Propylene Production Plant

advertisement

School of

Chemical

Engineering

SKKC 4143 PLANT DESIGN

2018/2019-SEM 1

FINAL REPORT

PROPYLENE PRODUCTION PLANT

LECTURER

DR ZARINA MUIS

DESIGN TEAM (GROUP 6)

NO.

TEAM MEMBERS

1. DINESH A/L SIVARAJU

2. SHAMIMY NAADIAH BINTI MOHD SHOKRI

3. NUR ZAHIRAH BINTI HASLI

MUHAMMAD AIMAN AMIRUDDIN BIN MHD

4.

KAMAL

MATRIC NO

A15KK0027

A11KK0140

A15KK0111

A15KK0220

ii

ACKNOWLEDGEMENT

First and foremost, we would like to express our gratitude to our beloved

lecturer of Plant Design subject, Dr. Zarina binti Ab Muis for her guidance and advice

in supporting us to complete this project. This report would not been completed

without the help from her.

Finally, we hope this report will be helpful for readers in studying about the

process of propylene production.

iii

TABLE OF CONTENTS

TITLE

ACKNOWLEDGEMENT

PAGE

ii

TABLE OF CONTENTS

iii

LIST OF TABLES

vi

LIST OF FIGURES

vii

CHAPTER 1: INTRODUCTION

1

1.1

Background of Propylene

1

1.2

Production of Uses of Propylene

2

1.3

Propylene Manufacturing

3

1.4

Process Flow Diagram

5

1.5

Market Survey

1.6

6

1.5.1 Introduction

6

1.5.2 Production of Propylene

7

1.5.3 Propylene Consumption

8

1.5.4 Local Outlook for Production of Propylene

10

1.5.5 Market Prices of Propylene

11

Process Screening

12

1.6.1 Gross Profit

12

1.6.2 Factors Affecting Screening Process

14

1.6.2.1 Temperature

1.6.2.2 Pressure

15

1.6.2.3 Safety

15

1.6.2.4 Environment

1.7

Site Location

1.7.1 Water Tariff

1.8

14

15

16

17

1.7.2 Electricity Tariff

19

Conclusion

19

iv

CHAPTER 2: PROCESS CREATION AND SYNTHESIS

20

2.1

Introduction

20

2.2

Sources of Raw Material and Its Specification

20

2.3

Physical and Chemical Properties

2.4

Synthesis Steps

2.5

Manual Mass Balance Calculation

2.6

21

22

37

2.5.1

Overall Mass Balance

37

2.5.2

Mass Balance for Mixer

38

2.5.3

Mass Balance for Reactor

39

2.5.4

Mass Balance for Separation Unit

40

2.5.5

Mass Balance for Separation Unit 2

41

2.5.6

Mass Balance for Separation Unit 3

42

2.5.7

Summary Table Mass Balance

43

Manual Energy Balance Calculation

44

CHAPTER 3: PROCESS SIMULATION AND HEAT INTEGRATION

3.1

3.2

47

Percentage Difference between Manual Calculation and

HYSYS Calculation

47

Heat Integration

49

3.2.1

Calculation of FCp

49

3.2.2

Process Energy Integration

55

3.2.3 Algorithm Table

55

3.2.4 Heat Exchanger Network

57

3.2.5 Comparison of Performance Before and After Heat Integration

59

3.2.6 Process Flow Diagram Heat Exchanger Network

60

CHAPTER 4: PROCESS OPTIMIZATION

4.1

Process Optimization

61

CHAPTER 5: EQUIPMENT SIZING AND COSTING

5.1

65

Sizing and Costing of Equipment

5.1.1

Oleflex Reactor

65

65

v

5.1.2

Pump

5.1.3

Cryogenic Separator

5.1.4

Distillation Column

5.1.5

Heat Exchanger

5.1.6

Cooler

5.1.7

Heater

66

67

69

75

83

85

CHAPTER 6: TOTAL CAPITAL INVESTMENT

6.1

Total Capital Investment

6.1.1

88

88

Estimation of Total Capital Cost Investment

CONCLUSIONS

91

93

REFERENCES

95

APPENDICES A

96

APPENDICES B

98

APPENDICES C

101

vi

LIST OF TABLES

TABLE NO.

TITLE

PAGE

1.1

Physical and Chemical Properties Propylene

1

1.2

Product and Application

3

1.3

Process Production of Propylene

4

1.4

Price of Propylene

11

1.5

Summary of Review and Screening of Alternative

13

Processes

1.6

Comparison between short-listed locations

16

2.1

Physical and Chemical Properties of Reactant

21

2.2

Physical and Chemical Properties of Product

21

2.3

Summary of Review and Screening of Alternative

24

Processes

2.4

Boiling Points of Propylene and Its Side Products

29

3.1

Mass Balance

47

3.2

Energy Balance

48

3.3

Stream Table Data

55

3.4

Shifted Temperatures

55

3.5

Summary of Temperature of Heat Exchanger

58

3.6

Heating Requirement Before and After Heat

59

Integration

3.7

Cooling Requirement Before and After Heat

59

Integration

4.1

Market Value of Propane, Hydrogen and Propene

62

6.1

Summary of Bare-module Cost for All Equipment

82

vii

LIST OF FIGURES

FIGURE NO.

TITLE

PAGE

1.1

Structural Formula of Propylene

2

1.2

Commercial Process Flow Diagram

6

1.3

Propylene Global Demand Profile

6

1.4

Global Propylene Sources Summary

7

1.5

Global Propylene Production by Process

8

1.6

Propylene Top Producers

9

1.7

Malaysia Polypropylene Demand, Exports,

10

Imports and Capacity

1.8

Global Propylene Prices

11

1.9

Typical product yields (%) by mass from steam

14

cracking various hydrocarbon feedstock

1.10

Pengurusan Air Pahang Berhad (PAIP)

17

1.11

Syarikat Air Johor

17

1.12

Syarikat Air Terengganu (SATU)

18

1.13

Tenaga Nasional Berhad (TNB)

18

2.1

Typical product yields (%) by mass from steam

24

cracking various hydrocarbon feedstock

2.2

Flowsheet with separation units of propylene

28

production process (Alternative 1)

2.3

Flowsheet with separation units of propylene

30

production process (Alternative 2)

2.4

Flowsheet with Temperature, Pressure and Phase

Change Operations in The Propylene Production

Process

31

viii

2.5

Flowsheet Task Integration for The Propylene

36

Production Process

3.1

Algorithm Table

56

3.2

Heat Exchanger Network

57

3.3

Temperature Profile H1

58

3.4

Temperature Profile H2

58

3.5

Temperature Profile H3

58

3.6

Temperature Profile H4

58

3.7

Process Flow Diagram Heat Exchanger Network

60

4.1

Solver Feature of Microsoft Excel

64

1

CHAPTER 1

PROJECT SELECTION

1.1

Background of Propylene

Propylene, also known as propene or methyl ethylene is a colourless and

flammable gases. It is an unsaturated organic compound which having chemical

formula of C3H6. It has one double bond which is the second simplest member of the

alkene class of hydrocarbons. The double bond presence in the propylene make it

boiling point is slightly lower than propane and thus more volatile. Propylene is comes

from cigarette smoke, combustion from forest fires, motor vehicle and air craft

exhaust. Propylene has low acute toxicity from inhalation and inhalation of this gas

can cause anaesthetic effects. Physical and chemical properties of propylene are shown

in Table 1.1.

Table 1.1: Physical and Chemical Properties Propylene [1]

Properties

Formula

Molecular weight (g/mol)

Value

C3H6

42.081

Boiling point (°C)

-48

Melting point (°C)

-185

Flash point (°C)

-108

2

Density (kg/m³ )

1.91

Solubility (mg/L)

Very soluble in water, 200

mg/L at 25°C

Colour

Colorless

Figure 1.1: Structural Formula of Propylene

Propylene is traded commercially in three grades which are chemical, polymer

and refinery. Chemical-grade propylene has minimum purity of 92-95%. Polymergrade propylene typically has minimum purity of 99.5-99.8% and contains the

impurities like propane, methane, ethane, ethylene, propyne, butenes, propadiene,

methylacetylene, butadiene, acetylene, diolefins, carbonyl sulfide, hydrogen, carbon

monoxide, carbon dioxide, oxygen, nitrogen, water and sulphur. Refinery-grade

propylene usually contain 50-70% propylene admixed with other low relative

molecular mass hydrocarbons.

