Lec1 Introduction Process Control

advertisement

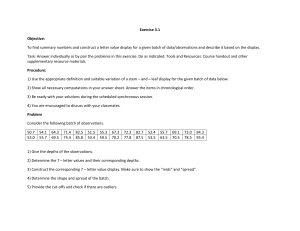

Week-1 Lecture-1 Introduction to Process Control…!!! By Dr. Fiaz Ahmad, B.Sc, M.Sc Electrical Engineering, PhD Mechatronics Engineering [Specialization: Power System monitoring and Control] 1 Introduction Manufacturing converts with the raw materials into marketable products Industry is primarily responsible for this function Depending on the product being manufactured, a number of unique processes are generally grouped into systems. Industrial Systems respond to ◦ Temperature ◦ Pressure ◦ Flow ◦ Level 2 Introduction Manual control operations With technological advancement, techniques were developed for automated manufacturing operations that control a system with very little human intervention The computer now serves as a tool to assist in this operation For large manufacturing facility computers are tied together in a large network. These networks are used to schedule and oversee ◦ Material ordering and routing ◦ Parts production ◦ Assembly ◦ Quality evaluation ◦ Testing and ◦ Shipment The entire operation depends on the control of manufacturing processes. Technically trained personnel must be aware of these operations. 3 THE SYSTEMS CONCEPT During control field infancy, industrial process systems were limited to a number of simple motor control applications and the devices were ◦ Magnetic contactors, electrical switch gears, gaseous tubes, rheostats, and potentiometers generally Developments in solid-state electronics and microcomponent design have brought important technological changes to the field. ◦ Microprocessors, programmable controllers, artificial intelligence, and electronic devices A person working with this type of equipment must have an understanding of the complete system to be able to locate faulty components when a malfunction occurs. 4 THE SYSTEMS CONCEPT The word system is defined as “an organization of parts that are connected together to form a functioning machine or operational procedure.” In this respect, there is a wide variety of different systems used in industry ◦ ◦ ◦ ◦ Electrical power system Hydraulic and pneumatic Temperature systems Industrial processes are also controlled by pressure, flow rate, fluid level,, and transmission systems 5 THE SYSTEMS CONCEPT Each industrial system has a number of characteristics that distinguish it from other systems. However, there is a common set of elements found in each system like the terms energy source, transmission path, control, load, and indicator. 6 Industrial Batch Process 7 Dual Compressor CNG System 8 Bottle Line Simulator 9 Nuclear Reactor 10 IAC-12-C3.4.3 11 12 Desired value Controller Final Control Measuring Element Element Process inputs outputs 13 Industrial control Classification Motion & Process Control Motion Control ◦ Automatic control system that controls the physical position or motion of an object. E.g., Industrial robotic arm that performs welding operations and assembly procedures Three common characteristics of motion control systems (servos, or servomechanisms) 1. Control type 1. 2. the position, speed or acceleration of a mechanical object 2. Controlling parameters measurement 3. Response time i.e., fraction of second Examples are CNC machines, printing presses, office copiers, packaging equipments and electronic pick & place machines 14 Industrial control Classification Process Control ◦ One or more process variables are regulated during the manufacturing of a product. ◦ These variables may include temperature, pressure, flow rate, liquid & solid level, pH, or humidity ◦ This regulated process must compensate for any external disturbances that changes the variable ◦ Response time is typically slow, varies from few seconds to several minutes. 15 Process Control: Categories Batch or Sequential Process The process in which ingredients are sequentially prepared, mixed, reacted, cooked, heated, or cooled, finished, and packed—all in accordance with a time-sequenced schedule worked out by a process engineer. Continuous Process In a continuous process, one or more operations are being performed as the product is being passed through a process. Raw materials are continuously entering and leaving each process step. Examples are paper, plastics, rubber, chemicals, hydrocarbons, pharmaceuticals, food, etc 16 References Industrial Process Control by Dale Patrick 17