1-s2.0-S0022309315000708-main

advertisement

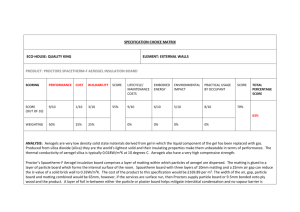

LETTER TO THE EDITOR Journal of Non-Crystalline Solids 416 (2015) 1–3 Contents lists available at ScienceDirect Journal of Non-Crystalline Solids journal homepage: www.elsevier.com/ locate/ jnoncrysol Letter to the Editor Synthesis and characterization of carbon fiber/silica aerogel nanocomposites Ślosarczyk Agnieszka a,⁎, Strauchmann Wojciech a, Ziółkowski Piotr a, Jakubowska Paulina b a b Poznan University of Technology, Institute of Structural Engineering, Poland Poznan University of Technology, Institute of Chemical Technology, Poland a r t i c l e i n f o Article history: Received 5 January 2015 Received in revised form 13 February 2015 Accepted 15 February 2015 Available online xxxx Keywords: Silica aerogel; Sol–gel synthesis; Carbon fibers; Chemical modification a b s t r a c t Nanoporous silica aerogel–carbon fiber composites were prepared via a sol–gel process by surface modification at ambient pressure. Oxidizing modification of the carbon microfibers improved the adhesion between hydrophilic silica gel and the carbon material surface. Suggested solution contributed to the blocking of hydroxide bonds of silica gel via reaction with the oxidized carbon material surface, which lowered the contraction of gel volume during its drying in atmospheric pressure and led to the more stable structure. © 2015 Elsevier B.V. All rights reserved. 1. Introduction Receiving good structural parameters of aerogel does not improve the main drawback of silica aerogels, which is their brittleness. One of the ways to improve the aerogel brittleness is the use of fibers. Nevertheless, there are very few articles on the synthesis of nanocomposites as silica aerogel-fibers. First research on this subject was conducted in 1990's [1]. Paramenter and Milstein modified silica aerogel with silica fibers, alumina fibers and aluminaborosilicate fibers. Those fibers are characterized by a relatively high mass density, which significantly changes the density of the created nanocomposites. Research proved that applied fibers considerably limited the contraction of silica aerogel, but they lowered its mechanical parameters, such as compressive strength and elastic modulus. Much better parameters were achieved by Meador and co-workers while modifying silica aerogel with much lighter carbon nanofibers and di-isocyanate [2]. In the case of this solution an improvement of compressive strength by 5% was achieved. However, Zhang and co-workers were the first to apply polypropylene fibers as silica aerogel component [3]. They used polypropylene fibers 12 mm long obtaining good structural properties of silica aerogel without significant changes in its density. A drawback of hitherto solutions for this type of modification was the lack of fiber surface modification and lack of chemical bonding between fibers and silica gel. The main aim of presented studies was to form the silica aerogel– carbon fiber nanocomposites with more durable structure. The synthesis of aerogel and its composites with carbon fibers was performed ⁎ Corresponding author at: Piotrowo 5 str., 60–965 Poznan, Poland. E-mail address: agnieszka.slosarczyk@put.poznan.pl (Ś. Agnieszka). http://dx.doi.org/10.1016/j.jnoncrysol.2015.02.013 0022-3093/© 2015 Elsevier B.V. All rights reserved. in two-step sol–gel process using the drying in atmospheric pressure. The chemical modification of carbon fibers in nitric acid was carried out to enhance the adhesion between carbon fibers and silica aerogel skeleton. In addition, the chemical modification of aerogel nanocomposites in TMCS/n-hexane mixture was performed. The structure and temperature stability of silica aerogel–carbon fiber composites were tested through the following methods: BET analysis, thermogravimetric measurements TGA and Fourier Transform Infrared Spectroscopy FTIR. 2. Materials and methods As the precursor of silica aerogel synthesis the tetramethylsilane TMOS (Sigma-Aldrich) in methanol solution (CHEMPUR) was used. The catalyst of reaction was the aqueous solution of ammonium with the concentration of 29–30% (Sigma-Aldrich). The chemical modification of silica aerogel was performed using the trimethylchlorosilane TMCS (Sigma-Aldrich) and n-hexane (CHEMPUR). As component of silica aerogel–carbon fiber composites, low-modulus carbon fibers from coal-tar pitch with density of 1.64 g/cm3 were used (OsakaGas Corp.). Carbon fibers have the diameter of 13 μm and length of 700 μm, and are characterized by shape factor of L/d = 50. They have a low graphitization level and small specific surface area 0.96 m2/g (according the BET method) with very small micropore content (0.0009 cm3/g). The physical and chemical characterization of synthesized nanomaterials was performed by the using of BET and thermo-gravimetric analysis. Surface area and pore volume of aerogel composites were estimated based on adsorption isotherms in low-temperature nitrogen sorption in the temperature of 77 K using the equation of BET isotherm and analyzer ASAP 2010 (Micrometrics). Thermo-gravimetric analysis