Complete Fire Protection from a Single Source

advertisement

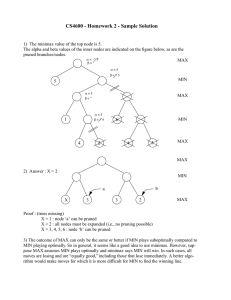

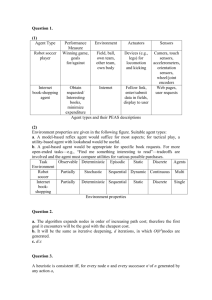

Overall Idea Complete Fire Protection from a Single Source CONTENT Experience 4 A single source 5 Sprinkler systems 6 Minifog water mist systems 7 Deluge systems / Hydrant systems 8 Foam-based suppression system 9 Dry chemical-based suppression systems 10 Fire prevention systems 10 Fire detection systems 11 Gas-based suppression systems 12 Structural fire protection 14 Fire extinguishers 14 Special solutions 15 Services 16 Addresses 17 3 MINIMAX Experience Minimax Chronicle 1902The company is founded in Berlin by Wilhelm Graaff and develops the legendary Minimax conical extinguisher. Employees coin the trademark: minimum effort, maximum efficiency = Minimax 1905Minimax acquires the production center in Neuruppin. 1909Minimax is the number 1 worldwide – with foreign subsidiaries in Europe and the USA. Minimax conquers the world with its products – 300,000 devices produced by some 1,000 employees are exported annually to 28 countries. 1926Launch of the first Minimax foam generators. 1991Minimax GmbH with its head office in Bad Oldesloe and a branch office in Bad Urach is founded. Minimax GmbH is the leading company of all fire protection activities of the Preussag AG. 1998Minimax extends the fire protection research center in Bad Oldesloe 2001Preussag AG concentrates on their core business: tourism. Minimax gains a new shareholder with Barclays Private Equity Deutschland. 2002Minimax celebrates its 100th anniversary! 1929Selbsttätige Feuerlöschanlagen GmbH (SFH) is established in Hamburg. The company is focusing already at this stage on permanently installed extinguishing systems. 2003Investcorp acquires Minimax. Minimax GmbH and Minimax Holding GmbH merge into Minimax GmbH & Co. KG. 1945Minimax is built up again in West Germany after the destruction of the administration buildings in Berlin and after expropriation of the factory in Neuruppin. 2005Minimax GmbH & Co. KG bundle their activities in the range of the mobile fire protection in a discrete association – the Minimax Mobile Services GmbH & Co. KG 1953In Bad Urach near Stuttgart the most up-to-date German factory for fire extinguishers, fire extinguishing devices and extinguishing systems for fire fighting vehicles is established. 2006Industri Kapital acquires Minimax from Investcorp. 1958Minimax extends the factory in Bad Urach 1966SFH (Selbsttätige Feuerlöschanlagen GmbH) relocates its factory to Bad Oldesloe in Northern Germany 1967The fire protection research centre is inaugurated with its own “fire house“ in Bad Oldesloe. 4 1969Minimax is taken over by Preussag AG and merged with SFH 2007Minimax expands business in the USA with the acquisition of CFP. 2009Inauguration of new fire protection research center. 2009Minimax merges with Viking and becomes one of the core brands of the newly established Minimax Viking Group. 2014Kirkbi acquires stake in Minimax Viking. MINIMAX A single source International complete service provider Fire is one of the most underestimated of all risks. A fire can break out anywhere – the important thing is how fast it can be detected and extinguished. For over 110 years, Minimax has been one of the leading brands in fire protection. The expert teams of Minimax implement suitable fire protection solutions from a single source for all sectors, objects and applications. In the automotive industry, power stations, logistics warehouses, data centers, office and administrative buildings or on ships – wherever there is a risk of fire, Minimax has a range of individual solutions to ensure optimal protection for people, buildings, machinery and the environment. As an internationally active provider of integrated solutions, Minimax offers a singularly broad range of tried and tested as well as innovative fire protection systems that meet the most stringent demands in every detail and combine to form a particularly effective and economic overall solution. Our product quality and quality of service solutions is tested regularly – for us, a matter of course; for our clients and many approval bodies, the guarantee for safe fire protection solutions which comply with all applicable regulations. Intensive development work carried out in our own fire protection research center ensures that the company will continue to develop