makiontto2005-Induction motor model for the analysis of capacitive and induced shaft voltages

advertisement

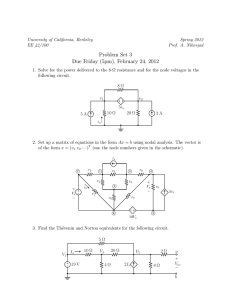

Induction Motor Model for the Analysis of Capacitive and Induced Shaft Voltages Petri Mäki-Ontto and Jorma Luomi Power Electronics Laboratory, Helsinki University of Technology P.O. Box 3000, FI-02015 TKK, Finland Abstract — The paper proposes a three-phase motor model that is suitable for the analysis of bearing voltages and currents in converter-fed ac motors. Both capacitive and induced shaft voltages are taken into account. The induced shaft voltage, being the reason for high-frequency circulating bearing currents, is important in larger machines. For modeling the induced shaft voltage with a sufficient accuracy, different stator core models are compared. The motor model can be connected to threephase circuit simulation models of frequency converters and cables. Simulation results are validated with experimental results obtained using a 1.4-MW induction motor fed by a frequency converter. Circumferential flux Common-mode current Circulating bearing current Fig. 1. Paths of common-mode current and circulating bearing current in the motor. The axial distribution of the circumferential flux is illustrated with the sizes of the circles. I. INTRODUCTION Modern frequency converters have introduced new requirements for the modeling of induction motors since there is a need to investigate high-frequency phenomena in these motors and whole drive systems. Increased switching frequencies and short rise times of the PWM voltage pulses require a high bandwidth of the simulation model. A frequency converter also produces a common-mode voltage, and parasitic capacitances in the motor provide low-impedance paths for high-frequency common-mode currents. In addition, the frequency dependence of the resistances and inductances has an influence on these phenomena. Common-mode voltages and common-mode currents can cause destructive currents in motor bearings. On the one hand, the distribution of the common-mode voltage between parasitic capacitances in the motor will cause a capacitive shaft voltage [1]. On the other hand, the high-frequency common-mode current will generate a circumferential magnetic flux in the stator core, which causes an induced shaft voltage [2]. These two types of shaft voltages are the reasons for discharge bearing currents and high-frequency circulating bearing currents, respectively. The common-mode impedance of an electric drive depends on various components included in the system: power grid; frequency converter; filters; power cables; motor; and groundings. Therefore, the motor model should be compatible with the models of the other parts of the system. Several models have been presented for the calculation of the capacitive shaft voltage [3], [4]. For the determination of the model parameters, impedance measurements in a wide frequency band may be required, as in [4]. Expressions have also been derived for the circumferential flux and induced shaft voltage caused by a harmonic component of the common-mode current [5]. However, a complete model for the evaluation of 0-7803-8987-5/05/$20.00 ©2005 IEEE. both capacitive and induced shaft voltages has not yet been presented. Such a model would be very useful in the analysis of bearing currents and, for example, in designing an output filter for a frequency converter and motor combination. This paper presents an induction motor model suitable for the analysis of bearing currents in both frequency domain and time domain. Both the capacitive shaft voltage and the induced shaft voltage are taken into account. The motor model can be included in a three-phase circuit simulation model of the whole electric drive. II. MODELING OF INDUCED SHAFT VOLTAGE Steep edges of the PWM voltage pulses generate a highfrequency common-mode current through the capacitance of the stator winding insulation. As illustrated in Fig. 1, this current flows through the stator core and causes a circumferential magnetic flux in the stator yoke [2], [5], [6]. The flux generates the induced shaft voltage in a loop formed by the stator, the rotor, and the bearings. The induced shaft voltage, being the reason for high-frequency circulating bearing currents, is especially important in larger machines. In the laminated stator core, the high-frequency commonmode current and the magnetic flux flow along the iron sheet surfaces in a thin layer, corresponding to the skin depth δ= 2 ωµσ (1) where ω is the angular frequency of the harmonic component in question, and σ and µ are the conductivity and the incremental permeability of the core material, respectively. The incremental permeability has its maximum value in the case of zero biasing flux density, and it approaches µ0 1653 Stator frame N sheets u sh1 N+2 Zb Zb u cm Stator winding Z Fig. 2. Contour plot of magnetic field strength (corresponding to equal currents between curves) in winding insulation and five iron laminations. 