UNUSUAL INTERGRANULAR CORROSION FAILURE OF ALLOY

advertisement

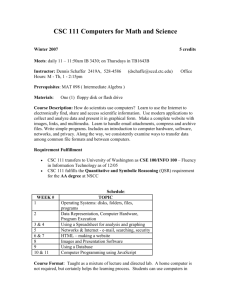

UNUSUAL INTERGRANULAR CORROSION FAILURE OF ALLOY C276 PRESSURE TRANSDUCER DIAPHRAGM Michael M. James Senior Consultant - Materials Engineering DuPont – Houston TX 2 Overview • Chemical Plant in the Texas Gulf Coast • Manufacture of Vinyl Acetate Monomer • CO2 Removal from the Reaction Loop • Potassium Carbonate Solution (30%) Used for CO2 Removal • Vanadium Pentoxide Added as a Corrosion Inhibitor 2011 CSC 3 Typical CO2 Removal Process Stack Acid Gas Regenerator Stripper Absorber Reboiler Feed Gas Heat Rich Solution 2011 CSC Lean Solution 4 Absorber Stripper Photograph Of The CO2 Absorber and Stripper Columns 2011 CSC 5 Overview of Installation / Condition • Level in the Absorber Column Monitored Using Differential Pressure Cell Transmitter • Transmitter Uses Thin Wall Diaphragm Design • Type 316L Diaphragm Corroded After 4 Years in Service (Recurring Problem) • Replaced With Alloy C276, Plant Had One In Stock • Thought To Have Better Corrosion Resistance Than Type 316L Stainless Steel in the Process 2011 CSC 6 Typical Installation Of Differential Pressure Cell For Level Control 2011 CSC 7 Thin Wall Diaphragm Style DP Cell 2011 CSC 8 Construction of Thin Wall Diaphragm Sensor 2011 CSC 9 Photograph Showing Overall View of Lower DP Cell Installation DP Cell DP Cell 2011 CSC 10 DP Cell 2011 CSC Installation Of DP Cell In The Absorber Column 11 Upper Lower 2011 CSC 12 Photo Showing Lower DP Cell And Diaphragm As Removed From The Column Deposits 2011 CSC 13 Photo Showing Upper DP Cell And Diaphragm From Redundant Transmitter As Removed From The Column Deposits 2011 CSC 14 Photograph of Alloy C276 Diaphragm Removed from Lower DP Cell 2011 CSC 15 Observations from Visual Examination of the Diaphragm • Deposits Covered The Area Of The Diaphragm • The Deposits Could Be Easily Cleaned Off, Not Very Adherent • Under The Deposits The Surface Of The Diaphragm Appeared Shiny, With Little Evidence Of Corrosion • In The Areas Where No Deposit Build Up Was Present, The Surface Of The Diaphragm Had A Matte, Rough Appearance 2011 CSC 16 SEM Photograph of the Diaphragm Surface Under the Deposits General Corrosion Intergranular Corrosion 2011 CSC 17 Macro Photograph Showing Matted Rough Surface of the Diaphragm 2011 CSC 18 SEM Photograph Showing Close Up of Rough Area of Diaphragm 2011 CSC 19 SEM Photographs Showing Intergranular and General Corrosion of the Alloy C276 Diaphragm in Rough, Matted Areas 2011 CSC 20 Cross-sectional Photomicrograph of Diaphragm 2011 CSC 21 Deposit Analysis Elt. Line Intensity (c/s) Error 2-sig Conc Units Elt. Line Intensity (c/s) Error 2-sig Conc Units Al Ka 8.96 0.631 0.836 wt.% Al Ka 8.23 0.524 0.522 wt.% Si Ka 32.50 1.202 2.313 wt.% Si Ka 19.29 0.802 0.939 wt.% K Ka 311.13 3.719 13.457 wt.% Cl Ka 9.41 0.560 0.301 wt.% V Ka 89.96 2.000 5.860 wt.% K Ka 858.34 5.349 27.448 wt.% Cr Ka 49.52 1.483 3.507 wt.% V Ka 85.02 1.683 4.512 wt.% Mn Ka 17.08 0.871 1.472 wt.% Cr Ka 262.03 2.955 15.440 wt.% Fe Ka 558.31 4.981 63.246 wt.% Fe Ka 435.06 3.808 39.465 wt.% Ni Ka 46.45 1.437 9.310 wt.