trend-setting, innovative solutions well into the future. A comprehensive service – from training through maintenance and all the way to fault management – completes the Minimax offer. Research for a fire-proof future Every year fires claim many human lives, in addition to billions of dollars in assets. In 1967, Minimax set up the “Fire Research Center” in Bad Oldesloe to provide new impulses for systematic fire protection research. Since then, full-scale emergencies have been staged here in keeping with the motto “We have a fire, so you don’t”. ceiling, the ceiling height can be lowered with minimal effort to 2 m. In addition, some 14 kilometers from the Minimax Mobile Services headquarters in Bad Urach, Minimax boasts a fire research center spanning across 2500 m2 to test new fire protection solutions. The fire hall and the technical center were renewed in 2009. A fire test room with an area of 320 m2 and a height of up to 15 m is now available for tests. Through integration of a mobile suspended Minimax Fire Research Center: Fire in a high rack warehouse 5 OVERVIEW Sprinkler systems Sprinkler systems are self-acting fire extinguishing systems based on an uncomplicated well as a safe functioning principle. A network of piping and sprinkler heads is installed throughout the areas of the building requiring protection is constantly under pressure. Under normal conditions the sprinkler head is closed off by a liquid-filled bulb. If, due to the effects of a fire, the ambient temperature in the immediate vicinity rises by approximately 30 °C above the maximum temperature expected under normal conditions, the glass bulb bursts. The pressurized extinguishing water then flows through the piping into the sprinkler head and the resulting water jet hits the spray plate which diverts the water to the areas to be covered. At the same time the water flow in the piping network trips the alarm systems. After the fire is extinguished the activated sprinklers are replaced, and the system is ready for operation again. In order to provide effective solutions for diverse fire risks, Minimax sprinklers are offered in a range of versions with special spraying characteristics. All sprinkler system components are also available as part of the Minimax product portfolio. The different types of systems, such as wet or dry systems or pre-controlled dry systems, are adapted to meet specific criteria, for instance areas prone to frost or special risk areas. 6 Undercover Sprinkler Preaction Sprinkler OVERVIEW Minifog water mist systems Since 1993, Minimax has been installing highpressure and low-pressure water mist systems under the Minifog trademark and is thus one of the pioneers of water mist technology. Minifog is suitable for various applications, whether for protection of rooms or of equipment. Water mist technology features extremely efficient exploitation of the physical properties of water. The extinguishing water is applied through special nozzles and sprinklers and/or increased operating pressure as a fine water mist with the result that the total surface area of the extinguishing water is multiplied many times through the formation of fine droplets. The water absorbs the heat of the fire particularly efficiently, and so the base of the fire and its surroundings are immediately cooled effectively. Also evaporation of the extinguishing water in the fire captures a great deal of additional latent heat, and at the same time the steam produced impedes the supply of oxygen to the base of the fire: The reduction of the oxygen concentration in the immediate vicinity of the flame zone has an additional smothering effect. The arrangement of the nozzles and optimal droplet formation mean that the base of the fire can still be reached even if there are inhibiting factors such as thermal currents or air movement. 