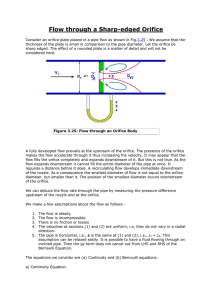

Orifice Meter Orifice Meter 1. Introduction The first recorded use of an orifice device for fluid measurement was in 1797 by Giovanni B. Venturi, an Italian physicist whose work led to the development of the modern Venturi meter in 1886 by Clemons Herschel. In 1890, it has been reported that an orifice meter designed by Professor S.W. Robinson of Ohio State University was used to measure gas near Columbus, Ohio. In 1903, T.B. Weymouth began a series of tests in Pennsylvania leading to the publication of coefficients for orifice meters with flange taps. At the same time, E.O. Hickstein conducted a similar series of tests at Joplin, Missouri from which he developed data for orifice meters with integrated pipe taps. The orifice meter is used widely as a device for measuring the flow rate of a fluid in a pipeline. Compared with other head meters, such as the venturi meter and the nozzle, the orifice meter is less expensive to fabricate and install; however, the permanent energy loss is relatively high. The orifice plate can have a square edged or sharp-edged hole. For measurement of the pressure drop across the orifice, the pressure taps can be at corner, radius, pipe, flange, or vena contracta locations. The direction of flow through the orifice can be horizontal, vertical, or inclined. The measured pressure drop across the orifice is related to the flow rate by means of an orifice coefficient, which accounts for friction. A differential pressure meter creates a pressure drop by combining a conduit and a restriction. A nozzle, Venturi or thin, sharp-edged orifice can be used as the flow restriction. Prior to 1 Orifice Meter Orifice Meter using any of these devices for measurement, it is necessary to empirically calibrate them by passing a known volume through the meter and noting the reading to provide a measurement standard for other quantities. Due to the ease of duplication and the simple construction, the thin, sharp-edged orifice has been adopted as a measurement standard. Extensive calibration work has also been performed on the device, making it widely accepted as a standard means for measuring fluids. Provided the standard mechanics of construction are followed, no calibration is required. An orifice installed in a pipeline along with a manometer for measuring the drop in pressure (differential) as the fluid passes through the orifice is shown in Figure 1. The minimum cross-sectional area of the jet immediately after the orifice is known as the “vena contracta”. Fig.1: Typical Orifice Flow Pattern Flange Tap Diagram 2 Orifice Meter Orifice Meter 2. How an Orifice Meter Works As fluid approaches the orifice, the pressure increases slightly and then drops suddenly as the fluid passes through the orifice. The pressure continues to drop until it reaches the “vena contracta” and then it gradually increases until it is approximately 5D to 8D. At this point, it reaches maximum downstream pressure which is lower than the pressure upstream of the orifice. The pressure decrease as fluid passes through the orifice is due to the increased velocity of the natural gas passing through the reduced area of the orifice. When the velocity decreases as the fluid leaves the orifice, the pressure increases and tends to return to its original level. The pressure loss is not fully recovered due to loss of friction and turbulence in the stream. The pressure drop across the orifice (Figure 2) increases when the rate of flow increases. When there is no flow, there is no differential pressure. The differential pressure is proportional to the square root of the velocity. Therefore, it follows that if all other factors remain constant the differential is proportional to the square root of the flow rate. Fig.2 : Orifice plate showing vena contracta. 3 Orifice Meter Orifice Meter 3. Shape & Size of Orifice meter Orifice meters are built in different forms depending upon the application specific requirement, The shape, size and location of holes on the Orifice Plate describes the Orifice Meter Specifications as per the following: Concentric Orifice Plate Eccentric Orifice Plate Segment Orifice Plate Quadrant Edge Orifice Plate Fig.3 : Holes on the Orifice Plate. 3.1 Concentric Orifice Plate It is made up of SS and its thickness varies from 3.175 to 12.70 mm. The plate thickness at the orifice edge should not be exceeded by any of following parameters: 1. D/50 where, D = The pipe inside diameter 2. d/8 where, d = orifice bore diameter 3. (D-d)/8 4 Orifice Meter 3.2 Orifice Meter Eccentric Orifice Plate It is similar to Concentric Orifice plate other than the offset hole which is bored tangential to a circle, concentric with the pipe and of a diameter equal to 98% of that of the pipe. It is generally employed for measuring fluids containing Media having Solid particles Oils containing water Wet steam 3.3 Segment Orifice Plate It has a hole which is a semi circle or a segment of circle. The diameter is customarily 98% of the diameter of the pipe. 3.4 Quadrant Edge Orifice Plate This type of orifice plate is used for flow such as crude oil, high viscosity syrups or slurries etc. It is conceivably used when the line Reynolds Numbers* range from 100,000 or above or in between to 3,000 to 5,000 with a accuracy coefficient of roughly 0.5%. 4. Flow Measurement By Orifice Meter An orifice meter is essentially a cylindrical tube that contains a plate with a thin hole in the middle of it. The thin hole essentially forces the fluid to flow faster through the hole in order to maintain flow rate. The point of maximum convergence (vena contracta) usually occurs slightly downstream from the actual physical orifice. This is the reason why orifice meters are less accurate than venturi meters, as we cannot use the exact location and diameter of the 5 Orifice Meter Orifice Meter point of maximum convergence in calculations. Beyond the vena contracta point, the fluid expands again and velocity decreases as pressure increases. Fig. 4 : Orifice meter Figure 4 shows an orifice meter with the variable position of vena contracta with respect to the orifice plate. By employing the continuity equation and Bernoulli’s principle, the volumetric flow rate through the orifice meter can be calculated as described previously for venturi meter. where Co is the orifice discharge coefficient, S2 is the area of crosssection of the orifice, V2 is the flow velocity through the orifice, β is the ratio of the diameter of orifice to that of the diameter of pipe, ΔH is the manometric height difference × (specific gravity of manometric fluid – specific gravity of water), and g is the acceleration due to gravity. 6 Orifice Meter Orifice Meter Rather than use this or any other unwieldy equations and because assumptions would have to be made, the simple solution is to use the supersonic formula and allow for a reduction in flow when making the initial guess. 7