low voltage.. - Moonlite Electric and Construction

advertisement

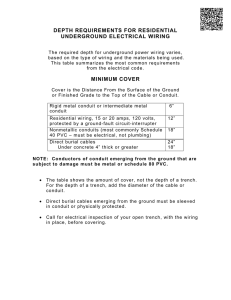

26 20 00-1 14-263 SECTION 26 20 00 LOW VOLTAGE ELECTRICAL TRANSMISSION PART 1: GENERAL 1.1 GENERAL: A. The materials described in the succeeding paragraphs are intended to set a standard of quality. All materials shall be new. B. Materials furnished shall bear the inspection label of the National Board of Fire Underwriters, where applicable. All materials shall be new. 1.2 BUILDING WIRE: (120/208 V and 277/480 V System): A. Interior wire and panel feeders shall be copper with N.E.C. type “XHHW” insulation for feeders and type “THHN/THWN” for branch circuits, color coded red, black and blue for phase for wires for 120/208 VAC; brown, orange, and yellow (277/480 VAC), green for grounds, and white (120V) or grey (277V) for grounded neutral. No wire smaller than No. 12 AWG shall be used in power and lighting systems. Wire for 15 and 20 ampere, single pole branch circuits shall be No. 12 except that where length of run from first outlet to panel exceeds 50 ft., for 120V and 125 ft. for 277V, branch circuit wiring to first outlet shall be No. 10. Fire alarm system wiring to be No. 14 A.W.G. B. Wiring for power, light panel, and service feeders shall be of size indicated on the drawings. Wiring shall be as manufactured by Phelps-Dodge, American Wire and Cable Company, Okonite Company, Hazzard or other approved equal. 1.3 UNDERGROUND EXTERIOR AND INTERIOR CONDUIT: A. Conduit shall be plastic PVC heavy wall type II, Schedule 40 PVC 1120 conforming to ASTI DD1784, with approved Schedule 40 PVC couplings and necessary fittings. All elbows to be long sweep type. Underground exterior conduits shall be completely encased in 4” of concrete all around with Underground Line Marking Tape installed 6 to 8 inches below finished grade. Tape to be bright colored plastic, 6” wide and 4 mils thick with printed legend. B. Conduit and fittings shall be as manufactured by Carlon or approved equal. 1.4 BUILDING CONDUIT: A. All conduit except for aboveground branch circuits 1 ¼” and smaller, and except for above ground branch telephone conduits, television, computer, and fire alarm system conduits shall be iron pipe size, rigid, steel, galvanized or intermediate metallic conduit with threaded fittings. Conduit and fittings shall conform to Federal Specifications WW-C-581E, hot dipped galvanized inside and outside, including threads with threaded type fittings. 26 20 00-2 14-263 B. Conduit for above ground branch circuits 1-1/4” and smaller and branch telephone, television, computer, security and fire alarm system conduits to individual outlets shall be EMT thin wall type with expansion gland, rain tight steel fittings with insulated throats, as manufactured by T & B or equal approved. Where elbows are used, they shall be long radius type. Turns in conduit 1” and larger shall be threaded type made with factory “ells”. Conduit for power, lighting, telephone, television and fire alarm circuits shall be not less than ¾”. BX flexible tubing shall not be used. MC Cable may be used for circuit and switch wiring in walls where permissible. All homerun wiring to panel to be in conduit. Where flexible conduit necessary, use Greenfield flexible metal conduit. C. Conduits shall be as manufactured by Walker Brothers, Pittsburgh Standard, National Electric Co.,or other approved equal. D. Grounded type insulated bushings with separate double lock nuts shall be used on all conduit terminations in panel cabinets, pull boxes and wiring gutters except where not required on EMT tubing terminations. Use grounding bushings on conduits terminated in concentric knockouts where entire knockout not removed. E. Conduits passing through expansion joints in the building shall be provided with expansion fittings as manufactured by O-Z Electrical Manufacturing Co., Inc. with grounding jumper around expansion fitting. 1.5 OUTLET AND JUNCTION BOXES: A. Interior outlet boxes shall be galvanized steel with the required number and size of knockouts, shall be not less than 4” size; octagonal for ceiling, square or rectangular for walls, and shall be larger where required by code and/or number of wires in box. Outlet boxes shall be not less than 1 ½” deep but, in no case, shall the size and depth of boxes be less than that required by the N.E.C. Outlets in concrete slabs shall be deep concrete type. Outlets in finished concrete blocks walls shall be set in the core of the block with plaster extension ring through shell of the block to the surface. Outlets in finished plaster and sheetrock walls shall be installed to the face of the rough masonry or back surface of ceilings or wall with extension ring of required depth to finish flush with the finish surfaces. Outlets for concealed work shall be stamped steel. Exposed interior outlets and all exterior outlets shall, be cast iron, or aluminum threaded hub with neoprene gasket. Small junction boxes shall be stamped steel. Larger junction boxes shall be of size indicated on the drawings or required, constructed of galvanized steel, code gauge. D. Boxes shall be as manufactured by Steel City Electric Company, Walker Electric Company, Metropolitan Crouse-Hinds or B & C. 26 20 00-3 14-263 1.6 WIRING CONNECTORS: A. Split bolt, solderless, compression type connectors shall be used on all wire No. 8 and larger. Connections on wire No. 10 and smaller shall be provided with wing nut connector as approved. B. Connectors shall be as manufactured by National Electric, Thomas & Betts, Ideal or other approved equal. 