1.2

Production and Uses of Propylene

Propylene is produced primarily as a by-product of petroleum refining and of

ethylene production by steam cracking of hydrocarbon feedstock. In steam cracking,

a mixed stream of hydrocarbons ranging from ethane to gas oils is pyrolysed with

steam. Product obtained in the process can be change to optimize production of

ethylene, propylene, or other alkenes by altering feedstock, temperature and other

parameters. The catalytic dehydrogenation of propane can also been used for the

production of propylene.

3

Propylene is a major industrial chemical intermediate that serves as one of the

building blocks for an array of chemical and plastic products and also the first

petrochemical employed in the industrial scale. The main uses of refinery propylene

are in liquefied petroleum gas (LPG) for thermal use or as an octane-enhancing

component in motor gasoline. The most important derivatives of chemical and polymer

grade propylene are polypropylene, propylene oxide, isopropanol, cumene and

acrylonitrile. Other commercial derivatives include acrylic acid and esters, oxo

alcohols and aldehydes, epichlorohydrin, synthetic glycerine and ethylene-propylene

copolymers. Table 1.2 below shows the main products of propylene and its application.

Table 1.2: Product and Application

1.3

Product

Application

Polypropylene

Mechanical parts, containers, fibres, films

Propylene oxide

Propylene glycol, antifreeze, polyurethane

Cumene

Polycarbonates, phenolic resins

Acrylonitrile

Acrylic fibres, ABS polymers

Oxo-alcohols

Coatings, plasticizers

Acrylic acid

Coatings, adhesives, super absorbent polymers

Propylene Manufacturing

Propylene is commercially generated as a co-product, either in an olefins plant

or a crude oil refinery’s fluid catalytic cracking (FCC) unit, or produced in an on

purpose reaction like propane dehydrogenation. The different process of the

production of propylene will be analysing before we choose the best reaction process

to produce propylene. The criteria of the selective reaction are based on their cost of

raw material, environmental impacts, safety, percentage yield of conversion and other

factors that will affect reaction process. Table 1.3 below shows several processes with

a lower cost propylene production.

4

Table 1.3: Process Production of Propylene

Process

Olefin Metathesis

Description

Metathesis is a reversible reaction between

ethylene and butene in which double bonds are

broken and then reform to form propylene.

Propylene yields about 90%.

This process may also been used when there is no

butene feedstock. For this case, part of the

ethylene will feeds an ethylene-dimerization unit

that convert ethylene into butene.

Propane

Dehydrogenation

A catalytic process that convert propane into

propylene and hydrogen (by product).

The yield of propylene is about 85%.

The reaction by product (mainly hydrogen) is

usually used as fuel for the propane

dehydrogenation reaction.

So, propylene tends to be the only product unless

local demand exists for the hydrogen by product.

Steam cracking

(naphtha)

In steam cracking, a gaseous or liquid

hydrocarbon feed like naphtha is diluted with

steam and briefly heated in a furnace without the

presence of oxygen.

The reaction temperature is very high, at around

850 °C, but the reaction is only allowed to take

place very briefly.

In modern cracking furnaces, the residence time is

reduced to milliseconds to improve yield.

5

1.4

Process Flow Diagram

The main objective of this process is to produce 100,000 Ib/hr of propylene with

polymer-grade propylene of 99.5% purity. Dehydrogenation of propane is chosen as

our desired reaction because of its simplest reaction. The commercial Process Flow

Diagram (PFD) is shown in the Figure 1.2. The plant consists of three main sections:

i.

Reactor

ii.

Catalyst Regeneration

iii.

Product recovery

Hydrocarbon feed is mixed with hydrogen-rich recycle gas and is introduced

into the heater to be heated into the desired temperature (over 540 °C) and then enter

the reactors to be converted at high mono-olefin selectivity. Several interstage heaters

are used to maintain the conversion through supplying heat continuously since the

reaction is endothermic.

Catalyst activity is maintained by continuous catalyst regenerator (CCR) or

shutting down reactors one by one and regenerating the reactor by the regeneration air,

the continuous catalyst regenerator is where the catalyst is continuously withdrawn

from the reactor, then regenerated, and fed back to the reactor bed. Reactor effluent is

compressed, dried and sent to a cryogenic separator where net hydrogen is recovered.

The olefin product is sent to a selective hydrogenation process where dienes and

acetylenes are removed. The propylene stream goes to a de-ethanizer where light-ends

are removed prior to the propane-propylene splitter. Unconverted feedstock is recycled

back to the depropanizer where it combines with fresh feed before being sent back to

the reactor section.

6

Figure 1.2: Commercial Process Flow Diagram

1.5

Market Survey

1.5.1

Introduction

Propylene is perhaps the most versatile building block in the petrochemical

industry, in terms of its variety of end-use products and its multitude of production

sources. In 2015, the global demand for propylene, polymer grade and chemical grade

combined, is estimated at 94.2 million tonnes. The chart in Figure 1.3 outlines the

propylene global demand profile for 2015.

Figure 1.3: Propylene Global Demand Profile

7

1.5.2

Production of Propylene

Propene production increased in (Europe and North America only) from 2000

to 2008, it has been increasing also in East Asia, most notably Singapore and

China. Total world production of propene is currently about half that of ethylene.

About 56% of the worldwide production of propylene is obtained as a co-product of

ethylene manufacture, and about 33% is produced as a by-product of petroleum

refining. About 7% of propylene produced worldwide is on-purpose product from the

dehydrogenation of propane and metathesis of ethylene and butylenes; the remainder

is from selected gas streams from coal-to-oil processes and from deep catalytic

cracking of vacuum gas oil (VGO). The supply of propylene remains highly dependent

on the health of the ethylene industry as well as on refinery plant economics.

The chart in Figure 1.4 summarizes the global propylene sources in 2015.

Figure 1.4: Global Propylene Sources Summary

Since lighter feedstock is used, it has reduced propylene co-product production

resulting in an increased investment in on-purpose production. As shown in Figure 6,

8

30% of global propylene supply will be from unconventional sources by 2025. PDH

has been through a phase of major expansion in the Middle East but the focus is now

moving to China and the US.

Figure 1.5: Global Propylene Production by Process

1.5.3

Propylene Consumption

The market dynamic of propylene is influenced by polypropylene.

Polypropylene accounts for around 65% of global propylene production, ranging from

53% in North America to more than 90% in Africa and the Middle East.

Top world companies are leading the production of propylene with

LyondellBasell, Netherlands on top of propylene producing companies by 2009. The

top propylene-producing companies are listed as bellow:

9

Propylene Top Producers

Relliance Industries, India

Formosa Plastics Group, Taiwan

PetroChina, Bejing, China

SABIC, KSA

ExxonMobil Chemical, USA

Ineos Group, England

Total SA, France

Sinopec, China

LyondellBasel Industries, Netherlands

3.8

4

4

4

5

5.8

6.1

9

15.8

Figure 1.6: Propylene top producers

As shown in Figure 1.6, after experiencing zero growth or declines in 2008 and

2009, global propylene consumption grew at a rate of almost 7.5% in 2010, led by

Asia at 11% year-on-year. The economic recession of 2008/2009 reflected both a

reduction in pull-through demand for polypropylene, as well as a supply-chain

inventory rundown, reminiscent of the early 1980s downturn. World petrochemical

industries have historically witnessed very few upheavals that combined the effects of

both energy volatility and depressed downstream demand.

The fifteen largest worldwide producers of propylene accounted for almost

51% of world capacity as of 2010, representing about the same level of concentration

as five years ago. The most significant changes in the last two years have been Sinopec

taking over the top spot, a position long occupied by ExxonMobil, and PetroChina

jumping from the seventh spot to number four.

World consumption of propylene is forecast to grow slightly better than global

gross domestic product (GDP) rates over the next five years. Average growth will be

5% per year, higher than GDP in general and higher than ethylene specifically, with

growth for polypropylene being much better than that for polyethylene. Growth will

10

be led by the Middle East, Asia, Central and Eastern Europe, and South America at

12.5%, 6.5%, 5%, and 4.5% per year, respectively. Asia is a mixed bag of growth rates

with China and India at 8–10% annually and the mature economies of Japan, the

Republic of Korea, and Taiwan at 1–2% per year. Near-term growth will be relatively

slow in the mature economies of North America and Western Europe.

1.5.4

Local outlook for production of propylene

Malaysia’s petrochemical sector has contributed significantly to the

development of local downstream plastic processing activities. Malaysia is one of the

largest plastics producers in Asia, providing a steady supply of feedstock materials for

the plastic processing industry such as propylene.