of LETTER TO THE EDITOR Ś. Agnieszka et al. / Journal of Non-Crystalline Solids 416 (2015) 1–3 2 Table 1 Physical properties of aerogel–carbon fiber nanocomposites. Surface area BET, m2/g Density, g/cm3 Average pore diameter, nm Shrinkage of composites, % Aerogel without fibers Aerogel with fibers in the amount of 0.01 g Aerogel with fibers in the amount of 0.03 g Aerogel with fibers in the amount of 0.05 g Aerogel with fibers in the amount of 0.07 g 572.1 0.302 12.1 62 583.5 0.337 11.9 48.7 586.8 0.358 11.6 41.3 529.0 0.400 11.9 35.2 559.2 0.406 12.3 29.9 aerogels was performed in nitrogen atmosphere by means of NETSCH apparatus, type TG 209 F3. During measurements the following parameters were used: flow rate of inert gas 30 ml/min, speed of sample heating 10 °C/min, and temperature range 30–1000 °C. To identify functional group on the silica aerogel–carbon fiber composite surface the infrared spectroscopy was applied. Infrared absorption spectra ATR-FTIR for tested aerogels and its composites were determined by means of FT-IR NICOLET 5700 apparatus (Thermo Electron Corporation). All measurements were performed in the wave number range from 600 to 4000 cm−1. 3. Experimental Silica gel was made in two-step method using the sol–gel synthesis. Two solutions were mixed together — solution A (3.0 ml of TMOS mixed with methanol to obtain 5 ml of liquid) and solution B (0.72 ml NH4OH at concentration of 0.5 mol/l mixed with methanol to obtain 5 ml of liquid). The connection of these two solutions initiates a hydrolysis reaction, as a result of which sol is created, that is further transformed into gel in the process of condensation (gelation). In the subsequent step gel was aging, first in the mixture of water and methanol for two days, and next only in methanol for 7 days. The synthesis of silica aerogel composites was performed in the same way. Before introducing the carbon fibers to TMOS solution they were treated chemically in hot nitric acid. Carbon fibers were placed in a three-neck flask, poured by concentrated nitric acid and then heated gradually to 120 °C using the reflux condenser. The oxidative treatment was performed by 3 h. After that, carbon fibers were washed out with water and dried at 110 °C in air for 5 h. The estimation of oxidation degree of carbon fiber surface by means of electrochemical as well as FTIR analysis was presented in earlier publications [4,5]. The last stage of silica aerogel and its composite with carbon fiber synthesis was the elimination of dissolvent from the nanostructure of aerogel by drying in ambient pressure. Firstly, the water and methanol located in the pores were changed into a water-free solvent, and then the reaction with TMCS/n-hexane mixture at 50 °C was performed. 4. Results and discussion The structural properties of pure silica aerogel and carbon fiber– silica aerogel nanocomposites are shown in Table 1. The average diameters of the pores were calculated on the basis of nitrogen adsorption isotherms with BET method, basing on the 4 V/Å formula, where V stands for total pore volume determined in a single point of adsorption isotherm with p/p0 = 0,99. It was shown that the presence of carbon fibers in silica aerogel composite does not disturb the structural properties of aerogel. Aerogels with carbon fibers have similar average structural parameters as those without fibers: surface areas (529–587 m2/g) and pore diameters (11.6–12.3 nm). In the case of pure silica aerogel surface area equals 572.1 m2 /g and pore diameter was calculated as 12.1 nm. Taking into consideration the effective diameter, the pores are classified according to IUPAC as follows: ultra-micropores (below 0.8 nm), micropores (between 0.8 and 2 nm), mesopores (from 2 nm to 50 nm), and macropores (above 50 nm). Based on the IUPAC classification and structural parameters obtained in BET analysis, it is obvious that the synthesized silica aerogel and silica aerogel–carbon fiber nanocomposites maintain a porous structure and belong to mesopore materials. In addition a confirmation of mesopore structure is the shape of adsorption and desorption isotherms shown in Fig. 1. According to the classification of porous materials made by de Boer in 1958 [6], from the shape of the desorption hysteresis loop it can be found that pore structures are both cylindrical capillary pores open at both ends and cylindrical pores closed at one end with a narrow neck at the other, like an “ink-bottle”, which are assigned to the materials with the mesopore structure. In comparison to pure silica aerogel, the aerogels with carbon fibers exhibited higher density. For unmodified aerogel density equaled 0.302 g/cm3, and for aerogels with different amounts of carbon fibers the values of density were varied from 0.337 to 0.406 g/cm3. The higher 1200 100 1 Silica aerogel without CF Silica aerogel with CF 98 2 800 96 600 94 TG, % 3 Volume Adsorbed (cm /g) 1000 400 3 92 4 1 - without CF 2 - with 0.01g CF 3 - with 0.03g CF 4 - with 0.05g CF 5 - with 0.07g CF 90 200 88 0 0,0 0,2 0,4 0,6 0,8 1,0 Relative Pressure (p/p 0) Fig. 1. N2 adsorption and desorption isotherms for pure silica aerogel and its composites with carbon fibers. 