2 with magnetic saturation [7]. The circumferential highfrequency magnetic field in the stator yoke is biased by the periodic distribution of the rotating fundamental-frequency magnetic field. The incremental permeability thus varies along the circumference, and this permeability distribution rotates at the fundamental frequency. An average value of the incremental permeability can be used for the analysis of the circumferential magnetic flux. In the following, it is assumed that the flux is concentrated in the yoke and the problem is rotationally symmetric. The circumferential magnetic field was calculated numerically in [5]. In Fig. 2, the magnetic field and the commonmode current are illustrated in five 0.5 mm thick iron laminations. The other dimensions and the relatively low frequency of 30 kHz were selected for visual clarity in this example. The field lines would be nearly indistinguishable from the geometry lines at relevant frequencies (about 1 MHz) since the skin depth in the core material is of the order of 10 µm. i cm ⎛r ⎞ 1 ln ⎜ 2 ⎟ 2πσδ ⎝ r1 ⎠ 3 4 N+1 C 1 ib Fig. 3. Detailed common-mode circuit model. winding is equal to the common-mode voltage u cm (Node 1), and the common-mode current i cm is distributed to individual laminations through winding insulation capacitances. The capacitance between the stator winding and a single lamination of the stator core is C , and each of the N laminations is modeled by two impedances Z according to (2). The induced shaft voltage u sh1 is the potential of Node N + 2 in the circuit of Fig. 3. The circulating bearing current is denoted by i b . The bearing circuit is modeled by a series connection of two bearing impedances Z b (which also include the impedances of the end shields and the rotor). For analysis, the circuit model of Fig. 3 can be formulated in terms of the ( N + 2 ) × ( N + 2 ) admittance matrix A. Detailed Common-Mode Circuit Model Since the current and the corresponding magnetic flux flow at the surfaces of the laminations, each lamination surface can be modeled by an impedance of a layer whose thickness equals the skin depth, i.e. by the impedance Z = (1 + j) Z (2) where r1 and r2 are the inner and outer radii of the stator yoke, respectively. A detailed model of the common-mode circuit is depicted in Fig. 3. The winding resistances and inductances are not yet taken into account, and the capacitive shaft voltage is also omitted. The terminals of the winding and the grounding are at the leftmost end of the core in all examples given in this paper. It is assumed that the electric potential of the stator 1654 " − jω C − jω C − jω C 0 ⎤ ⎡ jω NC − jωC ⎢ ⎥ 3 1 ⎢ − jω C " + jω C − 0 0 0 ⎥ ⎢ ⎥ 2Z 2Z ⎢ ⎥ 1 1 ⎢ − jω C − 1 # 0 0 ⎥ + jω C − ⎢ ⎥ Z 2Z 2Z ⎢ ⎥ 1 ⎢ − jω C ⎥ % % − 0 0 0 ⎥ 2Z Y=⎢ ⎢ ⎥ 1 1 ⎢ ⎥ C 0 j 0 # # % + − ω ⎢ ⎥ Z 2Z ⎢ ⎥ ⎢ 1 3 1 ⎥ 0 0 − + jω C − " ⎢ − jω C ⎥ Z ⎥ 2Z 2Z ⎢ ⎢ 1 1 1 ⎥ 0 0 0 0 − + ⎢ 0 ⎥ 2 Z Z Z b⎦ ⎥ ⎣⎢ m sections B. Reduced Common-Mode Circuit Model The distribution of the common-mode current i cm between individual laminations depends on the impedances in the circuit. At lower frequencies, the voltage drop over the capacitances is dominating, and the current i cm / N enters each lamination through the capacitance C . The total current distribution is linear within the iron core: the current in the rightmost sheet is i cm / N , and the current in the leftmost sheet is i cm as can be seen in Fig. 2. At lower frequencies, it is possible to use the commonmode core impedance [5] ⎛r ⎞ N ln ⎜ 2 ⎟ Z c = (1 + j) 3πσδ ⎝ r1 ⎠ i cm Cws m Zd Zd Zd Zd m m m ib m m 1 N µδ ⎛ r2 ⎞ ln ⎜ ⎟ 1 + j 2π ⎝ r1 ⎠ and the corresponding induced shaft voltage is Zc m u sh1 Fig 4. Reduced common-mode circuit model. i cm ib Cws (4) (5) − Zb (3) C. Simple Common-Mode Circuit Model If equal current is assumed to enter each