1.7 WIRING DEVICES: A. Devices indicated are manufactured by Arrow & Hart Company. Equivalent wiring devices as manufactured by P & S, G.E., or Hubbell will be acceptable. All devices industrial heavy duty grade. Devices to be gray. B. Toggle Switches: 20 ampere capacity, quiet type, A & H No. 1991, single pole; two pole switches, No. 1992; No. 1993, 3 way, No. 1994, 4 way. Shall meet Federal Spec. No. WS 96-E. C. Duplex Receptacles: 20 ampere capacity, 3 wire - grounding type with hex ground screw. A&H No. 5362. Shall meet Federal Spec. No. WC 596-F. Duplex receptacles in Dining/Corridor Area to be Hubbell No. USB 20X21 with two USB power connectors. D. Ground Fault Receptacle: Duplex 20A capacity, A & H #GF5342; weatherproof cover for exterior or damp locations. Shall meet Federal Spec. No. WC 596-F. Exterior receptacles and receptacles in wet labs to be provided with “in-use” covers. E. Cover Plates: Stamped steel, cadmium finish, Crouse Hinds DS Series to fit cast iron FS or FD boxes, for exposed outlets, concealed interior outlet plates to be type 302 stainless steel. F. Floor Outlets: (Provide blank inserts as needed to complete box interiors): Type A: Wiremold #EFB65-OG with Telephone and data outlets and 2 duplex receptacles with standard plates and EFB610CTCGY cover. One outlet to have plate for intercom telephone outlet and building entry intercom connection. G. Range Receptacle: 3 pole, 50A capacity, 3 wire and ground, A & H NO. 5752AN with No. 5745N plug. H. Clothes Dryer Receptacle: 20 pole, 30A capacity, 3 wire and ground, A & H #5744 with #5732AN plug. I. Food Service Equipment and Rangetop Receptacles: To be ampere rating indicated and to match plug furnished with equipment. J. Motion Detectors: 1. Type A: (Classrooms, Offices, Store Rooms, Facility Lounge) Passive Infrared, ceiling mounted, with auxiliary relay for occupancy signal to VAV boxes, Watt-Stopper CI-200 with BZ-100 power pack and low voltage cabling. 26 20 00-4 14-263 2. Type B:(Toilets) Ultra-Sonic, Watt-Stopper ceiling mounted, # WT1105 with recommended power pack. 3. Type C: Wall mounted, dual technology type, line voltage, Watt-Stopper DW-100. 4. Type D: (Gym and Dining) Ceiling mounted, passive infrared, Watt-Stopper # CI-200-1 with Power pack. Provide with wire guard in Gym/Play Area. 1.8 CABLE TRAY: Shall consist of 6”, 9”, 12” and 18” wide center support ladder tray assembly with center aluminum tray forming spine from which cross rungs are attached on 6” center. The cross rungs shall be bent up to a height of 3 ½” and shall emanate from the bottom of the spine at 90 degree angle, that divides the tray in two sections. a. The tray shall be constructed of 6063-T6 aluminum alloy and shall be designed to support a load of 50 pounds per linear foot when supported on 12 foot centers. Cable Tray to be center hung. b. Splice Connector shall be two bolt rectangular splice connector which telescopes into the spine of the tray. Splice connectors shall allow for thermal expansion/contraction of tray system. The slice connectors shall be provided with a vertical hole to accept a ½ inch threaded rod to support the tray overhead. Rod to pass through hole and be provided with nut and washer. c. All horizontal and vertical 90 degree elbows, tee’s and crosses shall be made with right angle couplings which clamp to the spine without need for drilling or cutting of spine. All horizontal and vertical angles of less than 90 degrees shall be made with angle connection which telescope into spine of the tray and fastens in same manner as splice connectors. d. All edges of cable trays, fittings and connector shall be rounded and smooth to prevent injury to cable. Rung caps shall be provided on all rungs. Provide also conduit bushing drop out for each conduit location. e. Cable tray and fittings shall be No. B1113-0322 as manufactured by Mono-Systems Inc., or approved equal as manufactured by Atlas, Square D, B-Line, or equal. 1.9 SERVICE SWITCHBOARD AND POWER PANELS 1200A AND LARGER: A. Dead front, free standing convertible, totally enclosed, safety type, power circuit breaker panel, with front removable branch switch units, with solid neutral, busses and mains and with necessary ground bars for 4 wire, 3 phase service, and shall be designed for and approved for service entrance. Panel board shall be Class 2700 switchboard as manufactured by Square D, or equivalent as manufactured by ITE, or General Electric. All current carrying parts to be copper. 