1550 Top Mounted Level Switch (Form GI865)

advertisement

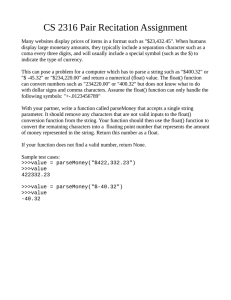

1550 Top Mounted Level Switch General ral Instructions The SOR® 1550 Electric Level Switch mounts into the top of a vessel. Electric switching action is provided by the float moving a magnet into the field of a hermetically sealed reed switch. NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative in your area for a return authorization number (RMA).. This product should only be installed by trained and competent personnel.. Before Installing the Level Switch Inspect the unit for any shipment damage. Check for mechanical clearance of the float. Float must move freely without binding throughout its stroke. Use an acceptable thread compound when installing unit to ensure a leak-free fit and avoid thread galling. Electrical Connection Electrical connection is free wire leads with a 1/2” NPT(F) conduit connection. Use two wrenches - one to hold hex conduit connection, the other to tighten conduit fitting. Switching element is a hermetically sealed reed switch. Wiring schematics shown on page 2. ricaaall Ensure that all wiring conforms to all applicable local and national electrical codes and install unit(s) according to relevant national and local safety codes. Do not exceed catalog stated electrical ratings. Improper current input to switch will cause permanent damage to contacts. Table of Contents Design and specifications are subject to change without notice. For latest revision, go to www.SORInc.com Form 865 (04.16) ©SOR Inc. Electrical Connections ........................ 1 SIL Installation ................................. 2 Wiring ........................................... 2 Float Attachment ............................... 3 Special Conditions............................. 3 Dimensions ..................................... 4 ATEX and IECEx Marking Details ............ 4 Declaration of Conformity .................... 6 Troubleshooting ................................ 7 Replacement Parts ............................ 7 Registered Quality System to ISO 9001 1/8 Safety Integrity Level (SIL) Installation Requirements The SOR pressure switches have been evaluated as Type-A safety related hardware. To meet the necessary installation requirements for the SIL system, the following information must be utilized: Proof Test Interval shall be one year. Units may only be installed for use in Low Demand Mode. Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a Form 1538 (03.12) ©2012 SOR Inc. 1oo1 (one out of one) configuration. Wiring for SPST and SPDT Switch Operation SPST Reed Switch Capsule Normally Open White Lead Common Black Lead SPDT Reed Switch Capsule Normally Closed White Lead Normally Open Blue Lead Common Black Lead Wiring for DPDT Relay For Type 1550 Level Switches equipped with DPDT relays, a wiring schematic and pin position schematic is shown below. When the 1550 is actuated, the coil will energize and “make” both NO1 and NO2 while it will “break” NC1 and NC2. This provides a DPDT circuit. DPDT Relay Schematic 8 C2 NC 2 5 NO 2 6 Switch Capsule Black Lead White Lead 1 C1 NC 1 4 NO 1 3 2 Power Supply Relay Coil 7 2 1 C1 3 NO1 2/8 4 NC1 8 7 C2 5 NC2 6 NO2 Form 865 (04.16) ©SOR Inc. Float Attachment (Series 1500 with Flange) Place two drops of Loctite 271 inside the threaded hole of the float. Thread the float onto the set screw and hand-tighten. SET SCREW NOTE: Do not remove the set screw as it secures the pivot arm to the shaft. NOTE: Do not remove the stem guide as it may cause damage to the unit. APPLY TWO DROPS LOCTITE 271 INSIDE THREADED HOLE OF FLOAT FLOAT Linear = mm/inches Drawing 0390747 Special Conditions for Safe Use This apparatus may have a combined nameplate which carries multiple approvals (intrinsically safe and flameproof). The equipment should be marked as to which protection method it is installed as and shall not be changed or utilized in any other means than was originally marked by the end user. When marked and installed as Ex i equipment, the permanently attached leads must be suitably protected against mechanical damage and terminated in a suitable junction box or terminal facility having a degree of