Figure 1.7: Malaysia Polypropylene Demand, Exports, Imports and Capacity

11

1.5.5

Market price of propylene

Propylene production from crackers have been constrained due to low

ethylene prices, which prompted an increase in lighter feedstocks like ethane,

which produces the least amount of co-products like propylene. With ethane

feedstock

costs higher and volatile,

ethylene

spot

prices

have

risen

and naphtha cracker margins are no longer negative. But the demand fall-off has

not

been

as

steep

as

expected

amid

a

tight

market

for

downstream polypropylene (PP). While imports of PP have increased, domestic

operating rates have remained relatively good. PP is the largest consumer of US

propylene, but indications for other downstream sectors are similar. A market

source said that demand seems to be strong across most major derivatives.

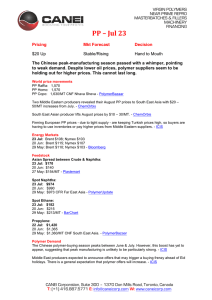

Figure 1.8: Global Propylene Prices

Table 1.4: Price of Propylene

Price

Product

Propylene

RM/Ib

RM/Kg

1.49

3.285

12

1.6

Process Screening

1.6.1

Gross Profit

There are three methods of producing propylene in industry. Each method uses

different raw material and vary according to price. The methods are:

1. Olefin Metathesis

2. Propane Dehydrogenation

3. Steam cracking

All the three methods will be screened and will be chosen based on the criteria on

economic potential. Conversion rate used for the following calculations is 1 USD =

RM 4.14.

Gross profit will be calculated based on this formula:

𝐺𝑟𝑜𝑠𝑠 𝑝𝑟𝑜𝑓𝑖𝑡 = 𝑃𝑟𝑜𝑑𝑢𝑐𝑡 𝑣𝑎𝑙𝑢𝑒 − 𝑅𝑎𝑤 𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙 𝑣𝑎𝑙𝑢𝑒

The stoichiometry of the reactant and products are taking into account without

considering the side products.

1) Olefin Metathesis is a reversible reaction between ethylene and butylene in which

double bonds are broken and then reform to form propylene.

𝐶2 𝐻4 + 𝐶4 𝐻8 → 2𝐶3 𝐻6

Chemical

Ethylene

Butylene

Propylene

C2H4

C4H6

C3H6

1

1

2

28.05

56.10

42.08

Mass

28.05

56.10

84.16

Kg/ Kg Propylene

0.3333

0.6666

1

1.39

0.65

1.05

Molecular formula

Kgmol

Molar

mass

(kg/kgmol)

USD/Kg

13

RM/Kg

5.75

2.62

4.36

Gross Profit = 4.36(1) - 5.75(0.3333) – 2.62(.6666) = RM 0.70/ Kg Propylene

2) Propane Dehydrogenation is a catalytic process that convert propane into

propylene and hydrogen

𝐶3 𝐻8 → 𝐶3 𝐻6 + 𝐻2

Chemical

Propane

Molecular formula

Hydrogen

Propylene

C3H8

H2

C3H6

1

1

2

44.09

2.016

42.08

Mass

44.09

2.016

42.08

Kg/ Kg Propylene

1.0478

0.048

1

USD/Kg

0.43

0

1.05

RM/Kg

1.76

0

4.36

Kgmol

Molar

mass

(kg/kgmol)

Gross Profit = 4.36(1) – 1.76(1.0478) – 0(0.048) = RM 2.52/ Kg Propylene

3) Steam Cracking is where saturated hydrocarbons are broken down into smaller,

often unsaturated, hydrocarbons.

However, propylene is merely a by-product, it is synthesized by other methods,

such as propane dehydrogenation. Ethylene is mainly produced in steam cracking.

Figure 1.9 shows the typical product yields (%) by mass from steam cracking various

hydrocarbon feedstock.

14

Figure 1.9: Typical product yields (%) by mass from steam cracking various

hydrocarbon feedstock

As it can be seen from the figure, it is not feasible to consider using steam cracking to

produce propylene as the highest yield (%) is 19.

1.6.2

Factors Affecting Screening Process

Table 1.5: Summary of Review and Screening of Alternative Processes

Olefin Metathesis

C2H4 + C4H8 2C3H6

Gross Profit

RM 0.70/Kg propylene

Dehydrogenation of

propane

C3H8 C3H6 + H2

RM 2.52/Kg propylene

Butane and ethylene is

Safety

flammable, and ethylene also

Propane is flammable.

may cause dizziness

Catalyst

Al2O3

Al2O3

By-product

No by-product

Hydrogen

Operating

Temperature: 90-100ºC

condition

Pressure: 100 – 110 bar

Conversion

90% percent of conversion

86% percent of conversion

Flammability

Flammable

Flammable

Temperature: 560 – 650 ºC

Pressure : slightly below

atmospheric pressure

1.6.2.1 Temperature

The operating temperature of olefin metathesis process is lower than the

dehydrogenation of propane. High temperature process unit are not economically

feasible because it takes large amount of energy to reach the temperature. Thus, olefin

15

metathesis makes the case of being more economically feasible and safer to work as

well as high temperature carries risk.

1.6.2.2 Pressure

Dehydrogenation of propane operates at nearly atmospheric pressure, which is

more economically feasible as it is a well-known fact that compressing units are

expensive. Which is why even if olefin metathesis operates at lower temperature, it is

still more expensive to bring the pressure to 100 bars.

1.6.2.3 Safety

The aspect of safety carries a risk, as both methods are flammable. The catalyst

used as well is same and Al2O3 does not carry any serious health apart causing irritation

to eyes and skin upon contact.

1.6.2.4 Environment

None of the chemicals used carries any exotoxicity. Thus, the two methods

does not pose a major threat to the environment.

In conclusion, dehydrogenation of propane is better economic choice as the

difference between two methods gross profit is RM 1.82/ Kg propylene. Furthermore,

the operating cause would be slightly cheaper for dehydrogenation of propane due to

the low-pressure requirement compared to olefin metathesis. Hence, dehydrogenation

of propane of propane is chosen.

16

1.7

Site Location

Location for the chemical plant plays very important role because it can affect

the plant operation and its success. For the construction of the propylene plant, we

have listed three main industrial estates that are located at south and east coast of

Peninsular Malaysia. The industrial lands are

Tanjung Langsat Industrial Land Pasir Gudang, Johor

Gebeng Industrial Land,Pahang

Kerteh Industrial Land, Terengganu

Table 1.6: Comparison between short-listed locations

Specification

Location

Land Availability

(Hectare)

Land Price (per

square feet)

Raw

Material

Supply

Tanjung Langsat, Gebeng, Pahang

Kerteh,

Johor

Terengganu

Pasir

Gudang Gebeng Industrial Kerteh Industrial

Industrial Land

Land

Land

4

250

4.98

RM 71

Rm 15

RM 30

-Titan

Petrochemicals

Sdn Bhd

-Peninsular

Gas

Utilisation Project

– Gas Malaysia

Berhad

-North-South

Transport

Expressway

Facilities

(PLUS)

-Senai

International

Airport

-Tanjung Langsat

Port Facilities

Port

-Johor Port

-Tanjung Pelepas

Port

Distance

from 42km from Johor

Bahru

town

Tenaga Nasional

Power Supply

Berhad (TNB)

Petronas

Berhad

Gas -Petronas

Gas

Berhad

-Petronas

Penapisan

(Terengganu) Sdn

Bhd

-Kuantan-Kerteh

Railway

-East

Coast

Expressway

-East

Coast

Expressway

-Kuantan-Kerteh

Railway

-Kerteh Airport

Kuantan Port City -Kertih Terminal

(KPC)

-Kertih Port

40km

from

Kuantan

Tenaga Nasional

Berhad (TNB)

42km

from

Kemaman

Tenaga Nasional

Berhad (TNB)

17

Syarikat Air Johor -Semambu

(SAJ)

Reservoir

-Pengurusan Air

Pahang

Berhad

(PAIP)

Chemical

and

Chemicals

and

Type of Preferred

Petrochemical

Petrochemical

Industry

-Universiti

Availability

of -Industrial

Training

Malaysia

Labor

Institute

(ITT) Pahang

Johor

-Pusat

-Universiti

Pembangunan

Teknologi

Kemahiran

Malaysia (UTM)

Pahang

Water Supply

Kualiti Alam

Environmental

Effect &Effluent

Disposal

Hot and Humid

Climate

1.7.1

Water Tariff

-Syarikat

Terengganu

(SATU)

Air

Kualiti Alam

Chemical

and

Petrochemical

-Pusat

Pembangunan

Kemahiran Negeri

Terengganu

(TESDEC)

-Universiti

Malaysia

Terengganu

(UMT)

Kualiti Alam

Hot and Humid

Hot and Humid

18

Figure 1.10: Pengurusan Air Pahang Berhad (PAIP)

Figure 1.11: Syarikat Air Johor (SAJ)

Figure 1.12: Syarikat Air Terengganu (SATU)

Based on Table 2,3 and 4, the price rate is RM RM 0.84/m 3, RM 3.30/m3 and

RM 1.15/m3 respectively. Therefore, the cheapest price for PAIP (Pahang) which is

RM 0.84/m3 while SAJ (Johor) has the highest price which is RM 3.30/m 3.

