Journal of Materials Chemistry

advertisement

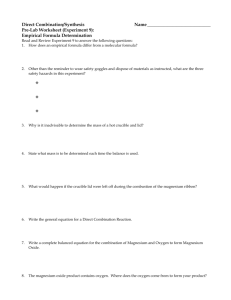

1 5 Journal of Materials Chemistry PAPER b807920j 1 5 1 10 Synthesis and characterisation of magnesium substituted calcium phosphate bioceramic nanoparticles made via continuous hydrothermal flow synthesis 10 2 Aqif Anwar Chaudhry, Josie Goodall, Martin Vickers, Jeremy Karl Cockcroft, Ihtesham Rehman, Jonathan Knowles and Jawwad Arshad Darr* 15 15 20 20 25 25 30 30 35 35 40 40 45 45 50 50 55 55 ART B807920J_GRABS PAPER 1 5 1 www.rsc.org/materials | Journal of Materials Chemistry Synthesis and characterisation of magnesium substituted calcium phosphate bioceramic nanoparticles made via continuous hydrothermal flow synthesis† 1 5 Aqif Anwar Chaudhry,abc Josie Goodall,a Martin Vickers,a Jeremy Karl Cockcroft,a Ihtesham Rehman,b Jonathan Knowlesd and Jawwad Arshad Darr*a 10 15 20 25 Received 9th May 2008, Accepted 24th September 2008 First published as an Advance Article on the web ????? DOI: 10.1039/b807920j 10 Continuous hydrothermal flow synthesis (CHFS) technology has been used as an efficient and direct route to produce a range of largely crystalline magnesium substituted calcium phosphate bioceramics. Initially, magnesium substituted hydroxyapatite, Mg-HA, according to the formula [Ca10xMgx(PO4)6(OH)2] was prepared in the CHFS system for x ¼ 0.2 [where x:(10 x) is the Mg:Ca ratio used in the reagents]. Biphasic mixtures of Mg-HA and Mg-whitlockite were obtained corresponding to x values in the range x ¼ 0.4–1.6. The direct synthesis of phase pure crystalline Mgwhitlockite [based on the formula (Ca3yMgy(HPO4)z(PO4)22z/3] was also achieved using the CHFS system for the range y ¼ 0.7–1.6 (this corresponds to the range x ¼ 1.6–5.3). With increasing substitution of magnesium for calcium, the material became ever more amorphous and the BET surface area generally increased. All the as-precipitated powders (without any additional heat treatments) were analyzed using techniques including X-ray powder diffraction, Raman spectroscopy and Fourier transform infra-red spectroscopy. Transmission electron microscopy (TEM) images revealed that in the case of y ¼ 1.2, the Mg-whitlockite material was comprised of ca. 28 nm sized spheres. The use of the CHFS system in this context facilitated rapid production of combinations of particle properties (crystallinity, size, shape) that were hitherto unobtainable in a single step process. 1. Introduction 40 45 Synthetic hydroxyapatite, HA, [Ca10(PO4)6(OH)2], is a bioceramic that is chemically similar to the mineral component of hard tissues (biological apatite) and resorbs slowly. HA is widely used in hard tissue augmentation and replacement.1 In contrast, beta-tricalcium phosphate, b-TCP, [Ca3(PO4)2], another bioceramic, is resorbable in vivo.2,3 Consequently, the use of biphasic HA and b-TCP mixtures for bone grafts can facilitate rapid bone formation around the implant site compared to HA alone.4,5 It has been reported previously that when biphasic calcium phosphate (BCP) ceramic (55% HA, 45% b-TCP) was implanted in femoral cortical bones of dogs, new bone formed more quickly for BCP compared to HA alone.6,7 Ionic substitutions are often introduced into synthetic bioceramics in order to more closely match the chemical compositions found in biological apatites. Indeed, biological apatites differ from synthetic HA in that the former also contain 50 a 55 20 25 30 30 35 15 Clean Materials Technology Group, Department of Chemistry, University College London, Christopher Ingold Laboratories, 20 Gordon Street, London WC1H 0AJ, UK. E-mail: j.a.darr@ucl.ac.uk b Department of Materials and IRC in Biomedical Materials, Queen Mary University of London, Mile End Rd, London E1 4NS, UK c IRC in Biomedical Materials, Comsats Institute of Information Technology, Lahore Campus, Defence Road, Lahore, Pakistan d Division of Biomaterials and Tissue Engineering, UCL Eastman Dental Institute, 256 Gray’s Inn Road, London WC1X 8LD, UK † Electronic supplementary information (ESI) available: Tables, XRD, DTA. See DOI: 10.1039/b807920j carbonate (CO32), magnesium (Mg2+), zinc (Zn2+), sodium (Na+), silicate (SiO44) and fluoride (F) ions, to name a few.8–11 These ions can play an important role in the biological behaviour of biological apatites.12 In Mg2+ containing biological apatites13 such as those found in pathological calcifications, human dental calculus or carious lesions, a magnesium stabilized b-TCP (Mg-bTCP) or magnesium whitlockite [Mg-whitlockite, Ca18Mg2H2(PO4)14] is often formed.14–16 Dentine, enamel and bone typically contain up to 1.1, 0.4 and 1.0 wt% Mg2+ ions, respectively.17,18 In calcified tissues, the Mg2+ ion content is higher at the beginning of the calcification process and decreases with greater calcification.13,18,19 Mg depletion in people results in decreased osteoblastic and osteoclastic activities and bone fragility.13,20 Indeed, there are studies showing that younger bone in mammals contains higher Mg levels than older bone.21 Mg2+ substitution for Ca2+ in HA reduces crystallinity, increases solubility, and lowers the temperature at which conversion of HA into b-TCP occurs.12,17,19,22,23 As the amount of substituted magnesium affects thermal phase stabilities, this has implications for sintering behaviour.3 For example, the b-TCP to a-TCP phase transformation normally occurs at ca. 1180 C. However Mg2+ substitution for Ca2+ can increase the transformation temperature to ca. 1500 C.3,24 This enables improved sintering of b-TCP at elevated temperatures without deleterious formation of a-TCP (the latter is a less bioactive polymorph). Magnesium substituted HA (Mg-HA) can be made via ambient temperature precipitation reactions from This journal is ª The Royal Society of Chemistry 2008 J. Mater. Chem., 2008, 18, 1–10 | 1 