26 20 00-5 14-263 B. Single phase loads shall be connected so as to balance the phases as nearly as possible. Panel shall be completely enclosed in code gauge sheet metal cabinet with hinged door, with switch units mounted on heavy channels, with isolated buss compartment, with hinged, locked cover; with top, bottom and side wiring gutters, breakers shall be thermal-magnetic, quick-make-quick-break type. C. All current carrying parts shall be braced to withstand amps sym. fault current indicated on drawings. Panel shall be free standing as indicated on the drawings. D. All main breakers 800 amp and larger including all device disconnecting breakers are to be provided with ground fault protection. Ground fault devices will be as designed for operation in 480 volt, 3 phase, 4 wire, solidly grounded wye, 60 hz system. Ground fault protection shall consist of a ground sensor encircling all phase conductors including neutral connected to a coordinated solid state ground relay which initiates tripping of feed circuit interrupting device by energizing the shunt trip circuit. Ground sensor shall be of ASA relaying accuracy, 600 volts insulation class. Solid state ground relay shall be continuously adjustable current pick-up from 100 to 1200 amperes and time delay selections from .06 to .55 seconds. Relay accuracy within 2% of set values. Circuit interrupter shunt trip and relay shall operate from 120 VAC control power transformer connected to service entrance and/or power panel feeder with necessary overcurrent protection. Each ground fault system to have monitor panel to verify entire system, with or without tripping of circuit breaker, including ground fault indicator signal light, and push button testing with automatic reset. All components to be UL listed and installed per manufacturer’s recommendations. Ground fault devices shall be as manufactured by Square D or other approved equal as manufactured by G.E. or ITE. Equipment supplier to provide calculations to determine ground fault time delay setting. E. Panel shall be provided with a typewritten directory giving services of each branch unit, and branch units on panel shall be numbered and labeled with Micarta nameplate. Main and switch capacities shall be as indicated on the drawings. Lock shall be of the cylinder type. Field coat concealed backs with emulsified asphalt. F. Provide fault current study of power system as described in Section 26 00 00 of Specification. 1.10 DISTRIBUTION AND POWER PANELS: (600A to 1000A) A. Dead front, convertible, totally enclosed, safety type, power circuit breaker panel, bolted breaker with front removable branch switch units, with solid neutral, busses and mains and with necessary ground bars for 4 wire, 3 phase service, and shall be designed for and approved for service entrance when so used. Panel board shall be “I” line type as manufactured by Square D, or equivalent as manufactured by ITE Cutler Hammer, or General Electric. All current carrying parts to be copper. All panels to have ground busses. Certain panels to have 200 percent neutrals as specified. B. Single phase loads shall be connected so as to balance the phases as nearly as possible. Panel shall be completely enclosed in code gauge sheet metal cabinet with 26 20 00-6 14-263 hinged door, with switch units mounted on heavy channels, with isolated buss compartment, with hinged, locked cover; with top, bottom and side wiring gutters, breakers shall be thermal-magnetic, quick-make- quick-break type. Panels to be provided with auxiliary wireway and access cover as needed to allow safe installation of clamp- on current transformers to allow monitoring of load. C. All current carrying parts shall be braced to with stand amps sym fault current indicated on drawings. D. Panel shall be provided with a typewritten directory giving services of each branch unit, and branch units on panel shall be numbered. Main and switch capacities shall be as indicated on the drawings. Lock shall be of the cylinder type. Field coat concealed backs with emulsified asphalt. 1.11 LIGHTING AND POWER PANELS: (400A capacity and less) A. Shall be quick-make-quick-break, thermal-magnetic circuit breaker type NQOD (120/208VAC) or NEHB (277/480VAC) as manufactured by Square D, or equivalent as manufactured by ITE, Cutler-Hammer, or General Electric. B. 2 and 3 pole breakers shall be common trip. All breakers to be bolted type. C. All current carrying parts to be copper. Provide with feed through lugs where shown and required. All new panels to have isolated ground busses. Provide 200% neutral busses on all 120/208 VAC panels fed by NLP stepdown transformers and as noted on drawings. D. Panels shall be complete with branch switch units, mains, busses and with necessary ground bars complete code gauge sheet metal enclosure with hinged locked cover, wiring gutters top, bottom, sides and lugs. Typewritten directory shall be furnished and shall be filled out to indicated the service of each branch switch unit. Lock shall be of the cylinder type. Field coat concealed backs with emulsified asphalt. Panels to be provided with auxiliary wireway and access cover as needed to allow safe installation of clamp-on current transformers to allow monitoring of load. E. Provide fault current study of power system as described in Part 3 of Specification. 1.12 DISCONNECT SWITCHES: A. Shall be heavy duty type HD, interlocked cover, with pressure type switch, and fuse clips, fusible, except that motor disconnect switches at motor locations may be unfused with provision for padlocking, as manufactured by Westinghouse, Cutler Hammer, General Electric or Square D. B. Disconnect switches used as motor disconnects shall be horsepower rated. C. Fuses shall be renewable, cartridge type, as manufactured by Bussman, or other approved equal. 