Strategic Cost Management: Value Chain & JIT

advertisement

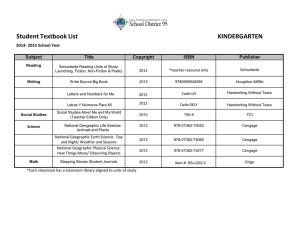

Cornerstones of cost management, 4e Chapter 11 Strategic cost management © 2019 Cengage. All rights reserved. Learning objectives 1. Explain what strategic cost management is and how it can be used to help a firm create a competitive advantage 2. Discuss value-chain analysis and the strategic role of activity-based customer and supplier costing 3. Tell what life-cycle cost management is and how it can be used to maximize profits over a product’s life cycle 4. Identify the basic features of JIT purchasing and manufacturing 5. Describe the effect JIT has on cost traceability and product costing © 2019to Cengage. All rights reserved. Introduction Cost management Strategic Decision Making and Cost Management • Strategic decision making – Choosing among alternative strategies • Goal - Selecting a strategy that provides a company with reasonable assurance of long-term growth and survival Strategic cost management – Use of cost data to develop and identify superior strategies that will produce a sustainable competitive advantage © 2019to Cengage. All rights reserved. Introduction Cost management Competitive Advantage, Total Product, and Post-Purchase Costs • Competitive advantage: Creating better customer value for the same or lower cost than offered by competitors – Customer value: Difference between customer realization and customer sacrifice • • Total product: Complete range of tangible and intangible benefits that a customer receives from a purchased product Post-purchase costs: Costs of using, maintaining, and disposing of the product © 2019to Cengage. All rights reserved. Introduction Cost management Strategies For Increasing Customer Value To Achieve Competitive Advantage • Cost leadership – Looks to provide the same or better value to customers at a lower cost than offered by competitors • Differentiation – Strives to increase customer value by increasing what the customer receives • Focusing – Places emphasis on a market or customer segment © 2019to Cengage. All rights reserved. Introduction Cost management Strategic Positioning • • Process of selecting the optimal mix of three general strategic approaches Role of cost management – Reduce costs – Strengthen the chosen strategic position © 2019to Cengage. All rights reserved. Introduction Cost management Value-Chain Framework • Industrial value chain: Linked set of value-creating activities – Firm must understand the entire value chain in order to create and sustain a competitive advantage • Compelling approach to understanding a firm’s strategically important activities – Recognition of complex linkages and interrelationships among activities within and beyond the firm is vital © 2019to Cengage. All rights reserved. Introduction Cost management Types of Linkages • • Internal linkages: Relationships among activities that are performed within a firm’s portion of the value chain External linkages: Relationship of a firm’s value-chain activities that are performed with its suppliers and customers – Types - Supplier linkages and customer linkages © 2019to Cengage. All rights reserved. Introduction Cost management Identification and Selection of Firm’s Activities • • • Firm’s activities can be used to produce or sustain a competitive advantage Help exploit a firm’s internal and external linkages Classification of activities – Organizational activities – Operational activities © 2019to Cengage. All rights reserved. Introduction Cost management Organizational Activities and Cost Drivers • Types of organizational activities – Structural activities: Determine the underlying economic structure of the organization – Executional activities: Define the processes and capabilities of an organization • Organizational cost drivers: Structural and executional factors that determine the long-term cost structure – Types - Structural and executional cost drivers © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.2 - Organizational Activities and Drivers (1 of 2) Structural Activities Structural Cost Drivers Building plants Number of plants, scale, degree of centralization Management structuring Management style and philosophy Grouping employees Number and type of work units Complexity Number of product lines, number of unique processes, number of unique parts, degree of Complexity Vertically integrating Scope, buying power, selling power Selecting and using process technologies Types of process technologies, experience © 2019 Cengage. All rights reserved. Exhibit 11.2 - Organizational Activities