SCMH Section 7.2.3 APQP

Revision Letter: B

Revision Date: 10-MAY-2017 www.iaqg.org/scmh Section 7.2

Aerospace APQP/PPAP Manual

Guidance material for International Aerospace

Standard 9145

Advanced Product Quality Planning

(APQP) Production Part Approval Process

(PPAP)

May 10, 2017

The intention of this document is to assist organizations with understanding the concept and process of APQP and is not intended to be a requirement, nor auditable.

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 2 of 101

APQP Overview and Element Cards

TABLE OF CONTENTS

APQP Overview

Page

4

Phase 1 Planning - Introduction

0.01 Project Inputs

1.01.1 Product Design Requirements

1.01.2 Producer Product Specification

1.02 Project targets – safety, quality/manufacturability, service life, reliability, durability, maintainability, schedule and cost 20

1.03 Preliminary Listing of Critical Items (CI) and Key Characteristics (KC) 22

1.04 Preliminary Bill of Material (BOM) 23

13

14

16

18

1.05 Preliminary Process Flow Chart

1.06 Statement of Work (SOW) Review

1.07 Preliminary Sourcing Plan

1.08 Project Plan

24

26

28

29

Phase 2 Product Design and Development - Introduction

2.01 Design risk analysis

2.02.1 Design records

2.02.2 Bill of Material (BOM)

2.02.3 Design for Manufacturing and Assembly (DFMA), tolerance, stackup analysis, etc.

31

32

34

35

2.02.4 Design for Maintenance, Repair and Overhaul (DMRO)

2.03 Special requirements, including product Key Characteristics (KCs) and Critical Items (CIs) listings

2.04 Preliminary risk analysis of sourcing plan

36

38

40

41

2.05 Packaging specification 43

2.06 Design review report

2.07

Development product build plan 45

2.08 Design verification and validation plans, and associated results 47

2.09 Feasibility assessment 49

Phase 3 Process Design and Development - Introduction

3.01 Process Flow Diagram

3.02 Floor Plan Layout

3.03 Production Preparation Plan

3.04 Process Failure Mode & Effect Analysis (PFMEA)

3.05 Process Key Characteristics

51

52

55

57

59

62

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 3 of 101

APQP Overview and Element Cards

3.06 Control Plan

3.07 Preliminary capacity assessment

3.08 Work station Documentation

3.09 Measurement Systems Analysis (MSA) Plan

3.10 Supply Chain Risk Management Plan

3.11 Material handling, packaging, labelling, and part marking approvals

3.12 Production Readiness Review (PRR) results

Phase 4 Product and Process Verification - Introduction

4.01 Production Process Runs

4.02 Measurement Systems Analysis (MSA)

4.03 Initial Process Capability Studies

4.04 Control Plan

4.05 Capacity Verification

4.06 Product Validation Results

4.07 First Article Inspection (FAI)

4.08 Production Part Approval Process (PPAP) file and Approval Form

4.09 Customer Specific Requirements

Phase 5 On-Going Production - Introduction

5.01.1 Measuring Performance

5.01.2 Maintenance, Repair and Overhaul (MRO) KPIs and plan(s) to reach the established targets

5.02 Continuous improvement actions

5.03 Lessons learned

80

81

83

84

86

88

89

90

92

94

95

96

64

68

69

71

74

76

78

98

99

101

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 4 of 101

1.

APQP Overview and Element Cards

APQP History

The IAQG Guidance material on Advanced Product Quality Planning (APQP) and

Production Part Approval Process (PPAP) is based upon the principles of quality planning as pioneered by Deming from the 1950s and the automotive industry during the later decades of the 20 th Century.

- GM, Ford & Chrysler collaboratively wrote and published the first APQP manual for the automotive industry in June 1994

It is widely recognized by IAQG members that the Aerospace industry some unique aspects that differentiates them from other industries. To meet the needs of the

Aerospace industry, the IAQG members have collaborated to develop this APQP guidance material. In doing so, this manual addresses the unique features of this business, like low volume, long life cycles, and high levels of regulation.

Since the initial publication of this APQP Manual, The Aerospace Industry has developed and released the internationally harmonized standard 9145

–

Requirements for Advanced Product Quality Planning and Production Part Approval

Process. This new standard was developed by representatives from member companies from all three sectors of the IAQG, AAQG, (Americas Aerospace Quality

Group), EAQG (European Aerospace Quality Group) and APAQG) Asia Pacific

Aerospace Quality Group).

2. Purpose of APQP

The purpose of APQP is to assure that new products satisfy customer needs and wants. This includes product needs as well as project timing and delivery. To accomplish this, necessary steps need to take place at the appropriate time within the product realization process. A successful APQP project will always start with a detailed plan based on key customer dates. A project management approach that continually reinforces identification and mitigation of risks, monitors status of tasks and deliverables, and escalates issues to management as necessary, is used to implement the plan. This approach provides effective early warning signals to drive on-time and on-quality delivery of products. Another success factor of APQP is the establishment of a cross functional team to ensure alignment of timing, understanding of deliverables, and avoidance of miscommunications. APQP drives a proactive and preventative mind-set.

3. Main Pillars of APQP

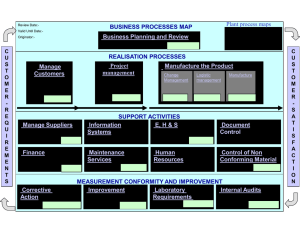

APQP is supported by three main Pillars. These pillars represent the structural needs for effective implementation of the APQP principles. (Figure 1)

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 5 of 101

APQP Overview and Element Cards

Figure 1

APQP Model

•

Organizational Commitment & Management Support

Implementation of APQP is a management driven strategic decision that requires support from the entire organization.

The information generated through the APQP process allows management to track and pace new/modified product development activities. Highlighting risks and monitoring status of APQP deliverables, promotes the execution of relevant actions needed to remove roadblocks that may jeopardize completion of requirements necessary for on-time product delivery.

•

Cross-Functional Team

The use of cross-functional teams builds unity of purpose across the business. It supports commitment and alignment with project timing and ensures effective communication across the various business functions. The teams should include functional representatives and stakeholders as appropriate to the project. Clearly defined roles and responsibilities will ensure timely completion of tasks in support of the overall project plan.

•

Effective Project Planning

The project plan is based on the customer’s needs. Key targets dates are cascaded throughout the value stream. All information is formalized into a project plan. Progress is tracked and reported on a planned schedule.

4. APQP Principles

The APQP principles are defined in terms of phases, elements, and deliverables.

(Figure 2)

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 6 of 101

APQP Overview and Element Cards

•

APQP phases represent distinct stages in the product realization process where specific activities are completed. The end of each phase is defined by the accomplishment of specific outputs (milestones) that support the overall success of the project.

•

Elements are the discrete activities that need to be completed during a specific phase.

•

Deliverables are tangible evidence that an activity has been completed effectively.

Figure 2

APQP Principles

4.1 The 5 Phases of APQP are defined as follows:

•

Phase 1 – Planning

Collect project inputs and set the project frame (product and process requirements, key actors, key tasks and timing plan).

•

Phase 2 - Product Design and Development

Design the product considering all identified requirements and risks.