26 20 00-7 14-263 1.13 PANEL DIRECTORIES: Typewritten panel directory shall be provided in all new panels indicated. 1.14 STEP DOWN TRANSFORMER: A. Contractor shall furnish and install Two winding, dry type transformers, as indicated on the drawings, 480 volt, 3 phase Delta Primary, 120/208 3 phase 4 wire secondary, all as indicated on the drawings. B. All Transformers shall be designed for quiet operation, drip proof construction, copper windings, natural ventilation, completely cased. Certain transformers shall have Class “H” insulated, 80 degree C Rise with internal noise isolation pads, copper windings, K factor of 13, Square D Type NLP, or equal. All other transformers other than NLP type are to be Square D class EE 7410, 80 degree C rise, copper windings. Transformers shall conform to applicable provisions of OSHA and shall be listed. Provide with electrostatic shields. Transformers to have TP-1 rating. C. Equivalent transformers as manufactured by G.E., Seimens, or Cutler-Hammer are acceptable. 1.15 TESTS: A. Upon completion of the work the Electrical Contractor shall demonstrate that the new installations are complete and in perfect operating order, with all wiring free from grounds or shorts, and with raceway system properly grounded, and that the installation is in accordance with the requirements of the plans and specifications and in accordance with the requirements of the National Board of Fire Underwriters and applicable state and local codes. B. All wiring connections at panels, fixtures, switches, and all splices shall test free from any faults and shall have an insulation resistance between conductors and between conductors and ground as required by the latest edition of the National Electrical Code. Ground resistance shall be measured by earth meggar device, and it shall not exceed 5 OHM. A written test report shall be submitted to Engineer. Tests shall be applied and performed in accordance with accepted good practices. C. Tests as required shall also be performed for any authorities having jurisdiction and tests shall be performed at the Contractor’s expense and the Contractor shall provide all apparatus, temporary works, etc., as required for the tests. D. Defects, where found, shall immediately be repaired and tests shall be repeated as required until the systems are demonstrated to be free of defects and have complied with test requirements. 26 20 00-8 14-263 16 GROUNDING: A. Panels, conduits, junction boxes, motor frames, switches, starters, and other required equipment shall be grounded. Equipment grounding conductors shall be not less than No. 8 AWG size stranded. Grounding conductors shall be protected as required by installation in conduit. B. Motors shall be connected to electrical grounding system. Green grounding conductor shall be installed in flexible conduit between motor and circuit breaker and/or disconnect switch and shall be fastened to circuit breaker enclosure and/or disconnect switch with washer-in-head machine screw. C. Recessed lighting fixtures shall be connected to electrical grounding system. Green grounding conductor shall be inside flexible conduit from recessed lighting fixture to outlet box, making connection to conduit in outlet box. D. Green grounding conductor shall be installed throughout entire wiremold system and with all new power and lighting circuits in building. E. Service ground to be provided with cw main and to structure as required by 2014 N.E.C. 1.17 CONDUIT INSTALLATION: A. Concealed conduit shall be routed as short and direct as possible. Exposed building conduit shall be installed neatly and shall be routed parallel to or perpendicular to building walls. Conduits generally shall be routed clear of pipes, ducts, etc., which would subject the conduit to high ambient temperatures. All power, lighting, auxiliary system conduits to be installed concealed wherever possible. Where branch circuit conduits are installed under floor slab to room outlets, provide one ¾” conduit from one outlet in each room up above room ceiling, or to bottom of structure if no ceiling, terminated with conduit bushing for future use as access to room outlets. If ceiling not accessible, extend conduit to nearest accessible location. B. Contractor shall install approved type slip fittings where conduit passes through building expansion and control joints. Trapped conduit shall be provided with approved drain fittings if trapped. Building conduit 1” and smaller shall be supported on 6’ centers with galvanized cast iron one hole hangers. Building conduit 1 ¼” and larger shall be supported on not over 12’ centered with standard type pipe hangers. Hangers shall be attached to block masonry with toggle bolts, to concrete with approved expansion shields or by shooting studs. C. Install a No. 10 B & S galvanized steel drag wire or 200 lb. test nylon pullcord in all empty conduits. D. Threads for i.p.s. conduit shall be clean cut, straight and true, and of sufficient length to permit proper coupling; long running threads will not be permitted in any part of the work. Provide conduit with proper supports during construction to prevent injuries. Joint i.p.s. conduit with galvanized screw type threaded couplings, red leaded, make up tight so that the ends of conduit butt together. 