ART B807920J 35 40 45 50 55 1 5 10 15 20 25 30 35 40 45 50 solution2,4,12,25–27 or by solid-state reactions at elevated temperatures.5,20 Magnesium substitution levels of up to 1.6 wt% have been reported using such precipitation reactions.13 Surprisingly, as much as 28.4 wt% substitution of Mg2+ in HA has also been claimed in the literature using mechanochemical synthesis routes.28 However, an excess of Mg2+ can also be undesirable as it is known to reduce bioactivity in certain biomaterials.29 As well as Mg-HA, other phases such as Mg-whitlockite (or Mg-bTCP), can also be made from precipitation reactions at relatively low temperatures (range 37 to 95 C) and acidic or neutral pH.22,26,30 For example, Mg2+ ions can stabilise the formation of Ca2.7Mg0.3(PO4)2.H2O.31 BCP mixtures are of interest for use in repair of periodontal and bone defects,32,33 as bone graft substitutes in mastoid cavity obliteration34 and scoliosis surgery.35 Within these applications, the particle size, presence of substituting elements and the crystallinity strongly affect resorbability. Thus, the ability to prepare biphasic mixtures with controlled crystallinity, size and phase composition is of great interest. Crystalline whitlockite is usually made from a wet precipitated amorphous phase that may require a further heat treatment step.22,23,31 Similarly, there do not appear to be any reports of bTCP being precipitated directly from solution.36 Rather, it is routinely obtained via solid-state reactions or via thermal decomposition of calcium-deficient hydroxyapatite (CDHA) near or above 750 C.2,4,26,37 Interestingly, when carbonate and magnesium ions are simultaneously substituted into HA at a basic (rather than acidic or neutral) pH of ca. 9, the resulting apatite is much more thermally stable.12,18,24 To date, there have been no reports of direct and rapid syntheses of crystalline Mg-HA or Mg-whitlockite. The majority of the reported synthesis methods tend to be multistep, energy intensive or time consuming processes. In our previous report, the authors previously described a novel method for the instant synthesis of crystalline nano-sized HA using a continuous hydrothermal flow synthesis system (CHFS) which utilises a flow of superheated water to effectively nucleate and crystallise the HA in flow without the need for any further processing or ageing.38 This method can be compared to more conventional synthesis methods conducted at room temperature which require ageing steps and/or heat-treatment to obtain crystalline HA.39–42 CHFS methods have been used previously by the authurs and others for the synthesis of a range of nanoceramic oxides.38,43–51 In this work, a CHFS reactor was used as a direct and efficient method to controllably produce a range of magnesium substituted calcium phosphates and biphasic nano-bioceramic mixtures, with differing crystallinities. In particular, the first rapid and CHFS of crystalline Mg-HA and crystalline Mgwhitlockite, respectively, are reported. 2. Experimental 55 2.1. Materials and analytical equipment Diammonium hydrogen phosphate, [(NH4)2HPO4, 98.3%], calcium nitrate tetrahydrate [Ca(NO3)2$4H2O, 99%] and magnesium nitrate hexahydrate [Mg(NO3)2$6H2O, 97%] were supplied by Sigma-Aldrich Chemical Company (Dorset, U.K.) and used as obtained. Aqueous ammonia (ca. 16.9 mol L1) supplied by VWR International (UK) was used to adjust the solutions’ pH (sold as 30% w/w). 10 mega-ohms deionised water was used in all reactions. Samples were freeze-dried using a Virtis Advantage Freeze Dryer, Model 2.0 ES, supplied by BioPharma. A JEOL 2010 A TEM (200 kV accelerating voltage) was used for generating images of particles. Elemental analyses for the powders were performed using a calibrated energy dispersive spectrometer (EDS) attached to the TEM. A calibrated Oxford Instruments Inca 400 EDX detector connected to a scanning electron microscope (JEOL 5410 LZSEM) was also used to carry out the elemental analysis for all the samples. Averages of 10 area scans were used to calculate average elemental compositions. The SEM was operated at 25 kV and all samples were placed onto conductive carbon paper and then carbon coated. Image Tool UTHSCSA version 3.0 software was used for estimating particle size. For batch sample work, PXRD (powder X-ray diffraction) data were collected on a Siemens D5000 X-ray diffractometer using Cu-Ka radiation (l ¼ 1.5418 Å, i.e. 15.415 nm) over the 2q range 5–70 with a step size of 0.02 and a count time of 1 s. Samples were placed into a 2.5 cm wide, 2 mm well in a holder as flat pressed powders (no further sample preparation). For Rietveld refinement work, PXRD data were collected on a Stoe StadiP transmission-geometry diffractometer using Ge <111> monochromated Cu Ka1 radiation (l ¼ 1.54056 Å). Diffraction patterns were obtained from samples sealed in 0.3 mm diameter borosilicate glass capillaries and 1 5 10 15 20 25 30 Table 1 Sample identification, corresponding wt% (using EDS attached to a SEM) and x and y values according to the formulae used. The x values assume a formula of Ca10-xMgx(PO4)6(OH)2 as observed for samples 2–5 and the y values are based on the formula Ca3yMgy(HPO4)z(PO4)22z/3 as assigned for samples 6–11 (for selected samples where y is quoted, the equivalent value of x is also given in brackets for comparison). The sample labelled as CaP is HA reported from results published elsewhere.38 The sample labelled as MgP represents a powder made using magnesium nitrate and no calcium nitrate. Key: Mg-HA ¼ magnesium substituted hydroxyapatite, Mg-W ¼ Mgwhitlockite, BCP ¼ Mg-HA + Mg-W. 40 Magnesium (wt%) 1 2 3 4 5 6 7 8 9 10 11 12 Sample ID Added Measured x y XRDa CaP 0.5Mg-CaP 1Mg-CaP 1.5Mg-CaP 2Mg-CaP 4Mg-CaP 6Mg-CaP 8Mg-CaP 10Mg-CaP 12Mg-CaP 14Mg-CaP MgP 0 0.5 1 1.5 2 4 6 8 10 12 14 — 0 0.7 1.0 1.6 