General Specifications - Corle Building Systems

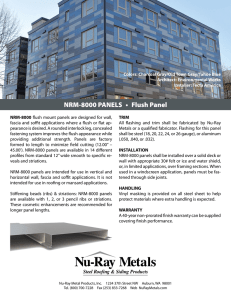

advertisement