26 20 00-9 14-263 Extend conduit to points indicated and cap conduit ends. E. Joints in plastic conduit shall be watertight, solvent type, applied in strict accordance with manufacturer’s instructions. All bends in PVC conduit to be made with heated bender. F. Make all bends in metal conduit with hydraulic or power bender without kinking conduit or appreciably reducing its internal diameter. Bender for intermediate metallic conduit to be type as recommended for that use by conduit manufacturer. G. The radius of inner edge of any bend shall be not less than ten times the internal diameter of the conduit unless otherwise indicated on the drawings. H. Conduit shall be fished for interference before pulling wire. Lay all underground exterior conduit true to line and grade with a minimum cover of 36 inches. Grade bottom of trench so that the conduit will drain all condensation into nearest service box. Install conduit in such a manner as to avoid traps. Bottom of trench shall be firm; tamp to obtain compaction before laying conduit as required or as directed. Where rock is encountered, lay conduit on a need of well tamped fine earth at least four inches thick between the rock and the conduit. All underground exterior conduit to have marker type installed in trench 6” above conduit. J. After backfill, test all conduit with a mandrel. Use a mandrel having a diameter one-quarter of inch smaller than the conduit and a length of two inches. Repair all conduits which will not allow the mandrel to be pulled through as directed by the Engineer. If the repairs cannot be effected, remove and replace the conduit at no additional cost to the Owner. K. Pull boxes shall be installed not over 150’ apart in straight runs, not over 100’ apart in conduits with one elbow between, and not over 75’ apart with two elbows between. Branch circuit conduit do not require pull boxes generally except where there are more than three elbows between outlet boxes. Additional junctions shall be provided as required by code. L. Insulated bushings with separate double lock nuts shall be used on all conduits entering panel cabinets, pull boxes and wiring gutters and shall be grounded type where required by Code. The conduit system shall be protected from damage during construction where necessary, and the ends of conduit runs shall be plugged to avoid filling with dirt, etc. 1.18 WIRING INSTALLATION: A. No wires shall be pulled until the conduit system is complete, until the building has progressed sufficiently so that construction procedures are not liable to injure wire or cables, and until raceways are dry and moisture can no longer be introduced into them. Approved wire pulling compound only shall be used to facilitate pulling of wire. Wires and cables shall be pulled into raceways utilizing a suitable brush, followed by a 85% diameter ball mandrel ahead of the wire. Color coding shall be followed throughout and like colors shall be connected to like colors. Sufficient slack shall be left on all wires to permit proper connection to terminals. Wiring joints for No. 10 wire and smaller, may be made or with connections specified previously in these specifications. Where joints are made with saddle type solderless mechanical connectors, 26 20 00-10 14-263 the joints shall be wrapped with rubber tape and friction tape of sufficient thickness to provide an insulation equal to the wire insulation. Splices shall be made in junction boxes only. Common neutral wires shall be arranged so that only one circuit conductor of a given phase may be connected to the common neutral. B. Wiring systems shall be complete. 1.19 OUTLET BOX INSTALLATION: A. Each new outlet designated on the drawings shall be provided with an outlet box. Each outlet box shall be installed so as to be accessible without removing structure, pipe work or duct work. Splices shall be made in junction boxes only. Outlet boxes on existing walls to be chased into plaster with conduit routed to box in furring. B. The contractor shall verify mounting heights of all outlet with the Architect before installation. C. Unused holes in outlet boxes shall be plugged. D. The Contractor shall verify the location and swings of all doors from the architectural plans, before installing any switch outlets. Switch outlets shall be on the lock side of the door. E. The concealed exterior sides and back of all steel cabinets, junction boxes, pull boxes, shall be thoroughly cleaned, given a prime coat of zinc chromate primer and a finish coat of emulsified asphalt. F. Outlets boxes shall be supported from the building structure. Supporting racks, building structure is not sufficient to support on ceiling material or other ceiling media. G. Lighting fixtures weighing up to fifty pounds must be supported by a direct thread-ed connection to the outlet fixture stud and the outlet box in turn must be supported to the building structure to carry this weight. H. Device mounting height shall be as follow unless noted otherwise on drawings: Device Mtg. Ht. Above Floor Panelboards 6’ - 6” (to top) Safety Switches 6’ - 6” (to top) Toggle Switches 4’ - 0” (centerline) Receptacles 1’ - 4” or 6” Above counter as Indicated. Office Telephone/Data Outlets 1’ - 4” or 6” above counter as indicated. 