2.1 3.9 5.8 8.0 9.1 11.4 13.1 — — 0.2 0.4 0.6 0.8 1.6 (2.4) (3.1) (3.9) (4.6) (5.3) — — — — — — — 0.7 0.9 1.2 1.4 1.6 — HA Mg-HAb BCPbc BCPbc BCPbc BCPbc Mg-Wc Mg-Wc Mg-Wc Mg-Wcd Mg-Wcd Highly amorphous a Structural assignment based on PXRD data gave patterns that were a good match to the following: b ICDD pattern 09-0432c ICDD pattern 70-2064Hydroxyapatite-Ca10(PO4)6(OH)2; d whitlockite-Ca18Mg2H2(PO4)14; the PXRD data show very broad humps which give a good approximation to ICDD pattern 70-2064 whitlockite. This journal is ª The Royal Society of Chemistry 2008 2 | J. Mater. Chem., 2008, 18, 1–10 ART B807920J 35 45 50 55 1 5 10 15 20 25 30 measured with a linear position sensitive detector (nominal aperture 4.5 2q), which was scanned from 2 to 95 2q in steps of 0.1 2q with a count time of 30 s per step. Samples were prepared by gentle crushing of the powders with a mortar and pestle, filling the capillaries with powder by tapping to fill the tube and then sealing the ends under a flame. Each scan was repeated 8 times, compared and checked for consistency, and then they were added together to create a single summed data set with data binned in steps of 0.02 2q. The long scan times were necessary to provide data of suitable statistical quality for Rietveld refinement purposes. Four high-resolution data sets were collected from samples with differing percentages of added Mg during the synthesis stage, namely CaP,38 0.5MgCaP, 1.5Mg-CaP and 4Mg-CaP (CaP represents HA as reported elsewhere by us38 and the number before Mg-CaP is the nominal Mg wt% value expected to be substituted into HA (in place of calcium) on the basis of the reagent composition (see Table 1). The XRD data were analysed with the PROFIL Rietveld refinement suite52 using known single-crystal models for the structures of HA53 and whitlockite.54 A Nicolet Almega Dispersive Raman Spectrometer (785 nm laser) was used in the wavenumber range 1267–91 cm1 averaging 20 scans for 2 s each. Fourier-transform infrared (FTIR) spectra of the samples were collected using a Nicolet FTIR 800 spectrometer fitted with a photoacoustic sampler (MTech PAS Cell). Samples were presented as flat powders in the cell with no special sample preparation. Spectra were obtained in the range 4000– 400 cm1, at 8 cm1 resolution averaging 256 scans. BET surface area measurements (using N2 gas adsorption method) were performed on a Micromeritics Gemini analyser; powders were first degassed at 110 C for 3 h prior to analyses. 2.2. 35 40 45 50 55 Apparatus and syntheses All samples (as shown in Table 1) were made using a CHFS system (see Fig. 1), which consists of the following basic components. The system consists of three Gilson 305 HPLC pumps fitted with 25 mL pump-heads, 316SS Swagelok 1/800 stainless steel fittings and tubing (except for the 3/800 countercurrent mixer, the design of which has been published elsewhere46) and a 2.5 kW electrically powered water preheater which were built from 1/400 fittings. A small 5 cm long and 2.5cm diameter, 200 W band heater (Watlow) was placed around a duraluminum interface jacket which surrounds a countercurrent mixer pipe.46 The superheated water feed was created by pumping water through the preheater (via pump 1). This feed was then mixed with calcium phosphate mixture at a 3/800 countercurrent mixer and then the resultant nanoparticles pass through a ¼00 and 97 cm long vertical water cooled stainless steel pipe (shown as C in Fig. 1). Each high pressure line for each pump also incorporates a pressure gauge (RS model no. 540-255), Nupro SS-4R3A pressure release safety valves (set to 29 MPa) and Swagelok non-return valves (not shown in Fig. 1 for clarity). Other parts of the system include a stainless steel mesh 7 micron filter (model SS-2TF-7) to remove any large aggregates and a Tescom back-pressure regulator (model 26-1762-24) to maintain system pressure (shown as F and B in Fig. 1). The CHFS system (see Fig. 1) allows pumping and then mixing of the Ca (with Mg) salt and a basic phosphate source at a ¼00 1 5 10 15 Fig. 1 Scheme of the three-pump continuous hydrothermal flow synthesis system used for the preparation of Mg-substituted calcium phosphates. Key: P ¼ HPLC pump, H ¼ heater, C ¼ cooler, F ¼ filter, B ¼ back-pressure regulator, R ¼ counter-current reactor, T ¼ stainless steel T-piece mixer. stainless steel Swagelok T-piece mixer (whereupon initial precipitation at ambient temperature occurs in flow). This slurry then meets the flow of superheated water in a stainless steel counter-current mixer (R in Fig. 1),42–46 whereupon the bioceramic material is crystallised in a continuous fashion. The products are then cooled, filtered to remove large agglomerates and pass out of a back-pressure regulator which maintains system pressure. Pump rates of 20, 10 and 10 mL min1 were used for superheated water, calcium (plus magnesium) nitrate solution and phosphate source solutions, respectively. A (Ca + Mg)/P molar ratio of 1.67 (0.0835 M/0.05 M) was hence maintained in the starting solutions. All reactions were carried out using a superheated water feed at 400 C and 24 MPa. Additionally, a small 5 cm long, 200 W, 2.5cm diameter band heater set to 400 C (unless stated otherwise) was used on the counter-current mixer (where the superheated water and metal salts mix and react) to maintain a high reaction temperature (this gave a mixture temperature of ca. 275 C as measured via a thermocouple which was placed 7 cm upstream of the duraluminum block). For a standard reaction, magnesium nitrate and calcium nitrate were accurately weighed and added to 100 mL deionised water so that the total metal ion concentration was 0.0835 M (see ESI† Table S1). The pH of a stock solution of 0.05 M diammonium hydrogen phosphate (13.2 g in 2000 mL deionised water) was adjusted to pH 10 by