7 OVERVIEW Deluge systems / Hydrant systems Deluge systems Hydrant systems If conditions are such that extremely rapid spreading of a fire can be expected, then Minimax deluge systems can provide maximum safety. Hydraulically, pneumatically or electrically activated deluge systems are able to extinguish fires quickly and with blanket coverage due to their open nozzles. Spray extinguishing prevents ongoing fires by cooling the combustible substance. In some risk areas a film-forming foaming agent is added to the water of a deluge system to enhance the extinguishing effect. Drinking water, used in many cases as an extinguishant, is a key element of hydrant systems. Since drinking water is also an important resource for our world, particularly stringent requirements are imposed for the planning and design of systems which are directly connected to the drinking water supply. Minimax hydrant systems comply with valid standards as well as the statutory provisions and guarantee highest possible security. Deluge systems are designed for space or equipment protection. In the case of space protection the water is distributed evenly across the whole area of the fire hazard. The nozzles are therefore arranged evenly spaced at ceiling level. In the case of equipment protection systems, defined objects particularly subject to fire hazard are provided with water spray for protection or for preventive cooling. The nozzles are therefore arranged to be specifically aimed at the equipment. For tall objects they may also be installed at several levels Distribution of the water is determined by the number, size and spray characteristics of the nozzles and arranged to suit the equipment and areas to be protected. 8 The maximat series, developed by Minimax, offers special components for the water supply of wall hydrants. These include pressure boosters and filling and draining devices, which are available in a range of versions to meet various needs. Minimax also offers a lot of different components of hydrant systems, for example fire extinguishing hose connecting equipment (wall hydrants), above-ground and underfloor hydrants and more. OVERVIEW Foam-based suppression systems Tank farms, incineration plants, refineries or plastics/tire depots have one thing in common: they pose a special risk. When flammable liquids or plastics catch fire, the fire spreads very quickly and toxic combustion gases are emitted. This results in damage running into millions as well as environmental pollution. Foam-based suppression systems offer the most effective fire protection for these risk areas. foaming agent and the foaming agent admixture rate. In case of a low air intake a wet, heavy extinguishing foam is produced (low expansion foam). If the air percentage is increased, the foam becomes drier and thus lighter (medium and high expansion foam). The air foam utilizes different extinguishing effects: cooling, suffocating, separating, covering, restraining and displacing. Reignition is prevented. Extinguishing foam is a highly effective mixture of water, foaming agent (concentrated) and air. A stable foaming agent percentage is added to the water flow with admixture devices. The produced mixture is foamed with air in subsequent foam generators. The foaming degree depends on the capacity of the used foam generator, the With a versatile foaming agent range, Minimax offers safe and flexible application. Perfectly aligned components – for example the innovative Minimax sprinkler for low expansion foam – are supplied in line with the individual needs of clients and according to respective fire protection requirements. 9 OVERVIEW Dry chemical-based suppression systems / Fire prevention systems Dry chemical-based suppression systems Oxeo Prevent oxygen reduction systems Powder-based suppression systems are permanently installed fire extinguishing systems. Extinguishing powders are highly efficient and fast-acting extinguishing agents. The sudden three-dimensional extinguishing effect of the powder cloud is due to the anti-catalytic effect, a chemical intervention in the combustion process, and, in fire hazard class A, also due to a smothering sinter layer formed by the melting powder. Extinguishing powders consist essentially of non-toxic inorganic salts, which are mixed with impregnation and pouring agents. The extinguishing powders are used for fires involving solid, liquid and gaseous materials and for metal fires. The principle of oxygen reduction is to permanently lower the oxygen concentration of the air to prevent the outbreak of a fire in the first place. The Oxeo Prevent system offers optimal fire protection when the areas to be protected are not frequented by people and have a relatively high impermeability for reasons of energy, climate or safety technology. In such areas the best possible fire protection is the Oxeo Prevent system: active fire prevention. If several rooms and objects are to be protected by powder-based suppression systems, one