•

Phase 3 - Process Design and Development

Design the manufacturing and assembly processes considering all identified requirements and risks.

•

Phase 4 - Product and Process Validation

Validate that the process is producing the specified product at the required rate.

•

Phase 5

– Production

Reduce variation, manage any non-conformity, continuous improvement, and feed lessons learned back into new product development projects and APQP.

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 7 of 101

APQP Overview and Element Cards

4.2 APQP Elements

APQP elements are the activities and deliverables completed during each phase. Effective project management ensures timely completion of activities and deliverables, and when necessary escalation and removal of roadblocks.

Effective implementation of the APQP plan results in on-time and on-quality products delivered to the customer.

This section of the SCMH contains a complete set of standard APQP elements for the aerospace industry. Not all elements will apply to every project. Each new project should include an evaluation of applicability for each element. The elements for each phase are as follows:

1.01.1 Product design requirements

1.01.2 Producer Product Specification

1.03 Preliminary listing of Critical Items (CIs) and Key Characteristics (KCs)

1.04 Preliminary Bill of material (BOM)

1.05 Preliminary process flow diagram

1.06 Statement of Work (SOW) Review

1.07 Preliminary sourcing plan

Phase 2 Product Design and Development

2.02.3 Design for Manufacturing and Assembly (DFMA), tolerance, stack-up analysis, etc.

2.02.4 Design for Maintenance, Repair and Overhaul (DMRO)

2.03 Special requirements, including product Key Characteristics (KCs) and

2.04 Preliminary risk analysis of sourcing plan

2.07 Development product build plan

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 8 of 101

APQP Overview and Element Cards

2.08 Design verification and validation plans, and associated results

Phase 3 Process Design and Development

3.03 Production preparation plan

3.04 Process Failure Mode & Effect Analysis (PFMEA)

3.05 Process Key Characteristics (KCs)

3.07 Preliminary capacity assessment

3.08 Work station documentation

3.09 Measurement Systems Analysis (MSA) Plan

3.10 Supply Chain Risk Management Plan

3.11 Material handling, packaging, labelling, and part marking approvals

3.12 Production Readiness Review (PRR) results

Phase 4 Product and Process Verification

4.02 Measurement Systems Analysis (MSA)

4.03 Initial Process Capability Studies

4.06 Product Validation Results

4.07 First Article Inspection (FAI)

4.08 Production Part Approval Process (PPAP) file and Approval Form

4.09 Customer Specific Requirements

5.01.2 Maintenance, Repair and Overhaul (MRO) KPIs and plan(s) to reach the established targets

5.02 Continuous improvement actions

Note: Additional details are provided in the Element Card.

Click on any element in the list to go directly to the Element Card.

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 9 of 101

APQP Overview and Element Cards

4.3 Element deliverables

Deliverables are the specific outputs defined for each element. Evaluation of the deliverables ensures effective completion of the activity as defined within the element. This document includes standardized content for some deliverables (e.g. FMEA, Control plan etc.). Standardized formats should be used whenever possible.

Each deliverable has an associated checklist. They consist of short sets of simple, clear, close-ended questions (designed to deliver Y/N answers) . The quality of the deliverables are assessed through the use of these checklists.

The checklist is also used to:

•

document references as evidence and records of deviations,

•

record corrective actions to correct deviations, and

•

establish the first level of Red/Yellow/Green rating; (based on answers to each questions).

5. APQP Management Process

1. Identify product

(new or modified)

APQP is applicable to all type of products (no matter their complexity). It requires an increased planning and monitoring effort. The organization should define where these responsibilities lie within the organization.

2. Nominate team

3. Check element applicability

4. Identify the product breakdown and create SOW

The scope of the APQP project should be based on a risk evaluation of the product and its sub-systems. Typically, risk categories will cover technology, manufacturing processes, supply chain performance, product criticality, and complexity.

Formally identify all project team members. Their nomination should specify their role within the team. Main roles include project leader, deliverable owners, and an APQP leader

(responsible for deploying APQP).

Based on product specific attributes, some of the key activities may not be applicable (e.g. design activities are typically not applicable for a process changed). Each activity will have an owner identified and/or nominated. See APQP Element

Applicability template at the bottom of this section.

Where appropriate, the final product is broken down into manageable sub-components. A formal Statement of Work

(SOW) that defines what needs to be done and when. The

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 10 of 101

APQP Overview and Element Cards

5. Decide make or buy

6. Cascade requirements to producer

7. Update APQP element applicability

8. Update Statement of Work

9. Agree on assessment timing based on risks or issues and create

APQP Plan

10. Perform assessments based on deliverables checklists

11. Escalate issues and get management feedback and support

SOW also defines the key project milestones that are the basis for planning APQP activities.

Note: Simple products may not need to be broken down into sub-components.

It has to be decided if the final product and the subcomponents (if any) will be designed and made in-house or fully/partially subcontracted. These Make-Buy decisions need to be made as early as possible in the planning phase.

Requirements are cascaded for each subcontracted product and/or sub-component. Technical requirements are formalized in a specification and non-technical requirements in a SOW.

They are the foundation of the customer/supplier agreement.

APQP element applicability may be revised based on producer feedback. For the activities under the responsibility of the producer, the activity owner needs to be formally identified and nominated.

Formalize updated requirements in the SOW. These can include both technical and non-technical in nature (i.e. APQP).

This exercise can be done during a formal APQP kick off meeting

When tasks, responsibilities and timing are defined and agreed to by all parties, the APQP leader creates the APQP plan. The plan is the basis for determining the frequency of APQP assessments.

Using APQP checklists (key questions are proposed by these documents), quality of the deliverables is assessed regularly to ensure their completion is on-time and on-quality.

A report that includes a summary of the assessment results is provided to management on a regular basis. The reporting structure is defined by the organization but must remain simple. Typically a checklist provides a deliverable status of

(Red/Yellow/Green) compiled for each element, and for one product. Subcomponents’ status are compiled through product layers (as per the product breakdown). Cross layer compilation

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 11 of 101

APQP Overview and Element Cards is based on a customer/supplier relationship (a Red status for a subcomponent may not endanger the customer product timing and consequently will not be escalated as Red).

6. APQP Reporting

6.1 Project Status - Red/Yellow/Green

Deliverable status is rated as Red/Yellow/Green based on the checklist status.

The basic ranking principles are as follows: (Figure 3)

Red :

Whenever a question cannot be answered with a clear yes, the deliverable owner should provide an action to recover on-time and on-quality. When an action plan cannot be provided or is not able to recover initial product timing, a red should be raised: THERE IS IMPACT TO THE FINAL PRODUCT

DELIVERY SCHEDULE

Yellow:

Yellows are highlighted when the answer to the question is no, but there is a robust action plan to recover situation: THERE IS NO IMPACT TO THE

PRODUCT DELIVERY SCHEDULE

Green:

All questions have a positive answer (Y) and are ongoing as planned

Figure 3

Red/Yellow/Green Status

6. 2 APQP Reporting

Impact of Red/Yellow status is evaluated from bottom up, i.e. managed on a producer/customer relationship between product layers. When one product is late (Red/Yellow), the project team will provide an action plan to recover and escalate its status to its customer. The customer project team evaluates the impact on its own product delivery and so on to the top product layer. The customer layers enable necessary actions to ensure on-time delivery. (Figure 4)

The same type of reporting takes place within the organization or with external producers. The final objective is to detect potential delays arising anywhere in the supply chain and implement necessary actions to reduce effects as soon as possible.