adding 60 mL of neat aqueous ammonia solution. All calculations were initially based on the formula for Mg-substituted HA, i.e., [Ca10xMgx(PO4)6(OH)2] (see Table 1). However, as a HA-like phase was not always obtained, it can be assumed that the x:(10 x) ratio is simply the Mg:Ca ratio used in the reagents (see Table 1). For the reactions where Mg-substituted HA was formed, the reaction proceeded via the following equation: xMg(NO3)2 + (10 x)Ca(NO3)2 + 6(NH4)2HPO4 + H2O / [Ca10xMgx(PO4)6(OH)2] + 12NH4NO3 + 8HNO3 This journal is ª The Royal Society of Chemistry 2008 J. Mater. Chem., 2008, 18, 1–10 | 3 ART B807920J 20 25 30 35 40 45 50 55 1 5 10 15 In order to investigate the effect of water temperature, the reaction for sample 10Mg-CaP was also repeated using a superheated water feed at 450 C and band heater at 450 C. The respective slurries were collected from exit of the backpressure regulator (at the end of the CHFS system) in 50 mL falcon tubes. Between consecutive collections, the CHFS system was purged with clean water for 10 minutes. Each slurry was centrifuged at 4500 rpm for one minute (per 50 mL suspension), ca. 45 mL of liquid was removed from each sample and 45 mL de-ionized water was added with shaking. Each sample was then re-centrifuged at 4500 rpm for 1 minute and 45 mL liquid was removed for a final time to give concentrated slurry. The slurries were placed in a freezer at 5 C for 60 minutes and then freezedried for 18 h at 1 104 mbar. The yields for the reactions carried out in this study are summarized in ESI† Table S2. 1 5 10 15 3. Results and discussion 20 25 30 35 40 45 50 55 The authors previously reported the synthesis of ‘‘instant hydroxyapatite’’, in which highly crystalline HA nanorods were synthesized in the CHFS system using a superheated water feed at 400 C and 24 MPa.38 In the same work, the authors reported that not only could the crystallinity be controlled by changing the superheated water temperature, but also the Ca:P ratio could be affected by changing the pH or the temperature (this ratio affects resorbability in vivo). As in the aforementioned case, the rationale behind the synthesis of Mg-substituted calcium phosphates was to see if we could generate bioceramics with unique physical or compositional attributes (particle size, ion substitution level, crystallinity and phase composition) that may possess novel physical or other properties. In this work we used solutions of calcium nitrate and magnesium nitrate as the metal ion feeds in the CHFS system. By controlling the Mg:Ca ratios in the starting solutions, it was possible to affect the Mg-substitution levels in the resulting bioceramics or mixtures. The products were obtained as soft white free flowing powders in high yield after clean up and freeze drying of the individual slurries. All powders were analysed without further processing or heat treatments. For selected samples, transmission electron microscopy (TEM) images were used to investigate the particle morphology with ever increasing magnesium content or with changes in phase. Fig. 2a and b reveal distinct nano-rods of size ca. 234 (93) 57 (16) nm, for sample 0.5Mg-CaP. TEM images of sample 4Mg-CaP (subsequently identified from PXRD data to be largely Mg-whitlockite) are shown in Fig. 2c and d. A mixture of both lozenge shaped particles and semi-spherical agglomerates of ca. 30–60 nm [average particle size is 43 (12) nm; 50 particles sampled] sized particles were observed, suggesting a deviation from the rod-like morphology observed at lower Mg-substitution levels and for phase-pure HA.38 Fig. 2e and f show TEM images of sample 6Mg-CaP in which agglomerates as large as ca. 600 nm in diameter are comprised of smaller primary particles (average particle size is 47 17 nm; 50 particles sampled). The TEM image in Fig. 2f suggests that the spherical particles are possibly hollow. TEM images of sample 10Mg-CaP in Fig. 2g and h show very small particles, ca. 37 nm 13 nm in diameter (range ¼ 20– 60 nm; 50 particles sampled). These particles also appear to be hollow, as observed for sample 6Mg-CaP. 20 25 Fig. 2 Transmission electron microscope images of sample (a) 0.5MgCaP (15000 magnification; bar ¼ 500 nm), (b) 0.5Mg-CaP (150000; bar ¼ 50 nm), (c) 4Mg-CaP (15000; bar ¼ 500 nm) and (d) 4Mg-CaP (100000; bar ¼ 50 nm), (e) 6Mg-CaP (10000; bar ¼ 500 nm), (f) 6MgCaP (10000; bar ¼ 50 nm), (g) 10Mg-CaP (10000; bar ¼ 500 nm), (h) 10Mg-CaP (100000; bar ¼ 50 nm). 30 35 Elemental analyses (by an EDS detector attached to a TEM) for selected samples (three areas selected per sample) suggested the magnesium substitution levels in powders were 0.5 wt% 0.2 wt% for the rods in 0.5Mg-CaP, 4.0 wt% 0.6 wt% for the agglomerates in 4Mg-CaP, 6.8 wt% 0.3 wt% for 6Mg-CaP and 8.3 wt% 0.9 wt% for 10Mg-CaP. In sample 4Mg-CaP the EDS was focused on three lozenge shaped particles which form a slightly different shape to the majority of the sample in the frame (the vast majority are rounded agglomerates) and these suggested a Mg content of 2.7 wt% 0.8 wt%. This suggests that the lozenge shaped particles in sample 4Mg-CaP may be slightly lower in Mg compared to the more rounded agglomerates. The lozenge shape can essentially be viewed as a rounded rod like shape (such as the rods observed at lower Mg substitution levels for Mg-HA). Average area scans measurements of the Mg content using an EDS detector attached to a SEM are shown in Table 1. Powder X-ray diffraction data were collected for all samples to investigate how Mg substitution affected phase composition and phase purity. The PXRD data for sample 0.5Mg-CaP, shown in Fig. 3a, gave a good match to the line pattern for crystalline HA [ICDD pattern 09-0432, Ca5(PO4)3(OH)]. In contrast, the PXRD data for sample 4Mg-CaP gave a good match to the reference line This journal is