central powder supply in pressure-proof steel tanks is recommended for all areas to be protected. Up to 4,000 kg of powder can be stored in one tank. Small-scale extinguishing systems are recommended for objects requiring limited protection. Such powder-based suppression systems have been standard-ized in design and size for a number of similar objects, which minimizes the cost. Preferred areas of application are exhauster hoods, exhaust air ducts, lab experiment facilities, etc.. 10 Due to the controlled supply of nitrogen, the Oxeo Prevent system keeps the oxygen content of the air in the protected area at a reduced level. The nitrogen displaces the calculated proportion of oxygen, resulting in a fire-proof atmosphere. The nitrogen for reducing the oxygen is produced economically by a nitrogen generator directly in the Oxeo Prevent system. The monitoring and control unit of the fire prevention system constantly checks the oxygen content of the air. OVERVIEW Fire detection and extinguishing control Fire detection systems are essential components of a responsible safety management concept. Each object and each area of use holds special risks and requirements. Minimax offers various models of standard fire detectors – such as smoke and heat detectors – and special fire detectors – such as bypass detectors – as well as alarm transmitters. Used in conjunction with the fire detection and extinguishing control panel, these components ensure an early warning of persons at risk and notification of the fire department, the monitoring and activation of extinguishing systems and smooth communication and information flows. Minimax fire detection systems detect fire dangers and incipient fires around the clock. UniVario industrial fire detectors Minimax has devised a product range for industrial use: UniVario industrial fire detectors. With their robust casing and installation technology, these intelligent, platform-based, micro-processorcontrolled heat and flame detectors can cope with even the toughest of conditions. HELIOS aspirating smoke detectors The active smoke detection system HELIOS consists of suction lines with suction openings and an assessment unit with smoke sensors and powerful fans. The response sensitivity of the device is individually adjustable. It is used, e.g. for the earliest possible detection of fires or in high-ceiling halls to facilitate maintenance. Fire detection and extinguishing control panels Our fire detection and extinguishing control panels span both standard control panels with line technology and ring bus panels for networked systems. With the diverse range of standard and special sensor technology, all configuration levels from compact small control panels to comprehensive large panels can be compiled individually. 11 OVERVIEW Gas-based suppression systems Protected areas with special fire hazards or sensitive technologies which can be damaged by the use of non-gaseous extinguishants need a special protection scheme. Minimax has the right solution. Our gaseous extinguishing agents are environmentally safe and provide fast, dependable protection of human life and material assets. Specially adapted to the individual application, they fight fires with no side effects or negative impact on the protected objects. Oxeo inert gas systems By adding inert gases, e.g. argon or nitrogen, Oxeo fire extinguishing systems reduce the oxygen content in the air in the event of a fire. Oxeo inert gas systems are therefore the right solution for protecting high-end systems, sensitive equipment or valuables that could be damaged by the use of other extinguishing agents. Argon and nitrogen are natural components of ambient air; furthermore, these gases are non-toxic and electrically non-conductive. The 300 bar technology has further increased the cost-effectiveness of the Oxeo extinguishing system. Higher filling pressure means that fewer cylinders are required. The innovative ConstantFlow technology makes use of high-pressure reducers, which reduce the pressure already at the inert gas cylinders. This means that pipes and selector valves for lower pressure levels can be used and that the pressure relief flaps common in gas extinguishing systems are significantly smaller. 