erosion-modeling-and-sand-management-with-ansys-cfd

advertisement

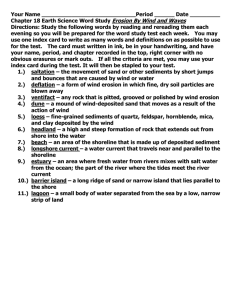

Erosion Modeling and Sand Management with ANSYS CFD Madhusuden Agrawal ANSYS Houston 1 © 2011 ANSYS, Inc. June 21, 2012 OUTLINE Particulate modeling in ANSYS CFD Sand Control and Sand Management • Sand Filtration • Sand Transport in pipelines • Proppant Placement Erosion Modeling • • • • • 2 Challenges in Erosion Modeling Key components of erosion modeling ANSYS solution for erosion modeling Erosion Module Examples © 2011 ANSYS, Inc. June 21, 2012 Recap: Particulate Modeling 3 © 2011 ANSYS, Inc. June 21, 2012 Challenges in Particulate Modeling Spans wide range of • Length scales • Time scales Physics • Particulate physics • Fluid particle interaction • Particle size distribution • Homogenous and • 4 heterogeneous reaction Particle structure interaction © 2011 ANSYS, Inc. June 21, 2012 From: Fundamental of Multiphase Flow, C. E. Brennen Particulate Flows Regimes Diluted vs. Dense Flow t12/tcol t12/teddy 102 100 10-2 104 102 1-way coupling 2-way coupling Particles enhance turbulence negligible effect on turbulence Particles reduce turbulence 100 10-7 10-2 10-5 102 dilute Relative motion between particles Particle-particle interaction Apparent viscosity of the solid phase 5 © 2011 ANSYS, Inc. June 21, 2012 4-way coupling 10-3 10-1 101 (x1-x2)/dp dense Dilute Dense Large Small Weak Strong Particle-fluid interactions Particle-particle interaction es 100 Modeling Particulate Flow Lagrangian Eulerian Particle Phase Hybrid Sub grid scale Particle size Super grid scale Resolved P-P Interaction Modeled Resolved Fluid-P Interaction Modeled 6 © 2011 ANSYS, Inc. June 21, 2012 Platform for Simulating Particulate Systems ANSYS CFD provides a platform which can adapt to the multi-physics, multicomponents and multi-scale configurations of particulate flows and their industrial applications Eulerian Granular 7 © 2011 ANSYS, Inc. DPM June 21, 2012 DDPM-DEM MPM Models for Particulate Flows 9 Model Numerical approach Particle fluid interaction Particle-Particle interaction Particle size distribution DPM Fluid – Eulerian Particles – Lagrangian Empirical models for sub-grid particles Particles are treated as points Easy to include PSD because of Lagrangian description DDPM - KTGF Fluid – Eulerian Particles – Lagrangian Empirical; sub-grid particles Approximate P-P interactions determined by granular models Easy to include PSD because of Lagrangian description DDPM - DEM Fluid – Eulerian Particles – Lagrangian Empirical; sub-grid particles Accurate determination of PP interactions. Can account for all PSD physics accurately including geometric effects Euler Granular model Fluid – Eulerian Particles – Eulerian Empirical; sub-grid particles P-P interactions modeled by fluid properties, such as granular pressure, viscosity, drag etc. Different phases to account for a PSD; when size change operations happen use population balance models Macroscopic Particle Model Fluid – Eulerian Particles – Lagrangian Interactions determined as part of solution; particles span many fluid cells Accurate determination of PP interactions. Easy to include PSD; if particles become smaller than the mesh, uses an empiricial model © 2011 ANSYS, Inc. June 21, 2012 Sand Control 10 © 2011 ANSYS, Inc. June 21, 2012 Sedimentation in Oil & Gas • Sand is often produced in both onshore and offshore production systems • Sand production may be continuous, or sudden • The sediment consists mud, sand and scale picked up during the transport of the oil • Sand Management is important in oil production to ensure system integrity and efficiency • Excessive sand leads to • • • • 11 Partial or complete blockage of flowlines Enhanced pipe bottom corrosion and erosion Trapping of pigs Reduced production time and increased maintenance and operating costs © 2011 ANSYS, Inc. June 21, 2012 Internal flow of natural gas containing sand particles. particle trajectories are colored in grey. The erosive wear hotspots on the piping is colored out in red. Sand Control Sand control strategies • Preventing formation failure • Sand exclusion techniques • Sand management Key areas to understand fundamental nature of sand