lamination in the whole core, the common-mode impedance of the core is given by (3), and the bearing circuit impedance is given by (4). The common-mode circuit and the bearing circuit can be modeled by the simple circuit model shown in Fig. 5. The common-mode circuit is a series connection of the capacitance Cws and the core impedance Z c if the circulating bearing current i b = 0 . The circumferential flux in the stator core is [5] Cws m Zc Zb where (2) and (3) have been used. The number of laminations varies from hundreds in small motors to thousands in large motors, and the modeling of individual sheets would lead to very large circuit models. To reduce the model size, the circuit shown in Fig. 4 is proposed. In this reduced model, the core is divided into m sections, and equal current is assumed to enter each lamination within each section. The circuit consists of the contributions of the winding-to-core capacitance Cws and the impedances Z c and Z d . The number of nodes can be much lower than that in the detailed model of Fig. 3. A large m increases the accuracy and makes it possible to model the axial distribution of the current and flux at high frequencies. On the other hand, the implementation of the circuit model is easier if m is selected as small as possible. However, a small value of m causes a discretization error in the induced shaft voltage even at low frequencies (about 6.5 % for m = 5 and 1 % for m = 35 ). φ = i cm Cws m u cm in series with the total stator-winding-to-core capacitance Cws = N C . In accordance to Fig. 3, the core impedance for the bearing circuit is the series connection of all 2 N impedances of the lamination surfaces, i.e. Z d = 2 N Z = 3Z c Cws m u cm + 3 u1 2 − − 1 u2 2 + u1 u2 Zc Common-mode circuit 2Z b u sh1 Zd Bearing circuit Fig 5. Simple common-mode circuit model. u sh1 = jω φ . (6) The relation between the common-mode current and induced shaft voltage is obtained by combining (3), (5), and (6): u sh1 = 3 Z i . 2 c cm (7) In Fig. 5, this relation is modeled by the voltage-controlled voltage source 3 u1 / 2 in a separate bearing circuit, which is also valid when i b ≠ 0 . The effect of the circulating bearing current on the common-mode circuit is modeled by the controlled voltage source u 2 / 2 in the common-mode circuit. The presented core models are valid only for frequencydomain analysis. A core model suitable for time-domain simulations is obtained by modeling the frequency-dependence of core impedances Z c and Z d (or the impedance Z ) by means of a ladder circuit [8]. A four-step ladder circuit is shown in Fig. 6. A method based on [9] can be applied for determining suitable resistance and inductance values. The parameters needed are the low-frequency values of the resistance and inductance, and the maximum frequency. The ratio between the resistances of subsequent ladder steps is constant, and so is the ratio between the inductances. The model 1655 Lc2 Rc1 Lc3 Rc2 Rc3 Current (mA) Lc1 Rc4 3 D 2 C 1 A B 0 Fig. 6. Ladder circuit approximation for core impedance Z c suitable for both frequency-domain and time-domain modeling. 200 Phase (°) parameters are optimized by a least-squares fit of the ladder circuit impedance to the impedance Z c given by (3) in the frequency band considered. D 0 A B -100 III. COMPARISON OF COMMON-MODE CIRCUIT MODELS C -200 0 500 1000 1500 Sheet number 2000 Impedance (Ω) Fig. 7. Amplitude and phase of currents in the capacitances of the detailed model for different frequencies: 100 kHz (A); 700 kHz (B); 1.5 MHz (C); 5 MHz (D). 10 1 C 10 0 A B 10 4 10 5 Frequency (Hz) 10 6 10 7 Fig. 8. Common-mode impedance of winding insulation and core, obtained using different core models: detailed model (A); reduced model (B); simple model (C). C Voltage (V) The detailed model can be used for studying the commonmode current distribution in the stator winding insulation. The parameters given in Table I were used for the following examples. The distribution of the common-mode current ( i cm = 1 + j0 A ) in the winding insulation is shown in Fig. 7 for four frequencies. At 100 kHz, the amplitude and phase of the current are equal in each capacitance C of the model. At 700 kHz, there is some variation in the amplitude and phase curves. At 1.5 MHz, the amplitude of the current is clearly larger at the terminal end, and the phase of the current changes from a positive value at the terminal end to a negative