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 12 of 101

APQP Overview and Element Cards

Figure 4

Escalation Process

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 13 of 101

APQP Overview and Element Cards

Phase 1 Planning

Phase Definition:

Introduction

The goal of phase 1 is to establish the framework of the project. All inputs should be identified and captured. These inputs come from multiple sources: the customer, regulatory requirements, benchmark data, lessons learned, company knowledge and strategy.

Comprehensive input supports the building of technical, quality and manufacturing requirements, identification of parts to be outsourced, building of the sourcing plan, and finally the building of the APQP plan describing all APQP activities and a schedule aligned with the project needs. During this phase, the product and process concept becomes available, a project team is established, and stakeholders understand what tasks need to be completed along with the timing for their completion. Establishing a robust project plan during the

Planning phase is critical to the success of the project.

Completion of phase 1 is indicated by the finalization of the product concept, availability of the preliminary BOM, and completion of applicable activities and deliverables defined in the project plan.

Phase 1 Planning

1.01.1 Product design requirements

1.01.2 Producer Product Specification

1.03 Preliminary listing of Critical Items (CIs) and Key Characteristics (KCs)

1.04 Preliminary Bill of material (BOM)

1.05 Preliminary process flow diagram

1.06 Statement of Work (SOW) Review

1.07 Preliminary sourcing plan

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 14 of 101

APQP Overview and Element Cards

Element 0.01 Project Inputs

Element Owner: Business Development/Program Management Team

Element Definition:

The project inputs should come from as many sources as possible in order to have the most successful product launch. Project inputs should include the following five main sources:

1. Regulatory Requirements

2. Customer Needs o Project milestones and product delivery date o Projected volumes o Program lifecycle o Product and process assumptions

3. Product Performance o Historical problems internal and external including warranty o Reliability requirements o Quality requirements o Technical requirements

4. Lessons Learned o Best practices o Project management o Quality issues o Product design guidelines/procedures/data from similar product o Process design guidelines/procedures/data from similar product

5. Company Strategy o Business plan o Marketing strategy o Industrial strategy o Technical strategy

Project inputs should include lesson learned from previous designs, producer feedback, benchmark data, current manufacturing capability, internal/external product performance data and reliability data, warranty data and other relevant sources.

Deliverables:

Requirements document (Statement of Work) where changes are managed and recorded .

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 15 of 101

APQP Overview and Element Cards

Necessary Inputs: Source of inputs:

Regulatory requirements

Customer needs

Product performance

Lessons learned

Company strategy

Customer

Regulatory Agencies

Sales & Marketing

Design Engineering

Manufacturing Engineering

Quality Engineering

Project Manager

Resources:

Sales and marketing, design engineering, project manager

Methodology :

1. Gather regulatory and customer requirements, product performance requirements, lessons learned and company strategy including information from previous programs and applicable standards.

2. Identify the activities to be performed in a Statement of Work (SOW), which demonstrates commitment to achieving the established requirements.

3. Review and finalize SOW with customer.

4. Track changes.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 0.01

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 16 of 101

APQP Overview and Element Cards

Element 1.01.1 Product Design Requirements

Element Owner: Design Engineer

Element Definition:

The product ( technical) design requirements are created by taking customer wants and needs, as well as regulatory requirements and converting them into clearly defined design objectives.

Product design requirements typically include items such as:

•

Functional performance

•

Architecture constraints (e.g. space, interfaces, external envelop, etc.)

•

Type of material

•

Special processing constraints

•

Weight

•

Specific acceptance criteria based on attribute information (appearance, color, odor, noise, etc.)

•

Regulatory requirements (safety environment and trade compliance, etc.)

•

In-house best practices & lessons learned

•

Reliability

The product design requirements are intended to define and prioritize the constraints and expectations of the product. These requirements are reviewed and mutually agreed upon with the customer. As the result of the prioritization, a preliminary listing of CIs and KCs is defined.

Techniques such as Design for x (DFx) (six sigma, manufacturability, assembly, cost, test, maintainability, etc.) can help focus the design by considering the specific constraints highlighted and prioritized in the product technical design requirements, quality goals, reliability goals, & process requirements.

Deliverables:

Configuration controlled Product (technical) Design requirement document(s) agreed upon between producer and customer

Inputs:

Lessons learned (e.g. benchmark, warranty, performance, etc.)

Customer, regulatory & internal requirements

Supporting technical specifications

Source of input

Customer

Sales & Marketing

Design Engineering

Resources:

Customer, Design Engineering

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 17 of 101

APQP Overview and Element Cards

Methodology :

1. Analyze data from previous programs, applicable standards, and information obtained from customer/market, product/process design guidelines.

2. Create a formal technical requirements document.

NOTE: Concurrent engineering is a best practice to help ensure both customer needs and supplier knowledge are considered.

NOTE: Quality Function Deployment (QFD) is a tool that can be used to conduct this exercise.

3. Conduct a design review with the customer.

4. Obtain customer approval as required.

5. Monitor and track changes.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 1.01.1

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 18 of 101

APQP Overview and Element Cards

Element 1.01.2

Producer Product Specification

Element Owner: Design Engineering

Element Definition:

The design organization (producer owned design) demonstrates in a clear product specification that the customer’s requirements are understood and they have the capability to support all customer’s requirements (technical, process, reliability and quality, etc.). In this specification, the design organization will also consider its own best practices and consider constraints in defining product requirements. The Producer Product Specification should be reviewed and approved by a competent person within the Design Organization Authority.

Techniques such as Design for x (DFx) (six sigma, manufacturability, assembly, cost, test, maintainability, etc.) can help focus the design by considering the specific constraints highlighted and prioritized in the Product (technical) Design Requirements (see 1.01.1), quality goals, reliability goals, & process requirements.

Deliverables:

Approved configuration controlled Producer Product Specification

Necessary Inputs: Source of Input

Customer reliability and quality targets Quality Engineering

Producer reliability and quality targets

Product KCs

Technical requirements

Producer design guidelines

Design Engineering

Quality Organization

Manufacturing Engineering

Environmental and regulatory requirements

Process requirements

Resources:

Customer, Design Engineering and Manufacturing Engineering

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 19 of 101

APQP Overview and Element Cards

Methodology :

1. Collect all relevant information to support the creation of the product specification this will include: customer technical, reliability and quality requirements, preliminary CIs/KCs for product /program/process, supplier design guidelines, supplier technical know-how and supplier industrial constraints.

2. Create a product specification, which captures all requirements considering the DFx constraints identified as part of technical design requirements.

