ? Benzyl chloride a) Write the chemical equation of above process. C6H5CH2CI + 2 KOH + 2 O – C6H5COOH + KCI +H2O b) Name the starting materials, process name, catalyst being used and side product. Starting materials : benzyl chloride, potassium permanganate, sulphur dioxide Process name : Oxidation of benzyl alcohol Catalyst : Ru, Pd, Cu Side product : Benzene REFERENCES Lab Manual Yeap Tok Kheng,Chemistry SPM Highlights,Pearson Malaysia Sdn.Bhd,2014, p341-390