protection at least IP20. When marked and installed as Ex d equipment, the permanently attached leads must be suitably protected against mechanical damage and terminated in a suitable junction box or terminal facility. Form 865 (04.16) ©SOR Inc. 3/8 Dimensions 44.5 1.75 WRENCH FLAT 1 COLOR CODED AND MARKED WIRE LEADS 457.2 MIN LENGTH 18.00 13.5 0.53 144.5 5.69 Linear = mm/inches Drawing 0390428 1 PROCESS CONNECTION FLANGE 144.5 5.69 PROCESS CONNECTION 1-1/2 NPTM STD 2 NPTM OPT ELECTRICAL CONNECTION 1/2 NPTF STD 3/4 NPTF OPT STEM GUIDE 44.5 1.75 WRENCH FLAT L = DISTANCE TO ACTUATING LEVEL COLOR CODED AND MARKED WIRE LEADS 457.2 MIN LEN 18 00 13.5 0.53 L = DISTANCE TO ACTUATING LEVEL STEM I PR Dimensions are for reference only. Contact the factory for certified drawings for a particular model number. FLOAT TITLE DIM FLAN EO N SCAL With CK Accessory – ATEX and IECEx dual approved: Linear = mm/inches 13.5 0.53 1/2" NPTF ELECTRICAL CONNECTION 457.2 MIN LENGTH 18.00 COLOR CODED AND MARKED WIRE LEADS Drawing 0390764 22.2 WRENCH FLATS 0.87 177.8 7.00 177.8 7.00 44.5 WRENCH FLATS 1.75 FLANGE PROCESS CONNECTION _________" ___________# RF FLANGE AS SPECIFIED ON SALES ORDER 1-1/2" NPTM PROCESS CONNECTION L : _____ STEM GUIDE *DISTAN *L *L STEM P FLOAT 88.9 3.50 152.4 6.00 TITLE DIM LEV EO SCA 4/8 Form 865 (04.16) ©SOR Inc. ATEX and IECEx Marking Details For ATEX and IECEx Certified Models Manufacturer’s Registered Trademark Drawing 0720554 ATEX Listing Information Product Type Identification Product Model Identification Standards Assessed To ATEX Certification: EN 60079-0: 2009 & EN 60079-11: 2007 EN 60079-0: 2012, EN 60079-1: 2007, EN 60079-11: 2012 & EN 60079-26: 2007 IECEx Certification: IEC 60079-0: 2011, IEC 60079-1: 2007-04, IEC 60079-11: 2011 & IEC 60079-25: 2010-02 IEC 60079-0: 2004 & IEC 60079-11: 1999 Form 865 (04.16) ©SOR Inc. 5/8 Declaration of Conformity For ATEX Certified Models EC Declaration of Conformity Product Type 1500 Electric Switches Manufacturer SOR Inc., 14685 West 105th Street, Lene xa, Kansas 66215-2003 5NITED3TATESOF!MERICA Date of Issue April 20, 2016 We declare that the above products conform to the following specifications and directives Carries the Marking !4%8$IRECTIVE%5%QUIPMEN T)NTENDEDFORUSE IN0OTENTIALLY%XPLOSIVE!TMOSPHERES %.%. )%#)%# %.% . %.%. )%#)%# )%#)%# !4%8-ARKING )%#%X-ARKING II 1 G Ex ia IIC Ga 4²#d4Ad²#OR 4²#4A²# 4²#d4Ad²#OR 4²#4A²# II 2 G Ex d IIC Ga/Gb Reference Documents ATEX Notified Body Person Responsible Ex ia IIC Ga 4²#d4Ad²#OR 4²#4A²# Ex d IIC Ga/Gb 4²#d4Ad²#OR 4²#4A²# EC-Type Examination Certificate Baseefa06ATEX0271X, IECEx BAS 06.0063X )SSUED*ANUARY Baseefa13ATEX0056X, IECEx BAS 13.0035X )SSUED*ULY SGS Baseefa Ltd..OTIlED"ODY.O 2OCKHEAD"USINESS0ARK3TADEN,ANE "UXTON$ERBYSHIRE3+2 :5NITED+ INGDOM "ASEEFA#USTOMER2EFERENCE.O -ICHAEL*"EQUETTE60OF%NGINEERING -ICHAEL*"EQUETTE Engineered to Order with Off -the-Shelf Speed 14685 West 105th Street, Lenexa, KS 66215-2003 s53!s &!8 Form 1385 (04.16) SOR Inc. 6/8 Form 865 (04.16) ©SOR Inc. Troubleshooting Symptom Probable Cause Float in actuated position but no output signal. a. No power supply. b. Switch damaged. (Replace.) Float in de-actuated positon but still receiving an output signal. a. Switch damaged. (Replace.) Liquid in vessel at the actuation level but unit does not respond. a. Leaky or collapsed float. (Replace.) b. Liquid specific gravity too low. c. Float stem bound up or dirty. (Clean.) d. Float travel is obstructed. Verify float can move freely and is not obstructed when installed. Replacement Parts Part Number Description 3130-091 W9 - SPST Hermetically Sealed Switch Capsule 3130-245 W1 - SPDT Hermetically Sealed Switch Capsule 3130-259 W1 - SPDT Switch/Conduit Connection Assembly (CK Option Only) 3130-107 L9 - SPST Hermetically Sealed Switch Capsule 3130-244 L1 - SPDT Hermetically Sealed Switch Capsule 3130-260 L1 - SPDT Switch/Conduit Connection Assembly (CK Option Only) 3101-122 316SS Float. (Consult factory for other materials.) 3130-396 Actuator Arm Replacement Kit Form 865 (04.16) ©SOR Inc. 7/8 SORInc.com 14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767 8/8 Registered Quality System to ISO 9001 Form 865 (04.16) ©SOR Inc.