26 20 00-11 14-263 1.20 Classroom Telephone Outlets See details on dwgs Workroom Telephone Outlets 4'-0" above floor. Fire Alarm Sending Stations 4’ - 0” (centerline) Data Outlets 1’ -4” (unless noted otherwise) Fire Alarm Horn Strobe Lights 6’-6” Above Floor: See Details 8’ - 0” All other areas. Magnetic Door Holder 6’ - 6” Above Floor CONDUIT ROUTING: A. All conduit generally shall be routed concealed in walls, above ceilings, in furred spaces and underground. Where branch circuit conduits are installed under the floor slab to room outlets provide ¾” c from one outlet in room up to ceiling space and terminated with bushing for future access to room outlets.(See conduit installation instructions.) B. Conduit in mechanical rooms shall be routed exposed. All other surface raceway shall be wiremold. C. Exposed conduit shall be generally routed parallel and perpendicular to walls. 1.21 APPROVAL: A. Upon completion of the installation, the contractor shall furnish certificates of approval from the Inspection Authorities having jurisdiction indicating that the complete installation made under these specifications and the accompanying drawings applying thereto has been accepted by them, and that all charges in connection with their inspection have been duly paid. Such certificates must be presented with the contractor’s final invoice for payment. 1.22 MOTOR CONNECTIONS: A. Where connections are made to motors not near walls or columns, a vertical conduit attached to floor and to ceiling shall be installed and the wiring installed in and out of this conduit by means of condulets. A short length of flexible conduit shall be used between the conduit and motor connections. B. Electrical Contractor to extend all motor circuits to motor terminals and leave wiring for terminals by Mechanical Contractor. 26 20 00-12 14-263 1.23 NAME PLATES: A. Motor controllers, safety switches, panel boards, etc., shall be provided with identifying name plates securely fastened to the equipment (this in addition to branch service typewritten directories for panels). B. Plates shall be made of laminated Micarta with white core; Blue (277/480 VAC), Black (120/208 VAC) and 3/16” letters engraved to the white core, or other metallic plates approved for the purpose. Plates shall be of suitable size to suit the equipment to which they are attached. C. Provide all feeders with suitable identification if by color coding as to their designation in all junction boxes, pull boxes, gutter spaces through which they pass, and their terminal points of connection. D. Identification of feeder cables shall be by means of engraved fiber tags suitably fastened with twine to the cables. E. Device plates for toggle switches, toggle switch-type motor starters pilot lights, etc., whose function is not readily apparent, shall be engraved with ¼”high letters suitable describing the equipment controlled or indicated. F. Phase identification letters shall be stamped into the metal bus bars of each phase of the main busses or self adhering labels shall be affixed to busses of each new panelboard, etc. The letters shall be visible from at least one “normal posture” location without having to demount any current carrying or supporting elements. 1.24 TRANSIENT VOLTAGE SUPRESSION SYSTEM: 400 SERIES 460 SURGE PROTECTIVE DEVICE GUIDE SPECIFICATIONS 1.0 GENERAL 1.1 Summary : These specifications describe the electrical and mechanical requirements for a high-energy surge protective device (SPD). The specified system shall provide effective, high-energy surge current diversion and be suitable for use as Type 1, 20kA device per ANSI/UL 1449 Third Edition. 1.2 Standards : The specified system shall be designed, manufactured, tested and installed in compliance with the following codes and standards: Underwriters Laboratories; ANSI/UL 1449 3rd Edition 2006 Revision (effective 9/29/2009) Canadian Underwriters Laboratories (cUL) American National Standards Institute and Institute of Electrical and Electronic Engineers (ANSI/IEEE C62.34, C62.41, C62.45) Institute of Electrical and Electronic Engineers 1100 Emerald Book Federal Information Processing Standards Publication 94 (FIPS PUB 94) 26 20 00-13 14-263 National Fire Protection Association (NFPA 20, 70, 75 and 780) International Standards Organization (ISO) Company certified ISO 9001 for manufacturing, design and service The system shall be UL listed and labeled under ANSI/UL 1449 Third Edition and the voltage protection ratings (VPRs) shall be permanently affixed to the SPD. Type 2 units of the product family shall be cUL listed and labeled to UL1283 Standard for Electromagnetic Interference Filters. International Electrotechnical Commission (IEC) 1.3 System Description: The system shall be constructed using single or multiple surge current diversion modules utilizing thermally protected metal oxide varistors (TPMOV). The surge current circuit shall be designed and constructed in a manner that ensures surge current sharing. Use of gas tubes, silicon avalanche diodes or selenium cells are unacceptable unless documentation from a nationally recognized laboratory demonstrates current sharing of all dissimilar components at all surge current levels. 