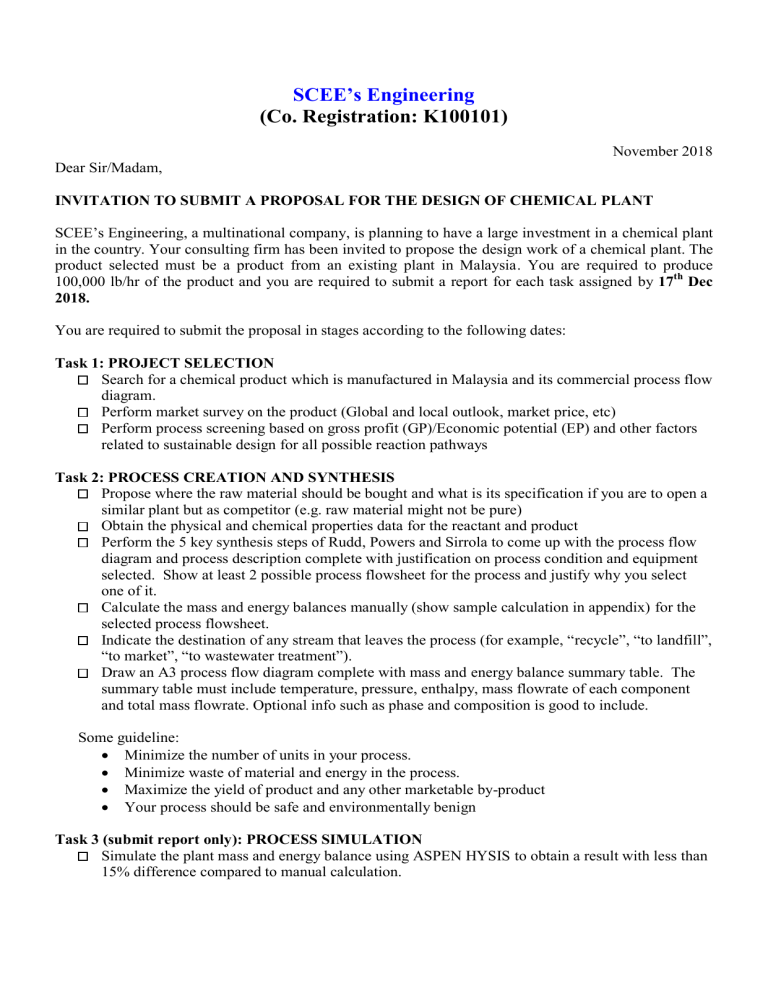

Design 1 Project 2018 tasks

advertisement

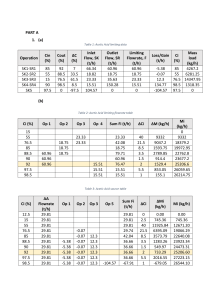

SCEE’s Engineering (Co. Registration: K100101) November 2018 Dear Sir/Madam, INVITATION TO SUBMIT A PROPOSAL FOR THE DESIGN OF CHEMICAL PLANT SCEE’s Engineering, a multinational company, is planning to have a large investment in a chemical plant in the country. Your consulting firm has been invited to propose the design work of a chemical plant. The product selected must be a product from an existing plant in Malaysia. You are required to produce 100,000 lb/hr of the product and you are required to submit a report for each task assigned by 17th Dec 2018. You are required to submit the proposal in stages according to the following dates: Task 1: PROJECT SELECTION Search for a chemical product which is manufactured in Malaysia and its commercial process flow diagram. Perform market survey on the product (Global and local outlook, market price, etc) Perform process screening based on gross profit (GP)/Economic potential (EP) and other factors related to sustainable design for all possible reaction pathways Task 2: PROCESS CREATION AND SYNTHESIS Propose where the raw material should be bought and what is its specification if you are to open a similar plant but as competitor (e.g. raw material might not be pure) Obtain the physical and chemical properties data for the reactant and product Perform the 5 key synthesis steps of Rudd, Powers and Sirrola to come up with the process flow diagram and process description complete with justification on process condition and equipment selected. Show at least 2 possible process flowsheet for the process and justify why you select one of it. Calculate the mass and energy balances manually (show sample calculation in appendix) for the selected process flowsheet. Indicate the destination of any stream that leaves the process (for example, “recycle”, “to landfill”, “to market”, “to wastewater treatment”). Draw an A3 process flow diagram complete with mass and energy balance summary table. The summary table must include temperature, pressure, enthalpy, mass flowrate of each component and total mass flowrate. Optional info such as phase and composition is good to include. Some guideline: Minimize the number of units in your process. Minimize waste of material and energy in the process. Maximize the yield of product and any other marketable by-product Your process should be safe and environmentally benign Task 3 (submit report only): PROCESS SIMULATION Simulate the plant mass and energy balance using ASPEN HYSIS to obtain a result with less than 15% difference compared to manual calculation.