in the reservoir and the wellbore Hydraulic fracturing (Proppant transport) 12 © 2011 ANSYS, Inc. June 21, 2012 Sand Exclusion Techniques 13 © 2011 ANSYS, Inc. June 21, 2012 Example: Sand Filtering Systems in O&G Sand control screen systems • Screens • Gravel and frac packing Bulk process 14 © 2011 ANSYS, Inc. June 21, 2012 Surface process Modeling Filtration with ANSYS Euler Granular Model • Porous media model with physical velocity formulation • Low permeability for the particulate phase • May not be able to simulate particle size dependent filtering Particulate Models • DDPM model with DEM closure for particle-particle interaction • Particles can be stopped by reflect or trap boundary conditions • Can model particle size effects. • Macro Particle Model will physically filter particles through pores 15 © 2011 ANSYS, Inc. June 21, 2012 Euler Granular Model for Filtration t = 16 sec. t = 60 sec. t = 100 sec. t = 135 sec. Solid Phase Volume Faction Contours 16 © 2011 ANSYS, Inc. June 21, 2012 Velocity Vectors of Solid Phase Filter Cake Formation in Vertical Wells… Journal of Petroleum and Gas Engineering Vol. 2(7), pp. 146-164, November 2011 Mohd. A. Kabir and Isaac K. Gamwo 17 © 2011 ANSYS, Inc. June 21, 2012 Filtration Modeling Using DDPM/DEM Outlet Inlet Filter: Allows particles below a threshold to pass through, Filter represented by a internal boundary condition. 18 © 2011 ANSYS, Inc. June 21, 2012 Filtration Modeling using MPM Particle separation through a filter element at three instances in time. The flow is from left to right. The small particles flow through the holes in the perforated plate and exit the pipe on the right. The plate blocks the bigger particles. 19 © 2011 ANSYS, Inc. June 21, 2012 Particulate Migration in Gravel Pack • Micro scale Simulation for fine particles transport through pores in gravel pack • Study Permeability alterations in the gravel pack due to fine particles entrainments, transport and deposition • Filtration of fine particles 20 © 2011 ANSYS, Inc. June 21, 2012 Sand Transport 21 © 2011 ANSYS, Inc. June 21, 2012 Example: Sand Transport in Pipelines • Sand-Water slurry flow in horizontal pipe • Pipe diameter D = 0.0505m • Pipe length L = 4m Gravity • 30% volume loading • Four Different Slurry Flow Rates • Expected Results DDPM with DEM Collision • Particle staggering for surface injection • Low value of Spring Constant as buoyancy force is important. dp/dx • Almost 3 millions parcels (Pa/m) To be published in collaboration with Shell 22 © 2011 ANSYS, Inc. June 21, 2012 SRC: Saskatchewan Research Council Slurry Velocity (m/s) Results: Pressure Gradient • Mean Static Pressure is plotted on the line coinciding with the axis of the pipe. • dp/dx is calculated between z=3m to z=4m as it varies linearly in this range for all the cases. dp/dx pipe length dp/dx slurry velocity dp/dx (Pa/m) 23 © 2011 ANSYS, Inc. June 21, 2012 Slurry Velocity (m/s) Effect of particle time step size Mixture Velocity (m/s) Baseline Particle Time Step Size (s) Smaller Particle Time Step Size (s) 0.7 2.50E-04 1.0E-04 1.42 1.00E-04 4.00E-05 3 5.00E-05 2.50E-05 • Reduced particle time step size to more accurately model collisions. – Little difference in predicted pressure gradient. – Considerable increase in simulation time. 24 © 2011 ANSYS, Inc. June 21, 2012 dp/dx slurry velocity dp/dx (Pa/m) Slurry Velocity (m/s) Sand Transport in Pipelines • It is important to keep particles suspended • Critical flow velocity which keeps sand particles moving along the pipe depends on • Liquid holdup and flow rates, Pipe diameter, Fluids properties, Sand properties, Pipe inclination angle • Many correlations exists for solids transportation in multiphase flow • Based on experiments for single phase flow on small pipes • Lot of variability in measurements Hjulstrom Diagram 25 © 2011 ANSYS, Inc. June 21, 2012 Sand Transport in Pipelines Transport paths • Traction or full contact – sand rolling or sliding across bottom • Saltation – sand hop/ bounce along bottom • Bedload – combined traction and saltation • Suspended load – sand carried without settling – upward forces > downwarde All these paths for sand transport can be addressed by Particulate modeling