3. Review the product specification with the relevant functions and customer as required.

4. The specification is then passed onto the authorized person(s) for approval and release.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 1.01.2

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 20 of 101

APQP Overview and Element Cards

Element 1.02

Project Targets – safety, quality/manufacturability, service life, reliability, durability, maintainability, schedule and cost

Element Owner: Program Manager

Element Definition:

Project targets include product safety, performance, quality, manufacturability, reliability, and service life. These targets should be based on customer expectations, regulatory requirements, and project specific objectives. Product quality should be monitored throughout the product lifecycle (development, series production, in service performance) using quality metrics. The use of quality metrics is especially useful for driving continuous improvement and customer satisfaction. The following list identifies typical project targets for these categories:

•

Product safety: safety fa ctor of mechanical design (stress related) and λ (failure rate) in electronic design

•

Performance: customer functional requirements

•

Quality: Defective Parts Per Million (DPPM), Defects Per Million Opportunities

(DPMO), Customer escapes, warranty returns, field problems, recurrent field and manufacturing problems, RFTY First Article Inspection Reports (FAIRs) and

Production Part Approval Process (PPAP)

•

Manufacturing: through put time (time to go to the whole Manufacturing process), lead time, Right First Time Yield (RFTY), First Pass Yield

•

Reliability: Mean Time Between Failure / Mean Time Between Repair / Mean Time

Between Unplanned Repair, and Operational Reliability

•

Service life: time to repair (when failure occurs in service) and quality targets in service.

Additional targets may include durability, maintainability, schedule, and cost. These targets can be described as follows:

•

Durability may include life time targets

•

Maintainability may include mean-time-to-failure, turn-time, operational reliability targets

•

Product schedule target are milestones defined by the organization to execute the activities to be performed according to their product development process

•

Product and Project cost shall include total cost of ownership (development, production, procurement, logistics and overhead cost).

All targets and metrics should be specific, measurable, agreed, actionable, reportable, challenging and time bound.

Deliverables:

Agreed upon list of Key Performance Indicators (KPIs) covering safety, quality/manufacturability, service life, reliability, durability, maintainability, schedule, and cost for the complete product lifecycle

Source of inputs Necessary Inputs:

All project inputs described in element

0.01

Project team, Finance

Sales & Marketing and Engineering

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 21 of 101

APQP Overview and Element Cards

Customer reliability and quality targets for product and program

Producer (internal/external) capability

Quality and Procurement

Resources:

Quality, Design and Manufacturing Engineering, Procurement, Marketing, Sales and Finance

Methodology :

1. Collect project inputs and product requirements for product and program.

2. Determine the appropriate project targets in order to meet the above.

3. Determine the associated KPIs and get approval from Quality and Program Managers.

4. Flow these goals into product and process design and to the supply chain.

5. Goal validation occurs in phase 2 thru 5.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 1.02

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 22 of 101

APQP Overview and Element Cards

Element 1.03 Preliminary Listing of Critical Items (CIs) and Key Characteristics

(KCs)

Element Owner: Design Engineering and Manufacturing Engineering

Element Definition:

CIs are the items which will have a significant impact on product realization and subsequently its use. KCs are attributes or features whose variation has a significant impact on the CI and/or product. The impact includes safety, performance, fit, form, function, manufacturability, service life, etc. These items require specific actions to ensure they are adequately managed through the design and manufacturing processes.

Customer and supplier knowledge of the product and the manufacturing processes will help determine the preliminary product and process CIs and KCs.

The determination of preliminary product and process CI/KC is done by a cross-functional team including Design and Manufacturing Engineering (including supplier Manufacturing

Engineering) supported by Quality. It is a best practice to use Quality Function Deployment

(QFD) and previous DFMEA/PFMEA on similar product/processes.

The list of CIs/KCs becomes part of the technical requirements.

Deliverables:

A preliminary listing of CIs and KCs agreed upon between supplier and customer

Inputs:

Lessons Learned

Source of Inputs

Design Engineering

Design Standards (Product knowledge)

DFMEA/PFMEA on similar products

Program Requirements

Technical (design and process) Requirements

Project Leader

Manufacturing Engineering

Producer

Resources:

Quality, Program Management, Design Engineering, Manufacturing Engineering experts (as required)

Methodology :

1. Each involved function (Quality, Program Management, Design Engineering, and

Manufacturing Engineering) should review the technical requirements and data inputs and create their CIs/KCs proposal.

2. The team meets and agrees on the preliminary CIs/KCs.

3. Flow preliminary CIs/KCs to product and process design and to supply chain when necessary.

NOTE: QFD is a tool which can be used to conduct this exercise. CIs/KCs are the result.

Reference Documents:

IAQG Standard 9103 Variation Management of Key Characteristics

SCMH Section 3.2 First Article Inspection

SCMH Section 7.1

Work Transfer Management

SCMH Section 7.2.4 Phase 1 Checklist 1.03

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 23 of 101

APQP Overview and Element Cards

Element 1.04

Preliminary Bill of Material (BOM)

Element Owner: Design engineering

Element Definition:

Complex products are best managed by breaking the product into manageable sub-systems

(Product Breakdown Structure (PBS)). These sub-systems are the basis for the Preliminary

BOM and drive the early make-buy decisions.

The team should establish a preliminary BOM using PBS and considering the early product/process assumptions. The preliminary BOM will be the starting point for subsequent product and process design as well as supplier selection activities.

Deliverables:

•

PBS for complex products and list of sub-systems showing the product assembly hierarchy

•

Preliminary BOM

Necessary Inputs:

Producer Product Specification

Design Standards (Product knowledge)

Lessons Learned

Producer benchmarking and capability evaluation

Source of input

Design Engineering

Cross-functional team

Manufacturing Engineering Manager

Procurement Manager

Supplier Performance Management

Industrial strategy

Purchasing strategy

Resources:

Design Engineering, Manufacturing Process Engineering, Procurement/Contract, Suppliers and Quality Organization

Methodology :

1. Design Engineering produces draft PBS.

2. The draft PBS is then reviewed and discussed with the support functions.

3. Based on inputs, the draft PBS is updated and preliminary BOM is developed.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 1.04

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 24 of 101

APQP Overview and Element Cards

Element 1.05 Preliminary Process Flow Diagram

Element Owner: Manufacturing Engineering

Element Definition:

The preliminary Process Flow Diagram (PFD) provides an anticipated overview of the sequence of manufacturing activities, from receiving to shipment to the customer. It should also take into account the transfer operations from step to step. A well-defined preliminary

PFD supports early process planning, e.g. logistics, supplier selection and engagement, facilities, equipment, etc.

The preliminary PFD should highlight the most critical activities, such as those requiring longer lead times or additional qualification(s). Development of the preliminary PFD should start once the preliminary BOM is complete. Representatives from potential manufacturing sources should be included, as appropriate.

Deliverables:

Preliminary PFD signed off by design and manufacturing engineering, production, procurement and quality.

Necessary Inputs: Source of input:

Technical requirements

Preliminary BOM

Quality requirements

Manufacturing process expertise

Key Characteristics and Critical Items

Design Standards (product knowledge)

Producer performance and capability

Design Engineering

Quality Engineering

Manufacturing Engineering

Procurement

Resources:

Design Engineering, Manufacturing Engineering, Quality Engineer, Procurement,

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 25 of 101

APQP Overview and Element Cards

Methodology:

1. Cross-functional (Engineering, Manufacturing Engineering, Procurement, Quality) team reviews the inputs from product specification, quality goals, preliminary process CIs/ KCs ,

Preliminary BOM and other project inputs.

2. Manufacturing Engineering proposes a manufacturing process within which all identified constraints have been considered.