5 86 0 100 200 300 400 500 600 o temperature, C Fig. 2. TGA for pure silica aerogel and its composites with carbon fibers. 700 LETTER TO THE EDITOR Ś. Agnieszka et al. / Journal of Non-Crystalline Solids 416 (2015) 1–3 3 104 100 96 100 96 88 84 92 reflection, % reflection, % 92 88 84 5 3 80 4 2 76 3 72 68 80 1 1200 1100 1000 900 800 wavenumber, cm 72 68 4000 4 2 1 - without CF 2 - with 0.01g CF 3 - with 0.03g CF 4 - with 0.05g CF 5 - with 0.07g CF 3500 1 700 -1 76 5 1 3000 2500 2000 wavenumber, cm 1500 1000 -1 Fig. 3. FTIR for pure silica aerogel and its composites with carbon fibers. values of density noted for aerogel composites are the result of additive of carbon fibers which have much higher density than pure silica aerogel. Moreover, the presence of fibers lowers the thermal resistance of the aerogel. Fig. 2 presents thermogravimetric curves gained for the pure aerogel and for the nanocomposite of siliceous aerogel–carbon fibers. In the whole range of measured temperatures the pure aerogel showed higher thermal stability than the nanocomposites with carbon fibers. Except for the aerogel with the highest amount of fibers (0.07 g) the remaining composites showed a very small decline in weight (up to 5%) in the temperature up to 450 °C, which was just slightly lower than that of pure aerogel. In the temperature of 700 °C the decline averaged less than 12%. The lowest thermal stability in the whole research range was shown by the composite with the highest amount of fibers. This is probably related to the loosening of the aerogel nanostructure due to the admixture of more and more carbon fibers. Micro-sized carbon fibers hinder the growth of homogeneous silica aerogel structure and lead to the decrease of aerogel thermal stability. On the other hand, the composites with carbon fibers showed lower contraction of samples during drying in ambient pressure. In the case of pure aerogel the volume decline equalled almost 60%, whereas for the composite with the highest fiber amount (0.07 g) the contraction equalled less than 30%. Lowering the aerogel contraction to this level during the drying is possible thanks to the application of carbon fibers after surface modification. On the surface of the carbon fibers carboxyl and hydroxyl groups are built, as a result of carbon fiber oxidation in the nitric acid. Those groups can react with hydroxyl groups present on the surface of the siliceous aerogel during its synthesis. Fig. 3 presents the FTIR analysis of the nanocomposites. The peaks appearing in the spectrum for wavenumbers from 1050 to 1100 cm−1 and 845 cm−1 are attributed to the Si–O–Si bond and Si– CH3 bond of a siliceous structure, respectively [7,8]. In the nanocomposites with carbon fibers a decline in the peak intensity was observed. This testifies that as a result of adding more and more modified carbon fibers, the number of free hydroxyl and hydrocarbon groups on the siliceous aerogel surface decreases. This is a consequence of an ion bond between hydroxyl groups present on the aerogel surface and the carboxyl and hydroxyl groups built up on the carbon fiber surface during their modification. Moreover, as a result of carbon fiber surface oxidation, their character is changed from hydrophobic to hydrophilic, which enables their dispersion in the aqueous solution of methanol. 5. Conclusion In the aspect of the aforementioned results of the research, the modification of the silica aerogel structure with carbon fibers seems to be an interesting solution. Hitherto research proved that the application of carbon fibers as components of silica aerogels gave positive results in limiting the aerogel contraction during drying. Chemical treatment of the carbon materials resulted in building on their surface oxygen functional groups and enabled a chemical reaction and creation of ionic bonds between those groups and hydroxide groups on the surface of silica gel, which strengthen the silica aerogel frame. Moreover, the blocking of hydroxide bonds of silica gel via reaction with oxidized carbon fiber surface lowered the contraction of gel volume during its drying in atmospheric pressure, prevented the adsorption of water and finally led to the more stable aerogel nanostructure. References [1] K. Paramenter, F. Milstein, J. Non-Cryst. Solids 223 (1998) 179–189. [2] M. Meador, S. Vivod, L. McCorkle, D. Quade, R. Sullivan, L. Ghosn, N. Clark, L. Capadona, J. Mater. Chem. 18 (2008) 1843–1852. [3] Z. Zhang, J. Shen, X. Ni, G. Wu, B. Zhou, M. Yang, X. Gu, M. Qian, Y. Wu, J. Macromol. Sci., Pure Appl. Chem. 43 (2006) 1663–1670. [4] A. Ślosarczyk, Cement Composites Modified With Selected Carbon Materials, LAP LAMBERT Academic Publishing, Saarbrücken, Germany, 2013. [5] J.M. Skowroński, A. Ślosarczyk, Przem. Chem. 88 (2009) 823–825 (in polish). [6] J.H. de Boer, The Structure and Properties of Porous Materials, Butterworth, London, 1958. [7] P. Sarawade, J. Kim, A. Hilonga, D. Quang, S. Jeon, H. Kim, J. Non-Cryst. Solids 357 (2011) 2156–2162. [8] J. Li, J. Cao, L. Huo, X. He, Mater. Lett. 87 (2012) 146–149.