and Drivers (2 of 2) Executional Activities Executional Cost Drivers Using employees Degree of involvement Providing quality Quality management approach Providing plant layout Plant layout efficiency Designing and producing products Product configuration Providing capacity Capacity utilization © 2019 Cengage. All rights reserved. Operational Activities and Drivers • • Operational activities: Day-to-day activities performed as a result of the structure and processes selected by the organization Operational cost drivers: Factors that drive the cost of operational activities © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.3 - Operational Activities and Drivers (1 of 2) Unit-Level Activities Unit-Level Drivers Grinding parts Grinding machine hours Assembling parts Assembly labor hours Drilling holes Drilling machine hours Using materials Pounds of material Using power Number of kilowatt-hours Batch-Level Activities Batch-Level Drivers Setting up equipment Number of setups Moving batches Number of moves Inspecting batches Inspection hours Reworking products Number of defective units © 2019 Cengage. All rights reserved. Exhibit 11.3 - Operational Activities and Drivers (2 of 2) Product-Level Activities Product-Level Drivers Redesigning products Number of change orders Expediting Number of late orders Scheduling Number of different products Testing products Number of procedures © 2019 Cengage. All rights reserved. Exhibit 11.4 - Organizational and Operational Activity Relationships © 2019 Cengage. All rights reserved. Value-Chain Analysis • Identifying and exploiting internal and external linkages to strengthen a firm’s strategic position – Exploitation of linkages relies on analyzing how costs and other nonfinancial factors vary • Objective - To control cost drivers better than competitors © 2019to Cengage. All rights reserved. Introduction Cost management Exploiting Internal Linkages • • Relationships between activities are assessed and used to reduce costs and increase value Knowing the cost drivers of activities is crucial for understanding and exploiting linkages © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.5 - Internal value chain © 2019 Cengage. All rights reserved. Exploiting Supplier Linkages • • Managing linkages in order for the company and the external parties to receive increased benefits Suppliers provide inputs and can have a significant effect on a user’s strategic positioning © 2019to Cengage. All rights reserved. Introduction Cost management Managing procurement costs using activitybased costing (1 of 2) • Purchasing managers should choose suppliers whose quality, reliability, and delivery performance are acceptable – Requirements Suppliers should be evaluated based on total cost and not just purchase price Supplier costs are assigned to products using causal relationships © 2019to Cengage. All rights reserved. Introduction Cost management Managing procurement costs using activitybased costing (2 of 2) • Activity-based costing – Defines suppliers as cost objects and traces costs related to purchase, quality, reliability, and delivery performance to suppliers – Defines products as cost objects and traces supplier costs to specific products © 2019to Cengage. All rights reserved. Introduction Cost management Managing customer costs • Failure to assign customer-servicing costs accurately will prevent sales representatives from managing the customer mix effectively – Customer-related costs allow the firm to classify customers as profitable or unprofitable – Once identified, actions can be taken to strengthen the strategic position of the firm © 2019to Cengage. All rights reserved. Introduction Cost management Product Life-Cycle Viewpoints • Product life-cycle: Can refer to a product class as a whole, to specific forms, and to specific brands or models – Revenue-producing life: Time a product generates revenue for a company – Consumable life: Length of time that a product serves the needs of a customer • Viewpoints are marketing-oriented and productionoriented © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.7 - General Pattern of Product Life Cycle: Marketing Viewpoint © 2019 Cengage. All rights reserved. Production Viewpoint • • Defines stages of the life cycle by changes in the type of activities performed Emphasizes life-cycle costs – Life-cycle costs: All costs associated with the product for its entire life cycle – Costs include: Research and development Production and logistics support © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.8 - Product Life Cycle: Production Viewpoint © 2019 