12 Carbon dioxide systems The extinguishing effect of carbon dioxide is based on the quick replacement of oxygen from the base of the fire. The high heat-absorption properties of the gas withdraw energy from the base of the fire and thus reinforce the extinguishing effect. Due to its special extinguishant properties, carbon dioxide systems are also able to protect stand-alone equipment. Carbon dioxide systems require only little space for storing extinguishant – large CO2 quantities can be easily stored in low-pressure containers. Carbon dioxide is a natural component of ambient air and electrically non-conductive. OVERVIEW Gas-based and compact suppression systems MX 1230 fire extinguishing systems MX 1230 fire extinguishing systems use the clean agent Novec™ 1230 by 3M™ for extinguishing fires. This extinguishant is neither corrosive nor electrically conductive and hence an ideal fire protection solution for rooms with electronic and electric equipment. The extinguishing agent Novec™ 1230 is unique in that it is stored at room temperature in a form as compact as water, but extinguishes as a gas with no residue and even distribution throughout the entire extinguishing area. In addition a compact version, the MX 1230 compact extinguishing system, is available: the control panel, extinguishant supply, and if desired, the nozzle, alarm horn and flashlight are all combined in one unit. OneU fire protection systems for 19“ racks With OneU, Minimax offers a unique active extinguishing system especially for cabinets with electrical and electronic devices, for example servers and IT equipment. 19“ racks, equivalent to a height of 44 mm. The integrated emergency power supply of OneU ensures uninterrupted operation even in the case of outages. With just a few hand maneuvers, the spacesaving OneU is installed in one-height units for 13 OVERVIEW Structural fire protection / Fire extinguishers Structural fire protection Fire extinguishers Joints, pipes, paneling, supply shafts and ducts are ideal routes along which fires can spread very quickly. Every duct – even through fire-proof walls, ceilings and floors – can easily become a safety breach. Structural fire protection is therefore an essential part of fire prevention. All fire hazard classes It helps to prevent and contain fires and to secure escape and rescue paths in the event of a fire. Minimax ensures compliance with structural fire prevention regulations. All Minimax systems are tested and approved in accordance with DIN 4102 and conform to the state of the art. For all fire hazard classes (A, B, C, D, F), Minimax offers ideal fire extinguishers manufactured in its very own production plant in Germany. Mobile fire extinguishers from 1 - 12 kg or liters and movable fire extinguishing units from 10 - 60 kg or liters. Fire extinguishers containing foam Foam cartridge extinguisher Powder fire extinguishers Carbon dioxide fire extinguishers Structural fire protection measures include: Cable fire stops Water mist fire extinguishers Cable coatings Fire extinguishers to fight burning fat Fire protection coating Fire extinguishers to fight metal fires Pipe fire stops Fire protection cladding Fire protection joints Fire protection spray plaster 14 Fire extinguishers containing water The operating and quality features are identical in all versions. Those who place particular importance on individuality and aesthetics will find an endless variety of options in the available design versions. OVERVIEW Special solutions Many objects and protection areas involve special fire risks and therefore have special requirements for a fire protection solution. With know-how and a broad range of products Minimax is the right partner where individual solutions are required. Examples of sectors: Automatic park systems Printing industry Paint spraying systems Airports Historic buildings and museums High-bay warehouses Industrial presses Telecommunications / EDP Power plants Hospitals Kitchens Laboratories Ships Silos and bunkers Steel works Machine tools Wind turbines 15 OVERVIEW Services Advice / Planning Fault signal management With its comprehensive planning and services, Minimax creates all the prerequisites for keeping damage to a minimum in the event of a fire. Fault signals issued by your fire protection system are transmitted to the Minimax fault reporting system. When a fault message is received, the employees at the control panel can determine the type of fault, the location of the affected system and the identity of the operator. Based on a previously prepared individual plan of