value at the other end of the core. At 5 MHz, this effect is even more pronounced, and most of the current flows through the capacitances near the terminal end of the core. The detailed model, the reduced model with m = 10 , and the simple model were compared by calculating the commonmode impedance and the induced shaft voltage as a function of the frequency. The common-mode impedance of the insulation and core is shown in Fig. 8. At frequencies below 400 kHz, all three models predict equal common-mode impedances. The simple model has one distinct critical frequency, after which the impedance increases, whereas the impedances of the other models decrease again after 1.7 MHz. The reduced model gives good results up to frequencies of a few megahertz. The induced shaft voltage is shown in Fig. 9. The reduced model gives again good results up to a few megahertz, but the accuracy of the simple model decreases rapidly above 1 MHz. A constant discretization error of about 3 % can be seen in the results obtained by using the reduced model. A larger value of m = 100 in the reduced model provides results that are identical to the results of the detailed model in the whole frequency band considered. 100 10 0 A B TABLE I CORE DATA Conductivity of core material Insulation capacitance Incremental permeability Lamination thickness Number of laminations Inner radius of the yoke Outer radius of the yoke σ Cws µ N r1 r2 10 ⋅106 (Ωm) −1 370 nF 700µ0 0.5 mm 2200 362 mm 430 mm 10 -1 10 4 10 5 Frequency (Hz) 10 6 10 7 Fig. 9. Induced shaft voltage obtained using different core models: detailed model (A); reduced model (B); simple model (C). 1656 Lσ s1 i cm Cws 6 Cwr u cm Ls Rs Cwr 6 Cwr 6 Cws 6 Ms Cws Csr Zb Zb u sh2 Fig. 10. Capacitive shaft voltage model. i cm Cws u cm − 1 u2 2 + u1 Z c − 1 u 2 2+ Cwr Zb 3 + u 4 1 − Csr u2 1 Z 2 d Zb u1 Z c 3 − u 4 1 + Zb 3 + u 4 1 − Csr u2 Zb 3 − u 4 1+ 1 1 Z Z 2 d 2 d Stator core, rotor, and bearings 1 Z 2 d Fig. 12. Three-phase motor model including the combined shaft voltage model. Stator core, rotor, and bearings and the core impedance Z d are split in two parts in the bearing circuit. It should be noted that the capacitive shaft voltage can also be added to the reduced model presented in Fig. 4. Fig. 11. Combined shaft voltage model including both capacitive and induced shaft voltages. IV. MOTOR MODEL A. Combined Shaft Voltage Model The capacitive shaft voltage is caused by capacitive couplings between the stator winding, the rotor core, and the stator core [1], [3]. It can be modeled by the equivalent circuit shown in Fig. 10. The circuit consists of the statorwinding-to-core capacitance Cws , the stator-winding-to-rotor capacitance Cwr , the stator-core-to-rotor capacitance Csr , and the bearing impedances Z b . The capacitive shaft voltage is denoted by u sh2 . The capacitances can be calculated from the dimensions of the motor. A combined model including both the induced and capacitive shaft voltage models is shown in Fig. 11. The simple common-mode circuit model presented in Fig. 5 is augmented with the capacitive shaft voltage model presented in Fig. 10. The polarity of the capacitive voltage is the same in both bearings, whereas the induced shaft voltage causes contributions that have opposite polarities at the opposite ends of the machine. Therefore, the controlled voltage source 3 u1 / 2 B. Three-Phase Model and Parameter Evaluation In Fig. 12, the combined shaft voltage model is included in a three-phase motor model. The model of stator winding consists of resistances Rs , self-inductances Ls , and mutual inductances M s . Ls includes most of the leakage inductance. In practice, it was found that a small part Lσ s1 of the leakage inductance should be placed in series with each winding phase model. In the investigated drive, Lσ s1 was 1.5 % of the total leakage inductance. The capacitances Cws and Cwr are divided into contributions of the individual phases (corresponding to π-equivalent circuits for each phase). The model in Fig. 12 corresponds to the no-load operation of the motor. In addition, the model could be augmented with a d-q model of the rotor winding and the equation of motion in a fashion described in [10]. In practical time-domain simulations, however, the required minimum time step is very small due to the rapid voltage changes of the PWM inverter, and the long time constants associated with the rotor winding and mechanics would lead to very long computation times. Therefore, the model in Fig. 12 is used for the simulations described in this paper. 