Cengage. All rights reserved. Consumable Life-Cycle Viewpoint • • Related to activities that define the stages of purchasing, operating, maintaining, and disposal Emphasizes product performance for a given price – Price is the costs of ownership that includes purchase, operating, maintenance, and disposal costs • Total customer satisfaction is affected by purchase price and post-purchase costs © 2019to Cengage. All rights reserved. Introduction Cost management Life-cycle management • Consists of actions taken that cause a product to be: – Designed and developed – Produced, marketed, distributed, and operated – Maintained, serviced, and disposed • Helps maximize life-cycle profits by taking advantage of revenue enhancement and cost reduction opportunities © 2019to Cengage. All rights reserved. Introduction Cost management Relationships among life-cycle viewpoints • • • Marketing viewpoint is revenue-oriented Production viewpoint is cost-oriented Consumable life-cycle viewpoint is customer value– oriented © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.9 - Typical Relationships of Product Life-Cycle Viewpoints (1 of 2) Marketing Product Life Cycle: Attributes Sales Introduction Low Growth Maturity Rapid growth Slow growth, peak sales Decline Declining Production Life Cycle: Attributes Introduction Growth Maturity Decline Expenses: Product R&D High Moderate Moderate Low Product R&D Moderate High Moderate Low Plant & equipment Low to moderate High Moderate Low Advertising Moderate to high High Moderate Low Service Low Moderate High Low © 2019 Cengage. All rights reserved. Exhibit 11.9 - Typical Relationships of Product Life-Cycle Viewpoints (2 of 2) Consumable Life Cycle: Attributes Introduction Growth Maturity Decline Customer value: Customer type Innovators Mass market Mass market, differentiated Laggards Performance sensitivity High High High Moderate Price sensitivity Low Moderate High Moderate Competition None Growing High Low Attributes Profits Introduction Negligible to loss Growth Peak levels Maturity Moderate to high © 2019 Cengage. All rights reserved. Decline Low Revenue Generation and Cost reduction strategies (1 of 2) • Revenue-generating strategies depend on marketing life-cycle stages and customer value effect – For viable revenue enhancement, customers must be willing to pay a premium for any improvement in product performance • Cost reduction strategies – Actions taken in early stages of the production life-cycle can lower costs for later production and consumption stages © 2019to Cengage. All rights reserved. Introduction Cost management Revenue Generation and Cost reduction strategies (2 of 2) – Careful product design and process design can help reduce: Manufacturing costs Logistical support costs Post-purchase costs – Activity-based costing information is critical for life-cycle cost reduction decisions Produces information about activities and cost drivers Encourages good life-cycle planning © 2019to Cengage. All rights reserved. Introduction Cost management Target Costing • Useful tool for establishing cost reduction goals during the design stage – Target cost: Difference between the sales price needed to capture a predetermined market share and the desired per-unit profit – Requires close interaction between the firm and its suppliers • Cost reduction methods – Reverse engineering – Value analysis – Process improvement © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.10 - Target-Costing Model © 2019 Cengage. All rights reserved. JUST-IN-TIME (JIT) MANUFACTURING (1 of 2) • • • • Demand-pull system Objective is to eliminate waste by producing a product only when it is needed Assumes that all costs other than direct materials are driven by time and space drivers Improves quality, increases productivity, reduces lead times, inventories, and setup times, and lowers manufacturing costs © 2019to Cengage. All rights reserved. Introduction Cost management JUST-IN-TIME (JIT) MANUFACTURING (2 of 2) • JIT manufacturers emphasize long-term contracts – Help reduce the uncertainty in demand for the supplier and establishes the mutual confidence and trust – Reduce the number of orders placed Helps drive down ordering and receiving costs – Reduce the cost of parts and materials – Ensure reasonably stable demand for a supplier’s products © 2019to Cengage. All rights reserved. Introduction Cost management JIT Purchasing • • Requires suppliers to deliver parts and materials just in time to be used in production Utilizes supplier linkages by: – Negotiating long-term contracts with a few suppliers located close to the production