action, staff members then proceed to inform the entities arranged. After visiting the building, grounds or construction site, Minimax specialists prepare customized fire protection solutions. Maintenance Regular checks are a fundamental prerequisite, so that not only the functioning of your fire protection systems is guaranteed, but also to maintain insurance cover at all times. Improvement / Prevention To ensure that protective systems still function properly after many years of stand-by service and comply with the state of the art, Minimax service includes much more than just maintenance. Minimax also offers specific measures and programs for increasing the safety and operational readiness, or user-friendliness of a fire protection system and for reducing operating costs. . 16 Training For employee training and the presentation of information to customers, Minimax maintains well-attended training centers in Bad Oldesloe and Bad Urach. On-site training is also offered upon client request. ADRESSES Minimax GmbH & Co. KG Germany Minimax GmbH & Co. KG Großenhainerstr. 8 01561 Thiendorf Phone: +49 35240 7796-0 Minimax GmbH & Co. KG Heinrich-Hertz-Straße 1 63303 Dreieich Phone: +49 6103 5880-0 Minimax GmbH & Co. KG Heinrich-Hertz-Str. 10 07629 Hermsdorf Phone: +49 36601 9374-0 Minimax GmbH & Co. KG Industriestraße 27 66129 Saarbrücken Phone: +49 6805 9424-0 Minimax GmbH & Co. KG Gottlieb-Dunkel-Straße 20/21 12099 Berlin Phone: +49 30 700008-0 Minimax GmbH & Co. KG Englerstr. 20 69126 Heidelberg Phone: +49 6221 43418-0 Minimax GmbH & Co. KG Beerboomscher Weg 1 18292 Krakow / See Phone: +49 38457 518-0 Minimax GmbH & Co. KG Schützenbühlstraße 12 70435 Stuttgart Phone: +49 711 98271-0 Minimax GmbH & Co. KG Im Weddern 25 23858 Reinfeld Phone: +49 4533 2066-0 Minimax GmbH & Co. KG Hausener Weg 6 79111 Freiburg Phone: +49 761 45564-0 Minimax GmbH & Co. KG Finienweg 24 28832 Achim Phone: +49 4202 9154-0 Minimax GmbH & Co. KG Marsstraße 5 85609 Aschheim Phone: +49 89 998898-0 Minimax GmbH & Co. KG Max-von-Laue-Straße 4-18 30966 Hemmingen Phone: +49 511 41044-0 Minimax GmbH & Co. KG Servicebüro Allgäu Edisonstr. 5 87437 Kempten Minimax GmbH & Co. KG Miramstr. 87, Geb. K 34123 Kassel Phone: +49 561 95174-0 Minimax GmbH & Co. KG Thomas-Mann-Str. 50 90471 Nürnberg Phone: +49 911 45002-0 Minimax GmbH & Co. KG Econova-Allee 29 45356 Essen Phone: +49 201 6164-0 Minimax GmbH & Co. KG Nürnberger Str. 117 97076 Würzburg Phone: +49 931 61589-290 Minimax GmbH & Co. KG Heinrich-Pesch-Str. 5 50739 Köln Phone: +49 221 54698-0 Minimax GmbH & Co. KG Competence Center Steel Econova-Allee 29 45356 Essen Phone: +49 201 6164-419 Minimax GmbH & Co. KG Gerberstraße 22 58095 Hagen Phone: +49 2331 2006-0 17 ADRESSES Minimax Fire Solutions International GmbH Minimax Fire Solutions International GmbH Business Unit Marine Protection Competence Center Offshore and Workboats Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 Minimax Fire Solutions International GmbH Business Unit Marine Protection Competence Center Tanker Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 Minimax Fire Solutions International GmbH Business Unit Marine Protection Competence Center Carrier Fischerweg 408 18069 Rostock Phone: +49 381 811237-0 Minimax Fire Solutions International GmbH Business Unit Marine Protection Competence Center Passenger Am Becketal 14 28755 Bremen Phone: +49 421 699 55 38 Minimax Fire Solutions International GmbH Business Unit Machine Protection Competence Center Automotive Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 Minimax Fire Solutions International GmbH Business Unit Machine Protection Competence Center Wind / Special Hazard Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 18 Minimax Fire Solutions International GmbH Business Unit Machine Protection Competence Center Wood / Paper /Textile Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 Minimax Fire Solutions International GmbH Business Unit Machine Protection (Office Bremen) Competence Center Industrial Turbines Steindamm 52/54 28719 Bremen Phone: +49 421 63890-0 Minimax Fire Solutions International GmbH Business Unit Machine Protection (Office Würzburg) Competence Center Machine Tools / Data Center Nürnberger Str. 117 97076 Würzburg Phone: +49 931 61589-0 Minimax Fire Solutions International GmbH Business Unit Plant Protection Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 Minimax Fire Solutions