ª The Royal Society of Chemistry 2008 4 | J. Mater. Chem., 2008, 18, 1–10 ART B807920J 40 45 50 55 1 1 5 5 10 10 15 Fig. 4 BET surface areas of ‘‘as precipitated’’ and freeze dried magnesium substituted calcium phosphates (and biphasic mixtures) with variation in magnesium content (measured using EDS) in the solids. The data points from left to right correspond to samples CaP, 0.5Mg-CaP, 1MgCaP, 1.5Mg-CaP, 2Mg-CaP, 4Mg-CaP, 6Mg-CaP, 8Mg-CaP, 10MgCaP, 12Mg-CaP and 14Mg-CaP. 20 25 Fig. 3 Powder X-ray diffraction patterns of ‘‘as precipitated’’ Mgsubstituted calcium phosphate powders for samples (a) 0.5Mg-CaP, (b) 1Mg-CaP, (c) 1.5Mg-CaP, (d) 2Mg-CaP, (e) 4Mg-CaP, (f) 6Mg-CaP, (g) 8Mg-CaP, (h) 10Mg-CaP, (i) 12Mg-CaP, (j) 14Mg-CaP and (k) MgP. Note: phase separation from pure Mg-substituted HA (Mg-HA) into a mixture of Mg-HA and Mg-whitlockite occurs from PXRD pattern (b) and for several higher Mg loadings. 30 35 40 45 50 55 pattern for crystalline Mg-whitlockite [ICDD pattern 70-2064, Ca18Mg2H2(PO4)14].55 Samples 1Mg-CaP, 1.5Mg-CaP and 2MgCaP were identified as biphasic mixtures, with a good match to the aforementioned patterns for HA and whitlockite, respectively (Fig. 3b–d). Increasing the magnesium content further (Fig. 3f–j) resulted in significantly broader PXRD peaks assigned as phase pure Mg-whitlockite [Ca3yMgy(HPO4)z(PO4)22z/3] (where y ¼ 0.7–1.2). This was not surprising given that magnesium is known to retard the crystallisation and growth of calcium phosphates in solution and to stabilise whitlockite.24 Of relevance to Mgwhitlockite, the batch hydrothermal synthesis of an analogous material, Mg3.5H2(PO4)3, was recently reported.56 It crystallised in a triclinic system with space group P1, Z ¼ 2, with unit-cell parameters: a ¼ 6.438(1) Å, b ¼ 7.856(1) Å, c ¼ 9.438(1), a ¼ 104.57(1) , b ¼ 108.61(1) , g ¼ 101.28(1) , V ¼ 739.99Å3). Previously, Mg-whitlockite crystals, Ca18Mg2H2(PO4)14, synthesised in a batch hydrothermal reactor, were reported in the rhombohedral space group R3c with ZR ¼ 1, a ¼ 13.765(8) Å and a ¼ 44.25(5) with the equivalent hexagonal parameters suggested to be a ¼ 10.350(5), c ¼ 37.085(12) Å and ZH ¼ 3.57 The PXRD data for our sample MgP (powder made using magnesium nitrate and no calcium nitrate) showed extremely broad peaks, suggesting the material is possibly amorphous. The broad peak positions roughly approximated to several standard line patterns, particularly ICDD patterns 11-0041-magnesium phosphate–Mg(PO4)3 and 08-0038–magnesium phosphate– Mg2P2O7. PXRD data of the sample obtained from the control experiment (re-run of sample 10Mg-CaP using superheated water at 450 C and band heater at 450 C) suggested the material was more crystalline (narrower peaks) than the similar sample made at 400 C (Fig. 3h) and gave a good match to the pattern for whitlockite (this PXRD pattern is reported in the ESI†). Fig. 4 shows the trends in BET surface areas for the magnesium substituted calcium phosphate samples. For sample 0.5MgCaP (phase pure Mg-HA) the BET surface area was 20.7 m2 g1. Samples 6Mg-CaP and 8Mg-CaP (phase-pure Mg-whitlockite) had lower surface areas of 10.3 and 11.7 m2 g1, respectively. This is unsurprising given the extent of agglomeration observed in Fig. 2c–f. The surface area shows a ca. five fold increase for samples 10Mg-CaP (50.2 m2 g1), 12Mg-CaP (54.3 m2 g1) and 14Mg-CaP (62.3 m2 g1). This suggests that there is possibly a threshold above which Mg substitution severely retards crystallisation and growth of particles in solution under these conditions. This hypothesis is supported by TEM images shown in Fig. 2c–h. Raman spectroscopy and FTIR spectroscopy were used to analyze the samples and aid identification of different calcium phosphates.12,58,59 Fig. 5 shows Raman spectra for magnesium substituted calcium phosphates. Peaks in Fig. 5a–d for samples 0.5Mg-CaP to 2Mg-CaP are very similar to those observed for phase pure HA. Peaks at ca. 1083 and 1054 cm1 in the Raman spectra, for these samples, correspond to asymmetric stretching (y3) of the P–O bond in phosphate. The peak around 970 cm1corresponds to the symmetric stretching mode (y1) of the P–O bond of the phosphate group. This peak is generally observed around 963 cm1 in HA.60 The shift could be due to magnesium incorporation into the HA lattice. Indeed, Rietveld refinement of the XRD data (discussed later) revealed a decrease in unit cell volume with increase in magnesium content (due to substitution of the larger calcium ion with the smaller magnesium ion). Therefore, the resultant compressive stresses in the lattice may lead to this difference in peak position.61 When the vibrational behaviour of the phosphate ions is discussed (with Mg substitution), the influence of two factors may also be considered: (i) the weakening of the intramolecular P–O This journal is ª The Royal Society of Chemistry 2008 J. Mater. Chem., 2008, 18, 1–10 | 5 ART B807920J 15 20 25 30 35 40 45 50 55 1 1 5 5 10 10 15 15 20 25 30 35 40 45 50 55 Fig. 5 Raman spectra in the range 1250–350 cm1 for samples (a) 0.5Mg-CaP, (b) 1Mg-CaP, (c) 1.5Mg-CaP, (d) 2Mg-CaP, (e) 4Mg-CaP, (f) 6Mg-CaP, (g) 8Mg-CaP, (h) 10Mg-CaP, (i) 12Mg-CaP, (j) 14Mg-CaP and (k) MgP. Note: the peak corresponding to O–P–O bending of the HPO42 group can be seen in (c) and increases for samples with higher magnesium loading. bonds owing to interionic Mgd+–Od interactions, and (ii) the repulsion potential of the lattice, which is inversely proportional to the unit-cell volume in the case of an isostructural series. As a result, a shift in the P–O vibrational modes is seen in the spectra. Peaks at 615 cm1 and 437 cm1 correspond to the y4 and y2 bending, respectively, of the O–P–O linkage in phosphate in HA. For the samples in the range y ¼ 0.5–1.6 (formula of [Ca3yMgy(HPO4)z(PO4)22z/3]), the Raman spectra