19

1.7.2

Electricity Tariff

Figure 1.13: Tenaga Nasional Berhad (TNB)

The industrial price of tariff rate for medium voltage general industrial tariff in

TNB is RM RM 37/kW, for each kilowatt of maximum demand per month. The price

rate is the same for all locations since TNB is the sole electricity supplier in Peninsular

Malaysia.

1.8

Conclusion

After considering all the short-listed locations, we have decided to build the

proposed 100,000 MTA propylene plant at Gebeng Industrial Land, Pahang. This is

due to the most important factor which is the price of the land is the cheapest in

Gebeng, RM 15/psf and has the largest area of land compared with Tanjung Langsat

and Kertih. Next, gebeng is also near to the East Coast Expressway and KuantanKerteh Railway which made our land transportation easier for raw material

transportation from Petronas Gas Berhad. For export or import purposes, Gebeng is

also near to the Kuantan Port City. The water tariff in Pahang is also the cheapest in

Pahang compared with Johor and Terengganu. In conclusion, we choose Gebeng due

to cheaper utilities costs and its strategic location.

20

CHAPTER 2

PROCESS CREATION AND SYNTHESIS

2.1

Introduction

By performing process screening based on gross profit (GP) and other factors

related to sustainable design for all possible reaction pathways, the dehydrogenation

of propane is chosen as the best reaction pathway to produce 100,000 lb/hr of

propylene. Next, Gebeng Industrial Land, Pahang is selected as the location for the

establishment of propylene manufacturing plant compared to Tanjung Langsat

Industrial Land, Johor and Kertih Industrial Land, Terengganu due to its lower land

price and adequate utilities.

2.2

Sources of Raw Material and Its Specification

The raw material needed to produce propylene is propane with catalyst,

aluminum oxide. Propane is suggested to be bought from Petronas Gas Berhad

Malaysia due to its near location which is located in Semambu Industrial Land,

Kuantan. As for the aluminium oxide, it will be brought from Superb Aluminum

Industries,Selangor. By using the available East Coast Expressway, the time needed

for transportation is quite short which about 3 hours is.

21

2.3

Physical and Chemical Properties

Table 2.1: Physical and Chemical Properties of Reactant

Properties

Propane

Chromium (catalyst)

C3H8

Al2O3

44.096

101.96

Boiling point (°C)

-42

3000

Melting point (°C)

-189.7

2030

Density (kg/m³ )

2.01 at 0°C

3970 at 0°C

Solubility (mg/L)

Very soluble in water,

Insoluble in water

Formula

Molecular weight (g/mol)

0.0624 mg/Ml at 25°C

Appearance

Colourless

White crystalline

powder

Odor

Std

enthalpy

of

formation ΔfHo298 (Kj/mol)

Odorless

Odorless

-119.8 (l)

-1675.7

-103.8 (g)

Table 2.2: Physical and Chemical Properties of Product

Properties

Propylene

Hydrogen (side

product)

Formula

C3H6

H2

42.081

2.016

Boiling point (°C)

-48

-253

Melting point (°C)

-185

-259.2

Density (kg/m³ )

1.81 at 15°C

0.08988 at 0°C

Solubility (mg/L)

Very soluble in water,

0.00162 mg/mL at 21°C

Molecular weight (g/mol)

0.2 mg/mL at 25°C

Appearance

Odor

Std

enthalpy

of

formation ΔfHo298 (kJ/mol)

Colorless

Colorless

Practically odorless

Odorless

+20.41

0

22

2.4

Synthesis Steps

Process synthesis involves the selection of processing operations to convert

raw materials to products, given that the states of the raw material and product streams

are specified. The most widely accepted approach for process synthesis is introduced

by Rudd, Powers, and Siirola (1973) in a book entitled Process Synthesis. There are 5

key synthesis steps which are:

1. Eliminate differences in molecular types

2. Distribute the chemicals by matching sources and sinks

3. Eliminate differences in composition

4. Eliminate differences in temperature, pressure, and phase

5. Task integration; combination of operations into unit processes and decide

between continuous and batch processing

Step 1 - Eliminate Differences in Molecular Type

There are three methods of producing propylene in industry. Each method uses

different raw material and vary according to price. The methods are:

1. Olefin Metathesis

2. Propane Dehydrogenation

3. Steam cracking

All the three methods will be screened and will be chosen based on the criteria on

economic potential. Conversion rate used for the following calculations is 1 USD =

RM 4.14.

Gross profit will be calculated based on this formula:

𝐺𝑟𝑜𝑠𝑠 𝑝𝑟𝑜𝑓𝑖𝑡 = 𝑃𝑟𝑜𝑑𝑢𝑐𝑡 𝑣𝑎𝑙𝑢𝑒 − 𝑅𝑎𝑤 𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙 𝑣𝑎𝑙𝑢𝑒

23

The stoichiometry of the reactant and products are taking into account without

considering the side products.

1) Olefin Metathesis is a reversible reaction between ethylene and butylene in which

double bonds are broken and then reform to form propylene.

𝐶2 𝐻4 + 𝐶4 𝐻8 → 2𝐶3 𝐻6

Chemical

Ethylene

Butylene

Propylene

C2H4

C4H6

C3H6

1

1

2

28.05

56.10

42.08

Mass

28.05

56.10

84.16

Kg/ Kg Propylene

0.3333

0.6666

1

USD/Kg

1.39

0.65

1.05

RM/Kg

5.75

2.62

4.36

Molecular formula

Kgmol

Molar

mass

(kg/kgmol)

Gross Profit = 4.36(1) - 5.75(0.3333) – 2.62(.6666) = RM 0.70/ Kg Propylene

2) Propane Dehydrogenation is a catalytic process that convert propane into

propylene and hydrogen

𝐶3 𝐻8 → 𝐶3 𝐻6 + 𝐻2

Chemical

Propane

Molecular formula

Hydrogen

Propylene

C3H8

H2

C3H6

1

1

2

44.09

2.016

42.08

Mass

44.09

2.016

42.08

Kg/ Kg Propylene

1.0478

0.048

1

USD/Kg

0.43

0

1.05

RM/Kg

1.76

0

4.36

Kgmol

Molar

mass

(kg/kgmol)

24

Gross Profit = 4.36(1) – 1.76(1.0478) – 0(0.048) = RM 2.52/ Kg Propylene

3) Steam Cracking is where saturated hydrocarbons are broken down into smaller,

often unsaturated, hydrocarbons.

However, propylene is merely a by-product, it is synthesized by other methods,

such as propane dehydrogenation. Ethylene is mainly produced in steam cracking.

Figure 1.9 shows the typical product yields (%) by mass from steam cracking various

hydrocarbon feedstock.

Figure 2.1: Typical product yields (%) by mass from steam cracking various

hydrocarbon feedstock

As it can be seen from the figure, it is not feasible to consider using steam cracking to

produce propylene as the highest yield (%) is 19.

Table 2.3: Summary of Review and Screening of Alternative Processes

Olefin Metathesis

C2H4 + C4H8 2C3H6

Gross Profit

RM 0.70/Kg propylene

Dehydrogenation of

propane

C3H8 C3H6 + H2

RM 2.52 / Kg propylene

25

Butane and ethylene is

Safety

flammable, and ethylene also

Propane is flammable.

may cause dizziness

Catalyst

Al2O3

Al2O3

By-product

No by-product

Hydrogen

Operating

Temperature: 90-100ºC

condition

Pressure: 100 – 110 bar

Conversion

90% percent of conversion

86% percent of conversion

Flammability

Flammable

Flammable

Temperature: 560 – 650 ºC

Pressure : slightly below

atmospheric pressure

In conclusion, dehydrogenation of propane is better economic choice as the

difference between two methods gross profit is RM 1.82/ Kg propylene. Furthermore,

the operating cause would be slightly cheaper for dehydrogenation of propane due to

the low-pressure requirement compared to olefin metathesis. Hence, dehydrogenation

of propane of propane is chosen. The operating temperature of olefin metathesis

process is lower than the dehydrogenation of propane. High temperature process unit

are not economically feasible because it takes large amount of energy to reach the

temperature. Thus, olefin metathesis makes the case of being more economically

feasible and safer to work as well as high temperature carries risk. Dehydrogenation

of propane operates at nearly atmospheric pressure, which is more economically

feasible as it is a well-known fact that compressing units are expensive. Which is why

even if olefin metathesis operates at lower temperature, it is still more expensive to

bring the pressure to 100 bars. The aspect of safety carries a risk, as both methods are

flammable. The catalyst used as well is same and Al 2O3 does not carry any serious

health apart causing irritation to eyes and skin upon contact. None of the chemicals

used carries any ecotoxicity. Thus, the two methods do not pose a major threat to the

environment.