3. Cross-functional team reaches agreement on the preliminary process flow and verifies alignment with the BOM.

Reference Documents:

SCMH Section 7.2.9 Process Flow Diagram Template

SCMH Section 7.2.4 Phase 1 Checklist 1.05

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 26 of 101

APQP Overview and Element Cards

Element 1.06 Statement of Work (SOW) Review

Element Owner: Customer Contract Manager

Element Definition:

The SOW is a formal document that defines the entire scope of the work involved for a producer and clarifies deliverables and timeline. The statement of work should include:

•

Deliverables and due dates

•

Tasks that lead to the deliverables, and who these tasks are assigned to

•

Resources needed for the project including facilities and equipment

•

Specifications and procedures

•

Governance process for the project .

The details in the SOW are reviewed by both parties to ensure all customer requirements are understood and the producer has the capability to comply. A compliance matrix is useful to summarize how the requirements will be met. Identified exceptions are resolved between both parties and SOW is revised accordingly.

Deliverables:

•

Signed SOW

Necessary Inputs:

Customer reliability and quality targets for product and program

Source of Inputs:

Design Engineering

Quality Organization

Preliminary BOM

Preliminary PFD

Technical requirements

Product and process CI/KCs

Timing requirements

Specifications and procedures

Manufacturing Engineering

Customer

Program Manager

Resources:

Quality, Design and Manufacturing Engineering, Sales, Program Management, Customer

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 27 of 101

APQP Overview and Element Cards

Methodology :

1. The customer develops and provides a formal SOW to the supplier.

2. Program Manager summarizes all customer requirements into a compliance matrix.

3. Each function confirms compliance to each item that it is responsible for and proposes possible recovery actions for noncompliant items.

4. Supplier presents the compliance matrix to the customer for review.

5. Customer determines acceptabilit y of the producer’s proposal and the SOW is revised accordingly.

6. SOW is formally agreed to by both parties.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 1.06

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 28 of 101

APQP Overview and Element Cards

Element 1.07

Preliminary Sourcing Plan

Element Owner: Procurement

Element Definition:

Once the preliminary BOM is developed, the organization will begin making the initial make/buy decisions, i.e. identify items that will be produced in-house and those that will be outsourced. This should be done as soon as possible so that producers are engaged early in the planning process.

A sourcing plan is developed for the identification and selection of producers that will be supporting the development and production of outsourced items. The sourcing plan should consider the overall program timing and ensure synchronization with program commitments.

Requirements for flow down to producers should be identified from the SOW and provided to the producer as early as possible.

Deliverables:

•

Make/buy decisions

•

Sourcing plan

•

Identified requirement to be flowed down to producer

Necessary Inputs: Source of inputs:

Project targets

Preliminary BOM

Producer product specification

Preliminary PFD

Design Engineering

Manufacturing Engineering

Program Manager

Contract Manager

Procurement Timing requirements

SOW

List of approved suppliers and their capabilities

Resources:

Procurement, Quality, Design & Manufacturing Engineering, Program/Contract Management

Methodology :

1. The team performs an analysis for make/buy decisions.

2. Procurement is advised of items to be purchased and is provided the necessary information regarding product and quality requirement that will be flowed down to suppliers.

3. Procurement determines supplier’s capability based on supplier’s performance history and similarity with previously provided products and/or services.

4. Procurement gathers key information (program timing, preliminary BOM) and develops a sourcing plan considering the above and identifying potential risks.

5. The team agrees to the sourcing plan and the associated risks identified.

6. Mitigation plans are developed as appropriate to the level of risk.

7. Procurement implements and monitors the plan.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 1.07

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 29 of 101

APQP Overview and Element Cards

Element 1.08

Project Plan

Element Owner: Program Manager

Element Definition

The project plan defines the scope, activities, and deliverables for Advanced Product Quality

Planning (APQP). APQP activities and deliverables may vary based on product complexity, associated risk, and customer requirements. The planning team should consider all deliverables included herein for applicability to the project (reference: Aerospace International

Standard 9145 Appendix B).

The plan includes scheduled start and completion dates for APQP deliverables aligned with customer, program, or project requirements. At a minimum, the plan should include key customer driven dates (e.g. first delivery, certification, entry into service). Each activity identified in the plan should have a designated responsible person.

The Project Plan is used to cascade dates to producers for key deliverables on the subassemblies and components that makeup the product.

Adherence to the project plan ensures that each activity is completed on time and the necessary resources are available. Progress against the plan should be monitored regularly and delays escalated through a defined reporting process. Frequency of reviews should be defined in the plan.

The plan is created during phase 1 and is agreed upon by and communicated to stakeholders, including customers and suppliers (as appropriate). It will only be modified if the overall project timing changes. Monitoring the APQP process and adherence to the timeline is a key to successful implementation. Project Plan is the basis for the team ’s commitment and ensures success of program timing.

Deliverables:

Agreed upon timing plan that includes activities, due dates and responsible parties

Necessary Inputs: Source of input

APQP applicable task lists

Project timing requirements

Cross-functional Team

Program Manager

Customer

Resources:

Sales, Program Management, Design and Manufacturing Engineering, Procurement, Quality,

Customer Support, Production

Methodology :

1. Program Manager provides the key dates that may affect the project timing requirements to the team.

2. The cross-functional team determines which APQP elements are applicable.

3. Task owners propose their preliminary timing plan to the Program Manager.

4. Program Manager collates all timing proposals.

5. The team reviews conflicts and agrees to an acceptable timing plan that will support program targets.

6. Program Manager communicates project plan to all stakeholders.

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 30 of 101

APQP Overview and Element Cards

7. Tasks are completed by responsible parties according to the plan timing. Risks and challenges are identified and reported as appropriate.

8. Progress is monitored and reported at specified intervals.

9. Program Manager escalates major issues to upper management.

NOTE: As external producers are identified, they should develop their own APQP project plan consistent with their custome r’s requirements. External producers will monitor and report their progress as requested.

Reference Documents:

SCMH Section 7.2.4 Phase 1 Checklist 1.08

SCMH Section 7.2.12 APQP Element Applicability Template

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 31 of 101

APQP Overview and Element Cards

2.0 Phase 2 Product Design and Development Introduction

Phase 2 discusses the translation of the product requirements, as determined in phase 1, into a controlled, verified and validated product design. During this phase the product key characteristics, the intended production processes, and potential suppliers used to realize the product, are identified. In addition, the feasibility of manufacture of the proposed design is assessed by the intended production source.

Phase 2 Product Design and Development

2.02.3 Design for Manufacturing and Assembly (DFMA), tolerance, stack-up analysis, etc.

2.02.4 Design for Maintenance, Repair and Overhaul (DMRO)

2.03 Special requirements, including product Key Characteristics (KCs) and Critical

2.04 Preliminary risk analysis of sourcing plan

2.07 Development product build plan

2.08 Design verification and validation plans, and associated results

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 32 of 101

APQP Overview and Element Cards

Element 2.01

Design Risk Analysis

Element Owner: Design Engineering

Element Definition:

A Design Risk Analysis is an analytical technique used to identify potential failure modes related to product performance (i.e. fit, form, function), durability, service life, reliability, manufacturability, maintainability and cost and to ensure that they have been considered and addressed by the design of the product. The Design Risk Analysis is performed by the design responsible organization and should be done early in the design phase to ensure that identified design risks are mitigated before the design is finalized.