in ANSYS CFD. 26 © 2011 ANSYS, Inc. June 21, 2012 Particle Transport – MPM Simulation Demonstrate Case of Particle Lift Off using MPM • Geometry of a long narrow channel • Steady state periodic flow profile applied at Inlet • A 200 microns diameter particle was placed on bottom of the • channel Advanced Turbulence Model Fine mesh (about 4 fluid cells across particle diameter) Initial Location of the Particle Flow Direction 27 © 2011 ANSYS, Inc. June 21, 2012 Particle Transport – MPM Simulation Lift Force Va lida tion in MPM Distance from Wall 75 70 65 60 Distance from Wall (microns) 55 Particle Trajectory 50 45 40 35 30 25 20 15 10 5 0 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 Axial Dis tance (m icr ons ) Axial Distance (in microns) MPM is a DNS technique which calculates particle forces directly from pressure and flow field MPM automatically predicts particle lift force without including any lift force correlation (Saffman etc) 28 © 2011 ANSYS, Inc. June 21, 2012 Proppant Placement 29 © 2011 ANSYS, Inc. June 21, 2012 Example: Proppant Transport • Complex multiphase flow problem • Proppant settles to the bottom – Mound develops – Reaches an equilibrium height • Until the equilibrium height – Proppant bed gets higher and then it spreads laterally Reference: Patankar, N.A., Joseph, D.D., Wang, J., Barree, R.D., Conway, M., Asadi, M., 2002. Power law correlations for sediment transport in pressure driven channel flows. International Journal of Multiphase Flow. 28. 1269–1292. 30 © 2011 ANSYS, Inc. June 21, 2012 Proppant Transport: Granular Model • Drag Force Modified for Dense system – Single particle drag + Concentration effect + Hindered settling effect • Collisional and frictional effects (becomes important near packing limit) are considered Full 3D – Wall Effects and Leak Off – Modeled Slurry flow: Mixture of Frac-Fluid and Proppant Fracture Width = 0.5 cm 40 ft 300 ft 31 © 2011 ANSYS, Inc. June 21, 2012 Proppant Transport: Granular Model 300 µm 500 µm time More settling was observed in 500 micron 32 © 2011 ANSYS, Inc. June 21, 2012 Proppant Transport: Wash Out Process 33 300 µm– Proppant 100 µm - Proppant The mound created a re-circulating zone upstream and allowed settling in this zone The mound grew over a period of time The mound started loosing proppant and the height decreased © 2011 ANSYS, Inc. June 21, 2012 Proppant Transport: DEM Analysis • The proppant transport process using DDPM-DEM • Lagrangian tracking process • Collision and frictional terms are modeled discretely • Problem description • Domain with dimensions: 3 X 0.3 X 0.01 m • Proppants of 0.5mm size particles, 1 kg/s – 1 Parcel = 10 particles – 1.8 million parcels at pseudo-steady state • Water at 4.5 kg/s 34 © 2011 ANSYS, Inc. June 21, 2012 Proppant Transport – DDPM DEM Volume fraction of proppant Velocity of proppant 35 © 2011 ANSYS, Inc. June 21, 2012 Summary: Sand Management • Sand Management is critical in oil production to ensure system integrity and efficiency • It is important to predict various phenomena involved in sand transport and sedimentation • ANSYS CFD provides a platform for comprehensive particulate modeling • Few examples of sand filtration, sand transport and proppant placement were demonstrated 36 © 2011 ANSYS, Inc. June 21, 2012 Erosion Modeling 37 © 2011 ANSYS, Inc. June 21, 2012 Sand Erosion • Sand Erosion of pipelines and equipment is a major problem • Solids entrained in the fluid impinge the walls of piping and equipment causing in removal of wall material, reducing the service life. • Erosion limits the expected life time of piping details, and is vital in risk management studies • It is critical to predict the erosion damages in a flow system accurately 38 © 2011 ANSYS, Inc. June 21, 2012 Challenges in Erosion Modeling • Erosion is Complex Phenomena, depends on – Particle properties and particle tracks – Local Flow and turbulence field – Surface conditioning – Multiphase effects • Erosion shield due to solid accumulation • Damping effect due to liquid film – Effect of local cavities due to material removal • Nearly imposition to have a universal erosion model – Different models for different flow regimes – Always need experimental data