26

Step 2 – Distribute the Chemicals

Reactor

T = 600 OC

m1C3H8

F lb/hr C3H8

P = 1 bar

m2C3H6

m3H2

R lb/hr C3H8

Overall Reaction Equation:

C3H8

C3H6 + H2

Basis: 100000 lb/hr of propylene (C3H3)

86% of conversion

C3H8

C3H6

H2

1

1

1

m1

m2=100,000.00

m3

MW (lb/lbmol)

44.10

42.08

2.01

n, (lbmole/hr)

2376.43

2376.43

2376.43

stoichiometry

Mass flowrate (lb/hr)

27

Number of moles of propylene formed

= (100,000 lb/hr)/42.08

= 2376.43 lbmole/hr C3H6

Assume 100% conversion, the mass flow rate of feed, m1 = 2376.43 x 44.1

= 104800.56 lb/hr

for 86% conversion, the mass flow rate of recycle, R = (1-0.86)/0.86 x 104800.56

R = 17060.53 lb/hr

Mass flowrate of H2 , m3

= (no. of mole) X (molecular weight)

= (2376.43) x (2.01)

= 4776.62 lb/hr

Mass flowrate feed to the reactor,

F = m1 + R

= 104800.56 + 17060.53 = 121861.09l

28

Step 3: Eliminate Differences in Composition

Alternative 1:

Figure 2.2: Flowsheet with separation units of propylene production process

(Alternative 1)

In the production of propylene, one reactor and three separators are used in

order to enable all chemicals involved to be supplied to their sinks. Figure 2.1 shows

the separation units that are needed in a propylene production process. The raw

material for the production of propylene consists of 0.98 propane and 0.02 ethane.

Even though the feed is not completely pure, but no separating unit is needed because

there is only small proportion of ethane in propane. The feed will then enter the reactor

at 600 °C and 1 atm. These pressure and temperature is selected because the

dehydrogenation process of propylene only will occur at these conditions [2].

After the reaction occurs, there are a lot of products produced from the

dehydrogenation process. In order to separate the products, 3 separation units will be

used. The first product that will be separated is hydrogen gas. The reason is, hydrogen

29

gas has a low value of critical pressure at 12.96 bar and it will be difficult to separate

the other products if the hydrogen maintain in the product mixtures. S2 will be used as

separation unit that will be operated at pressure 1 atm and at cryogenic temperature of

-129 °C [3] since hydrogen gas has low critical temperature at -240.01 °C. At column

temperature of -129 °C, hydrogen gas will leave the column as a vapour at the distillate

whereas propylene, propane and other side products will leave the column as liquid at

bottom.

Next, after separate hydrogen gas, we will separate propane and propylene

from the side product. From Table 2.4 at 1 atm, the boiling point of C 3 is very low, 47.7 ˚C, and hence if C3 were recovered at 1 atm as the distillate of the S3, very costly

refrigeration would be necessary to condense the reflux stream. At 17.5 bar, the bubble

point of propane and propylene mixture is at 40 ˚C. By operating the distillation

column at 20 ˚C, the propane and propylene mixture will leave the column as liquid at

the bottom.

The last unit operation would be used to separate the bottom products of second

separator into nearly pure species which is specified at 15 bar. Under these conditions,

the distillate (nearly pure propylene) boils at 38 ˚C. By operating the column at 40 ˚C,

the propylene will leave as the distillate and can be condensed with inexpensive

cooling water, which is available at 25˚C whereas the unreacted propane will leave at

the bottom and recycled back to the reactor.

Table 2.4: Boiling Points of Propylene and Its Side Products

Chemical

H2

C3H8

C3H6

C2H6

C2H4

Normal boiling

point

(1atm, ˚C)

-252.78

-42.00

-47.7

-89.00

-103.7

Boiling point (˚C)

15 bar

46.54

33.06

-16.02

-37.22

17.5 bar

53.62

44.95

-10.13

-31.84

30

Alternative 2:

Figure 2.3: Flowsheet with separation units of propylene production process

(Alternative 2)

At 17.5 bar, the bubble point of propane and propylene mixture is at 40˚C while

ethane and ethylene mixture is at -21˚C. By operating the distillation column (S2) at

20˚C, the propane and propylene mixture will leave the column as liquid at the bottom

while ethane and ethylene mixture will leave the column as the distillate.

The distillation column (S3) would be used to separate the upper product from

S2 into nearly pure species which is specified at 41 bar. Under these conditions, the

distillate (nearly pure ethylene) boils at 2˚C. By operating the column at 10˚C, the

ethylene will leave as the distillate whereas the ethane will leave at the bottom.

Since our main product is propylene, it is not necessary to separate the ethane

and ethylene mixture. This is because separation of ethane and ethylene mixture will

increase the cost as we need to build another distillation column to separate it.

Therefore, alternative 1 is chosen for the production of propylene.

31

Step 4: Eliminate Differences in Temperature, Pressure, and Phase

Figure 2.4: Flowsheet with Temperature, Pressure and Phase Change Operations in The Propylene Production Process

32

Figure 2.3 shows the changes of the state of chemicals. Since the original state of the

raw material is at 36 °C and 11 bar, its temperature is raised to 600 °C at 1 bar.

The process begins by mixing the raw materials (ethane and propane gas) with a

stream of recycle propane gas at 36 °C and 11 bar. The mixing of raw materials and

recycle propane undergoes the following operations:

1. The mixture is preheated before it is introduced to the reactor. The reaction

occurs at around 600oC and 1 bar.

2. The product mixture is then cooled to its dew point -129oC at 1 bar.

3. Then, the product mixture is introduced into a condenser (S1) that separates

the hydrogen gas from other liquid products.

In addition, the liquid mixture that condensed at -129oC at 1 bar from the condenser

is operated upon as follows:

1. Its pressure is increased to 17.5 bar.

2. The temperature is then raised to a liquid at its bubble point, 20 oC at 17.5 bar.

3. Then, the liquid mixture is introduced into a separation column (S2) that

separates the propane gas and propylene gas from other liquid products.

Next, the bottom products (propane gas and propylene gas) from separation

column (S2) are then entered into separation column (S3) at 40 oC. The propylene gas

with a boiling point of 33oC at 15 bar is come out as an upper product from separation

column (S3). The upper products (ethane gas and ethylene gas) from separation

column (S2) will be sell off to market. Finally, the propane liquid from the recycle

stream (at 40oC and 15 bar) undergoes the operation where its temperature is lowered

to the mixing temperature at 36oC at 11 bar.

33

Step 5: Task Integration

Figure 2.5 below shows task integration for the process of propylene production.

Task integration is where the selection of processing units, often referred as unit

operations, in which one or more of the basic operations are carried out. At this stage

in process synthesis, it is common to make the most obvious combinations of

operations, leaving many possibilities to be considered when the flowsheet is

sufficiently promising to undertake the preparation of a base-case design. Below are

the descriptions of unit processes shown in Figure 2.4:

1. Control valve

Control valve is used to regulate pressure and available for any pressure. In this

process, it is used to reduce the high pressure of the fluid to a desired pressure

which is 1 bar. The first control valve is used to reduce the pressure of the gas

in fresh feed from 11 bar to 1 bar. Another control valve is used to reduce the

pressure of liquid propane that is used to recycle back into the feed.

2. Mixer

The used of mixer is to mix gas from the fresh feed and recycle propane from

the splitter at desired temperature and pressure.