A Design Risk Analysis is a summary of the team’s inputs including an analysis of all functions/features identifying those that could go wrong based on experience, past or current concerns, as a system, subsystem or component is designed.

Design Failure Modes and Effects Analysis (DFMEA) methodology can be used as a record of this activity (reference SAE J1739).

A Design Risk Analysis is a living document that is updated throughout the product life cycle based on latest performance information, manufacturability, design changes, etc.

Design Risk Analysis for groups or families of parts, components, or assemblies are acceptable if the materials, parts, components, or assemblies can be confirmed as having been reviewed for commonality of design, function, and operating environment.

There is a close link between the Design Risk Analysis and the Process Failure Modes and

Effects Analysis (PFMEA). Updates to either may impact the other and should be taken into account.

A safety or criticality analysis done to fulfill regulatory requirements does not address the same scope as a Design Risk Analysis and cannot be substituted for or considered an equivalent.

Deliverables:

•

Design Risk Analysis highlighting design risks

•

Recommended actions for risk mitigation

•

Identification of CIs and product KCs

Necessary Inputs: Source of Input:

Technical specification

Past product performance test results

Lessons learned

Design Engineering

Cross-functional Team

Resources:

Customer, Quality Engineer, Design Engineering, Manufacturing Engineering

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 33 of 101

APQP Overview and Element Cards

Methodology :

The following steps apply when the DFMEA is used to perform the Design Risk Analysis:

1. Determine the function, features or requirements of design.

2. Identify and document the potential failures.

3. List the effects of the failure.

4. Rank the severity of the failure.

5. List the potential causes of the failure.

6. List the preventive methods taken to eliminate the cause.

7. Rank the frequency of each specific cause occurring.

8. List the detection methodology(s).

9. Rank effectiveness of the detection methodology(s).

10. Determine the Risk Priority Number (RPN), calculated as follows:

•

Severity of the risk X Likelihood of occurrence X Ease of detection

•

The higher the number, the higher the risk and the need to undertake an action to remove/reduce/detect the root cause(s) which generates the risk.

11. Select the recommended actions to be implemented, as needed.

12. After implementation of the recommended actions, re-rank Severity, Occurrence, Detection based on evidence of the effectiveness of the actions.

13. High risk items should generate a Key Characteristic in order to detect and control the risk.

These will be considered during the Process FMEA

Reference Documents:

SAE J1739 Potential Failure Mode and Effects Analysis in Design (Design FMEA), Potential

Failure Mode and Effects Analysis in Manufacturing and Assembly Processes

(Process FMEA)

SCMH Section 7.2.10 Design FMEA Template

SCMH Section 7.2.5 Phase 2 Checklist 2.01

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 34 of 101

APQP Overview and Element Cards

Element 2.02.1

Element Owner: Design Engineering

Design Records

Element Definition:

Design Records are the output of the design process and are based on the Product Design

Requirements and the SOW established in phase 1. These records are engineering documents that define all aspects of the product. They include:

•

Physical or electronic/digital drawings

•

Electronic/digital models

•

Software

•

Special process specifications

•

Material specifications

•

Supplementary specifications

•

Customer specifications

•

Product Function (Input / Output)

•

Product Envelope (Size & Weight)

•

Appearance specifications (if any)

•

Product KCs.

Design records also include authorized engineering changes not yet incorporated into the released engineering definition / specification.

Deliverables:

Complete engineering definition / specification of the product, which satisfies the requirements as defined in phase 1 and is approved by the Design Authority.

Necessary Inputs: Source of Input:

Statement of Work (SOW)

Lessons learned

Product breakdown structure (PBS)

Design Risk Analysis output

Resources:

Design Engineering

Methodology :

Customer

Program Management team

Design Engineering

Manufacturing Engineering

1. Consider output of phase 1 elements.

2. Incorporate all aspects of the design into the Design Records.

3. Review the Design Records to ensure they satisfy all applicable product requirements.

4. Submit Design Records for Design Review.

5. Implement design changes as defined by Design Review.

6. Approve Design Records and apply configuration control.

7.

Provide approved Design Records to the producer(s).

Reference Document

SCMH Section 7.2.5 Phase 2 Checklist 2.02.1

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 35 of 101

APQP Overview and Element Cards

Element 2.02.2

Element Owner: Design Engineering

Bill of Material (BOM)

Element Definition:

The Bill of Material (BOM) is the list of all components and materials contained in the Design

Records required to produce a finished product. The preliminary BOM, defined in phase 1, continues to mature through the design synthesis of phase 2.

In this phase, the BOM is fully defined and released for production. All future revisions are controlled through the configuration management process.

Deliverables:

Released BOM

Necessary Inputs:

Preliminary BOM

Product breakdown structure

Output of DFMA (element 2.02.3)

Output of DFMRO (element 2.02.4)

Source of Input:

Design Engineering

Resources:

Design and Manufacturing Engineering, Quality

Methodology :

1. Update the preliminary BOM.

2. Execute cross-functional reviews as appropriate, including outputs of DFMA and DFMRO.

3.

Release the BOM and include it in the approved Design Records.

Reference Documents:

SCMH Section 7.2.5 Phase 2 Checklist 2.02.2

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 36 of 101

APQP Overview and Element Cards

Element 2.02.3 Design for Manufacturing & Assembly (DFMA), tolerance, stack-up analysis, etc.

Element Owner: Product Engineering and Manufacturing Engineering

Element Definition:

This element emphasizes the need for collaboration between Product Design Engineers and

Manufacturing Engineers to ensure that:

•

The design process considered the manufacturing processes, such that the design solution delivers quality products, which can be fabricated and inspected in an efficient and cost effective manner.

•

Stack up analysis was performed to confirm that the product will function and can be assembled as intended.

•

The design process has considered the assembly processes and tooling capability such that the parts can fit together and that the intended tools, including any inspection devices, could be inserted into and extracted from the assembly needed. This includes ergonomic considerations of the space for the assembler’s hands or fingers, line of sight, etc.

•

Materials, such as specialized materials, electronic chips, will be available over the life of the product, and, as needed, a plan for obsolescence and/or alternate material has been established.

During the design collaboration, additional consideration is to be given to common failure modes of the manufacturing processes with an approach to design them out. Preliminary PFMEA should be developed concurrently with the design risk analysis to support this design element.

Rapid prototyping of parts can be used to validate the design analysis.

Deliverables:

A design that meets customer requirements and meets:

•

program quality goals for First pass yield (FPY) or Defects per million opportunities (DPMO)

•

applicable manufacturing standards

•

Factory Standard Cost and lead time goals

•

inspection/testing requirements

Necessary Inputs: Source of Input:

Manufacturing capability data

Preliminary process flow diagram

Technical design requirements

Quality performance data

Process planning

Manufacturing Engineering

Design Engineering

Quality Engineering

Quality Organization

Assembly standard practices

Catalogue of highest risk assembly hazards

Visualization and clash detection software

Resources:

Design Engineering, Manufacturing Engineering, Quality Engineers, Process Planner

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 37 of 101

APQP Overview and Element Cards

Methodology for Manufacturing :

1. Gather defect data from the manufacturing of similar parts.

2. Review the technical design requirements.

3. Review the design, feature by feature, to understand how each will be manufactured and inspected.

4. Identify difficult to produce or inspect features or geometric relationships.

5. Identify materials that are difficult to obtain or have high potential of obsolescence.

6. Identify features that drive ‘out of the cell’ process steps or other inefficient manufacturing practices (such as extra tool passes).