facility – Establishing more extensive supplier involvement • Vital considerations – Performance – Commitment © 2019to Cengage. All rights reserved. Introduction Cost management JIT - Plant Layout • Follows a pattern of manufacturing cells – Manufacturing cells: Contain machines that are grouped in families, usually in a semi-circle – Each cell is viewed as a mini-factory • Executional cost driver for a JIT setting is cell structure – Cell structure increases the ability of an organization to execute successfully and affects structural activity – Labor is multiskilled and not specialized © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.11 - Plant Layout Pattern: Traditional versus JIT © 2019 Cengage. All rights reserved. JIT - Grouping of Employees and Employee Empowerment • Each cell requires easy and quick access to support services – Centralized service departments are scaled down, and employees are reassigned to work directly with manufacturing cells • Employee empowerment increases productivity and overall cost efficiency – Fewer managers are required when workers assume greater responsibilities, and the organizational structure becomes flatter © 2019to Cengage. All rights reserved. Introduction Cost management JIT - Total Quality Control • JIT cannot be implemented without a commitment to total quality control (TQC) – Acceptable quality level (AQL): Approach to managing quality that is diametrically opposed to the traditional doctrine Permits or allows defects to occur provided they do not exceed a predetermined level © 2019to Cengage. All rights reserved. Introduction Cost management Exhibit 11.12 - Comparison of JIT Approaches with Traditional Manufacturing and Purchasing JIT Traditional 1. Pull-through system 1. Push-through system 2. Insignificant inventories 2. Significant inventories 3. Small supplier base 3. Large supplier base 4. Long-term supplier contracts 4. Short-term supplier contracts 5. Cellular structure 5. Departmental structure 6. Multiskilled labor 6. Specialized labor 7. Decentralized services 7. Centralized services 8. High employee involvement 8. Low employee involvement 9. Facilitating management style 9. Supervisory management style 10. Total quality control 10. Acceptable quality level 11. Buyers’ market 11. Sellers’ market 12. Value-chain focus 12. Value-added focus © 2019 Cengage. All rights reserved. Exhibit 11.13 - Product Cost Assignment: Traditional versus JIT Manufacturing Manufacturing Cost Traditional Environment JIT Environment Direct labor Direct tracing Direct tracing Direct materials Direct tracing Direct tracing Materials handling Direct tracing Direct tracing Repairs and maintenance Direct tracing Direct tracing Energy Direct tracing Direct tracing Operating supplies Direct tracing Direct tracing Supervision (department) Allocation Direct tracing Insurance and taxes Allocation Allocation Plant depreciation Allocation Allocation Equipment depreciation Direct tracing Direct tracing Custodial services Allocation Direct tracing Cafeteria services Direct tracing Direct tracing © 2019 Cengage. All rights reserved. Effect of JIT on Product Costing • JIT manufacturing converts many common costs to directly attributable costs – Increase in directly attributable costs increases the accuracy of product costing • All batch-level activities are converted into unit-level activities © 2019to Cengage. All rights reserved. Introduction Cost management JIT's Effect on Job-Order and ProcessCosting Systems • In implementing JIT in a job-order setting, the firm should first separate its repetitive business from its unique orders – Costs are accumulated at the cellular level • Process costing is simplified – Need to compute equivalent units vanishes – Calculating product costs involves collecting costs for a cell for a period of time and dividing the costs by the units produced for that period © 2019to Cengage. All rights reserved. Introduction Cost management Backflush Costing • • Uses trigger points to determine when manufacturing costs are assigned to key inventory and temporary accounts Varying the number and location of trigger points creates different types of backflush costing – Trigger points - Events that prompt the accounting recognition of certain manufacturing costs © 2019to Cengage. All rights reserved. Introduction Cost management Backflush Costing - Variations of trigger points • • • • Purchase of raw materials and the completion of goods Purchase of raw materials and the sale of goods Completion of goods Sale of goods © 2019to Cengage. All rights reserved. Introduction Cost management