3. Furnace

An industrial furnace or direct fired heater is equipment used to provide heat

for a process or can serve as reactor which provides heat of reaction. Furnace

designs vary as to its function, heating duty, type of fuel and method of

introducing combustion air. Since the reactor that we used required high

temperature which is 600˚C and the outlet temperature from the mixer is low

at 36°C, the furnace is used to heat up the stream. This follows heuristics 25

which explained unless required as part of the design of the separator or reactor,

provide necessary heat exchange for heating or cooling process fluid streams,

with or without utilities, in an external shell-and-tube heat exchanger using

countercurrent flow. However, if a process stream requires heating above

750°F (400°C), use a furnace unless the process fluid is subject to chemical

decomposition.

34

4. Oleflex Reactor

This type of reactor involves a process of catalytic dehydrogenation for the

production of light olefins from their corresponding paraffin. One of the

processes of catalytic dehydrogenation is production of propylene from

propane. The Oleflex process provides high quality of propylene, which then

leads to high quality polymers. This process used Pt-Sn catalyst to promote the

dehydrogenation reaction. In this process, the Oleflex reactor operated at

600˚C and 1 bar.

5. Heat Exchanger

A heat exchanger is a device designed to efficiently transfer or "exchange" heat

between two or more fluids. In other words, heat exchanger is used in both

heating and cooling processes. The fluids may be separated by a solid wall to

prevent mixing or they may be in direct contact. In this process, heat exchanger

is needed to increase or decrease the temperature of the stream.

6. Pump

The used of pump is to provide sufficient pressure to overcome the operating

pressure

of

the

system

to

move

fluid

like

liquid at a

required

flowrate. To achieve a required flow through a pumping system, we need to

calculate what the operating pressure of the system will be to select a suitable

pump. Since the pressure change operation involves in this process is liquid, it

is accomplished by a pump. The enthalpy change in the pump is very small and

the temperature does not change by more than 1˚C which means that used of

pump are not affect temperature of the stream.

7. Cryogenic Separator (S1)

The required temperature and pressure for the separation to occur is 129˚C and

1 bar. The used of this separator is to remove hydrogen from the mixture

vapour. Hydrogen is removed at the distillate while other components are

removed at the bottom as the liquid.

35

8. Distillation column (S2)

Distillation is a process where a liquid or vapor mixture of two or more

substances is separated into its component fractions of desired purity, by the

application and removal of heat. The process is based on the fact that the vapor

of a boiling mixture will be richer in the components that have lower boiling

points. Therefore, when this vapor is cooled and condensed, the condensate

will contain more volatile components. At the same time, the original mixture

will contain more of the less volatile material. The equipment used for

distillation process is distillation column. In this process, the column is separate

the components of C3 and C2. Components of C2 are removed at the distillate

since their boiling points are lower than C 3 components while C3 components

are removed at the bottom as a liquid.

9. Splitter (S3)

Since propane and propylene have similar molecular size and physical

properties, their separation is challenging. Therefore, propane-propylene

splitter is used as it can give high purity of propylene. The purified propylene

recovered at the top is condensed, and the other part of it is returned as reflux

while the propane is drawn off at the reboiler.

36

36°C

11 bar

1

C3H8

C2H6

36 °C

1 bar

36 °C

1 bar

3

2

V-100

Mix-100

600

°C

1 bar

H2

5

C2H4

C3H6

C3H8

Furnace

R-100

6

C2H6

600 °C

1 bar

Condenser duty

E-100

-103.7°C

1 bar

H2

7

C3H6

C2H4

C2H6

14

19

9

Rectifier

4

-129°C

1 bar

T-100

20 °C

17.5 bar

E-101

8

17.5

bar

13

E-103

18

T-101

V-100

V-101

V-102

15 bar

40 °C

15 bar

E-105

12

1 bar

17

-10.13°C

17.5 bar

38.1°C

15 bar

T-100

T-101

S-100

C3H6

C2H4

10

C2H6

15

E-102

C3H8

C3H8

C3H6

20 °C

17.5 bar

11 -129°C

17.5 bar

-129°C

1 bar

C3H8

20

Reboiler duty

E-104

40 °C

15 bar

16

21

20 °C

15 bar

P-100

V-101

22

36 °C

1 bar

E-106

40 °C

1 bar

Labelling

E-100

E-101

E-102

E-103

E-104

E-105

E-106

Mix-100

P-100

R-100

S-100

V-102

40 °C

15 bar

Figure 2.5: Flowsheet Task Integration for The Propylene Production Process

Description

Heater

Heat Exchanger

Evaporator

Heater

Evaporator

Heater

Cooler

Mixer

Pump

Oleflex Reactor

Cryogenic

Separator

Distillation

Column

Splitter

Control valve

Control valve

Control valve

37

2.5

Manual Mass Balance Calculation

2.5.1

Overall Mass Balance

Reactor

T = 500 OC

m1C3H8

F C3H8

100000

C3H6

P = 1 bar

gfrgfr

R C3H8

Overall Reaction Equation :

C3H8

C3H6 + H2

Basis : 100000 lb/hr of propylene (C3H3)

86% of conversion

C3H8

H2

C3H6

1

1

1

m1

m2

100,000.00

MW (lb/lbmol)

44.10

2.01

42.08

n, (lbmole/hr)

2376.43

2376.43

2376.43

stoichiometry

Mass flowrate (lb/hr)

n C3H8 = 100 000/42.08

= 2376.43 lbmole/hr

m2 = 2376.43 × 2.01

= 4776.62 lb/hr

m1 = 2376.43 × 44.10

= 104 800.56 lb/hr

R=

1−0.86

0.86

× 104 800.56

= 17 060.56 lb/hr

F = 104 800.56 + 17 060.56

= 121 861.12 lb/hr

38

2.5.2

Mass Balance for Mixer

F1

M-1

0.98 C3H8

F2

C3H8

0.02 C2H6

C2H6

1

2

9

R = 17060.53 lb/hr

C3H8

Stream 1

Stream 2

Stream 9

Mole

Fraction

Mass

Flowrate,

(lb/hr)

104

800.56

0.983

121861.09 1.0

17060.5

3

2029.78

0.017

2029.78

0

No.

Component

Mole

Fractio

n

Mass

Flowrate,

(lb/hr)

1

Propane

0.98

2

Ethane

0.02

Mole

Fraction

0

Mass

Flowrate

, (lb/hr)

39

2.5.3

Mass Balance for Reactor

2

3

R-1

123 999.88 lb/hr

123999.88 lb/hr

3

C3H8

0.98 C3H8

C4H10

0.017 C2H6

C5H12

C3H6

C4H8

H2

The percentage of conversion for propane and ethane are 86% and 60% respectively.

Stream 2

Stream 3

No.

Component

Mole

Fraction

Mass Flowrate,

(lb/hr)

1

Propane

0.983

121 861.09

0.0737

17 060.53

2

Ethane

0.017

2 029.78

0.0052

811.912

3

Propylene

0

0

0.4530

100 000

4

Ethylene

0

0

0.0077

1137.99

5

Hydrogen

0

0

0.4604

4858.15

Mole

Fraction

Mass Flowrate,

(lb/hr)

40

2.5.4

Mass Balance for Separation Unit 1

4

H2

3

S-1

123 868.582 lb/hr

C3H8

C2H6

C3H6

5

C2H4

B1 lb/hr

H2

C3H8

C2H6

C3H6

C2H4

Stream 3

Stream 4

Stream 5

No

.

Componen

t

1

Propane

0.0737

17 060.53

-

-

0.1367

17

060.53

2

Ethane

0.0052

811.91

-

-

0.0096

811.91

3

Propylene

0.4530

100 000

-

-

0.8395

100 000

4

Ethylene

0.0097

1137.99

-

-

0.0143

1137.99

5

Hydrogen

0.4604

4858.15

1

4858.15

-

-

Mole

Fraction

Mass

Flowrate,

(lb/hr)

Mass

Flowrate,

(lb/hr)

Mole

Fraction

Mole

Fraction

Mass

Flowrate

, (lb/hr)

41

2.5.5

Mass Balance for Separation Unit 2

6

C2H6

C2H4

5

S-1

119 010.43 lb/hr

C3H8

C2H6

C3H6

7

C2H4

C2H6

C3H6

Stream 5

Stream 6

Stream 7

No

.

Component

Mole

Fraction

1

Propane

0.1367

17 060.53

-

-

0.14

17

060.53

2

Ethane

0.0096

811.91

0.4

811.91

-

-

3

Propylene

0.8395

100 000

-

-

0.86

100 000

4

Ethylene

0.0143

1137.99

0.6

1137.99

-

-

Mass

Flowrate,

(lb/hr)

Mass

Flowrate,

(lb/hr)

Mole

Fraction

Mole

Fraction

Mass

Flowrate

, (lb/hr)

42

2.5.6

Mass Balance for Separation Unit 3

8

C3H6

7

117 060.53 lb/hr

S-3

C3H8

C3H6

C3H8

9

Stream 7

Stream 9

Stream 8

No.