% Ni Ka 69.70 1.524 10.326 wt.% Mo La 16.40 0.739 1.047 wt.% 100.000 wt.% 100.000 wt.% Coffee Grounds 2011 CSC Total Diaphragm Total 22 Control Valve Between Stripper and Absorber Columns Alloy C276 Parts Showing Accelerated Corrosion In Crevice Packed With Coffee Grounds End Post 2011 CSC Shaft (in ball) 23 Laboratory Testing • Unable to Get Process Solution Directly from The Absorber Column During Operation • Sample Ports Plugged with Coffee Grounds • Used Laboratory Solution Based on Best Analysis of Actual Process K2CO3 KHCO3 KBO2 V2O5 H2O (L) TOTAL (L) 2011 CSC WT WT WT WT WT WT % % % % % % 5.88% 25.67% 3.77% 0.94% 63.74% 100.00% 24 Laboratory Testing • Corrosion Coupons Installed In Vertical Orientation • Alloy C276 (UNS N10276) • Alloy 625 (UNS N06625) • 6- Mo Alloy (UNS N08367) • Type 316L sst (UNS S31603 • Covered Vertical Coupons with Coffee Grounds Removed from Absorber • Second Set of Coupons Suspended in the Solution 2011 CSC 25 Laboratory Testing – Corrosion Rates 2011 CSC Alloy Designation (UNS) Common Alloy Name Exposure Corrosion Rate mm/y (mpy) Corrosion Type / Comments S31603 316L SST Solid 0.001 (0.04) Unattacked S31603 316L SST Liquid 0.001 (0.04) Unattacked S31603 316L SST Liquid 0.004 (0.17) Unattacked N10276 Alloy C-276 Solid 0.003 Unattacked N10276 Alloy C-276 Liquid 0.002 (0.07) Unattacked N10276 Alloy C-276 Liquid 0.002 (0.08) Unattacked N06625 Alloy 625 Solid 0.002 (0.07) Unattacked N06625 Alloy 625 Liquid 0.006 (0.24) Unattacked N06625 Alloy 625 Liquid 0.0013 (0.04) Unattacked N08367 Alloy 6XN Solid 0.001 (0.04) Unattacked N08367 Alloy 6XN Liquid 0.0013 (0.04) Unattacked N08367 Alloy 6XN Liquid 0.0013 (0.04) Unattacked (0.12) 26 Corrosion Tests in Chlorine Dioxide Bleach Environments 2011 CSC 27 Discussion and Conclusions • Accelerated Corrosion of Alloy C276 in Comparison to Both Type 316L stainless steel and Alloy 625 When Exposed to the Actual Process Conditions • Studies Have Shown That Ni-Cr-Mo Alloys Corrode at Higher Rates Than Alloys Containing Less Chromium and Moly in Oxidizing Bleach Manufacturing Processes (1) • Vanadates Can be Highly Oxidizing, Similar to Chlorine in Bleach Manufacturing Processes • It May Be Possible to Get Localized Low pH Conditions Under Vanadate Containing Deposits • Possible to Get Highly Oxidizing Acidic Conditions Under Deposits Packed Against the Alloy C276 Diaphragm 2011 CSC 1. Allfonsson, Tuveson-Carlström, Wallén, Corrosion in Chlorine Dioxide Bleach Environments – Experiences with Stainless Steel and Nickel-Based Alloys , TAPPI Engineering Conference, September 1993, Orlando FL 28 Discussion and Conclusions • Current Diaphragms Are Made Of Alloy 625 And Have Been In Service For 2 Years • Still Reviewing Data To Determine If There Is A Better Option Than Alloy 625 Or Type 316L Stainless Steel • High Chrome, Low Nickel and Moly • Duplex Stainless Steels (Alloy 2304, 2003, 2205) • Precipitation Hardening Stainless Steel (17-7PH) 2011 CSC 29 Acknowledgements Brian Saldanha – DuPont, Wilmington DE Mike Rogillio – DuPont, LaPorte Chris Michna – DuPont, Houston Sheryll Fox-Loughin – DuPont, Wilmington 2011 CSC 30 QUESTIONS? 2011 CSC