1657 V. RESULTS 1658 Drive end Insulations Non-drive end Fig. 13. Experimental setup. The motor is equipped with insulations and copper brushes with adjustable connections. TABLE II PARAMETER VALUES USED IN SIMULATIONS Winding Parameters Ls 1707 µH * Ms –833 µH Lσ s1 0.6 µH * Rs 1.5 Ω * Cws 370 nF Csr 3.70 nF Cwr 0.228 nF Core Model Parameters Rc1 8.68 Ω Rc2 1.86 Ω Rc3 0.40 Ω Rc4 0.086 Ω Lc1 24.5 nH Lc2 186 nH Lc3 1415 nH * high-frequency values 3 Magnitude (Ω) A. Measurement of Capacitive Shaft Voltage In the capacitive shaft voltage measurement, a voltage probe was connected between the shaft and the end shield at the drive end of the motor. The measured common-mode current is shown in Fig. 15. The waveform is a typical example of an LC circuit response to steep voltage pulses. A high-frequency oscillation occurs in the current at the beginning of the voltage pulse, and the amplitude and length of the lowerfrequency pulses are determined by the slope and rise time of the voltage pulses ( i = Cws ducm dt ). The simultaneously measured common-mode voltage shown in Fig. 16 is in agreement with this reasoning. The current in Fig. 15 was used as the input for the simulation. The simulation result is shown in Fig. 17. A good correlation is found between the simulated and measured common-mode voltages. V 2 1 0 3 10 10 4 10 Frequency (Hz) 10 4 10 Frequency (Hz) 90 Phase (°) A six-pole 1.4-MW induction motor (690 V, 1500 rpm) fed by 1160-kVA frequency converter was used for laboratory experiments. The common-mode voltage at the motor terminals was calculated from the phase voltages measured using three voltage probes, and a Rogowski coil was used for measuring the common-mode current. The motor was prepared for measuring the capacitive and induced shaft voltages. Thick insulating rings and the connections depicted in Fig. 13 were placed in both end shields. Both shaft ends were equipped with slip rings and copper brushes. The capacitive shaft voltage was measured between the shaft and the end shield when both short-circuit connections were open (as in Fig. 13). The induced shaft voltage was distinguished from the capacitive voltage by closing one of the short circuits and measuring the shaft voltage at the opposite end. The parameter values used in the simulations are given in Table II. In high-bandwidth simulations, the frequency-dependence of the stator resistance and leakage inductance should be modeled. In the simulations presented in this paper, constant high-frequency values were used for these parameters. The oscillation frequency of the measured highfrequency component of the common-mode current was 700 kHz. The reduction in the slot leakage inductance and the increase in the winding resistance at this frequency were calculated using the finite element method. The resistance was increased by a factor of 1500, and the slot leakage inductance was reduced by 40 % as compared with the values at the nominal frequency. The value of the incremental permeability was determined from the measurements of the common-mode current and the induced shaft voltage. For the motor studied, µ = 700 µ0 was selected and the ladder circuit parameters were determined accordingly. The magnitude and the phase of the ladder circuit impedance and the impedance Z c given by (3) are shown in Fig. 14. The ladder circuit parameters were fitted in the frequency band of 10 kHz – 10 MHz. 5 10 6 10 7 5 10 6 10 7 45 0 3 10 Fig. 14. Stator core common-mode impedance Z c , given by (3) (solid) and by ladder circuit approximation (dashed). 50 30 25 Voltage (V) Current (A) 15 0 -15 0 -25 -30 0 0.1 0.2 0.3 Time (ms) 0.4 -50 0 0.5 800 60 400 30 0 -400 -800 0 0.1 0.2 0.3 Time (ms) 0.4 0.5 0 -60 0 0.5 0.1 0.2 0.3 Time (ms) 0.4 0.5 Fig. 19. Simulated capacitive shaft voltage. pacitive shaft voltages at the drive and non-drive ends were identical, whereas the polarity of the induced shaft voltage component at one end of the machine was opposite to the corresponding component at the other end. The simulation result is shown in Fig. 19. The waveform is similar to the measured result in Fig. 18, and the maximum and minimum high-frequency spikes are approximately equal. 1000 500 Voltage (V) 0.4 -30 Fig. 16. Measured common-mode voltage. 