Component

Mole

Fraction

Mass

Flowrate,

(lb/hr)

Mole

Fraction

Mass

Flowrate,

(lb/hr)

Mole

Fraction

Mass

Flowrate,

(lb/hr)

1

Propane

0.14

17060.53

1

17060.56

-

-

2

Propylene

0.86

100000

-

-

1

100000

43

2.5.7

Smmary Table Mass Balance

Stream

Component

MassFlowrate (lb/hr)

1

Propane

104 800.56

Ethane

2 029.78

Propane

121 861.09

Ethane

2 029.78

Propane

17 060.53

Ethane

811.91

Propylene

100 000

Ethylene

1 137.99

Hydrogen

4 858.15

4

Hydrogen

4 858.15

5

Propane

17 060.53

Ethane

811.91

Propylene

100 000

Ethylene

1 137.99

Ethane

811.91

Ethylene

1 137.99

Propane

17 060.53

Propylene

100 000

8

Propylene

100 000

9

Propane

17 060.56

2

3

6

7

44

2.6

Manual Energy Balance Calculation

Unit

Operation

Substances

Moles in

(mol/h)

Moles out

(mol/h)

Temp. in

(°C)

Temp.

out (°C)

Q (kJ/h)

Globe Valve 1

Propane

Ethane

1078176.47

30669.35

1078176.47

30669.35

36

36

-3752900

Furnace

Propane

Ethane

1253683.00

30669.35

1253683.00

30669.35

36

600

115286872.6

Reactor

Propane

Propylene

Ethane

Ethylene

Hydrogen

Propane

Propylene

Ethane

Ethylene

Hydrogen

Propane

Propylene

Ethane

Ethylene

Hydrogen

Propane

Propylene

Ethane

Ethylene

Hydrogen

1253683.00

30669.35

175516.83

1077930.13

12267.74

18402.29

1096329.768

175516.83

1077930.13

12267.74

18402.29

1096329.768

175516.83

1077930.13

12267.74

18402.29

1096329.768

175516.83

1077930.13

12267.74

18402.29

1096329.768

175516.83

1077930.13

12267.74

18402.29

1096329.768

175516.83

1077930.13

12267.74

18402.29

1096329.768

175516.83

1077930.13

12267.74

18402.29

1096329.768

600

600

156385320.3

600

-103.7

162104852.8

-103.7

-129

-3612689.8

-129

-129

-

Heat

Exchanger 1

Heat

Exchanger 2

Separator 1

45

Moles in

(mol/h)

Moles out

(mol/h)

Propane

Propylene

Ethane

Ethylene

175516.83

1077930.13

12267.74

18402.29

175516.83

1077930.13

12267.74

18402.29

Propane

Propylene

Ethane

Ethylene

Propane

Propylene

Ethane

Ethylene

Propane

Propylene

Ethane

Ethylene

Propane

Propylene

175516.83

1077930.13

12267.74

18402.29

175516.83

1077930.13

12267.74

18402.29

175516.83

1077930.13

12267.74

18402.29

175516.83

1077930.13

175516.83

1077930.13

12267.74

18402.29

175516.83

1077930.13

12267.74

18402.29

175516.83

1077930.13

12267.74

18402.29

175516.83

1077930.13

Heat

Exchanger 5

Propane

Propylene

175516.83

1077930.13

175516.83

1077930.13

Heat

Exchanger 6

Propane

Propylene

175516.83

1077930.13

175516.83

1077930.13

Unit

Operation

Pump

Heat

Exchanger 3

Heat

Exchanger 4

Separator 2

Valve

Substances

Temp. in

(°C)

Temp.

out (°C)

Q (kJ/h)

-129

-129

253588.27

-129

-10.13

17781946.57

-10.13

20

8044043.47

20

Top: -21

Bottom: 20

-23242481.41

20

20

20

38.1

25586291

38.1

40

258761.27

-93172.32

46

Unit

Operation

Separator 3

Globe Valve 2

Heat

Exchanger 7

Moles in

(mol/h)

Moles out

(mol/h)

Propane

Propylene

175516.83

1077930.13

175516.83

1077930.13

Propane

175516.83

175516.83

Substances

Propane

175516.83

Temp. in

(°C)

Temp.

out (°C)

Q (kJ/h)

40

Top: 33

Bottom: 40

26562391.2011

40

40

-409342.88

40

36

-88870.15

175516.83

47

CHAPTER 3

PROCESS SIMULATION AND HEAT INTEGRATION

3.1

Percentage Difference between Manual Calculation and HYSYS

Calculation

Table 3.1: Mass Balance

Stream No.

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Mass

(lbmole/hr)

(manual)

106830.34

106830.34

123890.87

123890.87

123868.58

123868.58

4858.15

119010.43

119010.43

119010.43

1949.90

117060.53

117060.53

117060.53

100000

17060.53

17060.53

17060.53

17060.53

100000

Mass

(lbmole/hr)

(Hysys)

104100

104100

120800

120800

120800

120800

5070

115700

115700

115700

1086

114600

114600

114600

97950

16880

16880

16880

16880

97950

% Diff

2.62

2.62

2.56

2.56

2.56

2.56

4.18

2.86

2.86

2.86

79.54

2.15

2.15

2.15

2.09

1.07

1.07

1.07

1.07

2.09

48

Table 3.2: Energy Balance

Energy, kJ/h

(manual)

Energy, kJ/h

(HYSYS)

% Diff

0

0

0

Furnace

115286872.6

88440000

30.36

Reactor

158385320.3

138900000

14.03

Heat Exchanger 1

&2

165717542.6

135500000

22.30

-

-

253588.27

166300

52.49

Heat Exchanger 3

&4

25825990.04

16480000

74.91

Separator 2

2324248.41

3612500

35.66

0

0

25845052.27

15750000

64.10

26562391.2011

25110000

5.78

0

0

0

-88870.15

2489000

103.58

Equipment

Globe Valve 1

Separator 1

Pump

Valve

Heat Exchanger 5

&6

Separator 3

Globe Valve 2

Heat Exchanger 7

0

49

3.2

Heat Integration

3.2.1

Calculation of FCp

Heat exchanger 1

Stream

inlet

600°C, vap.

Stream

inlet

22.2°C,

vap.

Component

Flow rate

Ib/hr

Flow rate

mole/hr

Ethane

1428.94

21554.93

Propene

1.59

17.156589

0.099

Propane

119357.53

1227740.33

0.1181

∑FCp

147 MJ/hr. K

Cp (KJ/mol.K)

0.083

50

Heat exchanger 2

Stream inlet

Stream inlet

600°C, vap.

-129C, mixture

Flow rate

Flow rate

Ib/hr

mole/hr

Ethane

571.57

8621.972

0.071977306

Propene

97955.36

1055873.85

0.084765251

Propane

16710.05

171883.65

Ethylene

799.88

12932.96

Hydrogen

4750.25

1068790.29

∑FCp

139 MJ/hr.K

Component

Cp (KJ/mol.K)

0.099924277

0.056673009

0.029384209

51

Heat exchanger 3

Stream

inlet 20°C,

liq

Stream inlet

-128.4°C, liq

Flow rate

Flow rate

Ib/hr

mole/hr

Ethane

545.31

8225.85

0.041326623

Propene

97789.68

1054087.89

0.049096559

Propane

16687.77

171654.39

0.05463887

Ethylene

693.13

11206.91

0.033932812

Hydrogen

0.8776

197.467

0.028864532

∑FCp

61.86 MJ/hr.K

Component

Cp (KJ/mol.K)

52

Heat exchanger 4

Stream

inlet

36.08°C,

mixture

Stream

inlet 40°C,

vapor

Flow rate

Flow rate

Ib/hr

mole/hr

Ethane

152.19

2295.69

0.054581189

Propene

97789.66

1054087.72

0.066170694

Propane

16687.77

171654.39

0.076427785

Ethylene

0.7595

12.2805

0.045014187

Hydrogen

0

0

0.028847632

∑FCp

83 MJ/hr.K

Component

Cp (KJ/mol.K)

53

Heat exchanger 5

Stream

inlet

35.39°C,

vapor

Stream

inlet 10°C,

liquid

Flow rate

Flow rate

Ib/hr

mole/hr

Ethane

335.48

5060.6428

0.05248998

Propene

215540.40

2323338.49

0.06353107

Propane

22.6386

232.865907

0.073061866

Ethylene

1.6741

27.0681

0.043306918

Hydrogen

0

0

0.02884394

∑FCp

147.9 MJ/hr.K

Component

Cp (KJ/mol.K)

54

Heat exchanger 6

Stream

inlet 36°C,

vapor

Stream inlet

-42.14°C, mixture

Flow rate

Flow rate

Ib/hr

mole/hr

Ethane

0

0

0.048853226

Propene

3.5082

37.8158

0.058879756

Propane

36759.84334

378120.61

0.067127685

Ethylene

0

0

0.040291784

Hydrogen

0

0

0.028844827

∑FCp

25.384 MJ/hr.K

Component

Cp (KJ/mol.K)

55

3.2.2

Process Energy Integration

Table 3.3 below shows the data for stream that involved with heat exchanger.