to tune model parameters 39 © 2011 ANSYS, Inc. June 21, 2012 Erosion Modeling – Traditional approach • Physical testing of new prototype designs – Time consuming – Degree of trial and error • Semi-empirical models and correlations of erosive wear – Limited to predicting peak values of wear – Usually exist only for simple standard geometries – API RP 14E • Ad-hoc methods that are independent of the sand production rate • “erosional velocity” – Based on an empirical constant (C-factor) and the fluid mixture density 40 © 2011 ANSYS, Inc. June 21, 2012 Erosion Modeling – CFD approach • CFD modeling provides the user with detailed information on the exact location and magnitude of the erosive wear. • Single phase Computational Fluid Dynamics simulations – Applicable for dilute particle phase – Based on Eulerian-Lagrangian methodology • Single phase simulation + DPM – Lots of literature and many erosion models – Provides detailed information on the exact location and magnitude of the erosive wear – Potential to allow design to be optimized prior to testing 41 © 2011 ANSYS, Inc. June 21, 2012 Erosion Modeling – CFD approach • Multiphase CFD Simulations – More realistic for full particle loading from low, medium to high range – Based on Eulerian-Granular multi-fluid approach – Captures four-way couplings including fluid-particle, particle-fluid, particle-particle, and turbulence interactions – Capture particle shielding and liquid damping effects – Lacks proper erosion models for abrasive erosion CFD Modeling Complement Experimental testing for Erosion Predictions 42 © 2011 ANSYS, Inc. June 21, 2012 ANSYS Solution for Erosion Modeling • Different particulate modeling options • DPM, DDPM, DEM, Eulerian-Granular • Wide Varieties of Erosion Models are available in ANSYS FLUENT • • • • • • • FLUENT’s Default Erosion Model Mclaury et. Al Erosion Model Salama & Venkatesh Erosion Model Tulsa Erosion Model DNV Erosion Model Erosion Model based on Wall Shear Stress Flexibility to incorporate any erosion model Contours of Erosion Rate • Erosion pattern in complex flows and geometries can be predicted with a good accuracy 43 © 2011 ANSYS, Inc. June 21, 2012 ANSYS Solution for Erosion Modeling • Typical variables affecting Erosion rate • Angle of impingement • Impact velocity • Particle diameter • Particle mass • Collision frequency between particles and solid walls • Material properties for particle and solid surface • Coefficients of restitution for particle-wall collision Incoming particulate Erosion caused by particle impact 44 © 2011 ANSYS, Inc. June 21, 2012 m : Mass flow rate of the particles f(a) : Impingement angle function V : Particle impact velocity b : Velocity exponent C(Dp): Particle diameter function Erosion Model for Dense System Dense DPM accounts for particle-particle interaction and solid volume effect on fluid phase ABRASIVE EROSION: Erosive due to relative motion of solid particles moving nearly parallel to a solid surface Erosion Model Based on Wall Shear Stress ERw A V SS n Overall Erosion Rate 45 © 2011 ANSYS, Inc. June 21, 2012 A = Constant (diameter function) n = Velocity Exponent SS = Wall Shear Stress ER ERsp ERw Coupling Erosion with MDM • Removal of solid surface material due to Erosion creates localized cavities which affect the flow field, particle tracking and hence the erosion. • Such dynamically changing eroded curvature effect needs to be incorporated for more accurate erosion calculation • ANSYS FLUENT has developed Erosion-MDM connectivity using a User-defined Function (UDF) to dynamically deform the solid wall surface based on local erosion rate • Similar workflow has been developed for ANSYS CFX 46 © 2011 ANSYS, Inc. June 21, 2012 Erosion Modeling – Coupled Simulation • The erosion rate is averaged and smoothed according to the equation: n L Ei Ei ri i , ri R ERnode ri n L R i , ri R ri ERnode L fL Wall _ density A value of 0 for “n” will result in equal weighting for all nodes within “R”. A very large value of “n” will render the smoothing algorithm negligible. 