1.4 Electrical Requirements (selection required) 1.4.1 Nominal System Operating Voltage 277/480VAC Service Panel);120/208VAC (Panelboards) “Y” Configuration _____3_______ Phase _____4_______ Wires plus Ground 1.4.2 Maximum Continuous Operating Voltage (MCOV): The SPD and all components in the suppression path (including all current diversion components) maximum continuous operating voltage (MCOV) shall be greater than 115% of the nominal system operating voltage to ensure the ability of the system to withstand temporary RMS over-voltage (swell conditions). 1.4.3 Operating Frequency: The operating frequency range of the system shall be at least 47 - 63 Hz. 2.0 Products 2.1 Performance Ratings 2.1.1 Surge Current Capacity: (Selection Required) _200(Service);100 (Power Panel) kA Surge Rating per Mode _400(Service); 200 (Power Panel) kA Surge Rating per Phase (L-N & L-G)) 2.1.2 Noise Attenuation: The filter shall provide an attenuation of 40 db max from 10 kHz to 100MHz, per 50 Ohm Insertion Loss Methodology from MIL 220A. 2.1.3 Enhanced EMI/RFI Filtering: Up to 60db from 10 kHz to 100MHz, per 50 Ohm Insertion Loss Methodology from MIL 220A. (Type 2 devices only) 2.1.4 ANSI/UL 1449 Voltage Protection Ratings: The maximum UL 1449 listed Voltage Protection Ratings for each and/or all of the specified protection modes shall not exceed the following: System ANSI/UL 1449 Third Edition VPR’s 26 20 00-14 14-263 Voltage 120/240, 120/208 240 Delta 277/480 347/600 480 Delta 600 Delta L-N 800Vpk N-G 800Vpk L-G 800Vpk L-L 1200Vpk NA 1200Vpk 1500Vpk NA NA NA 1200Vpk 1500Vpk NA NA 1200Vpk 1200Vpk 1500Vpk 1800Vpk 2000Vpk 2000Vpk 2000Vpk 2500Vpk 2000Vpk 3000Vpk 2.1.5 ANSI/UL 1449 Nominal Discharge Current: The ANSI/UL 1449 Nominal Discharge Current Rating shall be a minimum of 20kA. 2.1.6 Life Cycle Testing: The SPD shall be duty life cycle tested to withstand 10kA (8x20 s ), 20kV (1.2x50µs), IEEE C62.41 Category C surge current with less than 5% degradation of clamping voltage. The minimum numbers of surges the unit shall be able to protect against are: Number of Cycle Surges (Selection Required) ____3500____ Life Cycle Surges per Mode ____7000____ Life Cycle Surges per Phase 2.2 Design Requirements 2.2.1 Overcurrent Protection/Fusing: All suppression components shall be thermally protected and rated to allow maximum specified surge current capacity. Devices that utilize a single fuse to protect two or more suppression paths are not accepted. Individual surge components shall be UL listed to be capable of interrupting up to 200 kA symmetrical fault current with 480 VAC applied. Replaceable fusing is unacceptable. Overcurrent protection that limits specified surge currents is not acceptable. 2.2.2 Protection Modes: The SPD shall provide protection as follows: All modes, L-N or L-L, L-G and N-G (where applicable). Note: L = Line, G = Ground, N = Neutral 2.2.3 Enclosure: The specified system shall be provided in a weather-proof NEMA 4 metal enclosures. The cover of the enclosure shall be hinged on the left side and require a tool for access to internal components. Monitoring indication must be visible without opening the door. The enclosure maximum dimensions shall be 16 inches (406 mm) high, 16 inches (406 mm) wide and 8 inches (203 mm) deep. 2.2.4 Connections: Terminals/Compression lugs shall be provided to accommodate connection to phases, neutral, and ground where applicable. A three position terminal block with “NO”, “NC”, & “COM” indication shall be provided to accommodate relay alarm contact connection. 2.2.5 Internal Connections and Serviceability:. The system shall be designed for simple change out of any SPD by a qualified electrician. Designs that require factory service are not acceptable. All connections, conductors and terminals must be appropriately sized for specified surge current capacity. 2.3 Standard Features: 2.3.1 Unit Testing Capability—The SPD monitoring circuitry must continually verify the protection status during operation and display this information on the front cover status panel. The integrity of all fuses must be indicated on the status panel. 26 20 00-15 14-263 2.3.2 Unit Status Indicators—SPD shall have an integral status circuit that monitors the operational status of all modes of protection, including Line to Neutral, Line to Ground and Neutral to Ground. No manual testing is required to confirm the integrity of the suppression and filter systems.The SPD shall be equipped with red and green solid state indicators mounted within the enclosure and be externally visible. 2.3.3 Dry Contacts for Remote Monitoring—SPD must have a minimum of 1 set of electrically isolated Form C dry contacts, one normally open and one normally closed. 2.3.4 Power Loss Monitoring—SPD shall be equipped with power loss monitoring. 2.3.5 Audible Alarm—SPD shall be equipped with an audible alarm that is activated during a fault condition. In conjunction with alarm, an alarm on/off feature shall be provided to silence the alarm. 2.4 Optional Features: Provde as noted. 