Cold stream is referring to stream that needs heating while hot stream is referring to

stream that needs cooling. The ∆Tmin used in this project is 10˚C. The Tsupply and Ttarget

in table below are referring to temperature supply and temperature target.

∆Tmin = 10˚C

Table 3.3: Stream Table Data

Stream

Type

Tsupply (˚C)

Ttarget (˚C)

FCp

(MJ/hr.K)

C1

cold

22.2

600

147

C2

cold

-128.4

20

61.86

C3

C4

H1

cold

cold

hot

36.08

-42.14

600

40

36

-129

83

25.38

139

H2

hot

35.39

10

147.9

3.2.3

ΔH

(MJ/hr)

84936.60

9180.02

325.36

1983.51

82010.00

5234.18

Algorithm Table

∆Tmin chosen is divided into half which obtained 5˚C. To calculate the shifted

temperature, it is needed to adding or subtracting 5˚C for all of the temperature. For

cold stream, the actual temperature is adding by 5˚C while for hot stream, the actual

temperature is subtracting by 5˚C. Table 3.4 shows the calculated shifted temperature.

Table 3.4: Shifted Temperatures

Stream

Ts (˚C)

Tt (˚C)

C1

C2

C3

C4

H1

H2

27.2

-123.4

41.08

-37.14

595

30.39

605

25

45

41

-134

5

From table above, the pinch temperature, minimum cooling and heating

requirement are calculated and these values are calculated by using method of problem

table algorithm as shown in Figure 3.1 below.

56

T (˚C)

∆T (˚C)

∑FCpH -∑FCpC

(MJ/hr.K)

∆Hi (MJ/hr)

1st Cascade

605

6581.52

139

H1

595

10

550

-147

-8

-1470

41.08

C3

83

3.92

-91

-356.72

0.08

-8

-0.64

10.61

-33.38

-354.16

3.19

114.52

365.32

2.2

261.52

575.34

20

199.66

3993.2

41

147.9

H2

30.39

C1

147

25

5

42.14

-37.14

-123.4

C4

25.38

C2

61.86

86.26

10.6

51.76

77.14

139

-134

Figure 3.1: Algorithm Table

Hot Pinch temperature: 35.39

Cold Pinch Temperature: 25.39

-1470

5111.52

-5870

711.52

-6226.72

354.8

-6227.36

354.16

-6581.52

0

-6216.2

365.32

-5640.86

940.66

-1647.66

4933.86

533.51

7115.03

7187.61

13769.13

8661.01

15242.53

QH min

-4400

45

27.2

2nd Cascade

2181.17

6654.1

1473.4

Qc min

Pinch

57

3.2.4

Heat Exchanger Network

Then, heat exchanger network is design for the maximum energy recovery. The heat exchanger network design have above and below of

the pinch temperature. The heat exchanger network design is shows in Figure 3.2.

35.39

Above pinch

30.39

25.39

Below pinch

600

H1

H1

H3

35.39

H2

H2

-129

Add Cooler

22.2

Add Heater

H1

H2

20

-128.4

C2

H3

36.08

40

C3

Add Cooler

10

600

C1

H4

Add Heater

36

Add Heater

H4

-42.14

Figure 3.2: Heat Exchanger Network

C4

58

Table 3.5 below shows the summary of temperature for heat exchanger that obtain based

on heat exchanger network design. There are four heat exchangers that have been obtained.

Table 3.5: Summary of Temperature of Heat Exchanger

TH,in (˚C)

TH,out(˚C)

TC,in (˚C)

TC,out (˚C)

H1

600

35.39

25.39

497.3

H2

35.39

23.17

22.2

25.39

H3

35.39

-40.63

-128.4

20

H4

-40.63

-116.65

-42.14

25.39

Heat

Exchanger

After that, temperature profile of all heat exchangers is draw to determine the validity of

the heat exchange occurs. If there is any crossing in the temperature profile between the hot

and cold stream, the heat exchange is invalid. The temperature profile is shown in Figure 3.6

to 3.9.

600 ˚C

35.39˚C

497.3˚C

35.39˚C

23.17˚C

25.39˚C

25.39˚C

Figure 3.3: Temperature Profile H1

35.39˚C

20˚C

22.2˚C

Figure 3.4: Temperature Profile H2

-42.14˚C

-40.63˚C -116.65˚C

-128.4˚C

Figure 3.5: Temperature Profile H3

25.39˚C

-40.63˚C

Figure 3.6: Temperature Profile H4

59

3.2.5

Comparison of Performance Before and After Heat Integration

Table 3.6: Heating Requirement Before and After Heat Integration

Stream

Heating requirement before

Heating requirement after

heat integration (MJ/hr)

heat integration (MJ/hr)

84936.60

9180.02

325.36

1983.51

96425.49

69370.88

0

325.36

269.28

69965.52

C1

C2

C3

C4

Total

From Table 3.6,

Hot utility consumption before heat integration = 96425.49 MJ/hr

Hot utility consumption after heat integration = 69965.52 MJ/hr

Total savings =

96425.49 – 69965.52

96425.49

x 100%

= 27.4%

Table 3.7: Cooling Requirement Before and After Heat Integration

Stream

Cooling requirement before

Cooling requirement after

heat integration (MJ/hr)

heat integration (MJ/hr)

82010.00

5234.18

87244.18

10566.28

1807.25

12373.53

H1

H2

Total

From Table 3.7,

Cooling utilities consumption before heat integration = 87244.18 MJ/hr

Cooling utilities consumption after heat integration

Total savings =

87244.18 − 12373.53

87244.18

= 85.8 %

x 100%

= 12373.53 MJ/hr

60

3.2.6

Process Flow Diagram Heat Exchanger Network

C3H6

26

C1

36°C

11 bar

1

C3H8

C2H6

H2

C3H6

25 23.17°C

C2H4

15 bar

4

3

2

V-100

600 °C

1 bar

7

22.17 °C

1 bar

19.92 °C

1 bar

Mix-100

1 bar

1 bar

35.39 °C

1 bar

6

C3H8

600 °C

1 bar

C2H6

5

497.30 °C

25.39 °C HE2

HE1

Labelling

HE1

HE2

HE3

HE4

C1

C2

H1

H2

H3

Mix-100

P-100

R-100

S-100

10 °C

15 bar

H1

20

8

16

C2H4

C2H6

R-100

-26.95 °C

(To market)

20

15

HE3

24

-40.63°C

1 bar

9

T-100

C3H8

C3H6

T-100

V-101

36.08 °C

15 bar

H3

10

V-102

H2

-116.65°C

1 bar

40 °C

15 bar

43.37 °C

15 bar

21

-42.14 °C

1 bar

25.39 °C HE4

17.5 bar

H2

22

23

1 bar

19

18

17

42.79 °C

17.5 bar

36 °C

35.39 °C

15 bar

Rectifier

20 °C

17.5 bar

(To market)

T-101

C3H8

43.37 °C

15 bar

Reboiler duty

T-101

V-100

V-101

V-102

12

-129°C

1 bar

11

14

C2

-128.4°C

17.5 bar

13

-129°C

1 bar

S-100

C3H6

C2H4

C3H8

P-100

-129°C

1 bar

C2H6

Figure 3.7: Process Flow Diagram Heat Exchanger Network

Description

Heat Exchanger

Heat Exchanger

Heat Exchanger

Heat Exchanger

Cooler

Cooler

Heater

Heater

Heater

Mixer

Pump

Oleflex Reactor

Cryogenic

Separator

Distillation

Column

Splitter

Control valve

Control valve

Control valve

61

CHAPTER 4

PROCESS OPTIMIZATION

4.1

Process Optimization

Process optimization is a discipline of adjusting a process so as to optimize

some specific set of parameters without violating some constraint. The most common

goal of optimization is to minimize the cost and utilities and maximize profit.