reveal a peak corresponding to symmetric stretching of the P–O bond in the range 970 to 976 cm1 (see Fig. 5e–i). The Raman spectra for samples 4Mg-CaP, 6Mg-CaP and 8Mg-CaP (Fig. 5e–g) each reveal a peak at ca. 633 cm1, corresponding to bending modes of the O–P–O linkage in phosphate (of whitlockite). Increase of magnesium content to 1.5 wt% (and above) results in the appearance of new peaks in the Raman spectra at 415 and 555 cm1, which correspond to the respective y2 and y4 bending modes of the O–P–O linkage in HPO42 ions62 (of whitlockite). This is supported by the appearance of whitlockite peaks in the analogous PXRD data in Fig. 3. The FTIR spectrum for sample 0.5Mg-CaP (Fig. 6a) revealed peaks similar to those normally seen for HA; these include peaks at 3570 cm1 (strong) and 636 cm1 due to the stretching mode (ys) and the librational mode (yL), respectively, of hydroxyl groups.62,63 A band in the range 1150–990 cm1 corresponds to asymmetric P–O stretching (y3) of the phosphate group, whilst a peak at 964 cm1, corresponds to symmetric P–O stretching (n1) of phosphate. The peaks at 605 and 567 cm1 correspond to the y4 O–P–O bending mode, whilst the peak at 478 cm1 corresponds to the y2 O–P–O bending mode of phosphate. The weak peak centred at ca. 872 cm1 may be due to the bending mode (y2) of a minute amount of carbonate which is present. With an increase in magnesium content from 0.5 to Fig. 6 FTIR spectra in ranges (i) 3700–3400 cm1 and (ii) 1800–400 cm1, respectively, for samples (a) 0.5Mg-CaP, (b) 1Mg-CaP, (c) 1.5MgCaP, (d) 2Mg-CaP, (e) 4Mg-CaP, (f) 6Mg-CaP, (g) 8Mg-CaP, (h) 10MgCaP, (i) 12Mg-CaP, (j) 14Mg-CaP and (k) MgP. Note: the phosphate bands in the range 1150–950 cm1, become broader with increasing Mg substitution. 2 wt% (x ¼ 0.2 to 0.8), there was a general decrease in the intensity of hydroxyl peaks at 3570 and 633 cm1 in the corresponding FTIR spectra. This coincides with onset of Mg-whitlockite formation (as seen in the PXRD data) at greater THAN or equal to 1 wt% magnesium substitution (x ¼ 0.4). The FTIR spectra for samples with Mg substitution of 6 wt% (x ¼ 2.4) and higher (as seen in fig. 6f–j) revealed a phosphate peak (range 1550–1450 cm1) that became broader with increasing magnesium substitution. This coincided with a decrease in crystallinity of Mg-whitlockite (as seen in the PXRD data shown in Fig. 3). For biphasic samples and phase pure Mg-whitlockite (i.e. samples 1Mg-CaP to 14Mg-CaP, fig. 6b–j), the peak at 964 cm1 may be due to the presence of HPO42. Fig. 6k shows the FTIR spectrum for sample MgP. The weak bands centred at 1450 and 870 cm1 were assigned as the C–O stretching vibrations of a small amount of carbonate that may be present. b-TCP [Ca3(PO4)2], magnesium stabilised b-TCP [(Ca,Mg)3(PO4)2] and Mg-whitlockite [Ca18Mg2H2(PO4)14] are considered to be difficult to distinguish solely on PXRD data alone; in the literature, their names are often mistakenly used interchangeably.64 Our spectroscopic results suggest that the whitlockite phase reported herein may exist with the generic formula [Ca3yMgy(HPO4)z(PO4)22z/3] due to the presence of FTIR peaks corresponding to HPO42. A relatively large unit-cell group splitting is observed for n1 in both IR and Raman spectra and for n3 in Raman spectra. The spectroscopic data suggest that the mean wavenumbers of the P– O stretches within each series are insensitive to the amount of substituted magnesium ions. It is envisaged that it is due to two factors, namely, (i) the weakening of intramolecular P–O bonds due to the magnesium substitution (caused by the increased magnesium interactions) and (ii) increasing repulsion potential of the respective lattices in the same order. This journal is ª The Royal Society of Chemistry 2008 6 | J. Mater. Chem., 2008, 18, 1–10 ART B807920J 20 25 30 35 40 45 50 55 1 1 5 5 10 10 15 15 20 20 25 30 35 40 45 50 55 Fig. 7 Rietveld plot showing the fit of the high resolution transmission PXRD data of hydroxyapatite for sample 0.5Mg-CaP using a single-phase model and isotropic peak widths for all reflections. Dots indicate observed data, solid line calculated model, and vertical marks show the 2q positions of the hkl reflections with the difference pattern shown below. Peak width anisotropy as a function of hkl is particularly marked for 00l reflections as shown in the insert for the 002 peak at 25.9 2q. Rietveld refinements using the high-resolution PXRD transmission data were used to obtain accurate unit-cell dimensions for selected Mg-substituted samples and weight percent proportions of HA to Mg-whitlockite present. A typical fit is shown in Fig. 7. Rietveld refinement revealed anisotropic peak broadening for HA with the width of all 00l reflections being significantly narrower. This suggests preferential crystalline growth along the c direction, which is consistent with the rod-like forms as seen in Fig. 2(b). The Rietveld fits could be improved by the use of separate widths for the 00l reflections, with Rwp decreasing from 12.7% to 11.2% (Rexp ¼ 6.1%), though in practice this had a negligible effect on the unit-cell dimensions derived from the data. Mixed phase refinements with both HA and Mg-whitlockite present produced similar quality fits as indicated by the Rwp. Rietveld refinements of samples CaP, 0.5Mg-CaP, 1.5Mg-CaP and 4Mg-CaP revealed 100 wt%, 100 wt%, 70 wt%, and 5 wt% HA, respectively, and 0 wt%, 0 wt%, 30 wt%, and 95 wt% whitlockite, respectively. No other crystalline phases were observed in any diffraction pattern with the sole exception of the 1.5Mg-CaP PXRD pattern where a very small unidentified peak at 7.71 2q was observed which may be due to a small contaminant. Finally, and most importantly, refinements of the unit cell of the HA samples show that a systematic volume decrease occurs with increased levels of