2.4.1 Surge Counter—A resettable transient counter shall be available to tally transient voltage surge conditions. The readout shall be at least a six-digit LCD located on the unit’s front cover. Counter must maintain accurate counts for 10-years in the event of total power loss.PROVIDE 2.4.3 Surge Event LED—The SPD shall include LED indication on the front cover that illuminates when the SPD’s Nominal voltage is exceeded by 50%. Once activated, the Surge Event LED must remain illuminated until a reset function is manually activated. PROVIDE 2.4.4 N-G Overvoltage Detection— The SPD shall include LED indication on the front cover that illuminates when the neutral to ground voltage exceeds 20VRMS. 2.4.5 Remote Monitor Unit—A self-contained monitoring device shall be available to allow remote annunciation of the system status. Input power to the monitoring device shall be equipped with an 1828.8 mm (6-foot) long input power cord with a NEMA 5-15 plug. The monitoring device shall have an audible alarm, red and green LED’s, an alarm on/off switch to silence and a push-to-test alarm switch. 2.4.6 Rotary Disconnect Switch—The specified system shall include a disconnect located in-line with the SPD system enclosure with an external manual operator. The switch shall disconnect all phase conductors, not including neutral, from the high-energy surge current diversion modules.PROVIDE 2.4.7 Advanced Transient Detection System- The SPD shall be equiped with a power quality monitor including the following monitoring features: * Communication via RS-485, Modbus TCP/RTU, Form C, Ethernet with Embedded Webpage * Integral LCD Display providing real-time system RMS Voltage, Average Voltage, VTHD, Crest Factor, Phase Imbalance, & Frequency. * Event Date/Time stamp with Duration/Magnitude for Surge, Sag, Swell, Temporary Overvoltage (TOV), Overvoltage, Phase Loss/Outage, Voltage Interruption/Dropout, Voltage Harmonics (VTHD), Over/Under Frequency, & Neutral Bond conditions. Event thresholds shall be capable of password-protected user modification at the system display and Embedded webpage. * System memory shall be capable of on-board storage & retreival of a minimum of 1000 logged events. * Event diagnostics providing SPDs life cycle status with remaining surge protection percentage, and a resettable counter providing the number of Surge, Sag, and Swell events since last reset. 26 20 00-16 14-263 * Voltage quality analysis reporting capable of producing a downloadable report detailing recorded power quality events, potential solutions, and statistical summaries. 2.5 Quality Assurance: The manufacturer shall be ISO 9001:2008 certified. The manufacturer shall have been engaged in the design and manufacturer of such products for a minimum of 20 years. 2.6 Warranty: The manufacturer shall provide a full ten year warranty from date of shipment against any part failure when installed in compliance with manufacturer's written instructions, UL listing requirements, and any applicable national or local electrical codes. Manufacturer shall make available (local, national) field engineering service support. Where direct factory employed service engineers are not locally available, travel time from the factory or nearest dispatch center shall be stated. 2.7 Environmental Requirements Storage Temperature: -55 to +85°C (-67 to +185°F) Operating Temperature: -40 to +85°C (-40 to +185°F) Relative Humidity: 0% to 95% (non-condensing) Audible Noise: less than 45dB at 5 feet (1.5m) Operating Altitude: 0 to 18,000 feet (5,486m) above sea level 2.8 Testing 2.8.1 Component Testing and Monitoring: The proposed product shall be single pulsed surge current tested in all modes at the rated surge currents by an industry recognized independent test laboratory. The test shall include a surge impulse (6kV [1.2x50µs], 500 amp [8x20 s k the ] wa unit’s ve form) suppression to be nchm voltage. ar The applied impulse is followed by a single pulse surge of the maximum rated surge current magnitude, followed by a second 6kV [1.2x50µs], 500 amp [8x20 s ] im puls e a s a m e a n deviation (component degradation). Compliance is achieved if the two measured suppression voltage do not vary by more than 5%. 3.0 EXECUTION 3.1 Submittals 3.1.1 Documentation: These specifications are based on the Emerson Network Power 460 Series. All other manufacturers shall submit for 10-day pre-approval, a detailed compliance or exception statement to all provisions of this specification to allow consideration. Additionally, manufacturers shall submit test data verifying the following: life cycle testing, overcurrent protection, ANSI/UL 1449 Third Edition, noise attenuation and surge current capacity. Failure to do so will result in product disapproval. Any deviation from the published specification will result in an applicable deduct applied. 3.1.2 Equipment Manual: The manufacturer shall furnish an installation manual with installation, startup, and operating instructions for the specified system. 3.1.3 Drawings: Electrical and mechanical drawings shall be provided by the manufacturer that show unit dimensions, weights, component and connection locations, mounting provisions, connection details and wiring diagram. 3.2 Installation: The installing contractor shall install the parallel SPD with short and straight conductors as practically possible. The contractor shall twist the SPD input conductors together to reduce input conductor inductance. The contractor shall follow the SPD manufacturer’s recommended installation practices as found in the installation, operation and maintenance manual and comply with all applicable codes. 26 20 00-17 14-263 These guide specifications comply with the outlines of the Construction Specification Institute per CSI MP-2-2-85 and MP-2-1-88. GS-70111 Rev 1 1-15 END OF SECTION