0 -500 -1000 0 0.2 0.3 Time (ms) Fig. 18. Measured capacitive shaft voltage. Voltage (V) Voltage (V) Fig. 15. Measured common-mode current. 0.1 0.1 0.2 0.3 Time (ms) 0.4 0.5 Fig. 17. Simulated common-mode voltage. Fig. 18 shows the measured shaft voltage. In addition to the capacitive shaft voltage, contributions of the induced shaft voltage can be seen as high-frequency spikes. The ca- B. Measurement of Induced Shaft Voltage The induced shaft voltage was measured at the drive end when the short-circuit connection at the non-drive end was closed. The common-mode current was re-measured in order to get a source current for the simulation. The measured common-mode current and induced shaft voltage are shown in Figs. 20 and 21, respectively. It can be seen that the highfrequency spikes in the induced shaft voltage correspond to those in the common-mode current, but the lower-frequency pulses induce a shaft voltage that is less pronounced. The simulated induced shaft voltage is shown in Fig. 22. A good correlation is found between the simulation and measurement results. 1659 VI. CONCLUSION 30 Current (A) 15 0 -15 -30 0 0.1 0.2 0.3 Time (ms) 0.4 0.5 Fig. 20. Measured common-mode current. The induced shaft voltage can be modeled with a special common-mode circuit model, which represents the stator core laminations and the winding insulation. In the investigated drive, the complexity of this model can be further decreased, and a simple model is obtained without compromising the accuracy of the simulation results. Augmenting this model with a conventional capacitive shaft voltage model results in a combined model, which makes it possible to simulate both types of shaft voltages and the corresponding bearing currents simultaneously. The combined shaft voltage model can be added to a threephase model of an induction motor, which can be included in a three-phase circuit simulation model of the whole electric drive [11]. The comparison of measured and simulated shaft voltages shows that the model is able to predict both capacitive and induced shaft voltage phenomena with a good accuracy. 40 REFERENCES [1] Voltage (V) 20 0 -20 -40 0 0.1 0.2 0.3 Time (ms) 0.4 0.5 Fig. 21. Measured induced shaft voltage. 40 Voltage (V) 20 0 -20 -40 0 0.1 0.2 0.3 Time (ms) 0.4 0.5 S. Chen, T. A. Lipo, and D. Fitzgerald, “Source of induction motor bearing currents caused by PWM inverters,” IEEE Transactions on Energy Conversion, vol. 11, no. 1, pp. 25-32, March 1996. [2] S. Chen and T. A. Lipo, “Circulating type motor bearing current in inverter drives,” IEEE Industry Applications Magazine, vol. 4, no. 1, pp. 32-38, Jan./Feb. 1998. [3] D. Busse, J. M. Erdman, R. J. Kerkman, D. W. Schlegel, and G. L. Skibinski, “System electrical parameters and their effects on bearing currents,” IEEE Transactions on Industry Applications, vol. 33, no. 2, pp. 577-584, March/April 1997. [4] R. Naik, T. Nondahl, M. Melfi, R. Schiferl, and J. Wang, "Circuit model for shaft voltage prediction in induction motors fed by PWMbased AC drives," IEEE Transactions on Industry Applications, vol. 39, no. 5, pp. 1294-1299, Sept./Oct. 2003. [5] P. Mäki-Ontto and J. Luomi, “Common-Mode Flux Calculation of AC Machines,” in Proceedings of International Conference on Electrical Machines, ICEM'02, Bruges, Belgium, 2002. [6] P. Mäki-Ontto and J. Luomi, “Circumferential flux as a source of bearing current of converter-fed AC machines,” in Proceedings of 2002 Nordic Workshop on Power and Industrial Electronics, NORPIE/2002, Stockholm, Sweden, 2002. [7] R. M. Bozorth, Ferromagnetism. IEEE Press, New York, USA, 1993. [8] C. S. Yen, Z. Fazarinc, and R. L. Wheeler, "Time-domain skin-effect model for transient analysis of lossy transmission lines," Proceedings of the IEEE, vol. 70, no. 7, pp. 750-757, July 1982. [9] S. Kim and D. P. Neikirk, "Compact equivalent circuit model for the skin effect," IEEE-MMT-S International Microwave Symposium, San Francisco, CA, 1996, vol. 3, pp. 1815-1818. [10] P. Pillay and V. Levin, “Mathematical Models for Induction Machines,” in Conference Record of the 30th IEEE-IAS Annual Meeting, IAS’95, Orlando, FL, 1995, vol. 1, pp. 606-616. [11] P. Mäki-Ontto, J. Luomi, and H. Kinnunen, “Three-phase model for the circuit simulation of common-mode phenomena and shaft voltages in AC motor drive systems,” in IEEE International Electric Machines and Drives Conference, IEMDC’05, San Antonio, TX, 2005 Fig. 22. Simulated induced shaft voltage. 1660