substituted magnesium in the samples (see ESI† Fig.S3). Although there is a significant deviation from the line calculated for the 4Mg-CaP cell volume, this is understandable as refinement is based on the 5 wt% of HA present in this Mg-whitlockite sample but the EDS (attached to the SEM) Mg content value is approximated from a large section of the whole sample. Nevertheless, the overall decrease in unit cell volume of ca. 5 Å3 is clearly observed from sample CaP to 4Mg-CaP (assuming this averaged Mg-content is used for the latter), and this reflects the reduction in average cation size in exchanging Ca2+ with Mg2+ (cationic radii are approximately 1.06 and 0.72 Å, respectively, for a similar coordination number).65 The small magnitude of the value stems from the small number of Mg2+ ions being substituted into the overall structure (which is less than one Mg per unit cell). A similar effect is obtained from the refinement of the whitlockite cell parameters, where the unit cell volume for 1.5Mg-CaP is approx. 3480 Å3. Increasing the % magnesium from sample 1.5Mg-CaP to 4Mg-CaP results in a decrease in unit cell volume of about 52 Å3. It should be noted that the Rietveld refinement technique is not sensitive enough to determine Mg concentration in each phase and so only unit cell parameters for each phase present were refined with the structural parameters being constrained to those determined by the single-crystal models of unsubstituted hydroxyapatite and whitlockite. A series of Mg-substituted calcium phosphates and biphasic mixtures were synthesized using a CHFS system. The physical and crystallographic properties of these materials can be closely monitored. Mg-substituted hydroxyapatite rods, [Ca10xMgx(PO4)6(OH)2], were exclusively formed at low Mg substitution levels (where x ¼ 0.2). However, at higher Mg substitution levels, stabilization of phase-pure crystalline Mgwhitlockite [Ca3yMgy(HPO4)z(PO4)22z/3] was obtained (for y ¼ 0.7). There do not appear to be any reports on direct and rapid hydrothermal synthesis of crystalline Mg-whitlockite. A further increase in magnesium substitutio, resulted in decreased crystallinity and generally increased surface area for the Mg-whitlockite phase (up to y ¼ 1.6). The synthesis method employed herein also J. Mater. Chem., 2008, 18, 1–10 | 7 ART B807920J 30 35 40 45 4. Conclusions This journal is ª The Royal Society of Chemistry 2008 25 50 55 1 allows us to produce intimately mixed biphasic mixtures, which could be extremely useful in applications such as controlled resorbability bone grafts and related biomedical materials. 5 Acknowledgements 10 15 EPSRC is acknowledged for funding an EPSRC Advanced Research Fellowship entitled ‘‘Next Generation Biomedical Materials Using Supercritical Fluids’’ (JAD; grant GR/A11304). The Higher Education Commission (HEC), Government of Pakistan is thanked for a scholarship (AAC). Sun Chemicals is thanked for an industrial case award (JG). P. Boldrin is thanked for assisting in the preparation of this paper. Mick Willis and Zofia Luklinska are thanked for their help with TEM. Nicky Mordan (EDI, UCL) is thanked for her help regarding EDS (SEM) of all the samples. References 20 25 30 35 40 45 50 55 1 L. L. Hench, Journal of the American Ceramic Society, 1998, 81, 1705. 2 S. Kannan, I. A. F. Lemos, J. H. G. Rocha and J. M. F. Ferreira, Journal of Solid State Chemistry, 2005, 178, 3190. 3 K. Yoshida, N. Kondo, H. Kita, M. Mitamura, K. Hashimoto and Y. Toda, Journal of the American Ceramic Society, 2005, 88, 2315. 4 S. Kannan and J. M. F. Ferreira, Chemistry of Materials, 2006, 18, 198. 5 Y. Pan, J. L. Huang and C. Y. Shao, Journal of Materials Science, 2003, 38, 1049. 6 H. Yuan, C. A. van Blitterswijk, K. de Groot and J. D. de Bruijn, Journal of Biomedical Materials Research Part A, 2006, 78A, 139. 7 I. Mandubalal, T. P. Sastry and R. V. S. Kumar, Journal of Biomaterials Applications, 2005, 19, 341. 8 R. Z. LeGeros, Clinical Orthopaedics and Related Research, 2002, 81. 9 T. J. Webster, E. A. Massa-Schlueter, J. L. Smith and E. B. Slamovich, Biomaterials, 2004, 25, 2111. 10 B. Wopenka and J. D. Pasteris, Materials Science & Engineering CBiomimetic and Supramolecular Systems, 2005, 25, 131. 11 R. A. Terpstra and F. C. M. Driessens, Calcified Tissue International, 1986, 39, 348. 12 I. R. Gibson and W. Bonfield, Journal of Materials Science-Materials in Medicine, 2002, 13, 685. 13 I. Mayer, R. Schlam and J. D. B. Featherstone, Journal of Inorganic Biochemistry, 1997, 66, 1. 14 S. R. Kim, J. H. Lee, Y. T. Kim, D. H. Riu, S. J. Jung, Y. J. Lee, S. C. Chung and Y. H. Kim, Biomaterials, 2003, 24, 1389. 15 R. K. Tang, W. J. Wu, M. Haas and G. H. Nancollas, Langmuir, 2001, 17, 3480. 16 R. Lagier and C. A. Baud, Pathology Research and Practice, 2003, 199, 329. 17 E. Bertoni, A. Bigi, G. Cojazzi, M. Gandolfi, S. Panzavolta and N. Roveri, Journal of Inorganic Biochemistry, 1998, 72, 29. 18 Z. Zyman, M. Tkachenko, M. Epple, M. Polyakov and M. Naboka, Materialwissenschaft und Werkstofftechnik, 2006, 37, 474. 19 W. L. Suchanek, K. Byrappa, P. Shuk, R. E. Riman, V. F. Janas and K. S. TenHuisen, Journal of Solid State Chemistry, 2004, 177, 793. 20 S. Kannan, J. H. G. Rocha and J. M. F. Ferreira, Journal of Materials Chemistry, 2006, 16, 286. 21 A. Avaglioli, A. Krajewski, G. C. Celotti, A. Piancastelli, B. Bacchini, L. Montanari and G. Zama, Biomaterials, 1996, 617. 22 A. Bigi, G. Falini, E. Foresti, M. Gazzano, A. Ripamonti and N. Roveri, Journal of Inorganic Biochemistry, 1993, 49, 69. 23 R. N. Correia, M. C. F. Magalhaes, P. A. A. P. Marques and A. M. R. Senos, Journal of Materials Science-Materials in Medicine, 1996, 7, 501. 24 N. C. Blumenthal, Clinical Orthopaedics and Related Research, 1989, 279. 25 C. Ergun, T. J. Webster, R. Bizios and R. H. Doremus, Journal of 1 Biomedical Materials Research, 2002, 59, 305. 