7. Identify features that have been problematic based on the history of prior parts.

8. If possible, modify the design to remove features revealed in 4, 5, 6 and 7.

9. If features from 4, 5, 6 and 7 cannot be removed, task Manufacturing Engineering to look at alternate manufacturing or inspection approaches to mitigate the risks.

10. Consider error-proofing techniques.

Methodology for Assembly :

1. Gather assembly data of similar assemblies.

2. Review the new design, considering each assembly step and how it can fail or how its associated inspection can fail, consider error-proofing techniques.

3. Identify difficult to assemble sequences, excess steps , or ‘out of the cell’ sequences.

4. Identify assemblies that have been problematic in the past based on historical assemblies.

5. If possible, modify the design to remove the difficulties identified in 2, 3 and 4.

6. If the assembly cannot be redesigned , task Process Planning to design assembly sequences and tooling that mitigate the identified risks incorporating error-proofing techniques as appropriate.

Reference Documents:

SCMH Section 7.2.5 Phase 2 Checklist 2.02.3

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 38 of 101

APQP Overview and Element Cards

Element 2.02.4 Design for Maintenance, Repair and Overhaul (DMRO)

Element Owner: Product Engineering, Manufacturing Engineering and Aftermarket Technical

Support

Element Definition:

A unique feature of aerospace products is that the product lifecycle may span decades. This drives a disciplined maintenance, repair and overhaul activity.

Collaboration is required between Product Design Engineers, Manufacturing Engineers and

Aftermarket Technical Support to ensure that:

•

The design solution provides for in-service maintenance features that allow use of diagnostic tools and consumable components to be easily removed and replaced.

•

The design solution results in components that can be repaired on the equipment available at the repair supplier and re-qualified to overhaul tolerances.

•

Where repair is to be made in the installed condition, or away from a repair station, the design solution should allow for repair using portable tools. This includes ergonomic consideration of the space for tools, the repair mechanic’s hands or fingers, line of sight, effects of wind, rain, airborne contaminants, etc.

•

The design synthesis considers the needs of disassembly and assembly at overhaul.

•

Classed components should have a sufficient range of classes defined on the drawing to address the range demanded by assemblies with service time.

In the course of the design collaboration, additional consideration is to be given to common failure modes of the maintenance, repair or overhaul processes with a view to designing them out where possible (see also Phase 5 Maintenance, Repair and Overhaul (MRO) KPIs and plan(s) to reach the established targets).

Recommendations should emerge from the design cycle for development tests of the repair processes to demonstrate successful repair/overhaul sequence execution and repair durability. Program management should plan to have development hardware available for this purpose.

Deliverables:

•

A design solution that ensures that repair and overhaul of the product meets the lead time and cost goals established

•

A list of recommended tests or repair procedures to be validated in the design verification and validation test plan.

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 39 of 101

APQP Overview and Element Cards

Necessary Inputs: Source of Input:

Manufacturing capability data

Process planning best practices

Assembly standard practices

Catalogue of highest risk assembly hazards

Design software with visualization and clash detection capability

Maintenance Repair and Overhaul Data

Manufacturing Engineering

Design Engineering

Customer Services

Repair best practices

Overhaul best practices

Maintenance best practices

Resources:

Design Engineering, Manufacturing Engineering, Aftermarket Technical Support

Methodology for Maintenance :

1. Gather defect data from the maintenance, repair and overhaul history of similar products.

2. Review the new design feature by feature to understand how each will be maintained, restored by repair and rebuilt into the assembly.

3. Create repair time targets.

4. Identify difficult to maintain, repair or rebuild features.

5. Identify features that drive extra maintenance burden or repair process steps or other inefficient manufacturing practices.

6. Identify features that have been problematic based on the history of prior products.

7. If possible, modify the design to remove features identified in 4, 5 and 6.

Reference Documents:

SCMH Section 7.2.5 Phase 2 Checklist 2.02.4

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 40 of 101

APQP Overview and Element Cards

Element 2.03

Special requirements, including product Key Characteristics (KCs) and Critical items (CIs) listings

Element Owner: Design Engineering

Element Definition:

Special requirements have a high risk of not being achieved. Examples include performance requirements imposed by the customer that are at the limit of the industry’s capability, or requirements determined by the organization to be at the limit of its technical or process capabilities. Factors used in the determination of special requirements include product or process complexity, past experience, and product or process maturity.

Preliminary critical items (CIs) and key characteristics (KCs) are identified in phase 1. During the design processes and the Design Risk Analysis of phase 2, the preliminary list of CIs and

KCs should be reviewed. Additions to the list will be made when new risks, which cannot be eliminated by design, need to be controlled by key characteristics. The CIs and KCs are indicated in the design records. The finalization of critical items and key characteristics is an output of the Design Risk Analysis and PFMEA.

Deliverables:

List of the CIs and KCs.

Necessary Inputs:

Product design

Customer specifications

Design Risk Analysis and PFMEA

Source of Input:

Customer

Design Engineering

Manufacturing Engineering

Quality Engineering Preliminary CIs and KCs list

Resources:

Design Engineering, Manufacturing Engineering, Quality Engineering

Methodology :

1. Consult the list of CIs and KCs determined in 1.03

Preliminary listing of Critical Items (CIs) and Key Characteristics (KCs).

2. Conduct the Design Risk Analysis identifying high risk areas that cannot be designed out.

3. Conduct the design synthesis of DFMA and DMRO identifying high manufacturing risk areas that cannot be designed out.

4. Identify high manufacturing risk areas from the preliminary PFMEA(s) that cannot be removed by process changes.

5. During steps 2, 3 and 4, identify CIs and KCs that, when in control, reduces the risks to an acceptable level.

6. Update the preliminary CIs and KCs list with the new information.

Reference Documents:

International Aerospace Standard 9103 Variation Management of Key Characteristics

SCMH Section 7.2.5 Phase 2 Checklist 2.02.3

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 41 of 101

APQP Overview and Element Cards

Element 2.04

Preliminary Risk Analysis of Sourcing Plan

Element Owner: Manufacturing Engineering, Procurement, Program Management

Element Definition:

Risk associated with supplier selection should be identified and mitigated as appropriate and as early as possible. These risks may be associated with technology, logistics, lead-time, potential for part obsolescence, authenticity (counterfeit parts prevention), sole source, etc.

Judicious supplier selection is the first step towards minimizing supplier risk.

The sourcing risk evaluation should include:

•

Capacity

•

Capability

•

Performance (quality and delivery history of existing suppliers)

•

Financial stability

•

Certifications, as required, 9100, 9110, 9120, Nadcap, etc.

•

Regulatory requirements e.g. DOD, ITAR and other requirements

•

Logistics/Location

•

Total cost

•

New site/source qualification

•

Customer specific requirements .

Selected and/or potential suppliers should provide input to this risk analysis and its mitigation plan .

NOTE: The risk analysis of the sourcing plan is initiated in this phase and will continue through all subsequent phases .