International GmbH Business Unit Plant Protection Competence Center South East Asia Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 Minimax Fire Solutions International GmbH Business Unit Plant Protection Competence Center Europe Industriestraße 10/12 23840 Bad Oldesloe Phone: +49 4531 803-0 ADRESSES Worldwide Northamerica Minimax Fire Solutions, Inc. 7451 Longard Rd Building #4 Livermore, CA 94551, USA Phone: +1 925 583-1355 CFP Fire Protection, Inc. 17461 Derian Avenue, Suite #114 Irvine, CA 92614-5820, USA Cosco Fire Protection, Inc. Headquarter 29222 Rancho Viejo Road, Suite 205 San Juan Capistrano CA 92675, USA Firetrol Protection Systems, Inc. 11111 Landmark 35 Drive San Antonio, TX 78233-5786 Texas, USA Flamex, Inc. 4365 Federal Drive Greensboro N.C. 27410, USA Phone: +1 336 2 99-29 33 Southamerica Minimax Argentina S.A. Parque Industrial „Cir 2“ Ruta Provincial No. 36, Km 37,5 - El Pato Berazategui, Provincia de Buenos Aires Codigo Postal 1893, Argentinien Phone: +54 02229 498888 Minimax do Brasil Ltda. Av. Rosa Zanetti Ferragut 129 Jardim Primavera Vinhedo (SP) - 13.280-000, Brasilien Phone: +55 193886 6670 Europe Minimax Brandbeveiliging B.V. Van Maasdijkweg 67 3088 ED Rotterdam, Niederlande Phone: +31 10 2460106 Minimax France SAS Parc de la Croix aux Bergers - Bât A 7 avenue de Général Charles De Gaulle 91090 Lisses, Frankreich Phone: +33 1 6911 3560 Minimax Hungaria Kft. Madarász Viktor utca 47-49 H-1138 Budapest, Ungarn Phone: +3 1 481 03 21 Minimax Polska Sp. z.o.o. Kielpin ul. Ogrodowa 27/29 05-092 Lomianki, Polen Phone: +48 22 7 51 40 80/81 Minimax UK Ltd. 7 St. Johns Road Harrow Middlesex HA1 2EY, Great Britain Phone: +44 1978 713554 Minimax GmbH & Co. KG Zweigniederlassung Österreich Deutschstraße 5a 1230 Wien, Österreich Phone: +43 1615 6105-0 Fax: +43 1615 6105-16 Minimax GmbH & Co. KG Zweigniederlassung Tschechien Bohumil Kafka Branická 43 CZ 147 00 Praha 4, Tschechische Republik Phone: +420 2 44 461 130 Pefipresa Proteccao Contra Incendios Ltda. Av. Pedro Alvares Cabral n° 213 Manique de Cima 2710-297 Sintra, Portugal Phone: +351 21-4 64 74 10 Pefipresa S.A. San Cesareo 22 y 24 E-28021 Madrid, Spanien Phone: +34 91 7 10 90 00 Minimax GmbH & Co. KG Zweigniederlassung Türkei 19 Mayis Mah., Inönü Cad. Sümer Sok. No.5 Zitas Plaza / Is Merkezi, Blok D2 Daire 1 34736 (Kozyatagi) Kadiköy, Istanbul Phone: +90 216 361 40 40 Middle East MX Fire Solutions Saudi Arabia Co. Ltd. P.O. Box 1902 Al-Malaqa District Imam Saudi Bin Faisal St. Riyadh 11431 Königreich Saudi Arabien Phone: +966 2 263 62 31 MX Fire Solutions Saudi Arabia Co. Ltd. Kanoo Building 2 - Madinah Road P.O Box 13895. 21414 Jeddah Königreich Saudi Arabien Phone: +966 2 263 62 31 Cooperation Office Kuwait and agent for Minimax Fire Solutions International GmbH Kuwait Fire Fighting Safat P.O. Box 864, 13009 Kuwait Phone: +965 4 34 37 21 Cooperation Office Abu Dhabi and agent for Minimax Fire Solutions International GmbH Al Hussam Group Villa 13/1, Street No. 5 Sector 16, Zone 2 Karamah Area, P.O. Box 109169 Abu Dhabi Phone: +971 2 4461646 Cooperation Office Qatar and agent for Minimax Fire Solutions International GmbH Peninsula Engineering Group P.O. Box 5922, Office no. 6, building # 233 Elmadi building Street No. 230 Cring Road Area No. 41 Doha, Qatar Asia & Australia MX Systems International Pvt. Ltd. 202-A-202D, 2nd Floor 194, Arvind Chambers Western Express Highway Andheri (E) Mumbai - 400 069, Indien Phone: +9122-2682 2551 Fire Protection Installation Services (Thailand) Co., Ltd. SV Tower, 8 Fl. 900/5 Rama 3 Road, Kwaeng Bangpongpang Khet Yannawa, Bangkok 10120, Thailand Phone: +66 2 6826630-1 Minimax GmbH & Co. KG Zweigniederlassung Singapur # 03-15/19 German Centre 609916 Singapore, Singapur Phone: +65 6 5 62 86 30 Minimax (Beijing) Fire Fighting System Co. Ltd. No. 18, 5th Zone ABP No. 188 West Road, South 4th Ring Road Fengtai District 100070 Beijing, China Phone: +86 10 63 70 - 11 95 Minimax Fire Fighting Systems Pty. Ltd. Unit 35, 49-51 Mitchell Road Brookvale, NSW 2100, Australien Mobile: +61 439 160 377, Mobile: +61 455 516 169 MX Fire Solutions Malaysia SDN BHD B-05-05. Level 5, Block B, SkyPark@One City, Jalan USJ 25/1A, 47640 Subang Jaya, Selangor Phone: +60 3 5115 1180 19 Printed in Germany AL03e_07/04.10/0.5/08.16/HA/JM Minimax GmbH & Co. KG Industriestrasse 10/12 23840 Bad Oldesloe Germany Phone: +49 4531 803-0 Fax: +49 4531 803-248 www.minimax.de