26 R. Z. Legeros, D. Mijares, A. M. Gatti, and J. P. Legeros, Mgsubstituted tricalcium phosphates and biphasic calcium phosphates: Formation and properties, Biomaterials 2004 Congress Managers, 3 5 Sydney, NSW 2001, Australia, Sydney, Australia, 2004, p. 1448. 27 Y. Yamasaki, Y. Yoshida, M. Okazaki, A. Shimazu, T. Uchida, T. Kubo, Y. Akagawa, Y. Hamada, J. Takahashi and N. Matsuura, Journal of Biomedical Materials Research, 2002, 62, 99. 28 W. L. Suchanek, K. Byrappa, P. Shuk, R. E. Riman, V. F. Janas and K. S. TenHuisen, Biomaterials, 2004, 25, 4647. 29 C. M. Serre, M. Papillard, P. Chavassieux, J. C. Voegel and 10 G. Boivin, Journal of Biomedical Materials Research, 1998, 42, 626. 30 R. Z. LeGeros, A. M. Gatti, R. Kijkowska, D. Q. Mijares, and J. P. LeGeros, Mg-substituted Tricalcium Phosphates: Formation and Properties, Trans Tech Publications Ltd, Porto, Portugal, 2004, pp. 4 127–130. 15 31 I. V. Fadeev, L. I. Shvorneva, S. M. Barinov and V. P. Orlovskii, Inorganic Materials, 2003, 39, 947. 32 J. M. Bouler, R. Z. LeGeros and G. Daculsi, Journal of Biomedical Materials Research, 2000, 51, 680. 33 F. Gouin, J. Delecrin, N. Passuti, S. Touchais, P. Poirier and J. V. Bainvel, Revue de Chirurgie Orthopedique et Reparatrice de l Appareil Moteur, 1995, 81, 59. 20 34 G. Daculsi, M. B. Darc, P. Corlieu and M. Gersdorff, Annals of Otology Rhinology and Laryngology, 1992, 101, 669. 35 J. Delecrin, S. Takahashi, F. Gouin and N. Passuti, Spine, 2000, 25, 563. 36 T. A. Fuierer, M. Lore, S. A. Puckett and G. H. Nancollas, Langmuir, 1994, 10, 4721. 25 37 R. Enderle, F. Gotz-Neunhoeffer, M. Gobbels, F. A. Muller and P. Greil, Biomaterials, 2005, 26, 3379. 38 A. A. Chaudhry, S. Haque, S. Kellici, P. Boldrin, I. Rehman, A. K. Fazal and J. A. Darr, Chemical Communications, 2006, 2286. 39 C. S. Chai, K. A. Gross and B. Ben-Nissan, Biomaterials, 1998, 19, 2291. 30 40 C. Kothapalli, M. Wei, A. Vasiliev and M. T. Shaw, Acta Materialia, 2004, 52, 5655. 41 C. R. Kothapalli, M. Wei, R. Z. LeGeros and M. T. Shaw, Journal of Materials Science-Materials in Medicine, 2005, 16, 441. 42 G. Y. Hou, Z. H. Jin, X. H. Zheng and J. M. Qian, Rare Metal Materials and Engineering, 2007, 36, 1649. 35 43 J. A. Darr and M. Poliakoff, Chemical Reviews, 1999, 99, 495. 44 A. Cabanas, J. A. Darr, E. Lester and M. Poliakoff, Chemical Communications, 2000, 901. 45 A. Cabanas, J. A. Darr, E. Lester and M. Poliakoff, Journal of Materials Chemistry, 2001, 11, 561. 46 P. Boldrin, A. K. Hebb, A. A. Chaudhry, L. Otley, B. Thiebaut, 40 P. Bishop and J. A. Darr, Industrial & Engineering Chemistry Research, 2007, 46, 4830. 47 X. L. Weng, P. Boldrin, I. Abrahams, S. J. Skinner and J. A. Darr, Chemistry of Materials, 2007, 19, 4382. 48 T. Adschiri, K. Kanazawa and K. Arai, Journal of the American Ceramic Society, 1992, 75, 1019. 49 T. Adschiri, K. Kanazawa and K. Arai, Journal of the American 45 Ceramic Society, 1992, 75, 2615. 50 K. W. Sue, K. Kimura, M. Yamamoto and K. Arai, Materials Letters, 2004, 58, 3350. 51 Y. Hakuta, H. Ura, H. Hayashi and K. Arai, Materials Chemistry and Physics, 2005, 93, 466. 52 J. K. Cockcroft, 2005. 50 53 K. Sudarsanan and R. A. Young, Acta Crystallographica B, 1982, 24, 38. 54 L. W. Schroeder, B. Dickens and W. E. Brown, Journal of Solid State Chemistry, 1977, 22, 253. 55 E. Guneri and M. Akkurt, G.U.Journal of Science, 2005, 18, 321. 56 H. Assaaoudi, Z. Fang, I. S. Butler, D. H. Ryan and J. A. Kozinski, Solid State Sciences, 2007, 9, 385. 55 57 C. Calvo and R. Gopal, American Mineralogist, 1975, 60, 120. 58 I. Rehman, M. Karsh, L. L. Hench and W. Bonfield, Journal of Biomedical Materials Research, 2000, 50, 97. 59 I. R. Gibson, I. Rehman, S. M. Best and W. Bonfield, Journal of Materials Science-Materials in Medicine, 2000, 11, 533. This journal is ª The Royal Society of Chemistry 2008 8 | J. Mater. Chem., 2008, 18, 1–10 ART B807920J 1 60 G. Penel, G. Leroy, C. Rey and E. Bres, Calcified Tissue International, 1998, 63, 475. 61 G. Gouadec and P. Colomban, Progress in Crystal Growth and Characterization of Materials, 2007, 53, 1. 62 S. Koutsopoulos, Journal of Biomedical Materials Research, 2002, 62, 600. 63 I. Rehman and W. Bonfield, Journal of Materials Science-Materials in Medicine, 1997, 8, 1. 64 M. Mathew and S. Takagi, Journal of Research of the National Institute of Standards and Technology, 2001, 106, 1035. 65 R. D. Shannon, Acta Crystallographica., 1976, A32, 751. 1 5 5 10 10 15 15 20 20 25 25 30 30 35 35 40 40 45 45 50 50 55 55 This journal is ª The Royal Society of Chemistry 2008 J. Mater. Chem., 2008, 18, 1–10 | 9 ART B807920J 1 1 Authors Queries Journal: JM 5 5 Paper: b807920j Title: Synthesis and characterisation of magnesium substituted calcium phosphate bioceramic nanoparticles made via continuous hydrothermal flow synthesis 10 Editor’s queries are marked like this... 1 , and for your convenience line numbers are inserted like this... 5 10 Query Reference Query 15 1 For your information: You can cite this article before you receive notification of the page numbers by using the following format: (authors), J. Mater. Chem., 2008, DOI: 10.1039=b807920j. 20 2 Please supply a contents page entry: a figure (8 cm wide by 4 cm high), plus text (<30 words) emphasising the novel aspects of the work and highlighting the materials applications or properties. See the contents pages of any recent issue of J. Mater. Chem. for examples. 15 20 25 Remarks 3 Ref. 26: Please provide the following details: lst of editor names if any, publisher’s name, publisher’s location. 4 Ref. 30: Please provide the following details: list of editor names (if any), publisher’s name, publisher’s location. 30 25 30 35 35 40 40 45 45 50 50 55 55 This journal is ª The Royal Society of Chemistry 2008 10 | J. Mater. Chem., 2008, 18, 1–10 ART B807920J