Deliverables:

A sourcing plan with identified risks, aligned by each proposed supplier, and the mitigation plans

Necessary Inputs:

Technical Design requirements including:

Product technology requirements

Source of Input:

Regulatory Agencies

Customer

Manufacturing technology requirements

DFMA requirements

DFMRO requirements

Approved supplier list

Supplier data/performance history (see list above)

Regulatory requirements

Design Engineering

Manufacturing Engineering

Procurement

Suppliers

Resources:

Design Engineering, Suppliers, Manufacturing Engineering, Procurement, Quality

Methodology :

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 42 of 101

APQP Overview and Element Cards

1. Select suppliers that are likely to be capable of supporting the design effort and that are capable of producing the make to print or proprietary design elements.

2. Review all design requirements or all proposed design features for any risks they pose to successful manufacture at the rate required by the program. Consider risk related to technology, logistics, lead-time, potential for part obsolescence, authenticity (counterfeit parts prevention), manufacturability, etc.

3. Identify areas of concerns.

4. Review and propose appropriate risk mitigation actions and document them in the plan.

5. If applicable, provide input into the design change process and document it.

6. Use Design Reviews to review mitigation activities.

7.

Apprise stakeholders of progress and additional resource needed.

Reference Documents:

SCMH Section 7.2.5 Phase 2 Checklist 2.04

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 43 of 101

APQP Overview and Element Cards

Element 2.05 Packaging specification

Element Owner: Manufacturing Engineering

Element Definition:

To support a successful product launch it is essential that there is proper definition and planning for all new packaging required to handle and ship the product to subcontractors or to the customer.

This planning should also consider the refurbishment or modification of any existing packaging.

Deliverables:

Packaging specification agreed with the customers, where appropriate.

Necessary Inputs:

Process flow diagram

Internal packaging standards

Source of inputs:

Manufacturing Engineer

Packaging Engineer

Definition of packaging requirements & standard from customer (where defined)

Import/export regulations

Customer

Traffic and Logistics

Resources:

Manufacturing Engineering, Procurement (for outsourced processes), Packaging Engineer,

Production, Quality

Methodology:

1. Consider the packaging requirements for transporting product between each process step from receipt of initial goods through arrival at the customer.

2. Consider customer and regulatory requirements where applicable.

3. Points to consider during packaging design should include:

•

Damage prevention (impact, electrostatic damage, etc.)

•

FOD (Foreign Object Debris) from inappropriate packaging materials

•

Weight and size of packaging/container

•

Hazardous materials

•

Labeling and marking requirements

•

Lessons learned from other projects and from past quality issues

•

Test shipment (where feasible) to validate as early as possible

Reference Documents:

SCMH Section 7.2.5 Phase 2 Checklist 2.05

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 44 of 101

APQP Overview and Element Cards

Element 2.06 Design Review Report

Element Owner: Design Engineering

Element Definition:

A design review is a systematic and regularly scheduled cross-functional review of engineering drawings, specifications, functional requirements, material specifications and any changes to product related requirements. The purpose of a design review is to keep appropriate members of the organization, management team and customer (if applicable) apprised of the design activity verification progress, to identify potential problems, propose corrective actions, review proposed design changes and authorize progression to the next stage of the development process. Each review should demonstrate how the design requirements are fulfilled. In addition, the design requirements of DFMA and DFMRO should be incorporated without compromising conformance to product specification.

Deliverables:

Design review reports highlighting compliance status, design risks and mitigating actions

Necessary Inputs:

Engineering drawings

Engineering specs, functional requirements

Material specifications

Changes to drawings or specifications

Output of design verification and validation evaluations

Output of Design Risk Analysis, e.g. DFMEA’s

Source of Input:

Design Engineering

Quality Organization

Customer

Manufacturing Engineering

Outputs of DFMA and DFMRO

Resources:

Engineering, Customer, Suppliers, Supplier Quality, Quality, Purchasing .

Methodology :

1. Receive required inputs from appropriate stakeholders.

2. Review status of follow-up actions from previous design review.

3. Systematically evaluate inputs against the plan, including test plans and quality plans.

4. Identify areas of concern.

5. Review and propose appropriate actions to mitigate risks, delays, and other concerns.

6. Apprise stakeholders of progress, planned actions to mitigate identified risks and the need for additional resources.

7. Obtain concurrence from stakeholders to proceed to the next stage of the design process.

8. Evaluate changes to the design as they are proposed.

9. Provide input into the design change process.

Reference Documents:

SCMH Section 7.2.5 Phase 2 Checklist 2.06

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 45 of 101

APQP Overview and Element Cards

Element 2.07 Development Product Build Plan

Element Owner: Product Development Team

Element Definition:

A Development Product Build Plan establishes the product manufacturing requirements, inspections and assembly sequences to be performed to build pre-production products for product and process evaluations. The plan may need to be approved by the customer.

The plan should define:

•

Sources of material, components and assemblies

•

Minimum technology and manufacturing maturity levels for each product/part

•

Manufacturing processes to be used

•

Quantity of parts required

•

Detailed schedule for the manufacturing, inspection and reporting activities.

Lessons learned during the manufacture/build process may signal the need for design changes or process improvements.

Deliverables:

•

A Development Product Build Plan that defines the items as detailed above.

•

Formal reports documenting the outcome of the manufacture/build process including a record of the discrepancies that arise along with their proposed solutions.

Necessary Inputs: Source of Input:

Product design inputs

Customer specifications

Proto parts meeting design intent

Technical Design Requirements (TDR)

Preliminary Statement of Work

Voice of the Customer

Design Engineering

Resources: Product Development Engineers, Certification Specialist Engineers

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 46 of 101

APQP Overview and Element Cards

Methodology :

1. Refer to standard work instructions to identify tests/inspections known to validate the product.

2. Align the build plan with the verification and validation needs.

3. Identify inspection requirements including any additional inspections needed for new and/or unique features.

4. Identify the resources; product hardware, inspection facilities, assembly tooling needed to meet the build plan intent. Include the necessary product maturity levels needed for each build defined in the plan.

5. Create a master build plan that defines the timeline and resources for every validation event.

•

The requirement for formal report of each build activity should be included in the plan.

•

The plan should consider the impact of progressive release of design information.

6. Execute the Development Product Build Plan, track and report progress at the Design

Reviews.

Reference Documents:

SCMH Section 7.2.5 Phase 2 Checklist 2.07

SCMH Section 7.2 APQP

Revision Letter: B

Revision Date: 10-MAY-2017

Page 47 of 101

APQP Overview and Element Cards

Element 2.08 Design verification and validation plans, & associated results

Element Owner: Product Development Team

Element Definition:

Design verification and validation activities are performed to verify conformance to design intent and to validate Product Design conforms to customer requirements. These activities typically include:

•

Prototype testing (including trial builds)

•

Computer analysis and simulations

•

Physical and functional simulations .

The verification and validation plan should include a detailed schedule of the above activities as well as hardware availability, inspection and reporting activities. Prototype testing, should include:

•

Tests and inspections to be performed on each component or assembly and their related success criteria

•

Test(s) specifically requested by the customer.

Results of the design verification and validation activities are documented in formal reports and reviewed during the Design Reviews.