47 © 2011 ANSYS, Inc. June 21, 2012 Ei = Erosion rate for ith face ri = Distance of ith face center from the node L = Minimum cell length connected to the node R = Radius of region considered for averaging (user input is R/L) n = Rate of decay (user input) f = Maximum mesh move limit (user input) Erosion Module • Easy to use template to perform an Erosion Simulation through a single GUI Panel • • • • User inputs drive the UDF and journal file in the background Varieties of Erosion Models to choose Built-in Smart defaults for DPM settings Customized post processing for erosion rate • Complete Automation of Erosion-MDM coupled simulation • Including postprocessing and animation • Ability to allow multiphase erosion simulations • Choose secondary phase for particle tracking 48 © 2011 ANSYS, Inc. June 21, 2012 48 Option to run erosion-only or erosion-MDM coupled simulation Various erosion models to choose from Option to start a new ErosionMDM simulation or restart from the existing data file at previous time interval Opens Fluent’s panel to read the case file for the flow field Opens Fluent’s DPM injection panel to define particle injections Option to choose secondary phase flow velocities for DPM particle tracking Opens Fluent’s boundary condition panel to set DPM BCs for wall zones Opens Fluent’s DPM panel to set parameters for particle tracking Opens panel to define required parameters for Erosion-MDM coupling Opens Fluent’s panel to read the data file for the flow field Opens Fluent’s panel to start iterating for erosion-only analysis Opens panel to start erosion-MDM simulation Display erosion rate on all wall zones Erosion Module 49 © 2011 ANSYS, Inc. June 21, 2012 Display cumulative eroded distance at wall zones Example – Control and Delay Erosion Problem • Particle impact at the small area with high velocity causing excessive erosion Area of high erosion Solution • Modify exit flow from chock without causing additional pressure drop. • ANSYS multiphase flow solutions to understand and change particulate flow patterns Result Flow Inlet • Modified chock geometry leads to flow streamlines parallel to exit pipe. • Increase particle impact area while reducing particle impact velocity • Reduce chock maintenance and replacement cost 50 © 2011 ANSYS, Inc. June 21, 2012 Particle trajectories colored by velocity and associated erosion area for two chokes Courtesy of DNV Example: Single Phase vs Multiphase Erosion Double Elbow Geometry Relatively Low solid loading (~8% volume loading) DPM vs DDPM Simulation and same Erosion Settings Particle shielding effect captured in multiphase simulation Single phase predicts conservative erosion Single Phase Erosion 51 © 2011 ANSYS, Inc. June 21, 2012 Multiphase Erosion Sand Volume Fraction Example: Erosion in Gas-Liquid-Solid System Low Erosion due to liquid cushion and particle shielding Liquid Volume Fraction Contours Solid Volume Fraction Contours Vapor Velocity Contours 52 © 2011 ANSYS, Inc. June 21, 2012 Contours of Erosion Rate Erosion in a Pipe Assembly Courtesy of Suncor Tool Erosion in Gravel Pack: (OTC 17452 – Halliburton) CFD Simulation to analyze flow field and erosion pattern in frac pack tools Calibration of erosion model based on lab tests and Erosion pattern compared with large scale tests. Fluid Velocity Proppant VOF Turbulent Slurry flow with high proppant concentrations Non-newtonian fluids Calibration of Impact angle function 53 © 2011 ANSYS, Inc. June 21, 2012 Erosion pattern on the inside surface of upper extension sleeve Contour of Total Eroded Distance Erosion - MDM Contour of Erosion Rate 54 © 2011 ANSYS, Inc. June 21, 2012 Erosion - MDM Eroded Material is Removed -> Better Material Thickness Prediction FLOW Larger ID After 42 hr 55 © 2011 ANSYS, Inc. June 21, 2012 Plots of erosion contours in a 4 inch test case Summary: Erosion Modeling • It is important to predict erosion rate accurately • Erosion is a complex phenomena • Semi-empirical models and correlations are not enough • Need for CFD in erosion modeling • CFD can provide valuable information for erosion predictions • • • • 56 Multiphase flow modeling for dense slurry Erosion-MDM coupling ANSYS CFD equipped with all required modeling needs ANSYS CFD - Proven approach for many erosion studies for oil & gas industries © 2011 ANSYS, Inc. June 21, 2012 THANK YOU 57 © 2011 ANSYS, Inc. June 21, 2012